I’ve seen production lines held up because of welding issues—sometimes from outdated methods, other times from investing in the wrong technology. One bad decision can lead to wasted time and money. So, how do you choose between laser welding and MIG welding?

This question comes up often, and it’s not always a simple answer.

Through hands-on experience with manufacturers in automotive, aerospace, and heavy fabrication, I’ve seen both methods succeed, and fail in different settings. This review is built on real-world performance, not just manufacturer claims.

In this article, we’ll compare laser welding and MIG welding side by side. From cost to efficiency to long-term durability, you’ll get the details you need to make the right choice.

Let’s break it down.

1. Differences in Heat Source and Energy Application

Let’s start with the fundamentals: how each method actually generates and applies heat to the workpiece. This isn’t just theory, it directly affects how clean, strong, and efficient your welds will be.

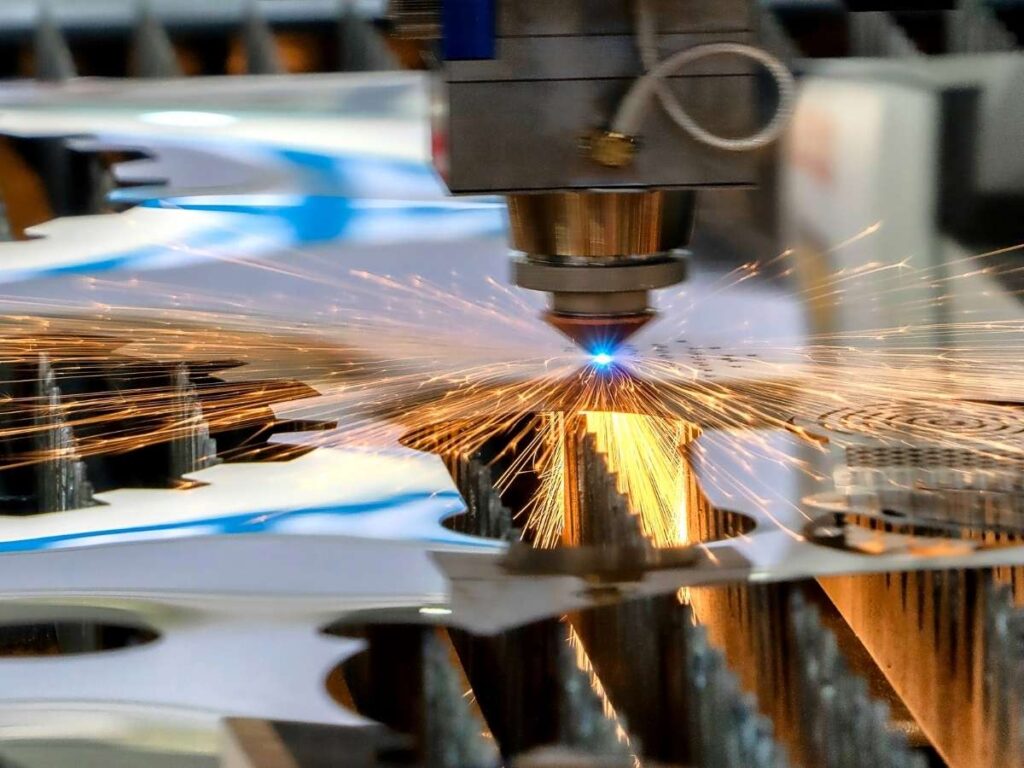

Laser Welding: Focused Beam for Precision Heat Input

- Laser welding uses a highly concentrated beam of light to generate heat. This beam is extremely narrow, which allows you to direct energy exactly where you need it without affecting the surrounding material.

- Because the beam is so focused, laser welding produces a very small heat-affected zone (HAZ). This reduces warping, distortion, and the risk of damaging heat-sensitive components or adjacent features.

MIG Welding: Electrical Arc with Filler Metal

- MIG welding uses an electrical arc that forms between a wire electrode and the base metal. The wire feeds continuously, melting into the joint and providing both heat and filler material at the same time.

- The arc generates broader, more distributed heat. As a result, the heat-affected zone is larger, which can lead to some material warping or stress in thinner or more sensitive metals.

If your team is working on high-precision components, or you regularly weld lightweight or delicate materials, laser welding gives you more control. If your jobs involve thicker pieces or less critical precision, MIG welding offers a more robust, forgiving process. It is well suited for structural frames, agricultural equipment, and general fabrication work.

