The laser cutting machine is in a stage of rapid development, especially the metal laser cutter. It is widely used in all walks of life. Metal laser cutter machines have been relatively mature in CNC metal cutting with the development of laser technology. The metal laser cutting machine can cut a variety of metals, alloys, and even highly reflective metal materials.

At present, the mainstream metal laser cutter on the market is the fiber laser machine. The most commonly used power is 1000W-4000W. Of course, there are also high laser power machines above 4000W for industrial applications. The CNC metal laser cutter mentioned in this article also refers to the fiber laser cutting machine. And it is also called fiber laser cutter, or laser metal cutting machine.

If you are considering buying a metal laser cutting machine, you can’t miss this article. It provides the answers to all your considerations before buying a metal laser cutter for sale. For example, the types, components, applications, and selection tips of the metal laser cutter. I believe that, after reading this article, you’ll have a comprehensive understanding of the laser cutter for metal.

Types of the metal laser cutter

The laser cutting process uses a high-power and high-density laser beam to irradiate the material. So the material is quickly heated to melt or evaporate. As the beam moves on the material, the melted holes continuously form slits with a very narrow width (about 0.1mm). This is how a metal laser cutting machine cuts various shapes from a metal sheet.

There are 3 major types of metal laser cutting machines on the market currently in terms of the laser source. They are CO2 laser, fiber laser, and YAG laser.

1.CO2 laser cutting machine

Some CO2 laser machines with high power can cut and etch thin metal sheets. But it is not suitable for cutting thick metal sheets. Because the CO2 laser beam wavelength is 10.6um, which is not easily absorbed by metal materials. However, the CO2 laser cutter is quite good at cutting non-metal materials.

Processing materials: wood, paper, fabric, leather, acrylic, rubber, glass, stone, etc.

Major applicable industries: crafts, advertising, decoration, toys, etc.

Advantages: A CO2 laser cutter mainly cuts or engraves non-metal materials. It has a compact size, which is easy to move and operate.

Disadvantages: Its photoelectric conversion rate is relatively low, so it consumes a lot of energy. There are multiple easily worn parts, such as the optical lenses. So the maintenance costs may be very high.

2.Fiber laser cutting machine

The fiber laser machine is mainly for cutting metal sheets, tubes, and pipes.

Processing materials: carbon steel, stainless steel, aluminum, brass, copper, alloys, some precious metals.

Major applicable industries: automobile, machinery, electricity, hardware, medical and fitness equipment, electric appliances.

Advantages: It has low energy consumption and a relatively high photoelectric conversion rate. It is suitable for cutting precise and tiny parts due to the stable laser beam and dense light spot.

Disadvantages: The core technical means of the laser is in the hands of only a few manufacturers. This results in the price of fiber lasers being generally expensive. Thus, the metal laser cutting machine price is also higher.

3.YAG laser cutting machine

YAG laser machine can cut and engrave multiple types of both metal and non-metal materials.

Processing materials: stainless steel, carbon steel, aluminum, aluminum alloy, gold, silver, plastics, rubber, resin, ceramics, etc.

Major applicable industries: household appliances, kitchen supplies, decoration, advertising.

Advantages: The YAS metal laser cutter is easy to operate and has high flexibility. It has relatively low production and maintenance costs.

Disadvantages: It is mainly used to cut sheets with a thickness of less than 8mm. And the cutting efficiency is relatively low.

From the development trend of metal cutting machines, fiber laser has gradually become the preferred machine for CNC metal cutting. Therefore, all the metal laser machines introduced below are fiber machines.

Major components of a fiber metal laser cutter

A fiber laser cutting machine mainly contains the following parts:

Machine bed, system, laser head, laser, auxiliary gas, water cooler, dust removal, safety protection, and other parts

Laser head

A laser head is the core component that plays the main cutting role on the metal laser cutter. A fiber laser beam is emitted from the laser generator and then focused and emitted from the laser head through the optical path system.

