Panel saw is an essential machine in the woodworking industry. It is widely used in cutting plywood, particleboard, fiberboard, veneer, laminated board, block board, spliced solid wood board, etc. Even now it has been applied to the woodworking industry, and many companies that cut other materials also use panel saws to cut materials. Panel cutting saw is mainly used for sawing and processing of panels to obtain panels with dimensions meet the specification requirements. In addition, it can cut lengthwise and crosswise, and even cut at angles, such as 30°, 45°, 90°, with saw blades set longitudinally and transversely.

However, the panel saw with out intelligent system is nothing special. But if you add a CNC system and turn it into a CNC panel saw, it will be completely different. Traditional sliding table saws like vertical sliding table saws or horizontal sliding table saws are very dependent on labor, especially when cutting some large work pieces, a lot of labor is required. CNC panel saws solve this problem very well. Through the control of the CNC system, it no longer needs to be pushed around manually. You just need to put the work piece on the feeding platform. And then the CNC system will control the machine to automatically perform various cuttings, greatly reducing the dependence on labor.

Due to the rich experience and proven technology in the woodworking machinery industry, the Blue Elephant CNC panel saws have very good quality. It has excellent performance, stable efficiency, and high cutting quality. And it is currently the leader of CNC panel saw manufacturers. The following, I- as the Blue Elephant editor, will take you to learn more about CNC panel saws. If you are interested, please continue to read.

Best Cutting Tool for Panel Furniture- Panel Saw

The panel saw machine refers to sawing machine used to cut sheets into sized parts by using a rotating panel saw blade. It is also called the panel cutting saw, automatic panel saw, wood panel saw machine, panel saw cutting machine, etc. In addition, the CNC panel saw can cut the furniture panels with the maximum thickness up to 120mm. And the height of its pressure beam is automatically adjusted with the thickness of the plate. Thus it minimizes the idle travel and greatly improves the processing efficiency. Besides, the great advantage of the panel cutting machine is that combined with CNC technology, it is superior to ordinary manual cutting saw machines. For example, the CNC panel saw can meet mass production and complex processes with much higher cutting efficiency and faster speed. In a word, the CNC panel saw machine makes the entire cutting process fully intelligent and can meet the needs of various wood cutting projects.

Cut Materials

These are the materials you can process by our Blue Elephant panel saw cutting machines. If it’s not on the following list, you can ask our sales staff to get cleared to cut your materials.

Approved

Chipboard

Plywood

MDF

Acrylic

Masonite

Melamine

Solid Wood

Veneer

Not Approved

Steel

Adamantium

Aluminum

Metal in general

Advantages of CNC Pane Saw

1. High production efficiency

The panel saw can automatically complete the plate alignment, cutting, loading, and unloading. The operator only needs to set the parameters on the computer and then install the circuit board on the workbench, which needs low labor intensity.

2. Cutting thickness up to 100mm

The automatic panel saw can cut four 25mm wood boards at the same time. It is the best panel saw for panel furniture manufacturers with large scales to cut wood panels in large quantities.

3. Long service life

Due to the small friction coefficient and small wear, it has a long service life and good accuracy retention. A panel saw cutting machine can work more than 10,000 hours.

4. Low friction loss

Due to the small friction, the CNC panel saw has a small starting torque, sensitive transmission, stable movement, high follow-up accuracy, good positioning accuracy, and good synchronization.

5. 90% plate utilization rate

High utilization rate is one of most notable features of panel saws. The software of the panel saw automatically optimizes the cutting layout and combination. According to customer requirements, the veneer specifications can be automatically formed into the required size of the sample.

