I remember staring at my CNC machine, wondering if I had made a mistake. The machine sat there, a big investment, but no clear way to turn it into profit. Bills were piling up, and I needed a way to make money fast.

If you’ve felt this way, you’re not alone. I’ve been there. But after months of trial and error, I found ways to turn my CNC machine into a steady income stream. Now, I want to help you do the same.

This article will show you how to turn your CNC machine into a money-making tool.

Whether you’re starting from scratch or looking to scale up, I’ll break down practical ways to find customers, price your work, and keep your machine running profitably.

By the end, you’ll have a clear roadmap to turn your CNC machine into a business—without wasting time or money.

Let’s get started.

1. Understanding CNC Machine Profitability

If you’re thinking about investing in a CNC machine, one big question comes to mind: Can it really make money? The short answer is yes—but success depends on how well you use it. A CNC machine isn’t just another piece of equipment. It’s a tool that can automate production, increase precision, and scale your business faster than traditional machining methods.

Let’s break down why CNC machines are a smart investment and who can benefit the most from starting a CNC business.

What Makes CNC Machines a Good Investment?

CNC (Computer Numerical Control) machines automate cutting, milling, and shaping processes with high precision. Unlike manual machining, CNC machines follow programmed instructions, eliminating human error and increasing production speed. But what does this mean for your business?

Key Reasons CNC Machines Are Worth the Investment

- Automation Saves Time & Labor Costs: CNC machines work with minimal supervision. Once programmed, they can produce parts continuously, reducing labor costs and increasing output.

- Precision Leads to Fewer Mistakes: A CNC machine follows exact specifications, meaning every part comes out the same. This level of accuracy reduces material waste and rework, saving money.

- Scalability for Different Business Models: Whether you’re making a single prototype or mass-producing parts, CNC machines handle both. This flexibility allows businesses to serve multiple industries without major equipment changes.

- Custom Work & High-Profit Margins: CNC machining isn’t just for mass production. Many industries need specialized, custom-made parts—often at premium prices. This opens doors for businesses offering unique machining services.

Are you using your CNC machine to its full potential, or is there a way to increase its profitability?

2. Best Business Ideas for Making Money with CNC Machines

I still remember the day I got my first CNC machine. I was excited but also nervous. It was a big investment, and I had no clear plan for making money with it. At first, I experimented: cutting signs, engraving wood, and making parts for friends. Some ideas worked. Others? Not so much. But over time, I figured out what sells and what doesn’t.

If you’re wondering how to turn your CNC machine into a real business, you’re not alone. I’ve been there. Let’s go over the best ways to make money with CNC machining so you can avoid wasted time and start earning faster.

Manufacturing and Selling CNC-Made Products

The first thing I tried was making and selling products. It seemed simple: cut some designs, list them online, and wait for orders. But I quickly learned that not everything sells. Finding the right products makes all the difference.

Popular CNC-Made Products to Sell

- Furniture: CNC machines can create detailed designs for tables, chairs, and cabinets. Businesses and homeowners love custom pieces.

- Custom Signs and Advertising Boards: Shops, offices, and restaurants are always looking for signage that stands out.

- Engraved Items and Personalized Gifts: Nameplates, keychains, and trophies—people will pay extra for custom engravings.

- Molds for Industrial Production: Factories need precision molds for manufacturing plastic, metal, and composite parts.

- Precision Machine Parts and Tools: Many industries need custom metal and plastic components that CNC machines can produce.

I started small, selling custom signs. It took time to find the right materials and designs, but once I did, orders started rolling in. The key? Make something people already need.

Offering CNC Machining As a Service

Not everyone has a CNC machine, but plenty of businesses need CNC work. This was a game-changer for me. Instead of making and selling products, I started cutting parts for others. No inventory, no waiting for sales—just pure service work.

Industries That Need CNC Services

- Automotive and Aerospace: Precision parts for engines, frames, and custom modifications.

- Medical Device Manufacturing: CNC machines are used to make surgical tools and prosthetics.

- Jewelry and Engraving Businesses: Jewelers need precise cuts for metal and stone.

- Small Businesses Needing Custom Parts: Many businesses need one-off or low-volume CNC work.

Could you offer CNC services instead of selling products? It might be an easier way to start earning.

CNC Machine Rental and Leasing

At one point, I wasn’t using my CNC machine every day. That’s when I realized—why not rent it out? Many people need a CNC machine for a short time but can’t afford to buy one.

Who Needs to Rent a CNC Machine?

- Startups and Small Businesses: Companies that need CNC work but can’t afford a full setup.

- DIY Makers and Craft Hobbyists: People working on personal projects or custom builds.

- Schools and Training Centers: CNC training programs often need machines for students.