The mainstream manufacturers of the laser head include Raytools, WSX, PRECITEC, OSPRI, etc. Blue Elephant provides the Raytools laser head for its laser metal cutting machine as standard. And the whole series of the laser heads is auto-focus. Other brands are optional for customers if required.

The wearing parts of the laser head mainly include the collimation protection lens, focus protection lens, nozzle, and ceramic ring.

The service life of the wearing parts of a laser head of a sheet metal cutting machine (continuous cutting):

| Name | Service life (h/piece) |

| Collimation protection lens | 640 |

| Focus protection lens | 160 |

| Nozzle | 240 |

| Ceramic ring | 2000 |

Note: The above usage time is theoretical data. And the actual service life will vary depending on the customer’s actual cutting working conditions.

Laser generator

The fiber metal laser cutting machine adopts the fiber laser generator. It has such features as good laser beam quality, high efficiency, good heat dissipation, and high reliability. Its beam wavelength is 1.06um, which can be absorbed easily by various metals.

The major manufacturers of fiber lasers include Raycus, MAX, GW, IPG, and others. Blue Elephant adopts Raycus laser as standard. And if customers require, we can also provide other brands.

The common laser power of the laser cutter for metal on the market ranges from 1000W to 20000W. In addition, different laser corresponds to different cutting limits.

Auxiliary gas

The metal laser cutter cutting different materials requires different auxiliary gases. For cutting materials of different thicknesses, the pressure and the flow rate of the auxiliary gas required are also different.

Common auxiliary gases are air, oxygen, and nitrogen. For example, cutting carbon steel uses oxygen with a purity of 99.5% and above. While cutting stainless steel requires nitrogen to avoid oxidation reaction and blow off the molten metals.

Among the three types of gases, the air is the cheapest and also the choice of most customers. However, an unqualified air compressor may bring bad effects to the operation of the laser sheet metal cutting machine.

Auto-focus system

Sometimes it may be necessary to adjust the laser’s focus during cutting because the sheet metal is not perfectly flat. Our auto-focus system is very efficient and can automatically adjust the focus controlled by a sensor on the laser head. This sensor always detects the gap between the nozzle and the material surface. When the cutting process begins, the sensor tracks the contour of the metal and adjusts the nozzle on the Z-axis. This helps maintain a constant focus and ensures clean and polished edges.

Fume removal

Various materials will release a small amount of smoke and gas during the laser engraving or cutting process. In order to extract these fumes and gases, we provide centrifugal fans for our fiber laser cutter machines. If customers required, we can also offer a dust collector for additional fees.

Cutting materials and application of a metal laser cutter

The metal laser cutting machine is mainly used for the fast cutting of many kinds of metal materials. For example, carbon steel, silicon steel, stainless steel, aluminum, titanium alloy, galvanized sheet, aluminized zinc sheet, copper, brass, etc.

The fiber laser cutter for metal needs the assistance of gases in the process of cutting metal. But different metals may require different auxiliary gases. For example, carbon steel is suitable for oxygen-assisted cutting, and the cutting is smooth and flat. While, stainless steel, copper, aluminum, and galvanized sheets are suitable for nitrogen-assisted cutting.

Besides metal sheets, the CNC metal laser cutter for sale can also cut many types of irregularly shaped steel materials. For instance, round pipes, rectangular pipes, angle steel, U-shaped steel, H-shaped steel, etc.

Today, fiber laser cutter machines provide large and small companies with the ability to cut metals economically. As a result, these companies can cut complex metal parts, prototypes, and custom parts in their factory in a cost-effective manner.

The steel laser cutting machine is used in various manufacturing and processing industries. For example, aviation, electronics, electrical appliances, automobiles, machinery, precision parts, ships, metallurgical equipment, household appliances, crafts and gifts, tooling, decoration, advertising, etc.

Laser cut metal products are quite popular in multiple industries and daily life. For instance, laser cut steel parts have high precision and accuracy requiring no further treatment. Laser cut stainless steel kitchen supplies provide much convenience to daily life.

