Cutting metal by hand? I’ve been there, and it’s not worth the effort. Rough edges, wasted materials, and inconsistent results eat into profits fast.

That’s why a quality metal laser cutter is a must-have for small businesses. Precision, speed, and efficiency mean higher output and fewer headaches.

I’ve put together this list of the best seven laser cutters after researching performance, durability, and cost. No technical fluff, just straightforward insights.

By the end of this guide, you’ll have a clear idea of which laser cutter fits your needs and budget. Whether you’re scaling up or starting fresh, there’s an option for you.

Let’s dive in!

Quick Comparison Chart

Choosing the right metal laser cutter for your business depends on factors like power, precision, automation, and budget. Below is a comprehensive comparison table to help you evaluate the top options and determine which one best suits your production needs.

| Feature | Kirin Laser KR-6000 | Trumpf TruLaser Series | Blue Elephant Metal Laser Cutting Machine | Amada FabriGear 400 | Mazak Optiplex Fiber | Han’s Laser HG-3010 | Penta Laser PentaCut 2000 |

| Laser Power | 6kW Fiber Laser | Up to 24kW Fiber Laser | 1kW – 6kW Fiber Laser | 4kW Fiber Laser | High-Power Fiber Laser | High-Power Fiber Laser | Medium-to-High-Power Fiber Laser |

| Cutting Area | Varies, typically mid-size | Varies by model, customizable | Standard: 3000×1500mm (customizable) | Large, accommodates tubes up to 400mm | Large, customizable | Mid-to-large cutting area | Standard sheet size, customizable |

| Material Compatibility | Carbon Steel, Aluminum, Brass | Stainless Steel, Aluminum, Mild Steel | Stainless Steel, Carbon Steel, Aluminum, Brass | Round, Square, Rectangular Tubes, I-Beams, H-Beams | Stainless Steel, Carbon Steel, Aluminum | Stainless Steel, Carbon Steel, Aluminum | Carbon Steel, Stainless Steel, Aluminum |

| Cutting Speed | High-speed for thick metals | Ultra-fast with BrightLine Fiber tech | Moderate speed with high precision | Optimized for structural metal cutting | Ultra-fast fiber laser cutting | Fast processing without sacrificing quality | Fast and efficient for mass production |

| Automation Level | Moderate Automation | High Automation | Basic Automation | Moderate to High Automation | High Automation | High Automation | Moderate Automation |

| Precision & Accuracy | High precision with minimal waste | Extreme precision with CoolLine process | Great for detailed, intricate cuts | Superior 3D cutting precision | Superior accuracy with intelligent setup | Extreme precision with burr-free edges | Consistent and stable cutting performance |

| User Interface | Intuitive with advanced controls | Touchpoint control with pre-set cutting data | User-friendly control system | Integrated CAD/CAM software | Ergonomic touchscreen interface | Touchscreen control with real-time monitoring | Intuitive touchscreen with pre-set parameters |

| Cooling System | Advanced cooling to prevent overheating | Efficient cooling with material recognition | Standard cooling system | Effective cooling for continuous operation | Energy-efficient cooling system | Advanced safety and cooling system | Standard cooling system |

| Best For | Heavy-duty industrial cutting, automotive, aerospace | High-volume industrial production | Small and mid-sized businesses, custom fabrication | Structural fabrication, automotive, heavy machinery | High-volume manufacturing, smart factories | Industrial-scale cutting, high-precision work | Small and mid-sized manufacturers, cost-effective solution |

| Price Range | $30,000 – $80,000 | $100,000 – $500,000+ | $20,000 – $70,000 | $150,000 – $400,000 | $120,000 – $450,000 | $80,000 – $250,000 | $50,000 – $150,000 |

1. Kirin Laser KR-6000

If you’re looking for a powerful yet user-friendly metal laser cutter, the Kirin Laser KR-6000 is a solid contender. With its high-speed performance and precision cutting capabilities, it’s built for businesses that need efficiency without sacrificing quality.

Key Features:

- High-Power Fiber Laser: This machine is equipped with a 6kW fiber laser, making it perfect for cutting thick materials like carbon steel, aluminum, and brass. It handles thicknesses up to 25-30mm with ease, ensuring clean, precise cuts every time.

