I almost threw away a perfectly good CNC machine. The signs were there—slower cycles, inconsistent precision, frustrating downtime. I assumed the only solution was to buy a new one.

But right before I placed the order, I met a machinist who asked me one simple question: “Why not retrofit?”

That question saved me thousands of dollars. But it wasn’t an easy process.

I learned the hard way what works, what doesn’t, and where to invest. Now, I want to help you avoid those same mistakes.

This guide will walk you through everything—choosing the right components, understanding costs, and making sure retrofitting is the right move.

By the end, you’ll know exactly how to upgrade your CNC machine without breaking the bank.

Let’s start!

1. What are Retrofit CNC Machines?

A retrofit CNC machine is an existing CNC machine that has been upgraded with modern technology. This process replaces outdated or worn-out parts—such as controllers, motors, and drives—without replacing the entire machine.

Think of it like upgrading an old car. If the engine and transmission still work, why buy a new one? A retrofit lets you keep the core structure while improving efficiency and precision.

What Can Be Upgraded in a CNC Retrofit?

The goal of retrofitting is to make your machine run like new (or better). Depending on your needs, you might upgrade:

- CNC Controller: The “brain” of the machine, responsible for processing commands and executing precise movements.

- Servo Motors & Drives: Critical for motion control, affecting speed, torque, and accuracy.

- Spindles: Upgrading to high-speed or more powerful spindles improves cutting efficiency.

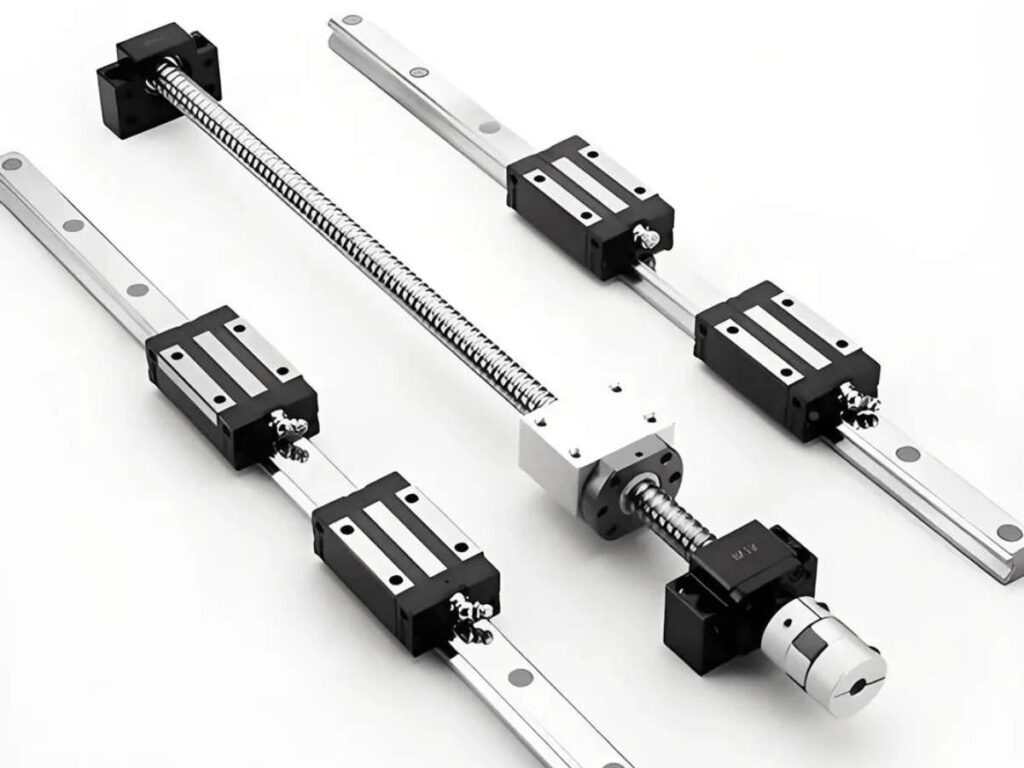

- Ball Screws & Bearings: Reduce backlash and increase positioning accuracy.

- Software & Interfaces: Modern CNC software improves workflow, automation, and integration with other systems.

Not every machine needs all these upgrades. The key is knowing which components will make the biggest difference for your operation.