Maximum cutting thickness of different laser power

We all know that the power of a metal laser cutter is reflected in the cutting thickness and cutting speed. The choice of power will affect the effect of metal cutting to a certain extent. The following table shows the maximum thickness of four metal materials that Blue Elephant metal laser cutter machines can cut using different power. These values are only theoretical values. The actual cutting thickness also depends on the specific use conditions and environment.

| Laser power | Metal | Max. Cutting thickness (mm) |

| 1000W | Carbon steel | 12 |

| Stainless steel | 4.5 | |

| Brass | 3 | |

| Aluminum | 3 | |

| 1500W | Carbon steel | 14 |

| Stainless steel | 5 | |

| Brass | 4 | |

| Aluminum | 4 | |

| 2000W | Carbon steel | 16 |

| Stainless steel | 12 (oxygen) | |

| Brass | 5.5 | |

| Aluminum | 5.5 | |

| 3000W | Carbon steel | 25 |

| Stainless steel | 10 | |

| Brass | 8 | |

| Aluminum | 7.5 | |

| 4000W | Carbon steel | 25 |

| Stainless steel | 20 | |

| Brass | 12 | |

| Aluminum | 10 |

Note: Generally speaking, it requires extremely strict cutting conditions if you want to ensure the cutting effect of the limit thickness. And continuous work cannot be guaranteed. So, we usually recommend a higher laser power for cutting metal sheets of the maximum thicknesses.

Metal laser cutter recommendation

Blue Elephant provides multiple types of metal laser cutters to meet customers’ different demands. Meanwhile, the same type also has plenty of configurations. Below are two best-selling metal laser cutter machines from Blue Elephant. Although there are differences in function, they both can perform CNC metal cutting tasks excellently.

Laser sheet metal cutting machine

I’ve ever recommended this metal laser cutter before in a previous article introducing metal cutting machines. It is Blue Elephant’s best-selling steel laser cutting machine. And its working size of 1500*3000 is also the most popular working size with metalworking companies. The laser metal cutting machine price is also affordable for small companies. It can perfectly meet the daily processing requirements for cutting thin metal sheets of small and medium enterprises.

In addition to the 1530 model, we also provide metal laser cutter machines with worktable sizes of 1540, 1545, 2040, 2060, and 2560. Therefore, our laser sheet metal cutting machine can cut most sizes of metal sheets on the market.

The metal cutting machine price varies according to different configurations. Generally, the larger the working size, the higher the laser power, the higher the metal laser cutting machine price.

The following video shows the cutting demonstration of this 1530 sheet metal laser cutting machine. It can realize the cutting of 2mm stainless steel, 3mm carbon steel, and flying cutting. The laser machine makes laser cut steel work easier and safer.

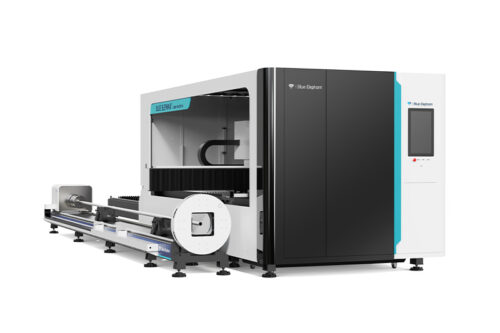

Fiber metal laser cutter for metal sheets and tubes

The sheet and tube metal laser cutter adopts a left and right two-part structure. One part is the same as the above-mentioned sheet metal laser cutting machine, which adopts an open platform structure. The other part is a structure dedicated to fixing and rotating pipes. It adopts a double-pneumatic chuck rotating mechanism to fix and rotate a pipe, which is convenient for fast cutting. It can realize fully automatic laser cutting and discharging of long metal pipes.