- Advanced Control Systems: The KR-6000 is designed for efficiency, offering smooth edges and minimal material waste. The automated control system allows for consistent quality, reducing the need for rework and saving both time and materials.

- High-Speed Cutting: Built for high-demand industries like automotive and aerospace, this machine delivers rapid cutting without compromising accuracy. Whether working on large-scale production or custom fabrication, the speed and efficiency keep operations running smoothly.

Cutting Capabilities:

- Versatile Cutting Capabilities: The KR-6000 is designed to cut various metals, including carbon steel, aluminum, and brass. Whether you’re working with thin sheets or thick plates, this laser cutter adapts to different project requirements.

- Optimized for Heavy-Duty Use: Unlike entry-level models, this cutter can handle continuous, long-hour operation without overheating. Its stable performance ensures long-term reliability, even in industrial environments.

Design and Usability:

- Space-Efficient and Compact: Despite its industrial-grade power, the KR-6000 has a compact design that fits seamlessly into small and mid-sized workshops. You won’t need a massive factory floor to integrate this machine into your operations.

- User-Friendly Interface and Cooling System: Featuring an intuitive control panel, this machine makes it easy to adjust settings and execute precise cuts. The advanced cooling system minimizes downtime by preventing overheating, keeping production consistent.

2. Trumpf TruLaser Series

The Trumpf TruLaser Series is a premium choice for businesses that demand precision, power, and cutting-edge technology. With a variety of models available, this series offers flexibility for both small-scale shops and large industrial operations.

Key Features:

- Intuitive Touchpoint Control System: The TruLaser Series is designed with a user-friendly interface, making operation smooth and hassle-free. The integrated cutting data and automated adjustments help operators achieve optimal performance without needing extensive training.

- Automation and Smart Connectivity: These machines are built to integrate seamlessly with automation systems, reducing manual work and increasing efficiency. With smart sensors and remote monitoring capabilities, businesses can streamline their production process while minimizing human error.

Cutting Capabilities:

- BrightLine Fiber for Precision: This feature ensures clean, high-quality cuts across different material thicknesses, reducing the need for post-processing. If your business requires detailed, intricate cuts with minimal burrs, this technology will significantly enhance production quality.

- CoolLine Process for Better Efficiency: By cooling the workpiece during laser cutting, this feature increases process reliability, especially for thick mild steel. It prevents overheating, reducing the chances of warping or distortion, which is crucial for maintaining consistent product quality.

Design and Usability:

- Diverse Models for Different Needs: The TruLaser Series includes a range of models, such as the 1000, 3000, and 5000 series. Whether you need an entry-level laser cutter or a high-power industrial machine, Trumpf has a model to fit your needs.

- High Laser Power for Thick Materials: Some models, like the TruLaser 5030 fiber, offer laser power up to 24 kW, making them capable of cutting through extremely thick and dense metals. This ensures you can handle demanding projects efficiently, whether you work with stainless steel, aluminum, or structural steel.

