I remember the first time I needed custom cardboard boxes for my business. I thought, How much could a simple box really cost? Then I saw the quote—and my jaw nearly dropped.

It felt like I was paying more for the packaging than the product itself. Frustrated, I dug into the numbers. I wanted to understand exactly what I was paying for and if there was a way to cut costs.

After years of working with manufacturers, I’ve learned how box prices are calculated. And now, I want to share that knowledge with you.

In this article, you’ll find:

- A breakdown of materials, labor, and production costs

- How order size and customization affect price

- Hidden fees you might not expect

- How to estimate costs yourself

By the end, you won’t just understand the numbers—you’ll have the tools to make smarter decisions.

Let’s get started!

1. What Determines the Cost of a Cardboard Box?

I know you were wondering—how hard can it be to order custom cardboard boxes? Just pick a size, choose a material, and get a price, right? But then the final cost shows up, and it’s higher than you expected. You start to ask yourself: am I overpaying? Can I bring the cost down without losing quality?

I’ve figured out exactly what affects the cost of a cardboard box—and now I’m breaking it down for you.

What Really Affects the Cost?

- Material Type: The kind of cardboard you choose makes a big difference. I used to think all cardboard was the same—until I learned that corrugated cardboard, which is stronger and more durable, costs more than a single-layer board. If your product needs extra protection, you’ll need to factor in a higher cost.

- Box Size: Larger boxes use more material, which naturally increases cost. Even small size changes—an inch here or there—can can have a noticeable impact. It’s easy to assume a slightly bigger box won’t matter much, but in packaging, every inch counts.

- Order Quantity: Bulk orders nearly always bring the price down per unit. Smaller batches may seem cost-effective at first, but unit costs are typically much higher. When possible, ordering a larger quantity upfront can lead to significant savings.

- Customization: Logos, special finishes, and unique designs all add to the total cost. While branded packaging can be important, it’s worth considering whether advanced printing or coatings are truly necessary. In many cases, a clean and simple box gets the job done just as well.

- Manufacturing Complexity: Boxes with simple folds are cheaper to produce than those with complex cuts or reinforced structures. Custom shapes, added flaps, or multi-layer builds drive up labor and tooling costs. Simpler designs are not only more affordable but often faster to produce.

- Shipping & Logistics: This is one area many overlooks. Heavier or oversized boxes increase shipping costs, especially for long-distance deliveries. It’s important to factor in not just the price of the box, but how much it’ll cost to move it.

Every decision you make—from the material to the size to the design—affects the final cost. The trick is balancing quality with price so you don’t overpay.

Why Do Prices Fluctuate?

- Raw Material Costs: Paper pulp prices go up and down depending on supply chain issues, tariffs, and even weather conditions. I’ve seen manufacturers raise prices overnight because of material shortages.

- Labor Costs: Skilled workers run the machines that cut, fold, and print boxes. If wages go up, so do production costs.

- Energy Consumption: Manufacturing isn’t just about cutting cardboard—it takes power to run machines, and rising electricity or fuel prices can push costs higher.

- Supply Chain Disruptions: We’ve all seen how supply chain issues can make even the simplest orders take longer and cost more. If a factory runs out of a certain type of board, you might have to pay extra or wait weeks for restocking.

I’ve learned that if you’re ordering boxes, it’s best to keep an eye on these factors. Timing your order right can make a huge difference in cost.

2. Key Cost Factors in Cardboard Box Manufacturing

When I first started learning about cardboard box costs, I assumed price was mostly about size. Bigger boxes cost more, smaller ones cost less—simple, right? Turns out, I was way off.

The truth is, several key factors influence how much you’ll pay for a box. Understanding these can help you make cost-effective choices, whether you’re ordering a few hundred or a few thousand.

Material Type and Quality

The material you choose affects not only cost but also durability.

- Corrugated vs. Solid Board: Corrugated boxes cost more than solid board because they provide better strength and cushioning. If your products need protection during shipping, corrugated is the way to go—but it comes at a higher price.