One of my first customers for rentals was a local artist who needed to cut complex patterns into wood. He had no CNC experience, so I trained him. That small job led to him recommending me to others—word of mouth matters.

Selling CNC Machines and Spare Parts

If you have industry connections, buying and selling CNC machines can be profitable. Many workshops and factories need affordable equipment but don’t want to buy new.

What You Can Sell

- New and Used CNC Machines: Many businesses prefer second-hand machines to save costs.

- Spare Parts and Components: Cutting tools, motors, controllers, and software upgrades.

- CNC Software and Accessories: Selling upgrades and add-ons can bring in extra income.

One of my biggest surprises was how much demand there is for used CNC machines. Not every business wants to buy brand-new. If you can refurbish and resell, it’s a great business model.

CNC Machine Repair and Maintenance Services

CNC machines need regular maintenance. When a machine goes down, businesses lose money. That’s where a CNC repair business comes in.

How to Start a CNC Repair Business

- Target Businesses That Rely on CNC Machines: Factories, machine shops, and manufacturers all need maintenance.

- Offer Preventive Maintenance Plans: Many businesses will pay for regular checkups to avoid costly repairs.

- Provide Emergency Repair Services: Downtime is expensive. Fast repairs are always in demand.

A friend of mine worked in CNC repair and made great money helping businesses avoid machine failures. He wasn’t selling products—he was selling reliability.

3. Essential Steps to Starting a Profitable CNC Business

Starting a CNC business can be exciting, but without the right steps, it’s easy to waste time and money. I learned this the hard way. When I first started, I didn’t have a clear plan. I bought a machine, made a few products, and hoped for sales. That approach didn’t work.

After some trial and error, I figured out what really matters: choosing the right machine, setting up a profitable model, and finding the right clients. If you want to avoid common mistakes and start strong, here’s what you need to do.

Step #1 Choose the Right CNC Machine for Your Business

Your machine determines what you can produce and who you can sell to. The wrong choice can limit your options, while the right one sets you up for success.

Consider These CNC Machine Types

- CNC Router: Best for wood, plastics, and light metals. Ideal for furniture, signs, and custom engravings.

- CNC Lathe: Specializes in cylindrical parts like shafts and fittings. Common in automotive and industrial applications.

- CNC Mill: Handles detailed metal and plastic machining. Used for precision parts and molds.

- CNC Plasma Cutter: Cuts through thick metals fast. Popular in metal fabrication and industrial manufacturing.

How to Pick the Right Machine

- Match the Machine’s Capabilities to Your Market: A plasma cutter is great for metal fabrication but useless for engraving wood. Choose based on what sells in your industry.

- Factor in Investment Costs vs. Profits: A high-end CNC machine can cost over $50,000. Will your market allow you to recover that cost quickly?

- Consider Future Growth: Will your machine be enough as your business expands, or will you need upgrades?

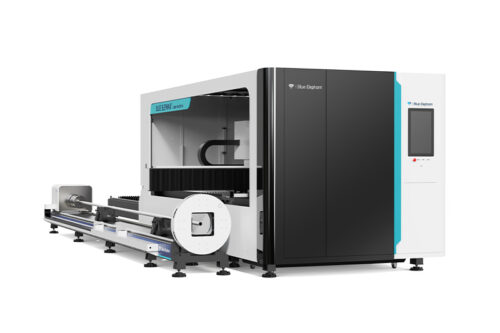

If you are looking for a durable and cost-effective CNC machine, at Blue Elephant, all our machines are designed to accommodate different regional standards, including voltage, sheet dimensions, and specific material requirements.

Step#2 Set Up a Profitable Business Model

A CNC machine won’t make money on its own. You need a solid business model that fits your resources and skills.

Decide on Your Main Revenue Stream

- Selling CNC Products: Manufacturing and selling furniture, signs, custom parts, or engravings.

- Offering CNC Machining Services: Providing precision cutting or milling services for businesses needing custom parts.

- Renting CNC Machines: Leasing out your machine to startups, schools, or small businesses.

Each model has different profit margins and customer expectations. The right choice depends on your market and investment level.

Plan Your Pricing Strategy

Many CNC businesses fail because they underprice their work. Here’s what to consider:

- Material Costs: Calculate expenses for wood, metal, plastic, or any other materials you use.

- Machine Time and Labor: Charge based on how long a job takes and how much effort it requires.

- Competitor Pricing: Research what others charge to stay competitive while making a profit.

Track Your Expenses to Avoid Losing Money

A CNC business comes with ongoing costs:

- Materials and Supplies

- Machine Maintenance and Repairs

- Electricity and Operating Costs

By keeping expenses in check, you’ll know exactly how much profit you’re making.