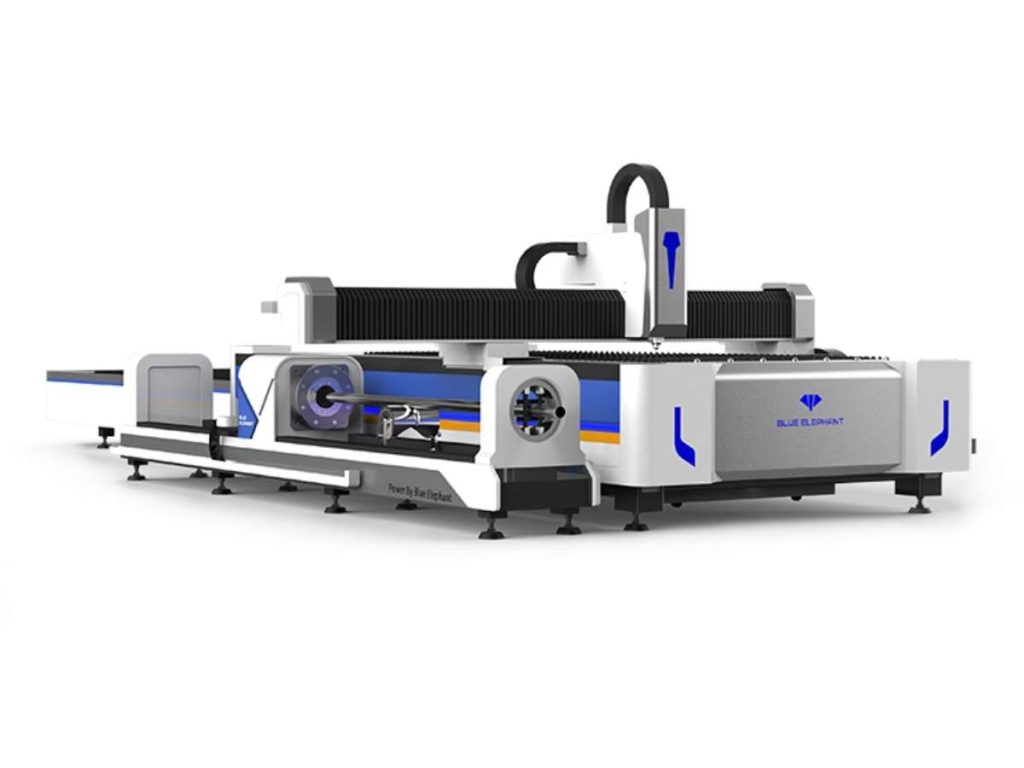

3. Blue Elephant Metal Laser Cutting Machine

For businesses that need a balance between affordability and high-performance cutting, the Blue Elephant Metal Laser Cutting Machine is a fantastic option. Designed for precision, speed, and ease of use, this machine is a great investment for both startups and growing manufacturers.

Key Features:

- Multiple Laser Power Options: The Blue Elephant comes in a variety of power configurations, typically ranging from 1kW to 6kW. This flexibility allows businesses to choose the right level of cutting strength based on their workload and material thickness.

- Generous Cutting Area for Large Projects: Standard models feature a 3000×1500mm cutting bed, providing ample space for large sheet metal processing. If you need something bigger, custom sizes are available to accommodate specialized production needs.

Cutting Capabilities:

- High-Precision Cutting for Detailed Work: This laser cutter is designed for intricate cuts, ensuring smooth, burr-free edges on every piece. Whether you’re working with decorative metalwork, signage, or industrial components, you can count on accuracy and consistency.

- Versatile Material Compatibility: It’s capable of cutting stainless steel, carbon steel, aluminum, brass, and more, giving you the flexibility to work on various projects. This versatility makes it an excellent all-round machine for businesses that handle different types of metal fabrication.

Design and Usability:

- User-Friendly Control System: The intuitive interface makes it easy to set up and operate, even for those new to laser cutting technology. Features like auto-focus and intelligent cutting adjustments ensure smooth workflow and reduced operator error.

- Sturdy and Durable Build: Constructed with high-quality materials, this machine is built to withstand continuous operation without frequent maintenance issues. Its robust frame helps minimize vibrations, leading to more stable and precise cuts.

