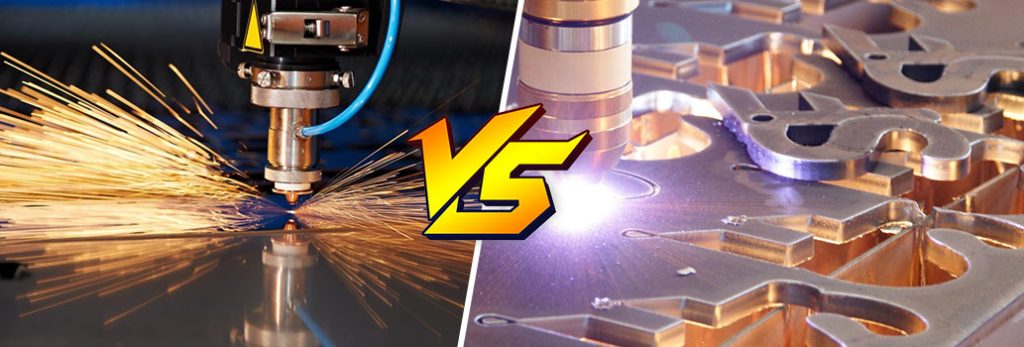

Which one should I choose to cut metal material, plasma cutting machine or laser cutting machine? This is probably a question that every person in the metalworking industry may ask. When it comes to cutting metal materials, there are two main cutting choices: plasma cutting machine and laser cutting machine. Both plasma cutting and laser cutting methods offer an effective solution for the fabrication of metals unsuitable for cutting by traditional methods. Then how to choose between the two? This article makes an ultimate introduction and comparison of the plasma cutter and the laser cutter, and gives several suggestions on how to choose. Hope it will provide some help for your metalworking.

Plasma Cutting Machine Principle VS laser cutting machine Principle

Principle of plasma cutting machine

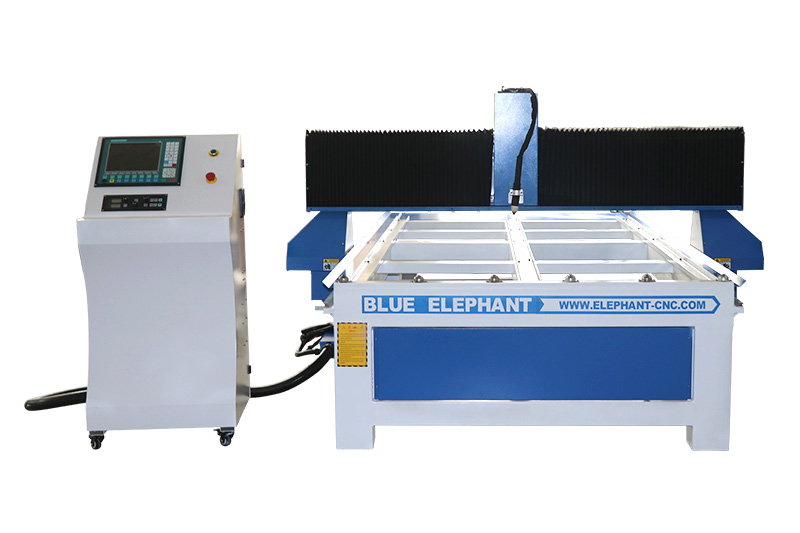

Plasma cutting machine can fall into hand-hold type and CNC type. The plasma cutting machine in this article refers to the CNC plasma cutting machine. It is also called CNC plasma cutter, CNC plasma table, and CNC plasma cutting table.

The CNC plasma table takes the compression air as the working gas and the high temperature and high-speed plasma arc as the heat source to melt and evaporate the incision of the metal part. And at the same time blow away the molten metal with high-speed airflow. Then the metal is cut off.

With different working gases, the CNC plasma cutting table can cut all kinds of metals that are difficult to cut by oxygen. Especially for non-ferrous metals, like stainless steel, aluminum, copper, titanium, nickel. The commonly used working gases include argon, hydrogen, nitrogen, oxygen, air, water vapor and some mixed gases.