2. Variations in Speed and Process Efficiency

Speed in welding doesn’t just mean how fast the torch moves across a seam. It also includes prep time, the actual welding pass, and post-weld cleanup. Efficiency is about how well that whole cycle fits into your production schedule.

Laser Welding: Fast Execution with Low Finishing Time

- Laser welding operates at high travel speeds, especially when automated. It melts a smaller volume of material, allowing for much quicker passes along a seam with minimal heat input.

- There is usually little to no spatter or slag, which cuts down on post-weld cleaning or finishing. In many cases, parts come off the table ready for the next step in assembly or inspection.

MIG Welding: Slower Welds and More Cleanup

- MIG welding generally takes more time, particularly on multi-pass welds or thicker joints. Because the heat input is more spread out, the weld pool is larger and requires slower movement to maintain control.

- MIG welds often produce spatter and require some post-weld grinding or wire brushing. That adds up over time, especially if you’re running a large number of parts through each day.

If you are aiming for a high-volume, repeatable process, laser welding will significantly reduce cycle time and labor. It is especially useful in automated environments where speed and consistency are critical. If you are handling custom work, mixed materials, or parts that vary in fit-up, MIG welding gives your operators more control. Even though it’s slower, it’s more adaptable to real-world imperfections.

3. Suitability for Different Material Thicknesses

Not all welding processes handle material thickness in the same way. Some methods are better for delicate sheet metal, while others excel in heavy-duty structural welding.

Laser Welding: Best for Thin to Medium Materials

- Laser welding is particularly effective on thin-gauge materials, such as stainless steel sheet, aluminum housings, and lightweight assemblies. Its low heat input means you can weld without blowing through or distorting the part.

- Some high-powered lasers can tackle medium-thickness materials with the right settings. However, once you start reaching heavy plate or thick-walled components, laser welding can become less efficient and more expensive per part.

MIG Welding: Well-Suited for Thick, Heavy Components

- MIG welding is more forgiving with thicker materials and large weld joints. It delivers a deep, wide weld pool that allows for structural strength and better gap-filling, which is especially helpful when parts aren’t a perfect fit.

- For industries that deal with heavy machinery, trailers, or industrial frames, MIG welding continues to be a go-to method. It offers reliable performance even when material cleanliness or precision isn’t perfect.

If most of your projects involve thin sheet metal or cosmetic parts, laser welding will give you better results with fewer side effects. You’ll spend less time on prep and rework due to heat damage or distortion. If your workload includes a lot of heavy welding, MIG welding will be more practical. It can penetrate deep into thick joints and deliver solid, long-lasting strength.

4. Differences in Weld Strength and Penetration

Strength is one of the top priorities in any welded structure, especially when you’re dealing with safety-critical applications or high loads. Both laser and MIG welding offer strong results, but they achieve that strength in very different ways.

Laser Welding: Strong and Precise in Targeted Areas

- Laser welding produces narrow but deep penetration when properly tuned. It allows you to fuse parts with a high degree of strength while minimizing thermal input and material damage.

- In thinner materials, laser welding can actually exceed MIG in terms of weld integrity, especially when you need a clean, narrow seam that still meets load-bearing requirements.

MIG Welding: Wider Beads with Reliable Hold

- MIG welds tend to be wider and offer more filler material, which results in excellent joint strength for thicker sections. The process is particularly good at handling parts that are not perfectly prepped or that have gaps between joints.

- While MIG may not be as precise as laser welding, it’s highly dependable in structural and mechanical applications. It also performs consistently well across a wide variety of material types and thicknesses.

Laser welding offers incredible precision with deep, narrow welds that suit precision assemblies, light frames, or tubing. If your parts need to remain light but strong, and they aren’t subject to heavy impact, laser can be the smarter long-term bet. MIG welding continues to dominate where rugged durability and load-bearing strength are the top priorities.

5. Variations in Weld Appearance and Finishing Requirements

Weld strength isn’t the only thing to consider — appearance matters too. Especially in industries where the final product is visible to customers or where cosmetic quality can affect brand perception.

Laser Welding: Neat, Narrow, and Minimal Cleanup

- Laser welding produces very narrow welds with smooth, uniform seams. There’s almost no spatter, slag, or burn marks, which means parts usually come out looking finished without any secondary work.