Step#3 Find Clients and Market Your Business

No clients, no business. Finding customers is just as important as running your machine. Whether you’re offering CNC services or selling products, the right marketing approach makes all the difference.

B2B Marketing Strategies

For those targeting businesses, networking and industry connections matter more than social media ads.

- Partner With Manufacturers Needing Precision Machining: Many factories and workshops outsource CNC work. Position yourself as a reliable supplier.

- Join Industry Trade Shows and Online Marketplaces: Events help connect you with buyers who need large-scale production. Online platforms like ThomasNet can help you reach industrial clients.

- Offer Bulk Pricing for Wholesalers and Retailers: Businesses prefer suppliers who can handle large orders consistently.

B2C Marketing Strategies

If you’re selling CNC-made products, you’ll need a different approach.

- Sell Through E-Commerce Platforms: Etsy, Amazon, and Shopify are great for custom CNC products like engraved signs or furniture.

- Use Social Media Advertising: Facebook, Instagram, and Pinterest are perfect for showcasing custom CNC work. High-quality photos and videos attract more buyers.

- Offer Customization Options: Many buyers are willing to pay more for personalized CNC work, whether it’s engraved gifts or custom furniture.

4. Maximizing Profits and Scaling a CNC Business

Once your CNC business is running, the next challenge is making it more profitable. At first, I thought more sales meant more profit, but I quickly learned that wasn’t always the case. I was wasting materials, dealing with unexpected machine downtime, and spending too much time on manual tasks.

If you want to increase profits, you need to focus on efficiency. And if you’re thinking about expansion, timing matters. Let’s go over how to cut costs, improve productivity, and know when it’s time to grow.

How to Reduce Costs and Increase Efficiency

Every CNC business has hidden costs. If you’re not careful, wasted materials, inefficient designs, and machine breakdowns can eat into your profits. Here’s how to fix that.

Use the Right Materials to Minimize Waste

- Choose materials that match your project needs: Some materials cut faster and last longer, reducing machine time and tool wear.

- Optimize sheet layouts: Nesting software can arrange your cuts efficiently, reducing material scraps.

- Buy in bulk: Large material orders often come with lower prices, saving money over time.

Early on, I underestimated how much money I was losing on scrap material. Once I switched to better nesting techniques, I cut waste by nearly 20%. That added up fast.

Invest in Software Automation for Design and Cutting Optimization

- Use CAD/CAM software to streamline design and toolpath creation.

- Automate repetitive tasks like cutting and engraving to save time.

- Simulate cuts before machining to avoid mistakes and wasted materials.

One of my biggest mistakes was running jobs without proper simulations. A single error meant throwing away an entire sheet of material. Investing in good software saved me from expensive mistakes.

Maintain Machines Regularly to Avoid Costly Repairs

- Clean and lubricate moving parts to extend machine life.

- Check and replace worn-out tools to maintain precision.

- Schedule preventive maintenance instead of waiting for breakdowns.

I once ignored a minor spindle issue because it didn’t seem urgent. A month later, the machine broke down completely, costing me thousands in lost production. Now, I stick to a strict maintenance schedule.

When to Expand Your CNC Business

Growth is exciting, but expanding too early can strain your finances. So, how do you know when it’s the right time to scale up?

Signs You’re Ready to Expand

- Demand Exceeds Production Capacity

- If you’re turning down orders because your machine can’t keep up, it’s time to grow.

- Look at production bottlenecks: Are you always running out of machine time or labor?

- Clients Request Additional Services

- Are customers asking for CNC capabilities you don’t have?

- Expanding into new services, like engraving or metal cutting, can open new revenue streams.

- Consistent Profits Allow for Reinvestment

- Before adding machines or staff, ensure your business has steady income.

- If profits are strong for at least six months, reinvesting in growth makes sense.

A few years back, I nearly bought a second CNC machine too soon. I was getting more orders, but my pricing wasn’t right, and I wasn’t making enough profit. Instead of rushing, I focused on efficiency first. By the time I expanded, my business was truly ready.

5. Common Mistakes to Avoid When Running a CNC Business

Running a CNC business can be rewarding, but it’s also easy to make costly mistakes. I learned this the hard way. When I started, I thought I just needed a CNC machine and a few customers. But without proper planning, I lost money, underpriced my work, and dealt with unexpected downtime that put my entire operation on hold.

If you want to build a strong and profitable CNC business, here are the most common mistakes to avoid.

Choosing the Wrong Market

A CNC machine is a powerful tool, but if you pick the wrong market, it won’t matter how good your work is.

Why This Happens

- Not Researching Demand Before Investing: Some people buy a CNC machine without knowing who will buy their products or services. Just because you can make something doesn’t mean there’s a market for it.

