A customer in Tanzania is engaged in the advertising industry. He has purchased a marking machine of another brand before, but after working for a long time, it fails to process. So this customer browsed various CNC websites and wanted to buy a color marking machine again. He has consulted several CNC companies selling marking machines, and carefully learned the machine’s processing performance, parts configuration, and price.

Fiber Laser Marking Machine for Sale

After comparison, he feels that the Blue Elephant marking machine is more cost-effective and the processing effect is more in line with his expectations. In addition, Blue Elephant has more prestige in the CNC machine industry, which can make him more confident to buy. At the same time, he expressed his appreciation for our salesmen, who have a positive service attitude, solid professional knowledge, and can solve his problems quickly and accurately.

According to the description of this Tanzanian customer, we learned that he wants a color marking machine that can not only mark billboards, but also process some 3D cylindrical objects, such as cups and rings. And the price should be moderate, not more than ten thousand dollars. The height of the column should reach 80cm and can be raised and lowered manually. So the salesman recommended this new laser marking machine to him, which has the advantages of good beam quality, fast marking speed, long service life, and flexible installation.

Advantages of the fiber laser marking machine

1. The size of this marking machine is only 175*175mm. It has a small footprint, is easy to operate, and can save space.

2. It has a wide range of applications and can process a variety of materials, including metals (iron, copper, aluminum, magnesium, zinc, gold, silver, titanium), glass, ceramics, plastics, leather, etc.

3. Permanent marks can be made on metal and non-metal materials. It is suitable for the processing of some products requiring fine and high precision.

4. There is no force on the surface of the workpiece, no mechanical deformation, and no corrosion on the surface of the material. It is especially suitable for marking brittle materials or materials with high hardness and high melting point.

5. It belongs to non-contact processing. With good marking quality, it has no damage to the product and no tool wear.

6. The laser beam is very thin, the processing heat-affected zone is small, and the processing material consumption is little.

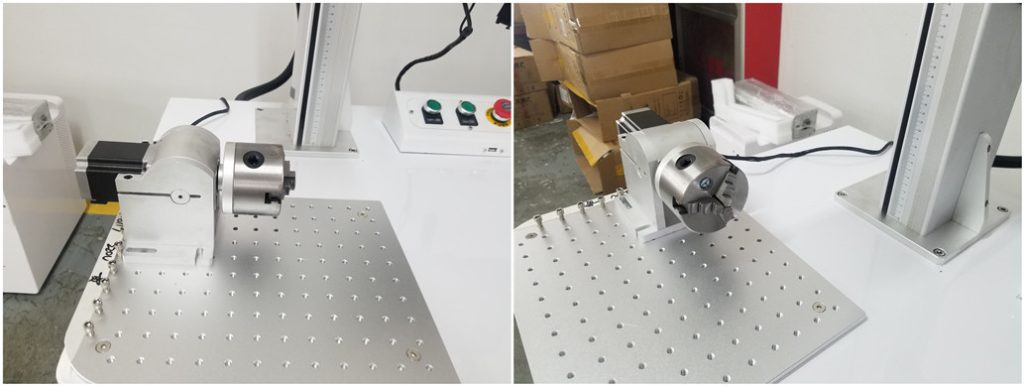

7. Equipped with a rotating shaft, which can meet the needs of customers for processing cylindrical objects.

8. It adopts computer control, which is easy to realize automation and high processing efficiency.

Precautions after Purchasing

1.To keep the optical components dry and dust-free, the laser marking machine should be kept in a dust-free and enclosed workroom as much as possible, and the indoor temperature should be kept at 10℃-35℃.

2.The cooling water is best to use deionized water. If there is no deionized water, distilled water can be used instead. The circulating cooling water should be replaced in time after using it for a period. It is recommended to change the circulating water at least once every two weeks to avoid affecting the laser efficiency.

3.Prevent fiber breakage. Serious bending will cause fiber breakage and laser system failure.

Video Zone

The following video is the fiber laser marker processing metal panels.