Principle of laser cutting machine

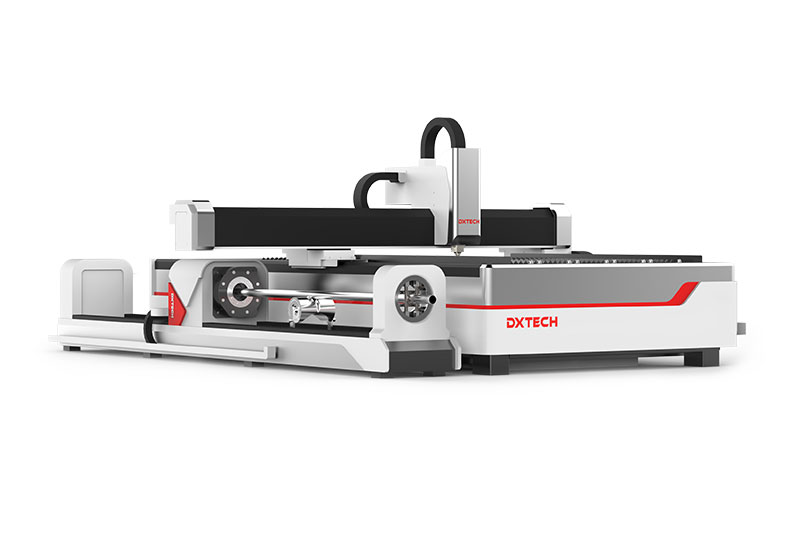

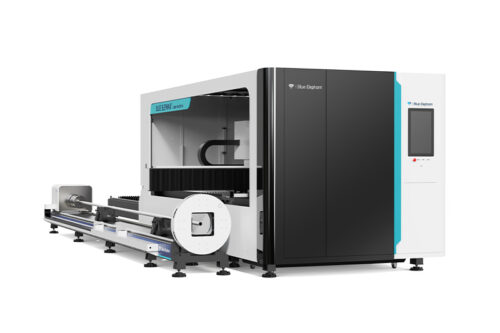

The laser cutting machine is a type of laser CNC machine, also known as CNC laser cutter, laser cut machine or CNC laser cutting machine. It utilizes a high power and density laser beam to focus on the work surface. This will heat the material to thousands or even tens of thousands centigrade within a very short time, causing the material to melt or vaporize. And then high-pressure gas blows off the molten slag or vaporized matter from the kerf to finish the cutting process.

Sine the laser beam is used to replace the traditional cutting tool, the mechanical part of the laser cut machine will not contact with the workpiece. So it won’t scratch the working surface during the cutting process.

There are two types of laser cutting machines, i.e. CO2 laser cutter and fiber laser cutting machine. Their working principle and cutting materials differ as well. The CO2 laser cutter is mainly for cutting non-metal materials, such as wood, MDF, acrylic, rubber etc. The fiber laser cutting machine, also the metal laser cutter, is mainly for cutting metal materials, like steel, carbon steel, aluminum, alloy etc.

Plasma Cutting Machine Application VS Laser Cutting Machine Application

Applications of plasma cutting machine

Plasma cutting is a processing method that uses the heat of a high-temperature plasma arc to partially melt (and evaporate) the metal at the cutting edge. And then use the momentum of the high-speed plasma to remove the molten metal to form the cutting slot. The CNC plasma cutting machine is suitable for cutting, cutting holes, patching and chamfering of a wide range of metal materials. It is mainly used to cut metal panels of medium thickness.

The CNC plasma table is widely used in automobiles, locomotives, pressure vessels, chemical machinery, nuclear industry, general machinery, construction machinery, steel structures, ships and other industries.

Features of the CNC plasma cutting machine include fast cutting speed, narrow cutting slot, small heat affected area, small deformation and low operation cost.

Applications of laser cutting machine

The laser cutting machine has wider applications than the CNC plasma cutter. Except for cutting a variety of metal materials, CO2 laser cutter can also cut wood, acrylic, ceramic, glass, rubber, PVC, feather, textile and other non-metal materials. However, the CNC laser cutter is not suitable for cutting highly reflective materials for a long time, like aluminum, copper etc.

