A client once told me, “I wish I had found the right CNC machine sooner—I wasted thousands on the wrong one.” That stuck with me.

The CNC market is crowded, and making the wrong choice isn’t just expensive, it’s a major setback for a small business.

If you’re in the same boat, looking for the perfect CNC machine, you’re in the right place. Whether you’re a dealer, repairer, or rental company, finding the right model matters.

I’ve done the hard work—researching, testing, and gathering insights from real businesses using these machines daily. This list isn’t based on hype; it’s built on real-world performance.

You’ll get a detailed breakdown of the best CNC machines for small businesses, covering pricing, features, and what makes each one stand out. By the end, you’ll know exactly which machine fits your needs.

Let’s get straight to it!

Quick Comparison Table

With so many CNC machines available, choosing the right one can be overwhelming. This comparison table breaks down the key specifications, strengths, and limitations of the top 10 CNC machines for small businesses. Whether you need precision or affordability, this table will help you find the best fit for your needs.

| CNC Machine | Work Area | Spindle Speed | Material Compatibility | Best For |

| Sainsmart Genmitsu 3018 PROver | 300 x 180 x 45 mm | Up to 10,000 RPM | Wood, acrylic, soft aluminum | Entry-level projects, prototyping |

| Carbide 3D Shapeoko XL | 400 x 400 x 75 mm | Depends on router (Dewalt/Makita) | Wood, plastic, soft metals | Small businesses, custom fabrication |

| Blue Elephant 1325 4x8ft 3 Axis CNC | 1300 x 2500 mm (4x8ft) | Customizable | Wood, MDF, soft materials | Professional woodworking, furniture, cabinetry |

| Bantam Tools Desktop CNC Milling Machine | Compact | 28,000 RPM | Aluminum, PCB, plastics | Small metalworking, engraving, prototyping |

| Tormach 1100M CNC Mill | 18″ x 11″ x 16.25″ | 7,500 RPM | Steel, aluminum, titanium | Small-scale production, precision machining |

| Pocket NC V2-50 Desktop 5-Axis Machine | Small desktop size | 50,000 RPM | Aluminum, steel, titanium, plastics | Aerospace, jewelry, medical prototyping |

| Haas Mini Mill | 16″ x 12″ x 10″ | 6,000 RPM (upgradeable) | Steel, aluminum, composites | Small business manufacturing, machine shops |

| ShopSabre 23 CNC Router | 24″ x 48″ | High-speed spindle | Wood, plastic, aluminum | Sign-making, woodworking, prototyping |

| BobsCNC Evolution 4 CNC Router | 24″ x 24″ x 3″ | Based on user-installed router | Wood, plastics | Budget-friendly CNC routing |

| Omnitech Selexx Pal CNC Router | Large work area | High-speed | Wood, composites | High-volume furniture and cabinetry production |

Each of these CNC machines serves a different purpose, from entry-level workshops to high-volume industrial applications. This comparison should help guide your investment in the right CNC machine for your business.