- Recycled vs. Virgin Paperboard: Recycled materials tend to be cheaper, making them a great option for budget-conscious orders. However, they may lack the same durability as virgin paperboard, which is stronger but more expensive. If you’re shipping heavy or fragile items, using virgin board might be worth the investment.

Box Design and Size

Not all boxes are created equal. Some designs cost more to produce than others.

- Larger Boxes: More material equals higher cost. Even an inch or two can make a noticeable difference in price, especially for bulk orders.

- Custom Shapes and Structures: If you need special cuts, flaps, or built-in reinforcements, expect to pay extra. Custom die-cutting requires special molds, adding to production costs.

I once thought a minor design tweak wouldn’t affect pricing much. Turns out, adding a custom fold increased the die-cutting cost significantly. Sometimes, simplicity saves money.

Order Quantity

How many boxes you order plays a major role in pricing.

- Higher Volumes = Lower Costs: Manufacturers offer discounts for bulk orders because it’s more efficient for them to produce large quantities at once. If you’re ordering regularly, increasing your order size can save a lot in the long run.

- Small-Batch Orders Cost More: If you only need a few hundred boxes, you might face setup fees that make the per-unit cost much higher. Some manufacturers have minimum order quantities for this reason.

If you’re ordering in small quantities, ask yourself: Would a slightly larger order help me save on costs? Sometimes, ordering a bit more can be more cost-effective than placing frequent small orders.

Production Speed and Labor Costs

How fast you need your boxes—and how they’re made—affects pricing.

- Manual Production: For small orders, hand-cut and assembled boxes might be the best option. It’s slower but avoids the high setup costs of automated production.

- Automated Production: Large-scale orders are usually machine-made, which reduces labor costs. However, automation requires expensive equipment, meaning manufacturers charge more for short-run custom jobs.

3. Raw Materials and Their Impact on Cost

From the number of layers to the type of paper used, every choice adds (or cuts) costs. Let’s break down how raw materials influence what you pay.

Types of Cardboard Materials

Not all cardboard is created equal. The type of material you choose affects strength, durability, and price.

- Single-Wall, Double-Wall, and Triple-Wall Corrugation:

- Single-wall: The most common and cost-effective option, great for lightweight items.

- Double-wall: Adds an extra layer for better durability but costs more.

- Triple-wall: Heavy-duty and strong enough for industrial use, but the price can be significantly higher.

- I once switched from double-wall to triple-wall for a shipment, thinking it was a minor change. Turns out, the cost difference was more than I expected! Always check if you really need the extra strength.

- Kraft vs. White Cardboard:

- Kraft cardboard: Made from unbleached paper pulp, it’s the most affordable and widely used option. It’s also more eco-friendly.

- White cardboard: Bleached for a clean, professional look. It’s great for printing and branding but comes at a higher cost.

- If you don’t need bright white packaging, sticking with kraft can save money without sacrificing quality.

Sourcing and Supply Chain Costs

Where your cardboard comes from also plays a role in pricing.

- Local Suppliers vs. International Imports:

- Ordering locally can save on shipping and logistics costs. It also reduces lead times, which is helpful if you’re on a tight schedule.

- Importing from overseas can sometimes be cheaper per unit, but long shipping times and customs fees can offset those savings.

- I once placed an order with an international supplier to save money. What I didn’t account for? Delays in customs and unexpected import fees that erased my savings.

- Fluctuations in Paperboard Prices:

- The cost of raw materials changes frequently due to supply chain disruptions, environmental regulations, and global demand.

- If paperboard prices spike, manufacturers pass those costs onto buyers. Keeping an eye on market trends can help you time your purchases better.

Now that you know how materials affect cost, what’s the right balance for your business? Do you need a stronger box, or could a lower-cost material work just as well?

Making the right choice could save you money without sacrificing the quality you need.