Compared with the CNC plasma table, the laser cut machine cuts thinner metal plates but with higher precision. It is widely applied in automobile manufacturing, aerospace, electricity and petroleum equipment manufacturing, decoration, advertising, illumination, metal plate work and other industries.

Features of such laser CNC machine include fast cutting speed, high machining precision and narrow cutting slot.

Advantages and disadvantages

Plasma cutting machine advantages and disadvantages

Plasma cutting is a low-cost cutting method. It uses a high-temperature plasma arc to melt the metal at the cutting edge. As a combination of the computer numerical controlled machine and the plasma arc, the plasma cutting machine has its own advantages and disadvantages.

Advantages:

The plasma cutting table is suitable for cutting a wide range of metal materials;

It can cut metal plates with medium and above thickness at a high speed, which is faster than laser cutting;

Plasma cutting has a lower kerf and small heat affected area;

The plasma cutter is not limited to the reflective properties of the metal, and it can cut highly reflective metal materials.

Disadvantages:

Compared with laser cutting, the plasma cutting machine may have:

Larger cutting slot, less smooth cutting surface and lower cutting precision;

Poor perpendicularity of the cutting surface: there will be an oblique cutting edge on the side of the cutting surface. These cutting edges are not perpendicular to the top surface;

More cutting slag: the cutting process will produce more cutting slag at the cutting surface. In order not to affect the quality of the subsequent process, the slag must be removed by grinding, which also increases the workload and labor cost;

Harmful gases and arc light: the principle of plasma cutting table determines that harmful smoke, gases and arc light will be generated during the cutting process. So operators shall do the personal protection properly.

If you want to see a working video of a plasma cutting machine, please visit:

This video shows our 1325 CNC plasma cutting machine cutting irregular shapes out of a square steel tube with a high speed. The machine has high precision and the finished part is exactly the same as the design.

Laser cutting machine advantages and disadvantages

As a product combining CNC and laser technology, the laser cutting machine has many advantages:

Non-contact cutting: the CNC laser cutting machine can cut with the mechanical part of the laser cutter head not contacting the work piece. It won’t damage the material surface;

High speed cutting: when cutting metal plates of 1mm thick, the cutting speed can reach approximate 10m/min. The cutting speed decreases as the thickness of material increases;

High cutting quality: small cutting slot, high precision, small heat affected area, smooth cutting surface and edge, without post-process;

Wide range of cutting materials: except for cutting metal, the laser cutter can also cut wood, plastics, rubber, PVC, acrylic, leather etc.;

However, the CNC laser cutter also has disadvantages and the high cost comes first. It may need slightly high cost for initial investment and later maintenance. Currently, the metal laser cutter is quite cost-effective in cutting thin metal plates. In terms of cutting medium thick plates, its cutting efficiency is lower than the plasma cutting machine.

For a working video of CNC laser cutting machine, you can visit:

This video shows our latest fiber laser cutting machine cutting 3mm-20mm carbon steel plates with high speed and high precision. The finished products are with neat and smooth edges and surfaces without subsequent processing. You can also visit our YouTube channel to see more of our amazing laser CNC machine.

Plasma cutting machine VS. laser cutting machine

Now, you’ve noticed the respective pros and cons of the plasma cutting machine and laser cutting machine. To understand which one is suitable for your project, you still need to compare them to see their differences.

The CNC plasma table is more suitable for cutting medium and above thickness metal plates. Theoretically, the maximum cutting thickness of the plasma cutter can reach over 100mm. But the best cutting range is probably within 80mm. The laser cutting machine has a greater advantage in cutting thin plates. Depending on its power and performance, it can cut different thicknesses of plates, and the maximum cutting thickness can reach about 30mm.

Cutting slot of the CNC laser cutter is very narrow as the laser beam is focused into a very small spot. And the laser cutting is a non-contact process, which will not damage the processing surface. However, compared with laser cutting, the cutting slot of plasma cutting is relatively larger, and the cutting surface is rougher.

