The first time I repaired a machine with laser welding, I was skeptical. Would it really be faster and stronger than traditional welding?

To my surprise, it not only worked better but also reduced downtime significantly.

If you’re in the business of dealing with machines, repairs, or rentals, you know efficiency is everything. That’s why laser welding is becoming a top choice across industries.

I’ve spent years working with welding professionals and machine dealers, understanding what works and what doesn’t. This article is built on real-world experience, not just research.

You’ll discover how laser welding compares to other methods when it makes sense to invest, and how it can impact your bottom line. By the end, you’ll have the clarity you need.

Let’s get started!

1. What Is Laser Welding?

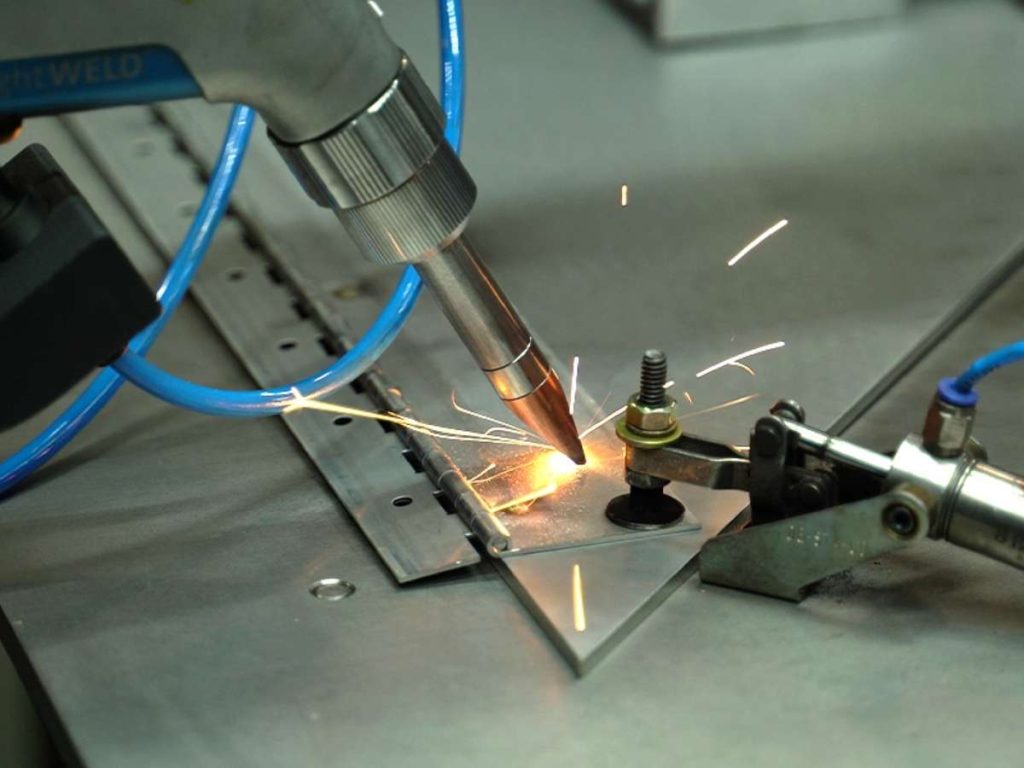

Laser welding is the process of using a high-energy laser beam to fuse metals or thermoplastics. Instead of relying on an open flame or an electrode, it uses light—pure, focused energy—to create deep, strong welds with minimal heat damage.

The result? Flawless, precise joints with little to no post-processing required. If you’ve worked with traditional welding methods like MIG, TIG, or arc welding, you know the challenges:

- Excessive Heat Warping: Ruins delicate components.

- Messy, Inconsistent Welds: Requires time-consuming rework.

- Slow, Labor-Intensive Processes: Eats up valuable production time and resources.

Laser welding changes the game. It’s faster, cleaner, and far more precise. You can weld thin, intricate components without the risk of damage, and you can do it in a fraction of the time it would take with conventional methods.