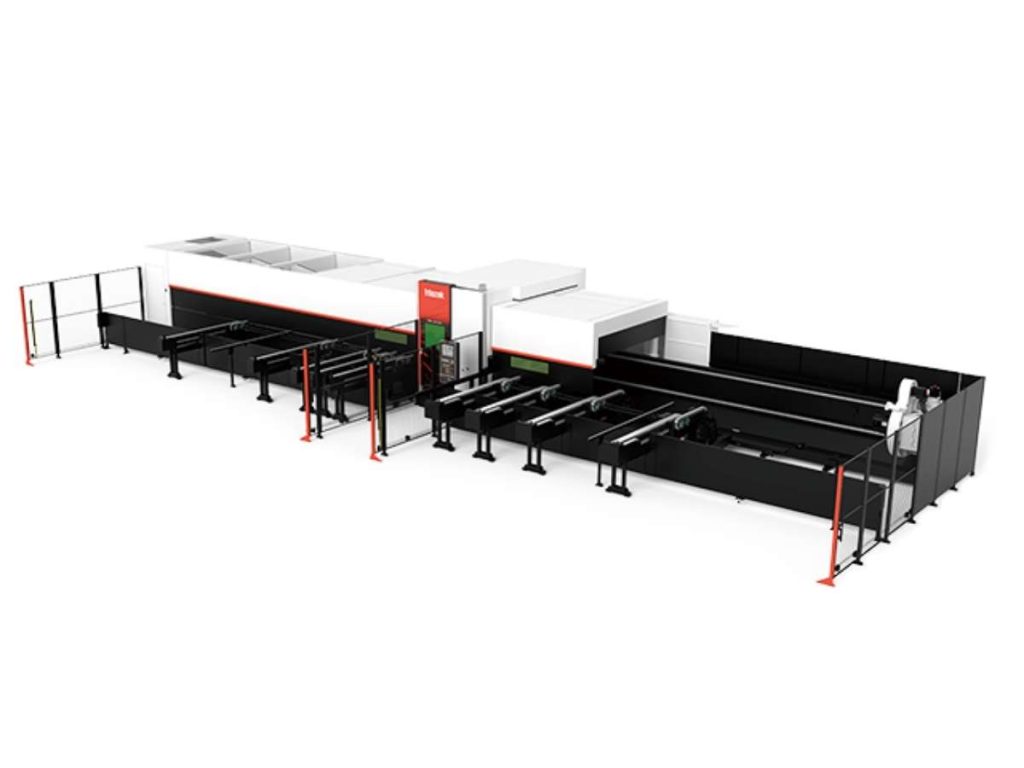

4. Amada FabriGear 400

If your business works with structural metal fabrication, the Amada FabriGear 400 is a game-changer. Designed specifically for cutting tubes and profiles, this machine provides unmatched precision and versatility for industries like construction, automotive, and heavy machinery manufacturing.

Key Features:

- Versatile Cutting for Tubes and Structural Metal: Unlike standard laser cutters, the FabriGear 400 specializes in processing round, square, and rectangular tubing. This makes it a must-have for businesses that require precise cuts for framework, support structures, and industrial components.

- High-Precision 3D Cutting: With its advanced 3D laser head, this machine allows for complex bevel cuts and precise edge finishes. Whether you need angled cuts for welding preparation or intricate joint fittings, the FabriGear 400 delivers accuracy down to the millimeter.

Cutting Capabilities:

- 4kW Laser Power for Heavy-Duty Cutting: The machine is equipped with a powerful 4kW laser, making it capable of slicing through thick-walled tubes and beams effortlessly. This ensures efficient processing of steel, stainless steel, and aluminum without compromising speed or precision.

- Large Cutting Capacity for Big Projects: It can handle tubes up to 400mm in diameter, making it ideal for large-scale production. If your business regularly fabricates heavy-duty metal structures, this machine provides the flexibility and power to handle demanding workloads.

Design and Usability:

- Integrated CAD/CAM Software for Seamless Workflow: The FabriGear 400 comes with built-in software that simplifies design and cutting processes. Operators can program complex cuts directly from a CAD file, reducing manual setup time and increasing overall efficiency.

- Automation for Higher Productivity: With automated material handling and positioning, the machine minimizes downtime and maximizes output. This means your team can focus on higher-value tasks while the FabriGear 400 handles the heavy lifting with precision and speed.