In terms of cutting thin metal plates, the fiber laser cutting machine can cut with a higher speed than the CNC plasma cutting table.

Laser cut machine offers a much higher level of precision compare to the plasma cutters.

The plasma cutting table is not affected by the reflective property of materials. But the metal laser cutter may be affected or limited when cut highly reflectively metal materials.

Although the CNC plasma cutter is limited to cutting, they can cut all types of metal. The laser cut machine can cut, engrave, or weld, and can process non-metal materials, like wood, acrylic, plastics, glass etc.

Capital investment required for a laser cut machine is considerably higher than for a plasma cutting table.

The laser cut machine uses less energy and generates less noise, making it a more eco-friendly metal cutting option.

CNC laser cutting machine has a tighter tolerance than the plasma cutting machine, making it ideal for precise cuts or parts that have intricate notching.

The laser cutter is typically more expensive to operate but offer a level of detail that the plasma cutter does not.

How to choose between plasma cutting machine and laser cutting machine

The differences between the laser cutting machine and the plasma cutting machine are important when selecting the best solution for your application. Although one approach is not necessarily superior to the other, each offers certain capabilities and benefits that make one more suitable to an application.

If you are still not sure about which one to choose, the following suggestions are for your reference.

When to choose plasma cutting

For any one of the below circumstances, I generally recommend you to select the plasma cutting machine:

The workpiece you need to cut has simple shapes, without many cutouts or intricate notching;

You need to cut metal plates with medium or large thickness, such as over 25mm thick;

You don’t have very strict requirements on the quality of cutting slot and cutting surface;

A large quantity of highly reflectively metal is required to be cut or long-time cutting of such materials is required.

When to choose laser cutting

However, I generally recommend you to choose the CNC laser cutting machine if any one of the following applies:

Tighter tolerance specifications, precise cut and/or small hole diameter workpieces are required;

Fast cutting of metal plates less than 6mm is required;

Except for metal, you need to cut other non-metal materials, such as wood, PVC, acrylic, rubber etc.;

Apart from cutting, you also want to engrave patterns on your workpieces;

You have higher requirements on the cutting precision and quality of cutting slot, edges and surface.

Conclusion

| Plasma cutting machine | Laser cutting machine | |

| Working substance | Compression air, plasma arc | Highly focused laser beam |

| Major function | Cut | Cut & engrave |

| Cut materials | All kinds of metal: Steel, stainless steel, copper, aluminum, cast iron, carbon steel, etc. | Wide range of metal: Stainless steel, carbon steel, silicon steel, aluminum, alloy, etc. Non-metal materials: Wood, acrylic, PVC, rubber, leather, glass, textile, etc. |

| Cutting thickness | Medium and above thickness, not suitable for cutting very thin plates (less than 2mm) | Thinner than the plasma cutter, not suitable for cutting medium and above thickness plates (over 30mm) |

| Cutting speed | Its cutting speed may reach maximum when cutting about 6mm thick metal plates. | The thinner the metal material thickness, the faster the cutting speed. |

| Width of cutting slot | Relative large | Narrow |

| Cutting precision | Good | Higher than plasma cutting |

| Major applications | Cutting medium thickness metal plates, with simple cutouts | Cutting thin metal plates with precise cutouts and complex notching; cutting and engraving non-metal materials |

The above comparison table lists the major property differences of the CNC plasma cutting machine and the CNC laser cutting machine. Hope this table can help you choose a suitable cutting machine for your application.

In short, the laser cutting machine is great for engraving details or cutting out small shapes from thin metal materials. Whereas plasma is better for more simple cuts on medium thick metal plates.

In conclusion, the material type, thickness and your requirements on cutting results determine whether to choose the laser cutting machine or plasma cutting table. Both these two machines have fast speed, high efficiency and wide applications. But one may more suitable for a specific project. Another thing need to pay attention to is that, both the laser cutting machine and plasma cutting machine may generate molten slag, gas, smoke or strong light during the cutting process. So be sure to take safety protection measures properly.