2. How Does Laser Welding Work?

The first time I watched a laser welding process up close, it felt like something out of science fiction. No sparks flying everywhere, no excessive heat buildup—just a focused beam of light creating a flawless, high-strength weld in seconds. But how does this technology actually work?

Working Principle

At its core, laser welding uses a highly concentrated beam of light to generate intense heat, which fuses materials together. Unlike traditional welding methods that rely on direct contact with an electrode or flame, laser welding delivers energy with extreme precision, making it ideal for intricate or high-speed applications.

Here’s what happens during the process:

- A laser beam is directed at the materials to be joined.

- The high-energy light rapidly heats the surface, causing localized melting.

- The molten metal fuses together and solidifies, forming a strong, clean weld.

This method minimizes heat-affected zones (HAZ), reducing warping, cracking, and post-weld cleanup.

Types of Laser Welding Methods

Not all laser welding techniques are the same. Depending on the material thickness, application, and required weld strength, businesses typically use one of the following methods:

- Heat Conduction Welding:

- The laser heats the material’s surface, allowing heat to conduct through and melt the joint.

- Best for thin materials and cosmetic welds where minimal penetration is required.

- Produces smooth, visually appealing welds with little post-processing needed.

- Deep Penetration Welding (Keyhole Welding):

- The laser creates a small cavity (keyhole) in the material, allowing deeper penetration and stronger welds.

- Ideal for thicker materials and high-strength applications like automotive and aerospace welding.

- Produces narrow, deep welds with high efficiency.

3. Types of Laser Welding Machines

Choosing the right laser welding machine for your business isn’t just about buying the most advanced model—it’s about finding the right tool for the job. Different laser welding machines excel in different applications, depending on material type, precision needs, and production volume. Below, we break down the four main types of laser welding machines and when to use them:

Fiber Laser Welding

If your business demands high-speed production with exceptional precision, fiber laser welding is the gold standard. At Blue Elephant, we manufacture advanced fiber laser welding machines designed for accuracy, durability, and production efficiency. It uses a fiber-optic cable to deliver the laser beam, ensuring:

- Extremely high energy efficiency for less power wasted, lower operating costs.

- Superior precision for ideal for thin metals, automotive parts, and delicate industrial components.

- Low maintenance for no mirrors or moving parts in the beam delivery system.

Best For: Automotive, aerospace, medical devices, electronics, and high-precision manufacturing.

CO₂ Laser Welding

CO₂ laser welding has been around for decades and remains a reliable choice for specialized applications. Instead of fiber optics, it uses a gas mixture (CO₂, nitrogen, helium) to generate the laser beam.

- Excellent for non-metallic materials like plastic, wood, and ceramics.

- Strong welding capability for carbon steel, stainless steel, and aluminum.

- Lower initial cost than fiber lasers but higher maintenance due to mirrors and gas requirements.

Best For: Manufacturing that involves metals and non-metallic materials, such as packaging, textiles, and electronics.

Diode Laser Welding

If you need a small, flexible, and energy-efficient solution, diode laser welding is worth considering. Unlike CO₂ or fiber lasers, diode lasers generate light directly from semiconductor diodes, reducing system complexity.

At Blue Elephant, we specialize in manufacturing high-performance diode laser welding machines that are built for efficiency, precision, and reliability.

- Highly efficient with lower power consumption.

- Compact and portable, making it ideal for small-scale applications.

- Best for localized, low-penetration welds in thin materials.

Best For: Small businesses, precision repairs, and applications where portability is needed.

Nd:YAG Laser Welding

Nd:YAG (Neodymium-doped Yttrium Aluminum Garnet) laser welding has been widely used in industrial applications for years. It offers:

- Better energy absorption for highly reflective materials like copper and aluminum.

- Pulsed or continuous wave operation, allowing greater control over heat input.

- Higher maintenance costs compared to fiber lasers due to frequent lamp replacements.

