This news will show you some key experiences and insights from the South African customer’s purchase of Blue Elephant panel furniture production line equipment. You may have a clear understanding of pre-purchase and post-purchase experience, and also master some specific processes of cross-border purchasing.

Pre-purchase Experience

The furniture and cabinet manufacturing industry in South Africa has always been a dynamic sector, continually seeking innovation and efficiency enhancements. Recently, a South African customer took a significant step forward in their furniture and cabinet production process by choosing Blue Elephant’s smart furniture production line equipment, including cutting machines, drilling machines, edge banding machines, and laser cutting machines. This investment was driven by their high level of trust in Blue Elephant and their unwavering confidence in future growth opportunities.

Blue Elephant has been renowned for its innovative, high-quality production line equipment, which was one of the key reasons that attracted this South African customer. After careful market research and equipment comparisons, they decided to establish a partnership with Blue Elephant to elevate their production process to a whole new level.

Purchasing Experience

First, this customer purchased Blue Elephant’s cutting machine, which is a key tool used to cut raw materials into the required size and shape. The cutting machine’s high accuracy and fast operation enable customers to efficiently prepare materials to meet order requirements, reducing waste and time. The customer was satisfied with the performance of the automatic loading and unloading machine and believed that it played a vital role in the success of the furniture manufacturing process.

Another key component is Blue Elephant’s six-sided drilling equipment and edge banding machine equipment. The six-sided drilling machine can drill multiple sides of the workpiece simultaneously or sequentially, significantly improving drilling efficiency. Additional features such as chamfering, cutting and engraving are also available. This expands the machine’s usefulness, allowing it to handle a wider variety of jobs. The edge banding machine can ensure that the edges of furniture and cabinets are processed very smoothly and beautifully. The edge banding machine’s automated features save significant labor costs while improving manufacturing consistency and quality.

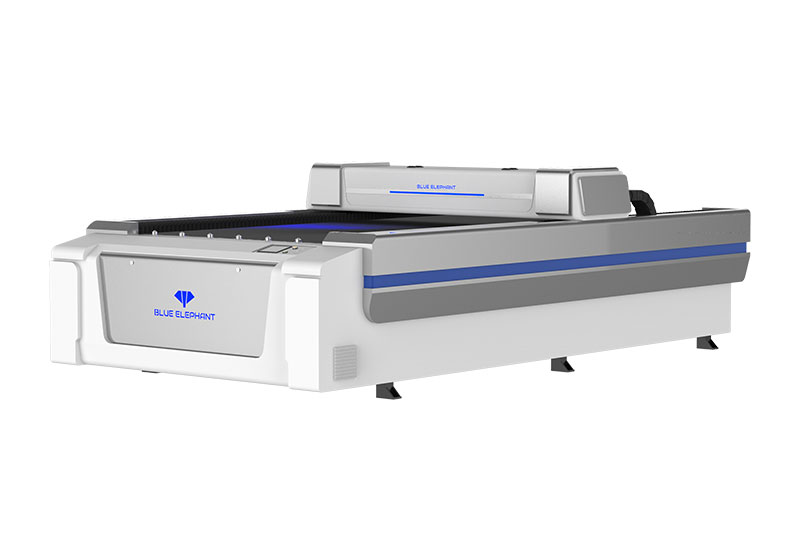

Finally, Blue Elephant’s laser cutting machines provide customers with a highly precise cutting method that can handle a variety of complex designs and requirements. This customer found that the laser cutting machine not only improved production efficiency, but also added more design flexibility to their products. This is critical to meeting the ever-changing needs of our customers.

Post-purchase Experience

However, simply purchasing these advanced devices is not enough. The South African customer was very grateful that Blue Elephant sent professional technicians for installation and technical guidance. This ensures that the equipment will run smoothly once it is put into use, reducing problems and downtime in production. The presence of professional technical support also provides customers with the opportunity to learn how to get the most out of these devices, allowing them to maximize their equipment’s potential.