2. Benefits of Retrofitting a CNC Machine

A few years ago, I thought my only option was to buy a new CNC machine. The old one was getting slower, and accuracy was slipping. I was frustrated with the downtime and the growing pile of rejected parts. But when I saw the price of a new machine, I had to pause.

That’s when I looked into retrofitting. At first, I wasn’t sure if it was worth it. Would upgrading parts really make that much of a difference? Could an old machine still compete with new models?

The answer was yes. And looking back, I wish I had done it sooner.

If you’re considering a retrofit, here’s what you stand to gain.

Reduced Costs

Buying a new CNC machine can drain your budget fast. Depending on the model, you’re looking at anywhere from $50,000 to $500,000—or more. But retrofitting? That cost can be 50-70% lower, while still giving you the performance boost you need.

I’ve seen shops spend hundreds of thousands on new machines when they could have extended the life of their current equipment for a fraction of the cost. A retrofit isn’t just cheaper—it also means:

- Upgrade Incrementally: Spread out costs instead of making one massive investment.

- Reduce Downtime: A retrofit takes weeks, while installing and learning a new machine can take months.

- Keep Your Workflow: Your team already knows how to operate the machine, so there’s no need for extra training.

If your machine’s frame and structure are solid, there’s no reason to replace it entirely.

Longer Machine Lifespan

CNC machines are built to last. But over time, controllers become outdated, motors wear out, and precision starts slipping. That doesn’t mean the entire machine is useless.

I once worked with a machinist who was ready to replace his 1998 CNC lathe. The controls were slow, and it struggled with accuracy. Instead of replacing it, he upgraded the controller and servo motors. That machine is still running today—more than two decades after it was built.

Retrofitting can add 5-10 years to your machine’s lifespan by replacing outdated parts instead of scrapping the whole system.

- Modern Controllers: Improve speed, automation, and efficiency.

- New Servo Motors and Drives: Restore precision and performance.

- Upgraded spindles: Handle tougher materials and complex cuts.

If the machine’s foundation is strong, retrofitting is like giving it a second life.

Better Precision and Performance

Inconsistent cuts. Rough finishes. Parts that don’t meet spec. If your machine is showing these signs, you don’t necessarily need a new one—you just need the right upgrades.

A friend of mine ran a small job shop specializing in aerospace parts. His machine started missing tolerances, leading to a spike in rejected parts. Instead of replacing it, he upgraded the ball screws and servo drives. Within a month, his accuracy improved so much that he landed a new contract with tighter tolerance requirements.

Retrofitting can help with:

- Tighter Tolerances: Improved repeatability and accuracy.

- Smoother Finishes: Less post-processing and wasted time.

- More Complex Jobs: Ability to take on higher-paying, precision-based work.

If quality is slipping, an upgrade might be all you need.

3. Essential Components to Upgrade in a CNC Retrofit

Upgrading a CNC machine isn’t about replacing everything—it’s about focusing on the components that deliver the biggest improvements. But where should you start?

I made the mistake of thinking I had to upgrade everything at once. It drained my budget fast, and some upgrades didn’t make much difference. Over time, I learned that a targeted approach works best.

If you’re retrofitting, these are the key components that can transform your machine’s performance without wasting money.

CNC Controller

If your CNC machine is slow, unreliable, or can’t run modern software, the controller is likely the issue. The CNC controller is the brain of the machine—it interprets code, processes tool paths, and controls movement.

Servo Motors and Drives

If your machine lags, jerks, or lacks precision, the problem might be in the servo motors and drives. These components control movement speed, accuracy, and torque, so outdated motors can cause sluggish performance or inconsistent cuts.

Spindle

Your spindle dictates how well your machine cuts, how fast it runs, and what materials it can handle. If your CNC struggles with tougher materials, produces poor finishes, or overheats frequently, an upgraded spindle could solve the problem.

Ball Screws and Linear Guides

Ball screws and linear guides control how smoothly and precisely your machine moves. Over time, these components wear out, leading to backlash, inconsistent tolerances, and rough finishes.

Automation and Sensors

Manual adjustments slow down production and increase errors. Upgrading to smart automation and sensors can cut down on wasted time and improve efficiency.

4. Signs That Your Machine Needs a Retrofit

How do you know when it’s time to upgrade your CNC machine?