Best For: Older industrial setups, heavy manufacturing, and specialized welding applications requiring deep penetration.

4. Key Components of a Laser Welding System

Investing in a laser welding system isn’t just about choosing the right machine—it’s about understanding how its key components impact performance, efficiency, and long-term costs. Each part plays a vital role in ensuring precision, durability, and seamless integration into your workflow.

Below, we break down the four essential components of a laser welding system and why they matter for your business.

Laser Source

The laser source determines power, efficiency, and material compatibility. Each type comes with its own strengths and trade-offs:

- Fiber Lasers: High efficiency, long lifespan, and low maintenance. Best for metal welding and precision applications. Expensive upfront but lower operating costs long-term.

- CO₂ Lasers: Works well with both metals and non-metallic materials like plastics and ceramics. Strong welding capability but higher maintenance due to gas refills and mirrors. Lower initial cost than fiber lasers but more upkeep.

- Diode Lasers: Compact, energy-efficient, and cost-effective. Best for low-power applications and thin materials. Limited penetration depth, making it unsuitable for heavy-duty welding.

- Nd:YAG Lasers: Good for reflective materials like copper and aluminum. Offers pulsed or continuous wave operation for better heat control. Higher operational costs due to frequent lamp replacements.

Beam Delivery System

How the laser beam reaches the weld area directly affects precision, efficiency, and flexibility. There are two main types of beam delivery systems:

- Optical Fiber Delivery: Highly flexible and allows integration with robotic systems. Minimal maintenance with no mirrors to realign. More expensive upfront but lower long-term costs.

- Free-Space Optics (Mirror-Based): Good for high-power lasers requiring stable beam control. Requires precise alignment, making it more maintenance-intensive. Can be cost-effective for fixed welding stations.

Workpiece Positioning System

Accuracy in welding depends as much on positioning as it does on the laser itself. The right positioning system ensures consistent, repeatable welds with minimal human error.

- Manual Positioning: Lower cost but requires skilled labor. Not ideal for high-volume production.

- CNC-Controlled Positioning: More precise and repeatable than manual methods. Higher upfront cost but improves long-term efficiency.

- Robotic Welding Systems: Fully automated for mass production, reducing labor costs and increasing consistency. High initial investment but delivers the fastest return on investment for large-scale operations.

Cooling Systems

Laser welding generates intense heat, and the cooling system prevents overheating, ensuring machine longevity and consistent weld quality.

- Air-Cooled Systems: Simple and cost-effective, requires no external cooling unit. Less efficient for high-power lasers, not ideal for continuous operation.

- Water-Cooled Systems: More effective for high-power and industrial applications. Higher initial and maintenance costs due to pumps and water circulation.

5. Applications of Laser Welding in Different Industries

Laser welding isn’t just a technological upgrade—it’s a game-changer for industries that demand precision, efficiency, and durability. Businesses that rely on high-strength welds are integrating laser welding into their operations to improve product quality. Here’s how laser welding is transforming key industries:

Automotive Industry

The automotive industry depends on high-speed, high-strength welding for everything from body panels to engine components. Traditional welding methods struggle with thin metals, but laser welding provides:

- Lightweight, High-Strength Joints: Reduces overall vehicle weight while maintaining durability.

- Faster Assembly Line Speeds: Increases production efficiency without compromising quality.

- Minimal Heat Distortion: Essential for precise parts like sensors, airbag components, and EV battery enclosures.

Aerospace and Aviation

When it comes to aerospace, precision and structural integrity are non-negotiable. Laser welding ensures high-strength, defect-free welds in turbine components, fuel systems, and structural frameworks. Key benefits include:

- Deep Penetration Welding: Creates strong, reliable joints in high-performance metals like titanium and nickel alloys.

- Reduced Material Stress: Prevents cracks and warping in high-heat environments.

- Lightweight Construction: Helps manufacturers meet fuel efficiency goals with lighter, more durable materials.