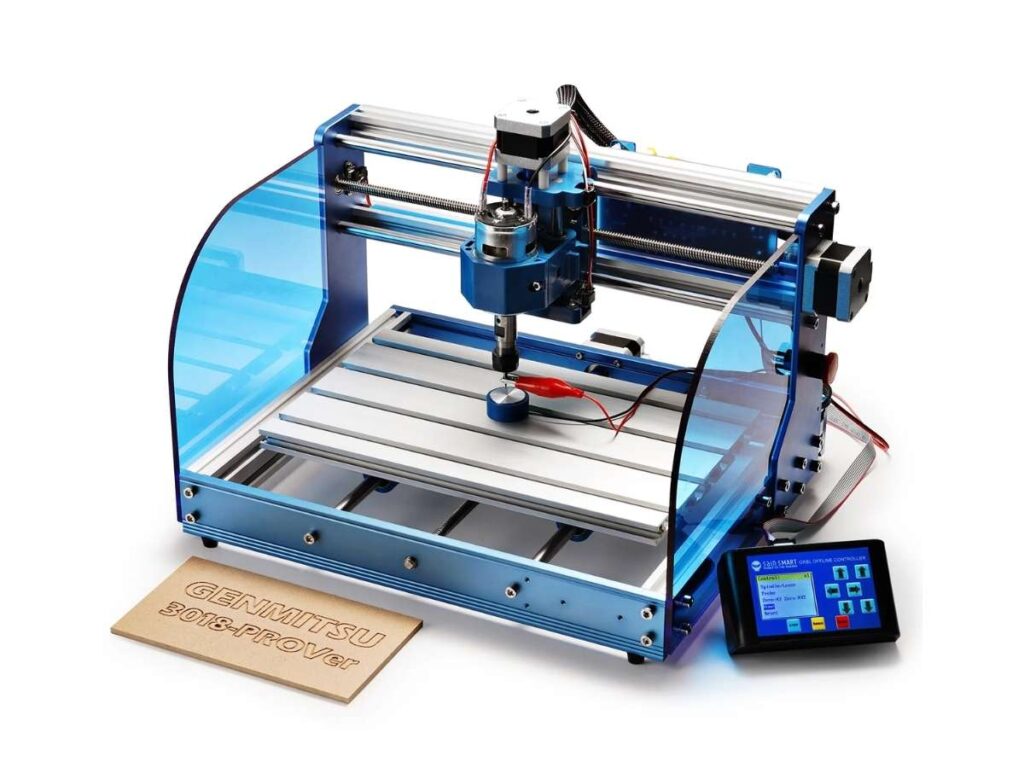

1. Sainsmart Genmitsu 3018 PROver

I’ve seen small businesses make one of 2 mistakes when choosing their first CNC machine: they either go too cheap and end up with an underpowered toy, or they overspend on something they don’t actually need. The Sainsmart Genmitsu 3018 PROver is that rare find—it’s affordable, but it actually delivers.

If you’re looking for an entry-level CNC router that gets the job done, this one is hard to beat. It’s compact, reliable, and perfect for small-scale production, testing, and prototyping.

- Price Range: Approximately $345

Key Features

- Plug-and-Play Setup: No complicated assembly—designed for quick startup.

- Compact & Efficient: Ideal for small workshops with limited space.

- Upgradable for More Power: Can be modified as your business grows.

- Built-In Safety Features: Includes an emergency stop switch for added protection.

- Material Compatibility: Handles wood, acrylic, soft aluminum, and more.

Pros & Cons

Pros:

- Cost-Effective: A solid CNC at a fraction of industrial machine prices.

- Quiet Operation: Suitable for small shops without industrial noise concerns.

- Easy to Modify: Expand its capabilities with upgrades.

Cons:

- Limited Work Area: The 300 x 180 x 45 mm workspace restricts larger projects.

- Not for Heavy Metals: Can cut soft aluminum but struggles with thicker metals.

2. Carbide 3D Shapeoko XL

The Carbide 3D Shapeoko XL is a solid choice for small businesses looking for a balance between affordability and performance. Built for precision and efficiency, this CNC router is well-suited for woodworking, prototyping, and light metalworking.

Its larger workspace and rigid design make it a step up from entry-level machines, allowing businesses to handle more complex projects without a massive investment.

- Price Range: Starting at $1,525

Key Features

- Generous Cutting Area: 400 x 400 x 75 mm workspace, providing room for mid-sized projects.

- Rigid Aluminum Frame: Ensures stability and precision during operation.

- Powerful Spindle Compatibility: Works with routers like the Dewalt DWP611 and Makita RT0701C.

- Intuitive Software: Comes with Carbide Create and Carbide Motion for easy operation.

- Versatile Material Support: Cuts wood, plastic, soft metals, and composites.

- Upgradable Design: Supports accessories like a dust collection system and a laser module.

Pros & Cons

Pros:

- Strong Build Quality: Provides stability and reduces vibration for cleaner cuts.

- Good Work Area for Small Businesses: Can handle a variety of projects without taking up too much space.

- User-Friendly Software: Suitable for businesses without extensive CNC experience.

- Customizable & Expandable: Can be upgraded with a stronger spindle, an enclosure, or an automatic tool changer.

Cons:

- Assembly Required: Some setup is needed before use.

- No Stock Spindle Included: A separate router must be purchased.

- Limited to Three Axes: Not suitable for businesses requiring multi-axis machining.