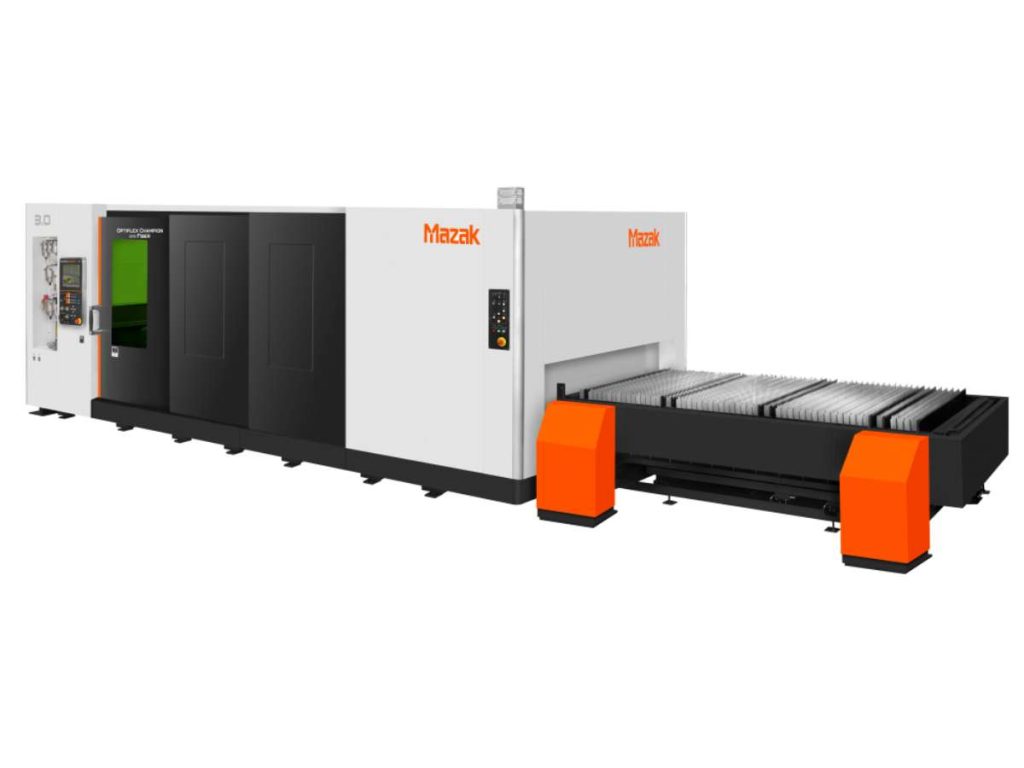

5. Mazak Optiplex Fiber

For businesses looking for high-speed, high-precision laser cutting, the Mazak Optiplex Fiber is a top contender. This machine is engineered for efficiency, offering advanced automation, smart technology, and a powerful fiber laser that can handle even the most demanding production environments.

Key Features:

- Intelligent Setup for Faster Operations: The Mazak Optiplex Fiber comes equipped with automatic nozzle changing, beam focus adjustment, and a real-time monitoring system. These features reduce downtime and make switching between different materials seamless, keeping production running smoothly.

- Smart Manufacturing Integration: This machine is designed to work with Mazak’s SMART MANUFACTURING system, which optimizes cutting parameters automatically. It reduces material waste, improves consistency, and helps businesses get the most out of every cut without constant manual adjustments.

Cutting Capabilities:

- High-Speed Fiber Laser Cutting: The Optiplex Fiber is built for rapid cutting speeds, making it perfect for high-volume production. Whether you’re cutting thin stainless steel or thicker aluminum sheets, this machine delivers exceptional edge quality at impressive speeds.

- Energy-Efficient Operation: Unlike traditional CO2 laser cutters, this fiber laser system consumes less power while delivering more precise and consistent results. Lower operational costs combined with increased output make it a smart long-term investment for manufacturers.

Design and Usability:

- Ergonomic and Intuitive Control Panel: The user-friendly touchscreen interface simplifies operation, allowing even less-experienced operators to run complex jobs with ease. Pre-set cutting parameters and real-time diagnostics reduce errors and improve workflow efficiency.

- Minimal Maintenance for Maximum Productivity: The fiber laser requires fewer consumables and less routine maintenance compared to CO2 laser machines. This means businesses can spend less time on upkeep and more time on production, boosting overall efficiency.