Medical Device Manufacturing

Medical-grade welding requires extreme precision—every weld must be flawless to meet safety and hygiene standards. Laser welding is used for:

- Surgical Instruments: Joins stainless steel and titanium without introducing contaminants.

- Medical Implants: Ensures a smooth, biocompatible finish for pacemakers, orthopedic implants, and dental devices.

- Micro-Welding for Electronics: Used in hearing aids, insulin pumps, and endoscopic tools.

6. Comparing Laser Welding with Other Welding Techniques

I remember watching a production line struggle with traditional welding. Sparks flying everywhere, thick weld seams needing hours of grinding. And it cost business time and money. Then, they switched to laser welding. No mess. No excessive heat damage. Just clean, precise welds that barely needed post-processing.

If you’re still relying on traditional welding methods, you might be losing more than you think. The question is—how does laser welding actually compare?

| Feature | Laser Welding | MIG Welding | TIG Welding | Resistance Welding | Ultrasonic Welding |

| Speed | Very fast; ideal for high-volume production | Moderate; slower with post-processing | Very slow; manual process | Fast for spot welds; batch-oriented | Fast for plastics and thin layers |

| Precision | Extremely high; minimal distortion | Moderate; visible weld seams | Very high; clean welds | Moderate; limited depth control | High; great for fragile plastic parts |

| Heat Control | Focused beam; minimal heat-affected zone | Large HAZ; risk of distortion | Better than MIG but still produces significant heat | High heat at contact points | Low; works through vibration |

| Automation Compatibility | Highly compatible with robotic/CNC systems | Somewhat compatible with automation | Difficult to automate | Common in automated setups | Fully automatable for plastics |

| Material Compatibility | Metals (steel, aluminum, copper, etc.); thin to medium | Thick metals; structural components | Thin metals; specialty metals | Mostly metals; best for sheet parts | Plastics and non-metals |

| Surface Finish | Clean welds; minimal post-processing | Requires grinding, finishing | Smooth, clean finish | Usually needs cleaning after | Very clean for plastic parts |

| Maintenance Needs | Low (especially fiber lasers) | Moderate; depends on wire feed and gas setup | High; requires frequent consumables | Moderate; electrode wear is common | Low; fewer moving parts |

| Upfront Cost | High | Low to moderate | Moderate | Moderate | Low to moderate |

| Long-Term ROI | High; reduced labor, waste, and downtime | Lower; more rework and material waste | Lower unless in niche precision applications | Good for specific, repetitive tasks | Good for plastic welding needs |

| Best Use Case | High-speed, high-precision industrial welding | Structural welding, general fabrication | Custom metalwork, prototypes | Mass production with similar components | Plastic joining in electronics and medical sectors |

If you’re working with plastics or delicate electronic components, ultrasonic welding may be the right tool. But if you need high-strength, high-precision metal welds, laser welding is the way forward.

7. Troubleshooting Common Laser Welding Issues

Laser welding is a game-changer for precision, speed, and efficiency. But like any advanced technology, it comes with its own set of challenges. If you’re facing similar issues, you’re not alone. The key is knowing why problems happen and how to fix them quickly. Here’s a breakdown of the most common laser welding issues and how to troubleshoot them:

Poor Weld Penetration

Symptoms: Welds appear too shallow or don’t fully fuse the materials together.

Possible Causes:

- Insufficient Laser Power: The energy isn’t high enough to penetrate deeply.

- Incorrect Focal Point: The laser beam isn’t hitting the optimal location.

- Inadequate Material Preparation: Surface contaminants prevent proper fusion.

How to Fix It:

- Increase laser power or slow down welding speed to allow deeper penetration.

- Adjust focal point to ensure the laser energy is concentrated where needed.

- Clean and prepare surfaces properly to remove oil, rust, or coatings.

Excessive Spatter

Symptoms: Small molten metal droplets scatter around the weld area.