Top Sale Panel Saw for Wood Cutting

1. Sliding table saw

Sliding table saw machine is mainly composed of the following 8 parts: frame, main saw, grooving saw, lateral guide baffle, working table, sliding push table, miter saw guide baffle, bracket, miter saw angle display device, and side guide baffle. The scribing saw blade and the main saw blade are fixed. And the mobile aluminum workbench is pushed forward and backward by hand to realize sawing processing. Due to the special structure of the guide rail of the mobile worktable, it is light and labor-saving when manually pushing and feeding. Moreover, the processing accuracy is high.

configuration parameters

| Model | H45E/ELE-6132Y |

| Dimensions | 3200*2540*900mm |

| Sliding table size | 3200*375mm |

| Sawtooth length, width, thickness | 3000mm*1200mm*78mm |

| Scribing saw diameter | 120mm |

| Main saw diameter | 320mm |

| Main saw speed | 4000/6000rpm |

Video

The following video is about the H45E economical sliding table saw for woodworking with good cutting quality and high cutting speed. It shows how the CNC precision saw cuts board at 90° and 45°, and how to make board slotting. This panel saw has strong cutting power and can cut various wooden boards with smooth edge. At the same time, the products made by it can be used in the manufacturing of doors, cabinets, table, and other furniture. It is suitable for furniture boards processing especially cabinet boards processing.

2. Computer beam saw

The computer saw works automatically without manual intervention, which is safer. At the same time, errors caused by human calculation or input are avoided. Avoid unnecessary losses. In addition, the control interface is simple and easy to use. One operator can manage two or more machines at the same time. At the same time it has comprehensive guidance and warning alarms to help correct faults. The computerized panel saw uses a manipulator to clamp the wood, and a high-precision servo system controls the feeding accuracy. In addition, the panel saw machine also uses square precision guide rails to ensure the running accuracy of the saw frame. All the best panel saw kits not only guarantee excellent cutting precision, but also increase work efficiency.

Computer panel saw with front loading platform

Computer panel saw with rear feeding device

This is also the latest multifunctional computer panel saw launched by Blue Elephant in 2023. The rear feeding computer panel saw is controlled by an intelligent computer control system to complete the automation of the whole process. In addition, it also has a rear feeding device, automatic lifting platform, infrared protection device, air float table, double beams, and double push handles. It both realizes the full intelligence of the operation process and excellent processing effect. Besides, the saw blade can be disassembled quickly. And its maximum sawing length can reach 3800mm, and the maximum sawing thickness can reach 120mm.

This video is divided into 4 parts: machine appearance, loading process, cutting demonstration, and sample making.

How Much is the Panel Saw Machine Price?

People are more concerned about the electronic panel saw machine price nowadays. Manufacturers on the market give the quotation about $20,000. But Blue Elephant has been adhering to provide each customer with the best panel saw machines and the most affordable panel saw machine prices. Therefore, our panel cutting saw price can be reached at least $2,000, such as the best small sliding table saw for sale. However, the more high-end computer panel saw has much expensive cost. It is usually sold at the price from $20,000 to $40,000. But if you want to replace or adjust some original parts of both sliding table saws or computer beam saws, then the sawing machine price may be different. So, if you plan to buy a safety speed panel saw, you should deeply and seriously consider the specific configurations before placing an order. Don’t worry. Even so, we will give you the best CNC panel saw price. By the way, please notice and remember that don’t put too much weight on the machine price, it will be somewhat misleading. Quality is much more important than the price.

Panel Saw Machine Samples

The four plank cross-sections pasted below were cut by our Blue Elephant CNC panel saws. It can be seen that the cutting surface of the board is smooth and glossy. And the thickness of the cut board can also be thick or thin.

Customer Praise & Feedback

In recent years, with the continuous growth of our company, we have developed more and more CNC furniture panel saws with different functions. Some customers buy panel saws for separate use, while others buy panel saws in combination to form a complete panel furniture production line. In order to give more customers a more real feeling, you can take a look at the purchase and use experience of the following two customers~