3. Blue Elephant 1325 4x8ft 3 Axis CNC Wood Router

A small cabinet-making shop once struggled with slow turnaround times and inconsistent cuts. Their old CNC machine couldn’t keep up with orders, causing delays and wasted materials. After upgrading to the Blue Elephant 1325 4x8ft 3 Axis CNC Wood Router, everything changed. Production speed doubled and they could finally take on larger, high-value contracts without hesitation.

Designed for professional woodworking businesses, this CNC router is built for efficiency, precision, and scalability. It can handle everything from cabinet doors to large signage projects, making it a perfect choice for manufacturers looking to expand their capabilities.

- Price Range:$$5,000 -$$8,000

Key Features

- Large 4x8ft Cutting Area: Ideal for processing full-size sheets of plywood, MDF, and other materials.

- Heavy-Duty Steel Frame: Reduces vibration, ensuring stability and accuracy.

- 3-Axis Precision: Provides smooth, high-accuracy cuts for woodworking, engraving, and furniture production.

- Powerful Spindle Options: Customizable with different spindle sizes to match specific business needs.

- User-Friendly DSP Control System: Simple interface for easy operation and minimal learning curve.

- High-Speed Performance: Rapid feed rates allow faster job completion without sacrificing precision.

Pros & Cons:

Pros:

- Designed for Business Use: Built to handle continuous operation in a production setting.

- High Precision & Smooth Finishing: Reduces material waste and rework.

- Handles Large-Scale Projects: Can process full 4x8ft sheets efficiently.

- Durable Construction: Built to last with minimal maintenance.

Cons:

- Higher Upfront Cost: Requires a larger investment compared to hobbyist CNC machines.

- Larger Footprint: Needs adequate workspace for proper installation and operation.

- Not for Metal Cutting: Designed primarily for wood, plastic, and soft materials.

4. Bantam Tools Desktop CNC Milling Machine

Not every small business needs a massive industrial machine. Sometimes, precision is more important than size. That’s exactly where the Bantam Tools Desktop CNC Milling Machine shines.

Whether it’s prototyping, small-batch production, or engraving detailed parts, this machine delivers professional-level milling in a compact footprint.

A small custom jewelry business once struggled with outsourcing its engraving work. Delays, quality issues, and high costs were eating into profits. After investing in the Bantam Tools Desktop CNC, they brought production in-house, cut lead times in half, and saved thousands.

- Price Range: Approximately $3,599

Key Features

- High-Speed Spindle: Up to 28,000 RPM for clean, precise cuts.

- Compact Desktop Size: Perfect for small workshops with limited space.

- Aluminum & PCB Ready: Handles soft metals, plastics, and circuit board engraving.

- Intuitive Software: User-friendly interface designed for small business owners.

- Automatic Tool Probing: Ensures accuracy with every cut.

Pros & Cons

Pros:

- Small but Powerful: Handles detailed milling work with ease.

- User-Friendly Interface: Great for beginners and experienced users alike.

- Minimal Setup Required: Ready to go with a simple learning curve.

Cons:

- Limited Work Area: Best suited for small to medium parts.

- Not for Heavy-Duty Milling: Can’t handle thick steel or large industrial projects.

5. Tormach 1100M CNC Mill

Some CNC machines are entry-level, and some are industrial giants—but what about those in between? That’s exactly where the Tormach 1100M CNC Mill comes in.

It’s the perfect middle ground for small businesses that need serious machining power without the price tag of a full-scale industrial unit.

A small aerospace parts manufacturer needed a reliable CNC mill that could handle aluminum, titanium, and steel with precision—without costing six figures. They chose the Tormach 1100M and haven’t looked back since. Now, they produce high-tolerance parts in-house, eliminate outsourcing delays, and control their quality at every step.

- Price Range: Starting at $9,495

Key Features

- Rigid Cast-Iron Frame: Built for stability, ensuring high-precision machining.

- Generous Work Area: 18” x 11” x 16.25” XYZ travel is enough for serious production.

- 7,500 RPM Spindle: Handles steel, aluminum, and composites with ease.

- PathPilot Controller: Intuitive software designed for machinists.

- Expandable & Upgradable: Supports automatic tool changers, power drawbars, and coolant systems.

Pros & Cons

Pros:

- Industrial-Grade Accuracy: Perfect for precision machining.

- Handles Tough Materials: Works with steel, titanium, and aluminum.

- Highly Upgradable: Grows with your business needs.

Cons:

- Higher Learning Curve: Requires more experience than entry-level CNCs.