I asked myself the same question when my old mill started acting up. At first, I ignored the small issues—longer cycle times, occasional positioning errors. But then the downtime increased, my scrap rate climbed, and I realized I was losing time and money by pushing the machine past its limits.

If your CNC machine is showing these warning signs, a retrofit might be the right move.

Slow or Unreliable Performance

Does your machine take longer than it used to? Are programs running slower, or does the spindle struggle to keep up?

These could be signs that:

- The controller is outdated and can’t process complex tool paths efficiently.

- Servo motors and drives are worn out, affecting speed and movement accuracy.

- The spindle is losing power, reducing cutting efficiency.

A friend of mine ran a CNC router in a small furniture shop. Over time, the machine took twice as long to complete the same job. After upgrading the controller and motors, he cut production time by 30%—without replacing the machine.

Inconsistent Accuracy and Quality

Precision is everything in machining. If your CNC isn’t holding tolerances like it used to, it could be due to:

- Excessive backlash in ball screws and linear guides.

- Servo drive issues causing inconsistent movement.

- Worn-out spindle bearings, leading to poor finishes and chatter.

Ask yourself:

- Do you frequently adjust offsets to compensate for inaccuracies?

- Are finished parts inconsistent, even when using the same settings?

- Have you noticed an increase in rejected parts or customer complaints?

If you’re seeing more scrap than usual, a retrofit could restore the accuracy you need.

Outdated or Limited CNC Controls

Are you still running an old control system? Does your machine struggle to handle modern CAD/CAM software?

Older CNC controllers often lack:

- Faster processing speeds, leading to longer cycle times.

- Advanced tool path capabilities, restricting what you can cut.

- Connectivity options, making automation and networking difficult.

If your control system is slowing you down, it might be time for an upgrade.

Frequent Downtime and Repairs

Do you feel like you’re constantly fixing your CNC machine? Are breakdowns happening more often?

Frequent failures usually point to:

- Worn-out electrical components (servo drives, wiring, or power supplies).

- Mechanical fatigue in spindles, bearings, or ball screws.

- Software incompatibility, making troubleshooting harder.

One manufacturer I know lost two days of production every month due to machine breakdowns. After retrofitting key components, downtime dropped by 80%, and he stopped worrying about surprise failures.

5. Common Challenges in CNC Retrofitting and How to Overcome Them

When I first retrofitted my CNC machine, I ran into problems I never saw coming—delays, software issues, and unexpected costs. To save you the frustration, here’s a table with the most common challenges and how to tackle them.

| Problem | Solution |

| Choosing the Wrong Components | Assess machine condition before upgrading. Work with experienced suppliers. Choose components that work together. |

| Underestimating Retrofit Costs | Get a detailed cost estimate. Prioritize upgrades. Account for hidden costs like software and downtime. |

| Extended Downtime During Installation | Schedule retrofits during slow periods. Order all parts in advance. Train operators before installation. |

| Software and Compatibility Issues | Test software compatibility before upgrading. Choose controllers that support legacy programs. Update CAD/CAM software if needed. |

| Operator Resistance and Training Gaps | Involve operators early. Provide hands-on training. Show them the benefits of the new system. |

| Finding Reliable Support and Parts After Retrofit | Work with a supplier offering strong after-sales support. Keep spare parts on hand. Document manuals, wiring diagrams, and software backups. |

| Unexpected Machine Failures Post-Retrofit | Conduct thorough testing before putting the machine into full production. Monitor performance closely in the first few months. |

| Poor ROI Due to Inefficient Upgrades | Focus on critical performance-boosting components. Track efficiency gains to measure the impact of the retrofit. |

| Electrical and Wiring Issues | Upgrade power supply and wiring as needed. Ensure compatibility between new and existing components. |

| Incorrect Calibration After Retrofitting | Work with professionals to fine-tune settings. Regularly check and recalibrate for optimal performance. |

| Overlooking Safety Features | Upgrade emergency stop systems and safety interlocks. Train operators on any new safety procedures. |

6. Maintenance and Support After Retrofitting

Retrofitting your CNC machine is a smart investment—but the work doesn’t stop once the upgrades are installed. Without proper maintenance and support, even the best retrofit won’t perform at its full potential.

If you’ve recently upgraded your CNC, here’s how to keep it running at peak performance for years to come.