The major parameters of this metal laser cutter for sheets and tubes are shown in the table below.

| Model | 1530, 1540, 1545, 1560, 2040, 2060, 2065 |

| Laser generator | Raycus, GW, IPG, optional |

| Laser power | 1000W/2000W/3000W/4000W |

| Laser head | Raytools, Precitec, WSX, optional |

| Machine bed | Tube-welded |

| Gantry | Extruded aluminum |

| Worktable | Interlaced blade table |

| Chuck | Dual drive pneumatic chuck |

| Length of tube | 3m/6m |

| Diameter of tube | 10-220mm |

| Motor | Servo, Fuji, or Yaskawa |

| X/Y-axis positioning accuracy | ±0.03mm |

| X/Y-axis repositioning accuracy | ±0.02mm |

You can have metal sheet cutting and tube cutting functions only by buying one metal laser cutter. That’s quite cost-effective. It can also improve your working efficiency.

In addition to the above two models, Blue Elephant also provides other metal laser cutter machines. For example, fiber laser cutting machine with double platforms or a protective cover, precision laser cutting machine, etc. All metal laser machines have excellent production and processing advantages in metal processing. So they can perform detailed laser cutting of various complicated patterns. Besides, the extremely fast response speed of the metal laser cutter machines greatly shortens the cutting solution cycle time.

Tips for choosing a metal laser cutter

1.Make clear your requirements to determine the machine information you required.

First of all, you must figure out the scope of production, processing materials, and cutting thickness of your business. Thus, you can determine the model, format, and quantity of the metal laser cutter you required.

In order to meet market demand, laser machine is developing in a more automated and intelligent direction. Various new concepts about the metal laser cutter are emerging in an endless stream. For instance, more sophisticated ultrafast or ultrahigh power fiber laser cutting machines. But the ultimate basis for purchasing a metal laser cutter is to best meet your own needs.

A 1000W fiber laser cutter for metal can cut 12mm carbon steel, 4.5mm stainless steel, and 3mm aluminum. While, a 4000W fiber laser cutter can cut 25mm carbon steel, 20mm stainless steel, and 10mm aluminum. Therefore, a metal laser cutter of 1000W-4000W can basically meet the processing demands of the companies cutting thin metal sheets. So there is no need to chase the high-power metal laser cutter.

2.Find an appropriate machine manufacturer and discuss the details.

There are many metal laser machine manufacturers on the market. So you need to spend time and energy to choose the most suitable one. It is best to choose a company with independent design and R&D capabilities, strong production and delivery capabilities, and high customer reviews. Because the machine quality and after-sales service of large companies will be guaranteed.

After choosing a manufacturer, you need to determine all matters related to the purchase of the metal laser cutter you want to buy. For example, the selection of machine parts, specific terms of the transaction, machine price, delivery time, freight, etc. All such terms and conditions shall be specified in a sales contract. Because this helps guarantee the rights and interests of both buyer and seller.

Pay attention to the major parts and components when choosing a metal laser cutter. Because their accuracy and quality may affect the metal cutting effect to some extent.

3.Don’t forget to check the after-sales service.

Any piece of equipment may damage to varying degrees during use. So you also need to consider whether it is easy to get the metal laser cutter repaired and the cost of the repair. Therefore, it is necessary to understand the manufacturer’s after-sales service through multiple channels during purchasing. For example, the response time, maintenance fees, spare part costs, etc.

Conclusion

Now the metal laser cutting machine has a very wide range of applications. It is used in all aspects of our lives and various industries And it also brings great convenience to our lives. The high-power large-format fiber laser metal cutter has a large cutting area and a fast cutting speed. It can cut thick metal sheets and has stable performance. So it is an inevitable trend in the development of metal laser cutting technology. The in-depth application of laser technology will further promote laser cutters towards high precision and high power.

However, remember to always choose the right metal laser cutter product based on your actual production needs. Small businesses should not blindly pursue high-power metal lasers. This is because the purchase cost invested in the early stage is high. And also, the performance of the laser machine cannot be effectively used, resulting in waste. The price of small and medium metal laser cutter machines is relatively more advantageous. And the effect of metal sheet processing is not inferior to that of high-power laser cutting machines.

Blue Elephant has ten years of experience in the R&D and production of metal laser cutting machines. Our laser machines are exported to more than one hundred countries and regions. If you are considering buying a metal laser cutter, please take a look at Blue Elephant first.