- Larger Investment: More expensive than basic desktop mills.

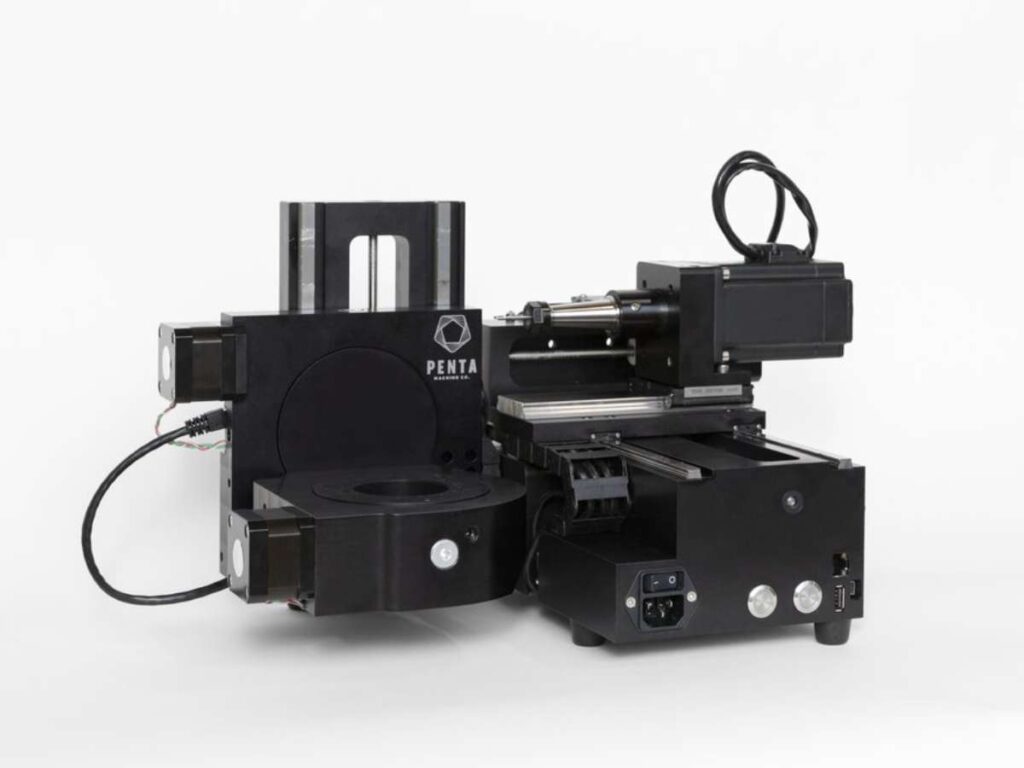

6. Pocket NC V2-50 Desktop 5-Axis Machine

A small aerospace prototyping firm once struggled with outsourcing complex 5-axis machining work. The wait times were long, the costs were high, and every revision meant more delays.

Then they discovered the Pocket NC V2-50 Desktop 5-Axis Machine—a compact powerhouse that changed their workflow overnight. Now, they produce high-precision prototypes in-house, test designs faster, and reduce lead times from weeks to hours.

For businesses that need precision and multi-axis machining without the size of a full industrial setup, this machine is a game-changer.

- Price Range: Approximately $5,000

Key Features

- True 5-Axis Machining: Cuts complex geometries that standard 3-axis machines can’t.

- Compact & Portable: Desktop-sized but built for professional use.

- 50,000 RPM Spindle: Handles high-speed precision cutting with ease.

- Rigid Aluminum Frame: Ensures stability for tight tolerances.

- Compatible with Tough Materials: Cuts aluminum, steel, titanium, and plastics.

Pros & Cons

Pros:

- Perfect for Prototyping: Ideal for precision parts in aerospace, medical, and jewelry industries.

- Takes Up Minimal Space: A 5-axis machine that fits on a workbench.

- High-Speed Performance: Produces intricate parts with extreme accuracy.

Cons:

- Small Work Area: Limited for large-scale production.

- Premium Price for a Compact Machine: More expensive than some larger 3-axis CNCs.

7. Haas Mini Mill

A machine shop owner once told a story about the moment they upgraded to a Haas Mini Mill. Before that, they relied on outdated equipment that couldn’t keep up with demand. They were constantly battling inconsistent cuts, slow cycle times, and frequent maintenance issues.