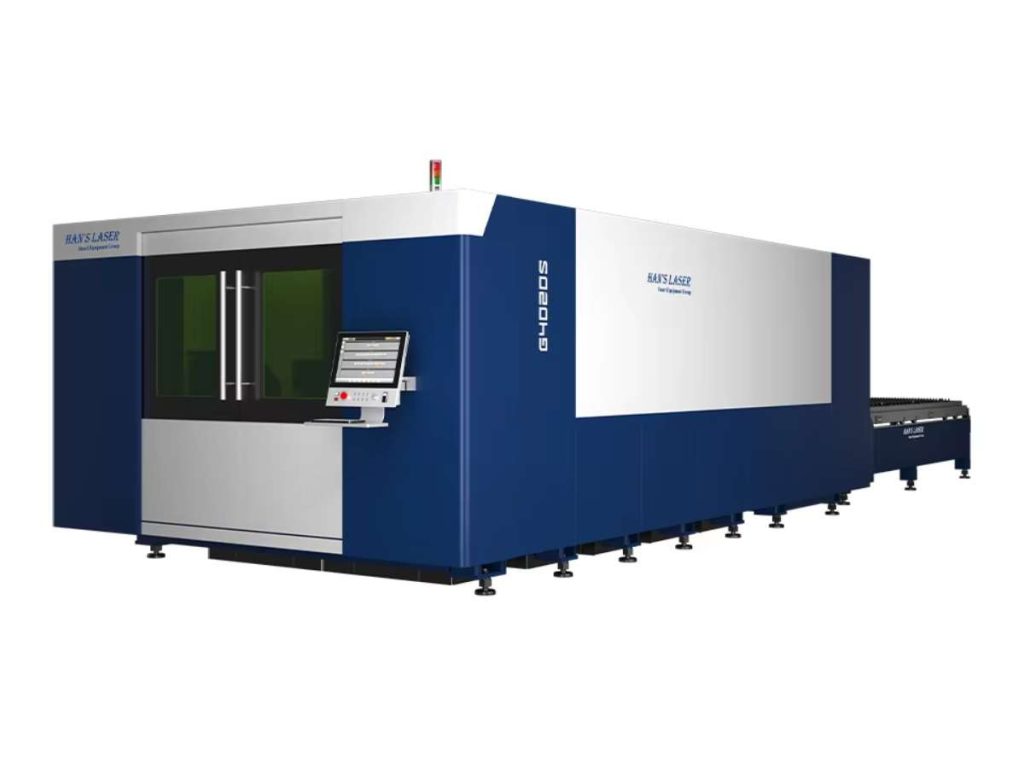

6. Han’s Laser HG-3010

If precision and efficiency are at the top of your list, the Han’s Laser HG-3010 is a machine worth considering. Designed for industrial-scale metal cutting, it combines high-power fiber laser technology with smart automation to help businesses increase productivity while maintaining top-tier cutting quality.

Key Features:

- High-Power Fiber Laser for Industrial Applications: The Han’s Laser HG-3010 is equipped with a powerful fiber laser. Whether you’re working with stainless steel, aluminum, or carbon steel, this machine delivers consistently clean cuts without excessive heat damage.

- Large Cutting Area for Versatile Production: With a cutting bed that accommodates standard sheet sizes and customizable options for larger formats, it offers flexibility for different types of projects. Whether you’re handling small precision components or large industrial parts, the HG-3010 is built to adapt.

Cutting Capabilities:

- Precision Cutting for High-Quality Results: This laser cutter is engineered for ultra-fine accuracy, reducing the need for post-processing. The smooth, burr-free edges ensure that parts are ready for assembly or further manufacturing right off the cutting bed, saving time and reducing waste.

- Fast Processing Speeds for Higher Productivity: Speed doesn’t mean sacrificing quality, the HG-3010 can cut faster than traditional systems while maintaining exceptional precision. Businesses can complete more jobs in less time, making it an excellent choice for high-volume manufacturing.

Design and Usability:

- Advanced Control System for Seamless Operation: The intuitive touchscreen interface allows operators to quickly adjust settings and optimize cutting parameters. With automated features like real-time monitoring and material recognition, it reduces human error and increases efficiency.

- Built-In Safety and Cooling Features: To ensure long-term reliability, the HG-3010 includes an advanced cooling system that prevents overheating and extends machine life. Additionally, built-in safety features protect operators and ensure compliance with industry standards, making it a safe and smart investment.