Create a Preventive Maintenance Plan

A well-maintained CNC machine lasts longer, runs more efficiently, and has fewer breakdowns. After a retrofit, your machine needs regular maintenance to protect your investment.

Key areas to focus on:

- CNC Controller: Check software updates, backup settings, and monitor system performance.

- Servo Motors and Drives: Inspect for overheating, unusual noises, and lagging response times.

- Ball Screws and Linear Guides: Clean regularly, lubricate, and check for signs of wear.

- Spindle and Bearings: Monitor for vibration, excessive heat, or reduced cutting performance.

- Cooling and Lubrication Systems: Make sure coolant levels are adequate and filters are clean.

Train Your Operators on the New System

New components mean new ways of operating. If your team isn’t trained properly, you won’t get the full benefits of your retrofit.

Focus on:

- Understanding new software and control systems

- Optimizing tool paths for better efficiency

- Recognizing warning signs of mechanical issues

- Properly maintaining upgraded components

Don’t let lack of training hold back your investment.

Set Up a Monitoring System for Performance Issues

Even with upgrades, CNC machines experience wear and tear. The best way to stay ahead of problems? Monitor performance in real time.

Things to track:

- Cycle times: Are jobs running as fast as expected?

- Error rates: Are there more rejected parts or positioning issues?

- Energy usage: Are power consumption levels stable?

- Temperature readings: Are motors, drives, or spindles running too hot?

With the right monitoring, small issues don’t become big problems.

7. How To Choose The Best Retrofit CNC Machines Provider

Retrofitting a CNC machine is a big investment. The right provider can help you upgrade smoothly and efficiently, but the wrong one? That can lead to costly delays, poor-quality components, and endless headaches.

So, how do you choose the best retrofit CNC provider? Here’s what you need to know.

Quality of Components and Compatibility

A retrofit is only as good as the parts used. Cheap or incompatible components can cause more problems than they solve.

Key areas to check:

- Controllers: Do they support modern software and automation?

- Servo motors and drives: Are they high-quality and energy-efficient?

- Spindles: Can they handle the materials you work with?

- Software compatibility: Will it integrate with your existing CAD/CAM setup?

Tip: Look for reliable suppliers like Blue Elephant that customized machines according to your specifications and offer sample testing.

Level of Technical Support and After-Sales Service

What happens if something goes wrong after installation? A good provider doesn’t just sell you parts—they offer ongoing support and troubleshooting.

Look for:

- Remote Diagnostics: Can they assist you online if an issue arises?

- On-Site Service: Do they offer in-person repairs if needed?

- Availability of Spare Parts: Will they stock replacements for future maintenance?

- Warranty Coverage: What parts and services are included?

Tip: Choose a provider with a strong reputation for after-sales support.

Customization and Scalability Options

Not every business needs the same retrofit. A one-size-fits-all approach might not work for your machine.

Check if the provider offers:

- Modular Upgrades: Can you add more features later?

- Custom Solutions: Do they adapt to your specific needs?

- Integration with Automation: Will it support robotic loading, smart sensors, or IoT connectivity?

One shop I worked with started with a basic retrofit but later wanted to add automation for high-volume production. Their provider didn’t offer scalable options, so they had to start over with a new company.

Tip: Think ahead—choose a provider that offers customized and expandable solutions.

Customer Reviews and Reputation

Would you trust a CNC retrofit provider with no reviews or success stories? Probably not.

Before choosing a provider, check:

- Customer Testimonials: Are clients satisfied with their service?

- Online Reviews: Are there complaints about delays, poor quality, or lack of support?

- Industry Reputation: Have they worked with major manufacturers?

Tip: If a provider can’t provide references, it’s a red flag. At Blue Elephant, we share case studies, testimonials, and certifications, and offer trial orders.

Conclusion

I almost threw away a perfectly good CNC machine because I didn’t know better. Now, I know that the right retrofit can transform an aging machine into a powerhouse.

You’ve learned the key factors—experience, quality components, strong support, and clear pricing. Now it’s your turn to make the right choice.

Choose suppliers like Blue Elephant, we provide affordable spare parts and lifetime online support for ongoing assistance.

Contact us today to take your machine to the next level!

Explore More Helpful Resources

For more helpful content, explore our collection of recommended reads:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.