4. Manufacturing Process and Cost Breakdown

The cost of manufacturing a cardboard box isn’t just about the materials—it’s about the entire process. Every step, from sourcing raw materials to finishing and packaging, affects the final price. Some factors are straightforward, like labor and machine costs, while others, like setup fees and energy consumption, are less obvious but just as important.

If you’ve ever wondered why some boxes cost more than others, here’s a breakdown of the key cost drivers in the manufacturing process.

Machine and Equipment Costs

- Die-Cutting Machines: Used for shaping and cutting boxes. Standard boxes use existing dies, but custom designs require new die molds, which add setup costs.

- Corrugators and Laminators: These machines create corrugated board by bonding multiple layers together. Thicker boards (double-wall, triple-wall) take longer to produce and consume more energy, increasing costs.

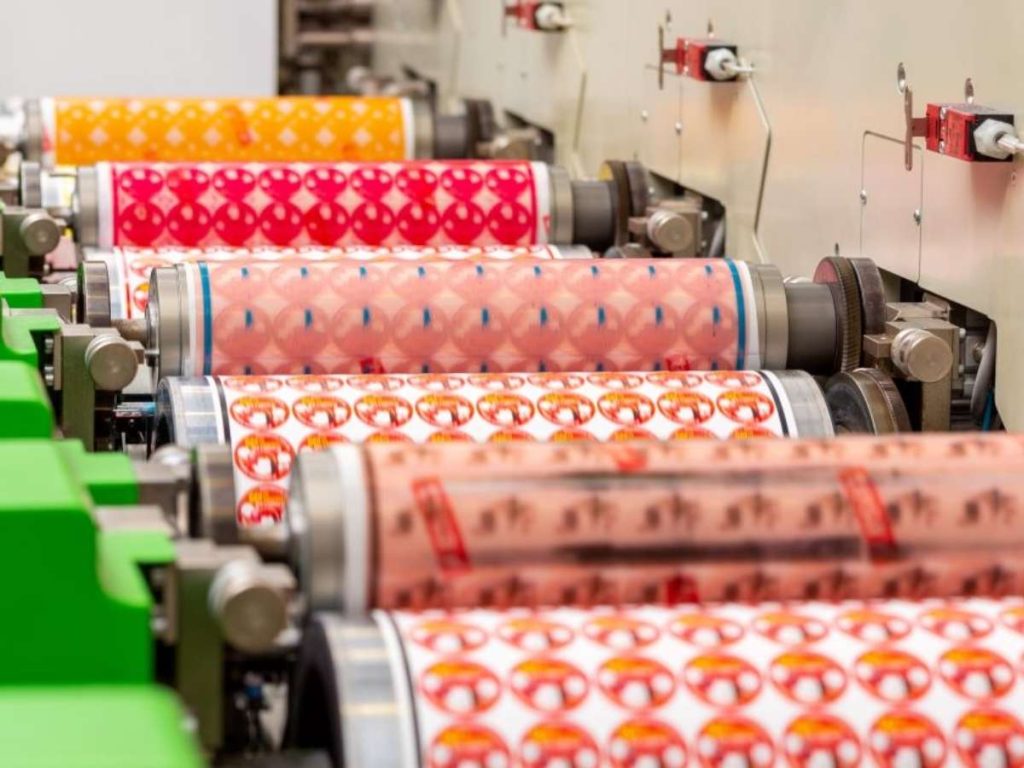

- Printing Equipment: Simple one-color prints are cheaper, while multi-color or lithographic printing requires higher setup fees and specialized inks.

- Folding and Gluing Machines: Automated folding and gluing are faster but require expensive machines, which means higher production costs for small orders that don’t offset setup expenses.

Manufacturers spread these costs across orders, so larger batches lower the per-unit price. If you only need a small run, you’ll likely pay more per box.

Labor and Production Speed Costs

- Manual vs. Automated Production:

- Manual assembly is cost-effective for small orders but slower.

- Automated production speeds up output and reduces labor costs per box, but factories charge more for small custom orders because they need to stop production and reset machines.