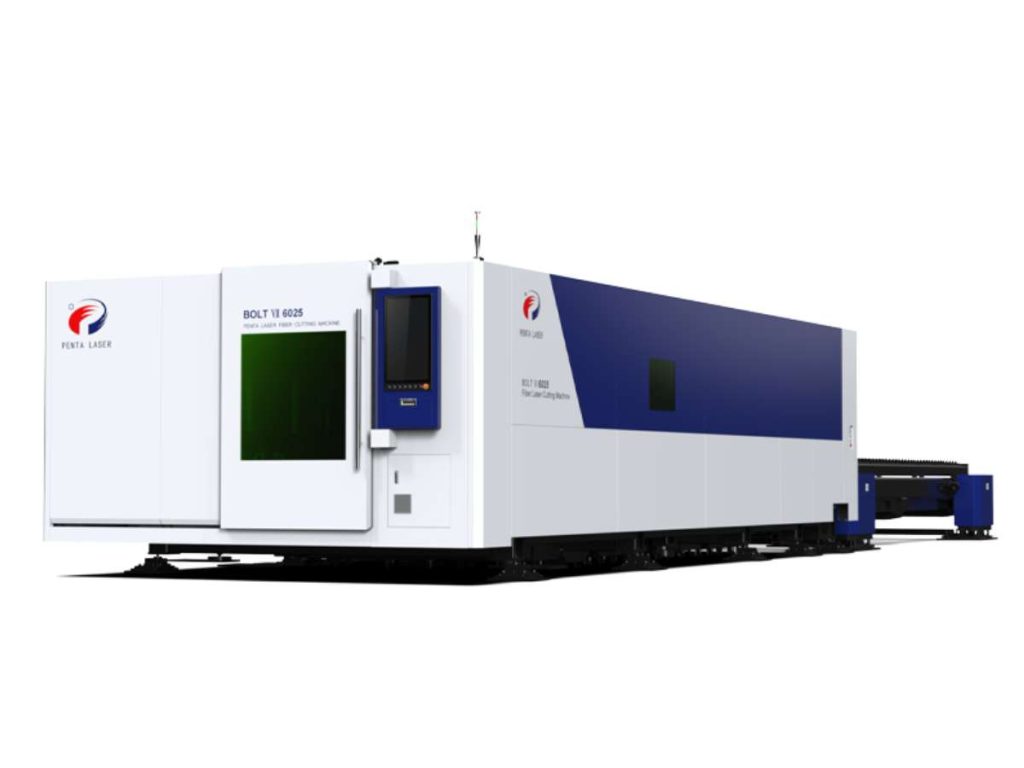

7. Penta Laser PentaCut 2000

For businesses that need a reliable, high-speed laser cutter without breaking the bank, the Penta Laser PentaCut 2000 is a strong contender. It combines precision, efficiency, and automation, making it a great choice for small to mid-sized manufacturers looking to scale their production.

Key Features:

- Fast and Efficient Cutting Performance: The PentaCut 2000 is designed for speed, enabling businesses to process more orders in less time. Its high-speed fiber laser ensures crisp, clean cuts without sacrificing accuracy, reducing material waste and improving overall efficiency.

- Stable and Consistent Output: This machine is built for continuous operation, with a reinforced structure that minimizes vibrations during cutting. Whether you’re working with intricate designs or heavy-duty industrial components, it delivers smooth and precise cuts every time.

Cutting Capabilities:

- Versatile Material Compatibility: The PentaCut 2000 can handle a wide range of metals, including carbon steel, stainless steel, and aluminum. Its adjustable power settings allow businesses to work with different material thicknesses, making it a flexible tool for various manufacturing needs.

- High-Power Laser for Thick and Thin Metals: This machine efficiently cuts both thin gauge sheets and thicker metal plates, making it suitable for diverse applications. Whether you’re in the automotive, aerospace, or custom fabrication industry, it adapts to different project requirements effortlessly.

Design and Usability:

- User-Friendly Interface for Easy Operation: The PentaCut 2000 features an intuitive touchscreen control panel, allowing operators to set up jobs quickly and accurately. With pre-programmed cutting parameters, even less-experienced users can achieve professional results.

- Automated Features for Higher Productivity: From auto-focus technology to real-time monitoring, this laser cutter is designed to streamline the workflow. Its smart automation reduces the need for constant manual adjustments, allowing businesses to run more efficiently with minimal downtime.

Conclusion

I still remember the mess of that first DIY metal job, uneven cuts, wasted time, and zero profit. Fast forward, and CNC machines changed everything for me.

In this article, we broke down the what, why, and how behind seven reliable metal CNC machines. From global leaders to trusted names like Blue Elephant in China, these machines are ready for your shop floor.

You’ve got the tools. Now’s the time.

So, what’s holding you back?

Contact us today, we’ll help you get started.

Check Out These Additional Resources

Want to learn more? Here are some articles filled with valuable tips and information to guide you further:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.