- This clean appearance is ideal for visible components, such as consumer electronics, food equipment, or architectural elements. It also reduces finishing labor, which can add up to big savings in both time and cost.

MIG Welding: Functional but Requires More Post-Processing

- MIG welds are thicker and often create some spatter or discoloration, especially during longer passes. The weld bead is bulkier and might not be aesthetically pleasing in applications where finish matters.

- While the weld is still structurally sound, it may require grinding, sanding, or painting if the part is visible or needs to meet visual standards. That means more time and labor, which can slow down your production line.

If your customers will see the welds or if visual quality is tied to your brand reputation, laser welding can reduce your finishing department’s workload significantly. Its clean lines often require no additional work before painting, polishing, or packaging. MIG is better suited for internal frames, construction parts, or components that get covered or coated later.

6. Automation Capabilities and Flexibility in Application

As more businesses shift toward automation to increase output and reduce labor costs, it’s worth taking a hard look at how each welding method integrates with robotic and CNC-based systems.

Laser Welding: Built for Automation and High Precision

- Laser welding is ideal for automation. It integrates seamlessly with robotic arms, gantry systems, and CNC-controlled machinery, making it a perfect match for repetitive, high-volume production environments.

- The precision of laser welding allows you to program exact weld paths and repeat them at incredible speeds. This level of control is valuable when working with fine tolerances, micro components, or multi-material assemblies.

MIG Welding: Automatable but Less Precise

- MIG welding can be automated using robots and weld cells, but it’s more sensitive to part fit-up and variation. Joints that aren’t perfectly aligned may lead to inconsistent welds or require rework.

- It also takes more setup time to automate MIG for changing part geometries. For job shops or operations handling a variety of projects, this flexibility limitation can be a challenge when automating.

If you plan to scale or introduce lights-out manufacturing, laser welding aligns more naturally with those goals. It’s built for consistency and high speed, which is exactly what automated workflows need. MIG still has a place in robotic cells, but expect more time spent on setup, fixturing, and operator oversight.

7. Tips to Consider When Choosing Between Laser and MIG Welding

At this point, you’ve probably got a good sense of how laser and MIG welding differ in terms of speed, appearance, strength, and flexibility. But even with all those technical comparisons, the final decision often comes down to the realities of your specific operation. Below are some practical angles I always recommend considering before making the investment.

Evaluate Your Material Types and Thicknesses

If you’re handling primarily thin stainless steel, aluminum panels, or intricate sheet metal parts, laser welding offers better speed, accuracy, and surface quality. The smaller heat-affected zone also keeps your parts from warping, which saves time and headaches later. But if you’re dealing with heavier steel, thicker sections, or components that require strong filler bonds, MIG welding is the better match for that workload.

Think About the Volume of Your Workload

Production volume plays a big role in whether the numbers will work in your favor. Laser welding is built for high-volume, repetitive manufacturing, where even small time savings add up across thousands of parts.

In those settings, the upfront cost is justified by long-term efficiency and minimal finishing work. MIG welding makes more sense if you do a lot of project-based work, repairs, or low-volume custom jobs that don’t warrant the time or cost of laser automation.

Consider Your Team’s Skill Level and Training Needs

Skill level within your team is another key factor to think about. Laser welding machines are more technical, often requiring operators to understand software settings, beam alignment, and safety protocols. That may mean a longer training curve or hiring more experienced technicians.

MIG welding, on the other hand, is easier to teach and allows your team to get up and running quickly, even with less experience or a broader range of skill sets.

Weigh Maintenance, Downtime, and Ownership Costs

Even the best machine won’t help you if it’s constantly down or difficult to service. Laser welding systems tend to need more specialized maintenance, and unplanned downtime can get expensive fast if you don’t have the right support in place.

MIG welders are simpler to maintain, and replacement parts or fixes are usually quick and cost-effective. While laser often wins on long-term operational costs, MIG still offers a lower total investment upfront and fewer surprises in day-to-day use.

Conclusion

Choosing the right method isn’t just about specs, it’s about what makes sense for your shop, your team, and your goals.

I remember standing in your shoes, trying to make the best decision for long-term growth.

The key is to start where you are, with what you know now.

What part of your welding process could be faster, cleaner, or stronger?

If you’re ready to take the next step, contact Blue Elephant today. We’d love to help you move forward.

Check Out These Additional Resources

Need more ideas? Browse through our extended range of products and discover something new:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.