Possible Causes:

- Excessive Laser Power: Too much energy causes overheating.

- Incorrect Shielding Gas Flow: Gas turbulence disturbs the weld pool.

- Contaminated Materials: Impurities cause erratic melting.

How to Fix It:

- Lower laser power or adjust pulse settings to prevent over-melting.

- Optimize shielding gas flow to create a stable environment.

- Ensure material cleanliness before welding.

Cracking or Brittleness

Symptoms: Welds develop cracks, either immediately or after cooling.

Possible Causes:

- Excessive Heat Input: Causes thermal stress and microcracks.

- Incorrect Material Selection: Some alloys are prone to cracking.

- Rapid Cooling: Sudden temperature changes create brittleness.

How to Fix It:

- Use preheating techniques to control thermal expansion.

- Adjust cooling rates by modifying laser parameters.

- Check material compatibility—some metals require specific welding conditions.

Porosity

Symptoms: Small holes or bubbles appear inside the weld, weakening its integrity.

Possible Causes:

- Gas Contamination: Air pockets get trapped in the weld pool.

- Shielding Gas Issues: Insufficient or improper gas flow.

- Moisture on Materials: Residual moisture turns into gas when heated.

How to Fix It:

- Increase shielding gas coverage to prevent oxidation.

- Use high-purity gases like argon or helium.

- Ensure materials are dry and preheated if needed.

8. Factors to Consider When Choosing a Laser Welding Machine

Choosing the right laser welding machine is a big decision—one that directly impacts your production efficiency, weld quality, and long-term costs.

I’ve seen businesses make the mistake of buying the most advanced model, only to realize it doesn’t fit their actual needs. The key? Choosing the right machine for your specific application. Here’s what you need to consider before investing:

#1 Material Type and Thickness

Not all laser welding machines work with the same materials. Some are designed for thin, delicate metals, while others can handle thicker, industrial-grade materials.

- Fiber Lasers: Best for steel, aluminum, copper, and other metals.

- CO₂ Lasers: Works well with plastics, wood, and ceramics in addition to metals.

- Nd:YAG Lasers: Good for reflective materials like aluminum and copper.

If you’re welding metals, fiber lasers are usually the best choice. For non-metal applications, consider a CO₂ laser.

#2 Production Volume and Speed

Are you running high-volume production, or do you need occasional, specialized welds? Your machine’s speed should align with your business’s production demands.

- For Mass Production: Look for a machine with high-speed, continuous operation and automation capabilities.

- For Small-Scale or Custom Welding: A compact, pulsed laser system might be more cost-effective.

#3 Weld Precision and Quality

Laser welding is already known for precision, but the level of control varies. If your parts require micron-level accuracy, you’ll need a machine that offers:

- Adjustable beam focus for ultra-fine control.

- Low heat-affected zones (HAZ) to prevent distortion.

- Consistent energy delivery for uniform welds.

#4 Budget and Return on Investment (ROI)

Laser welding machines aren’t cheap, but they pay off when used correctly. Consider:

- Upfront Costs: Fiber lasers are more expensive than traditional welding equipment, but they reduce long-term costs in labor, rework, and consumables.

- Operating Costs: Machines with high energy efficiency and low maintenance needs will save money over time.

- ROI Timeline: How quickly will the machine generate profit through faster production and reduced material waste?

If laser welding speeds up your workflow and cuts labor costs, it will likely pay for itself faster than you expect.

Conclusion

Laser welding is the future of industrial manufacturing, and now, you have everything you need to make an informed decision. From machine types and key components to troubleshooting and industry applications, you’ve got the roadmap.

But knowledge alone won’t create change.

I’ve seen businesses hesitate, unsure if switching was worth it. But the company I mentioned earlier? They took the leap. They invested in laser welding and saw their production speed double, defects drop, and profits rise.

Now it’s your turn. Will you hold onto the past, or step into the future?

Let’s talk, contact us today and discover how laser welding can transform your business.

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.