- Skilled Labor Costs: Workers operating machinery and performing quality control add to expenses. The more manual work required, the higher the labor cost.

- Overtime and Rush Orders: If you need an order fast, expect to pay a premium. Factories charge rush fees to prioritize urgent jobs.

Setup and Waste Costs

- Setup Fees: Before production starts, machines must be calibrated, printing plates installed, and die-cuts adjusted. Short runs have higher costs per box because these fees get divided among fewer units.

- Material Waste: Cutting and printing processes generate scrap material. Complex designs create more waste, which manufacturers factor into pricing. If your box shape leads to higher waste, your cost per unit will rise.

Energy and Facility Costs

- Electricity and Fuel: Running large machines consumes power, and fluctuating energy prices directly impact production costs. Factories with older, less efficient equipment may have higher costs.

- Storage and Handling: If your order sits in a warehouse before shipping, some manufacturers charge storage fees, especially for bulk orders.

5. Printing, Coating, and Customization Costs

Packaging isn’t just about protection—it’s also about presentation. A well-designed box can enhance your brand, attract attention, and make your product look premium. But every customization, from printing to coatings, adds cost. Some upgrades are worth it, while others may not justify the price.

Many businesses assume printing a simple logo won’t impact costs much, but the method, number of colors, and additional coatings can make a big difference. If you’re planning to customize your boxes, here’s what affects the price.

Printing Costs

The type of printing you choose depends on your design needs and budget.

- Flexographic Printing: A cost-effective option for large-volume orders. Works well for basic logos and simple one- or two-color designs.

- Lithographic Printing: Produces high-quality, detailed images. Ideal for luxury packaging but comes with higher setup fees. Best for large orders to offset the initial cost.

- Digital Printing: Great for small batches and full-color images. No setup costs, but higher per-unit pricing compared to flexographic printing.

- Screen Printing: Used for bold, high-contrast designs. Requires manual labor and specialty inks, making it more expensive for intricate details.

One business I worked with opted for lithographic printing because it looked premium. But after reviewing costs, they switched to flexographic for bulk orders, cutting their packaging expenses by nearly 30%.

Coating and Finish Costs

Coatings protect the box and enhance its appearance, but they also add extra expenses.

- Matte or Gloss Coating: A matte finish gives a soft, non-reflective look, while gloss adds shine. Both require additional processing.

- UV Coating: Protects the surface from fading and scratches. Adds durability but increases costs.

- Lamination: Adds a protective plastic layer, making boxes more durable, especially in humid environments. More expensive but necessary for moisture resistance.

- Spot Coating: Highlights specific areas of the box, making certain parts stand out. Looks premium but adds to production time and material costs.

Customization Costs

Beyond printing and coatings, structural customizations also affect pricing.

- Embossing & Debossing: Adds raised or pressed textures for a high-end look. Requires custom molds, increasing costs.

- Foil Stamping: Uses metallic foils to create a reflective, premium effect. Looks great but adds both material and labor expenses.

- Die-Cut Windows: Custom-shaped cutouts let customers see inside the box. Requires extra tooling and increases production time.

A retailer I know initially ordered embossed logos on all their boxes. After testing samples, they realized a high-quality print had the same impact at a fraction of the cost.

6. Additional Costs and Hidden Expenses

Cardboard box pricing isn’t always as straightforward as it seems. The initial quote might look reasonable, but once production starts, extra charges can start piling up. Many businesses, especially first-time buyers, don’t realize the hidden costs lurking beneath the surface—until they see the final invoice.

Unexpected fees can eat into your budget, making what seemed like an affordable option far more expensive. Let’s break down the most common additional costs so you can plan ahead and avoid surprises.

Setup and Tooling Fees

- Printing Setup Costs: Each new design requires a printing plate for flexographic printing or special calibration for digital and lithographic printing. These setup fees are often charged per design, meaning multiple versions of a box increase costs.

- Die-Cut Tooling: Custom-shaped boxes need specialized die-cut molds. If you’re ordering a unique shape for the first time, expect a one-time tooling fee that can be several hundred dollars.

