A few years ago, I almost bought a used laser marking machine from an auction. The price was unbeatable, but something felt off. After digging deeper, I found out the previous owner had constant issues with precision and reliability.

That moment taught me that price isn’t everything, performance matters more.

If you’re considering a second-hand machine, this review will help you look beyond the sticker price. I’ll cover the real costs, potential risks, and key factors to consider before making a purchase.

By the end, you’ll have a clear picture of whether a used machine fits your business needs or if a new one is the better choice.

Let’s break it down!

1. Advantages of Buying a Used Laser Marking Machine

New machines come with a hefty price tag, but used ones can seem like a smart way to cut expenses. For some businesses, this approach makes sense, if you know what you’re getting into. Let’s look at the real advantages of buying a second-hand laser marking machine.

Lower Upfront Investment

One of the biggest reasons businesses consider used equipment is simple, cost. A used laser marking machine can be significantly cheaper than a new one, freeing up capital for other areas like production, marketing, or employee training. If your priority is getting the job done without straining your budget, buying used might be the most practical way to scale your operations.

Immediate Availability

With new machines, there’s often a wait, sometimes months, for manufacturing, shipping, and installation. Used machines, on the other hand, are typically available right away. This can be a lifesaver if your current machine breaks down unexpectedly or if a new contract requires you to increase production quickly.

Avoiding Initial Depreciation

New equipment loses value the moment it’s purchased. By choosing a used machine, you skip that steep depreciation curve. This means you’re not taking a financial hit if you ever decide to upgrade or resell the machine later.

Access to Higher-End Models at a Lower Price

Buying used often allows businesses to afford higher-quality models that would be out of reach if purchased new. Instead of settling for a budget-friendly, entry-level machine, you might find a more advanced model at a fraction of the original cost, giving you better features and longevity. A higher-end machine may also come with better durability and precision, making it a smarter long-term investment.

2. Disadvantages of Buying a Used Laser Marking Machine

While buying a used laser marking machine can save money, it’s not always the best choice. I’ve seen businesses get great deals, but I’ve also seen companies struggle with unexpected repair costs and performance issues. Before committing to a second-hand machine, it’s important to consider the potential downsides.

Hidden Maintenance and Repair Costs

The lower upfront price of a used machine can be deceiving. If the previous owner didn’t maintain it properly, you could be dealing with frequent breakdowns, costly repairs, or even the need for replacement parts that are hard to find. What seemed like a budget-friendly purchase can quickly turn into an ongoing expense.

Limited Warranty or No Support

Most used machines come with little to no warranty, leaving you without manufacturer support when something goes wrong. Unlike a new machine that comes with service agreements and technical assistance, a second-hand unit often requires you to troubleshoot issues on your own or hire third-party technicians. This can lead to longer downtimes and unexpected costs.

Outdated Technology and Software Issues

Older machines may not have the latest features or software updates, making them less efficient or incompatible with newer production requirements. Some manufacturers stop supporting older models altogether, meaning you won’t get software patches or security updates. If your business relies on precision and efficiency, an outdated machine could slow down your operations.

Shorter Lifespan and Higher Risk of Failure

No matter how well a used machine was maintained, it has already gone through years of wear and tear. Components weaken over time, and at some point, they will fail. Investing in a used machine might give you a few good years, but it won’t last as long as a new one. If reliability is a priority, a second-hand option may not be worth the risk.

3. Key Factors to Consider When Buying a Used Laser Marking Machine

Buying a used laser marking machine isn’t just about finding a good price. I’ve seen businesses score great deals, but I’ve also seen others end up with machines that cost more in repairs than they saved upfront. To make sure you’re getting a machine that actually benefits your business, here are the key factors to consider before making a purchase.

- Machine Condition and Maintenance History: Ask for service records and maintenance logs to see how well the machine was taken care of. A poorly maintained unit might look fine on the surface but could have hidden issues that lead to costly repairs.

- Remaining Lifespan of Key Components: Some parts, like laser tubes or lenses, wear out over time and are expensive to replace. If the machine is close to the end of its expected lifespan, you might end up paying more for repairs than the machine is worth.

- Availability of Replacement Parts and Support: Older machines may have parts that are discontinued or difficult to source. If something breaks and parts are no longer available, your business could face serious downtime with no easy fix.

- Software Compatibility and Updates: Some manufacturers stop updating software for older models, which can lead to compatibility issues with newer systems. If you rely on advanced features or need seamless integration with other equipment, an outdated machine could limit your productivity.

- Testing Before Purchase: Never buy a used machine without seeing it in action first. Testing ensures it performs as expected and helps you catch any potential problems that might not be obvious from just looking at it.