Once the Mini Mill hit the floor, things changed. Production became faster, tolerances got tighter, and downtime nearly disappeared.

For small businesses looking for industrial-grade machining in a compact form, the Haas Mini Mill is a trusted, battle-tested solution. It’s built like a tank, cuts through aluminum and steel with ease, and holds tight tolerances for repeatable accuracy.

- Price Range: Starting at $34,995

Key Features

- Rigid Cast-Iron Construction: Reduces vibration and ensures precision.

- 16” x 12” x 10” Work Envelope: Compact, yet large enough for serious machining.

- 6,000 RPM Spindle (Optional Upgrade Available): Handles steel, aluminum, and composites.

- Industry-Standard Controls: Haas CNC interface for intuitive operation.

- Heavy-Duty Performance: Designed for non-stop production.

Pros & Cons

Pros:

- Reliable & Proven Performance: A staple in machine shops worldwide.

- Handles Tough Materials: Cuts steel, aluminum, and more.

- Low Maintenance: Built for durability and long-term operation.

Cons:

- Higher Initial Investment: Costs more than entry-level machines.

- Requires Adequate Shop Space: Small for an industrial mill but still needs room.

8. ShopSabre 23 CNC Router

There’s a reason why so many small businesses regret buying a cheap CNC router. A machine that can’t hold tight tolerances or runs into constant mechanical issues costs more in lost time and frustration than it saves upfront.

That’s exactly why the ShopSabre 23 CNC Router stands out—it’s built to perform like an industrial machine, but at a size and price small businesses can manage. Switching to ShopSabre 23 transforms your production—flawless precision, smooth cuts, and zero wasted materials. Now, you can take on more custom projects with confidence, knowing their machine can handle it.

- Price Range: Starting at $7,000

Key Features

- 24” x 48” Cutting Area: Large enough for small business projects without taking up too much space.

- Heavy-Duty Welded Frame: Industrial-level stability for vibration-free cutting.

- Compatible with Multiple Materials: Cuts wood, plastic, aluminum, and composites with ease.

- High-Speed Performance: Rapid movement without sacrificing accuracy.

- User-Friendly Controls: Easy-to-learn interface for businesses with or without CNC experience.

Pros & Cons

Pros:

- Reliable & Precise: Delivers professional-grade results without the industrial price tag.

- Built to Last: Heavy-duty construction ensures longevity.

- Handles Various Materials: Great for woodworking, sign-making, and metal engraving.

Cons:

- Higher Cost Than Hobbyist Models: A bigger investment but worth it for business use.

- Not Ideal for Large-Scale Industrial Production: Best suited for small-to-medium-sized businesses.