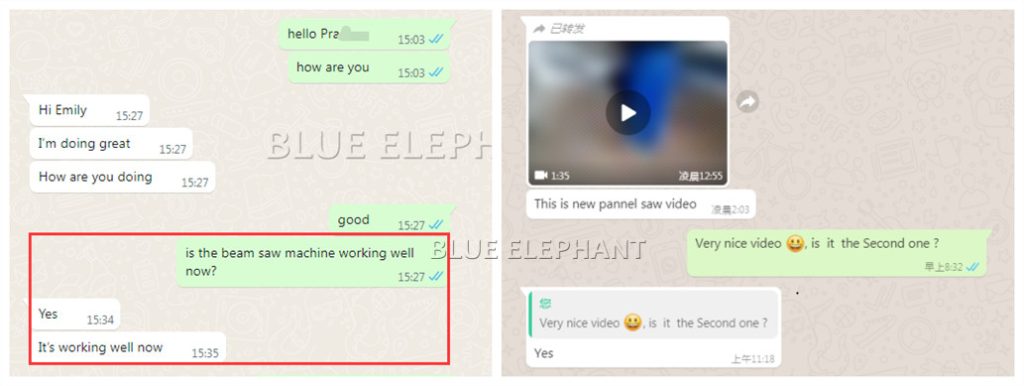

The first customer is from UAE. He is very satisfied with our ELE280 computer beam saw machine and shared us the machine working video. He said that our after-sales service personnel are very professional and patient. They helped him solve many problems, such as machine installation, machine operation, setting parameters, and so on. At present, the beam saw machine works well and has been put into production, which has improved a lot of work efficiency.

The other one is the Malawi customer. Actually, he bought our machine before. This is our second cooperation. We have had a great time working together and have a lot of trust in each other. If there is any problem, we will often communicate and share on Whatsapp. This time, after two months, the customer from Malawi sent us a working video of the Blue Elephant sliding table saw. In the video, the customer is cutting wood boards with the sliding table machine. He said that with the machine, he can cut more boards a day, which saves a lot of time and effort, and he is very satisfied.

In addition to these two foreign customers, there are many similar customer purchase experiences. If you want to know more, you can follow our official website and other social media channels for information.

Operation Precautions of Panel Saw

1. Before turning on the CNC panel saw, carefully check whether the machine head and tool holder are in place. And make sure there are no other debris on the workbench.

2. Make sure that the screws of each part of the panel saw machine are tightened. If there are any loose, tighten them before starting the panel saw.

3. Ensure that the rotation direction of the two saw blades is correct and in the same direction.

4. Let the panel saw machine idle for 1 to 2 minutes to see if the table saw is running normally.

5. The processed board should be close to the block and cannot be moved.

6. Adjust the cutting speed according to the thickness and hardness of the plate, and advance the machine tool at a constant speed but not too fast.

7. When cutting the board, use wooden strips to push forward.

8. Operators should wear masks, but should not wear gloves and loose clothes.

9. Don’t take objects directly beside the rotating saw blade with your hands. If necessary, you can use other long accessories to push it away before taking it.

10. If the edge corner of the board is defective, you should consider replacing the saw blade. So as not to crack the board or affect the quality of processing.

11. After the completing the cutting task, turn off the power and do a good job of cleaning the saw table and its surroundings.

6 Useful Tips to Maintain Panel Saws

In addition to routine cleaning, it is important to regular maintain every year. According to the sharing of our professional technicians, the following tips will tell you how to prolong the service life and performance of the CNC panel saw.

1. According to the workload, you should carry out the dust removal on the inside of the machine regularly to ensure the normal heat dissipation of the motor.

2. Regularly remove dust from the track of the push table to ensure the smooth operation.

3. Check the belt regularly and replace it in time if founding any wear.

4. Regularly inject oil to the lubricated parts of the fuselage to ensure the stable and quiet operation of the panel saw cutting equipment.

5. Overhaul the panel saw blade regularly.

6. Frequent refuel and add a good vacuum system to reduce the invisible wear and tear on the panel cutting saw machine caused by wood chips and dust.

Word at Last

Panel saw machine is one of the most indispensable and important components of the panel furniture production line. It is mainly responsible for multi-angle cutting of panels. Blue Elephant will not only accelerate the development of more types of panel saws, but also further optimize pre-sales and after-sales services. If you are a customer working in the panel furniture manufacturing industry, you can be assured to buy Blue Elephant CNC panel saw. Furthermore, we will give you the best sawing solutions for furniture making. Welcome to Blue Elephant CNC Company!