- Total Cost of Ownership: The initial price is only part of the equation, consider future maintenance, repairs, and energy efficiency. A cheaper machine with frequent issues could end up costing more than a slightly more expensive, well-maintained unit.

- Seller Reputation and Return Policy: Buying from a reputable seller can reduce risks, as they are more likely to provide honest details about the machine’s condition. If possible, look for a return policy or a short warranty to give yourself some protection against unexpected failures.

4. Used vs. Rental vs. Buying New: A Comparison

Choosing between a used, rented, or brand-new laser marking machine isn’t just about cost, it’s about what makes the most sense for your business in the long run. I’ve seen companies jump at the lowest upfront price only to regret it later when unexpected costs pile up. Others hesitate on investing in a new machine, worried about cash flow, when it might actually be the better financial decision over time.

To help you weigh your options, here’s a detailed comparison of the three choices:

| Factor | Used Machine | Rental Machine | New Machine |

| Upfront Cost | Lower initial cost, but potential hidden expenses. | Minimal upfront cost, usually monthly payments. | Highest initial investment, but predictable costs. |

| Long-Term Cost | May require repairs and maintenance, increasing total cost over time. | Continual payments add up, making it costly for long-term use. | Higher initial cost but lower maintenance expenses with warranty coverage. |

| Machine Condition & Lifespan | Depends on prior usage, could have wear and tear. | Typically well-maintained, but never fully owned. | Brand new with full lifespan and manufacturer support. |

| Customization & Control | Limited, may not be able to upgrade or modify older models. | No customization; you must use what’s available. | Full control over features, settings, and upgrades. |

| Availability & Lead Time | Readily available, but condition varies. | Instantly available, but selection may be limited. | May have lead times due to manufacturing and delivery. |

| Support & Warranty | Usually little to no warranty, making repairs costly. | Rental company handles maintenance, but service quality varies. | Comes with manufacturer support, warranty, and technical assistance. |

| Best For | Businesses looking for a budget-friendly option with careful inspection. | Short-term projects, temporary increases in demand, or testing before purchasing. | Companies prioritizing reliability, long-term efficiency, and lower overall costs. |

5. Maintenance and Support Challenges for Used Laser Marking Machines

Owning a used laser marking machine can save money upfront, but maintaining it is another story. Before buying used, it’s important to understand the maintenance and support challenges that can come with it.

Higher Risk of Breakdowns and Repairs

Used machines have already been through years of operation, meaning parts are more likely to fail. Components like laser tubes, cooling systems, and control panels wear out over time, leading to unexpected breakdowns. If you’re not prepared for frequent repairs, a cheap machine can quickly become an expensive burden.

Limited Access to Replacement Parts

As manufacturers release new models, they eventually stop producing parts for older ones. If you buy a machine that’s too outdated, you might struggle to find replacement components. This not only increases costs but also leads to long periods of downtime while you search for alternatives.

Lack of Manufacturer Support

Unlike new machines that come with warranties and technical assistance, used machines often lack direct manufacturer support. If you run into software issues or calibration problems, you may have to rely on third-party technicians, who may charge high fees or struggle to fix certain issues. Without reliable support, small problems can quickly turn into major setbacks.

6. Why Buying a New Laser Marking Machine is the Better Choice

Is a used laser marking machine really worth the risk? While the lower price may be tempting, the long-term benefits of buying new often make it the better investment. With a new machine, you get reliability, up-to-date technology, and no surprise repair costs that can eat into your budget.

Warranty coverage and manufacturer support are also major advantages. Instead of dealing with outdated parts or costly repairs, you’ll have access to expert assistance, software updates, and a machine built for long-term performance. Less downtime means more productivity.

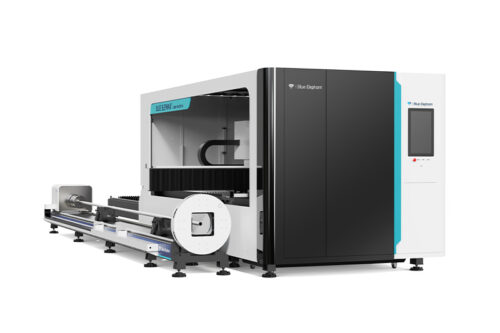

If you want a hassle-free, future-proof solution, buying new is the smarter choice. Blue Elephant, a trusted laser marking machine manufacturer from China, offers high-quality machines at competitive prices. Why not explore their options and see how a new machine can improve your operations?

Conclusion

Used machines can be tempting. But once you add the risks, the repairs, and the stress, it’s not always worth the trade-off.

Still on the fence? That’s okay. Buying equipment is a big decision.

But if you’re serious about long-term reliability, a new machine is hard to beat. Blue Elephant offers dependable laser marking machines that won’t leave you guessing.

Contact us today and take the first step toward a smarter investment.

Check Out These Additional Resources

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.