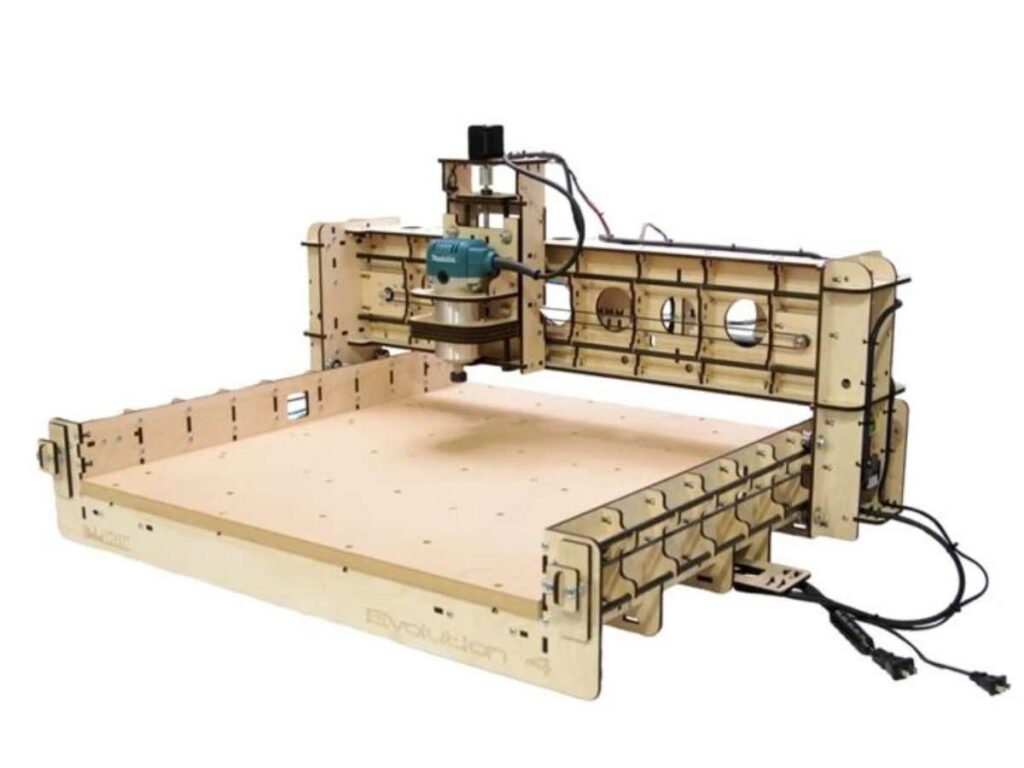

9. BobsCNC Evolution 4 CNC Router

Not every small business needs a $10,000 machine to get started with CNC routing. For businesses on a budget that still need precision and reliability, the BobsCNC Evolution 4 is a great entry-level option.

A local craftsman once needed a CNC router for custom engraving but wasn’t ready for a massive investment. They took a chance on the BobsCNC Evolution 4, and it completely changed their workflow.

Intricate designs became effortless, production sped up, and their business scaled faster than expected—all without overspending.

- Price Range: Approximately $1,000

Key Features

- 24” x 24” x 3” Cutting Area: Perfect for small and mid-sized projects.

- Rigid Wooden Frame: Surprisingly durable for a CNC at this price point.

- Open-Source Software Compatibility: Works with multiple CNC software options.

- Customizable Build: Easily modifiable for specific business needs.

- Affordable Price: One of the best budget CNC routers available.

Pros & Cons

Pros:

- Low-Cost Entry to CNC Routing: Great for businesses testing CNC applications.

- Lightweight & Compact: Doesn’t require much shop space.

- Highly Modifiable: Can be upgraded for better performance.

Cons:

- Requires Assembly: Comes in kit form, so setup takes time.

- Not Built for Heavy-Duty Production: Best for small businesses and hobby-level work.

10. Omnitech Selexx Pal CNC Router

A custom furniture business once struggled with keeping up with demand. Their old CNC router lacked speed and precision, causing delays and material waste. After upgrading to the Omnitech Selexx Pal CNC Router, production skyrocketed. Cuts were faster, finishes were smoother, and they could finally scale their business without bottlenecks.

The Omnitech Selexx Pal is built for businesses that need speed, precision, and reliability in a CNC router. Whether it’s high-volume cabinet making, furniture production, or custom panel work, this machine delivers industrial-grade results without the complexity of high-end manufacturing equipment.

- Price Range: $26,900.00

Key Features

- Heavy-Duty Steel Frame: Ensures stability and reduces vibration for consistent precision.

- Automatic Tool Changer (ATC): Speeds up production by switching tools automatically.

- Large Work Area: Handles full-size panels, perfect for furniture and cabinetry.

- Powerful High-Speed Spindle: Cuts through wood, plastic, and composites with ease.

- User-Friendly CNC Interface: Designed for small businesses to operate efficiently.

Pros & Cons

Pros:

- Ideal for High-Volume Production: Built for businesses that need efficiency.

- Time-Saving ATC Feature: Reduces manual tool changes for smoother workflow.

- Handles Large-Scale Projects: Perfect for big cuts, panels, and cabinetry work.

Cons:

- Higher Upfront Investment: Designed for serious businesses, not hobbyists.

- Larger Footprint: Requires dedicated workshop space.

Conclusion

I’ve seen firsthand what happens when businesses choose the wrong CNC machine—delays, wasted materials, and lost profits. But I’ve also seen the game-changing results of choosing the right one.

Now that you’ve explored the top 10 CNC machines for small businesses, the next step is simple—take action.

Remember the shop that struggled with production delays? After upgrading to the right CNC machine, their output doubled, profits increased, and stress disappeared.

That success is within your reach too.

So, what’s holding you back?

Contact us today and take your business to the next level!

Explore Related Resources

For more helpful content, explore our collection of recommended reads:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.