- Competing in Overly Saturated Markets: If too many businesses are offering the same CNC services, prices drop, and profit margins shrink. It’s hard to stand out in a crowded space.

How to Avoid It

- Study your competitors before choosing a niche.

- Look for industries that need reliable CNC services but don’t have many providers.

- Talk to potential customers before investing in specialized machines or materials.

When I first started, I made wooden signs because I saw others selling them online. But I didn’t realize how competitive that market was. It took me months to pivot into custom industrial parts, where competition was lower and profits were higher.

Underpricing Products and Services

Pricing is tricky. Charge too much, and customers look elsewhere. Charge too little, and you won’t make a profit.

Why This Happens

- Not Accounting for All Costs: Many CNC business owners only consider material costs, forgetting about machine maintenance, electricity, labor, and time.

- Offering Cheap Services to Get More Clients: It’s tempting to lower prices to attract customers, but it sets a bad precedent. Clients will expect low rates even when your costs go up.

How to Avoid It

- Calculate costs for materials, labor, overhead, and wear on your machine.

- Research competitor pricing but don’t assume you need to be the cheapest.

- Charge for the value you provide, not just the time spent cutting materials.

I once took a bulk order at a low price just to land a new client. After factoring in machine time, materials, and labor, I barely made any profit. Worse, the client expected the same low rate for future orders. Now, I price my work based on true costs and long-term sustainability.

Neglecting Maintenance and Downtime Costs

CNC machines are workhorses, but they need regular upkeep. Ignoring maintenance can lead to costly breakdowns that halt production.

Why This Happens

- Skipping Regular Servicing: Many CNC business owners wait until something breaks before fixing it, leading to expensive repairs and lost production time.

- No Backup Plan for Machine Failures: If your CNC machine suddenly stops working, do you have a plan to keep business running?

How to Avoid It

- Set a preventive maintenance schedule for cleaning, lubrication, and part replacement.

- Keep backup tools and spare parts to avoid long repair delays.

- If possible, have access to a second machine or outsource work in case of an emergency.

I once ignored a small spindle issue, thinking it wasn’t urgent. A few weeks later, the spindle failed in the middle of a big order, and my machine was down for two weeks. That mistake cost me both time and customers. Now, I never skip maintenance.

6. Tips on How To Maintain Making Money with CNC Machine

Starting a CNC business is one thing—keeping it profitable is another. I learned this firsthand. After my initial success, I assumed the money would keep flowing. But as competition grew and my machine required more maintenance, I realized that staying profitable meant constantly improving operations, reducing costs, and finding new ways to attract clients.

If you want long-term success, here are some key strategies to keep your CNC business running smoothly and making money.

Tip #1 Diversify Your Income Streams

Focusing on just one type of product or service leaves your business vulnerable to market shifts. Offering additional services like engraving, prototyping, or small-batch production can help you reach new clients and stabilize cash flow.

Selling CNC-related accessories such as spare parts or cutting tools can also add revenue, and digital design files offer passive income. I started with signage, but cutting parts for local manufacturers brought in more consistent, higher-paying work.

Tip #2 Build Long-Term Relationships With Clients

One-time jobs bring in short-term gains, but repeat customers are the foundation of lasting profitability. High-quality work, consistent delivery, and excellent communication encourage clients to return. Offering loyalty incentives or discounts for bulk orders adds more value. One client came to me for a single custom part—after a follow-up and offering more services, they became a regular source of business.

Tip #3 Optimize Production to Reduce Waste and Increase Profits

Inefficiencies in workflow and material usage can silently drain your margins. Nesting software helps minimize scrap by optimizing layouts, and CAD/CAM automation speeds up repetitive tasks. Even small adjustments, like organizing your workspace to reduce setup time, can make a difference. After tightening up my process, I saved 15% on materials—those savings went straight to profit.

Tip 4 Stay Competitive With Smart Pricing and Marketing

Even top-tier CNC skills won’t attract business without the right pricing strategy and visibility. Regularly review your pricing based on material costs, market demand, and competition. Keep a strong portfolio to show off your capabilities, and take advantage of trade shows and professional networks to reach B2B clients.

A CNC shop near me went out of business because they didn’t adjust prices when material costs increased. Meanwhile, others who adapted kept making money. Pricing smartly is just as important as cutting accurately.

Conclusion

Making money with a CNC machine isn’t about luck—it’s about smart decisions. Choosing the right business model, pricing your work correctly, and maintaining your machine will set you up for success.

I started where you are now, full of questions and uncertainty. But through trial and error, I built something sustainable. You can too.

If you’re looking for a reliable CNC machine supplier for your shop but concerned about installation issues. At Blue Elephant, we provide remote guidance or send engineers for on-site assistance.

Let’s make your dream business into reality. Contact us today!

Explore More of Our Resources

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.