- Reordering Costs: If you change your box design, you may need a new printing plate or die-cut mold, leading to another setup charge.

Storage and Warehousing Fees

- Bulk Order Storage: Ordering in bulk saves money per unit, but if you don’t have space to store them, some manufacturers charge a warehousing fee.

- Delayed Pickup Fees: Some factories charge extra if your shipment isn’t picked up within a certain timeframe. If you’re arranging your own logistics, double-check pickup deadlines to avoid unnecessary fees.

- Split Shipments: If you can’t take the full order at once and request multiple shipments, you may pay extra for storage and handling.

Shipping and Freight Charges

- Dimensional Weight Pricing: Shipping carriers charge based on the box size, not just weight. Larger boxes take up more space, increasing freight costs.

- Fuel Surcharges: Transportation costs fluctuate with fuel prices, which can make shipping unexpectedly expensive.

- International Import Duties: If you’re sourcing boxes from overseas, customs fees and taxes can add significant costs.

Quality Control and Rejects

- Defective Box Replacements: If your order has defects, you may need extra units to cover losses. Some suppliers replace defective boxes for free, but others charge for reprints.

- Color Matching Fees: If you need precise brand colors, some printing methods require custom ink mixing, which can cost extra.

7. Cost-Saving Strategies in Cardboard Box Manufacturing

Spending too much on packaging? You’re not alone. Many businesses unknowingly overpay for cardboard boxes simply because they don’t realize there are ways to cut costs. I’ve seen companies slash their packaging expenses without sacrificing quality—just by making a few smart changes.

If you’re looking to lower your costs, here are practical strategies that can help.

Optimize Box Design

- Reduce Excess Size: Larger boxes cost more because they use more material and increase shipping expenses. Right-sizing your boxes to fit your product saves money on both materials and freight.

- Use Standard Box Shapes: Custom shapes require die-cut molds, which add setup fees. If a standard box works, stick with it.

- Simplify Structural Features: Complex designs with extra flaps and reinforcements increase production time and waste, driving up costs.

Choose the Right Material

- Use Single-Wall When Possible: If your products don’t require extra protection, single-wall cardboard is significantly cheaper than double- or triple-wall.

- Consider Recycled Cardboard: Recycled materials tend to be more affordable than virgin paperboard and are widely available.

- Balance Strength vs. Cost: Some businesses overpay for high-strength boxes when they don’t need them. If your product isn’t fragile, a lower-grade material could work just fine.

Order in Bulk

- Higher Quantities = Lower Per-Unit Costs: Manufacturers offer volume discounts because bulk orders reduce setup time and increase production efficiency.

- Avoid Small Batch Runs: Small orders incur higher setup fees, making each box more expensive. If possible, consolidate your orders.

- Plan for Storage: If warehouse space is an issue, ask your supplier about split shipments rather than ordering small batches at full price.

Negotiate with Suppliers

- Ask About Volume Discounts: Even if you can’t place a huge order now, some suppliers offer progressive discounts based on long-term commitments.

- Compare Multiple Quotes: Prices vary between manufacturers, and even small differences in setup fees or material costs can add up.

- Look for Local Suppliers: If you’re paying high shipping fees, a nearby manufacturer could reduce logistics costs.

A business owner I worked with was about to place an order with a supplier overseas. After factoring in shipping costs and import fees, they found a local supplier that saved them money overall.

Conclusion

Cardboard box costs aren’t just about size and materials. Every decision—from printing to production speed—affects your bottom line. By understanding these factors, you can cut costs without cutting corners.

I’ve made mistakes before, overpaying for unnecessary features. Now, I know better. And now, so do you.

If you’re looking for a reliable CNC supplier but thinking about the safety of your machine during transit, we at Blue Elephant use secure packaging and provide real-time shipping updates to give you peace of mind.

Let’s optimize your costs and ensure safe delivery—contact us today!

Explore More of Our Resources

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.