When I started my workshop, I had just a corner in the garage. I wanted a CNC machine, but everything I saw was too big. Or too expensive. Or too complicated.

So I dug deeper.

Over time, I found small CNC machines that actually worked—machines that fit in tight spaces and still cut with power and accuracy.

In this guide, you’ll find a breakdown of the 8 best small CNC machines available today. Whether you’re a:

- Machine dealer looking for compact options to resell

- Factory owner needing an extra machine

- Or a small shop owner just getting started

By the end, you’ll know which one fits your space, budget, and work needs.

So, let’s get started!

Table Comparison

Choosing the right CNC machine depends on precision, workload, and material compatibility. This table gives you a quick side-by-side comparison of eight top small CNC machines to help you find the best fit for your business:

| CNC Machine | Travel (X/Y/Z) | Spindle Speed | Spindle Motor | Table Size | Control System | Power Requirements | Production Volume | Material Compatibility |

| Tormach 1100M | 18″ x 11″ x 16.25″ | 10,000 RPM | 1.5 HP | 34″ x 9.5″ | PathPilot® | 115V or 230V | Low- to mid-volume, prototyping | Aluminum, Brass, Steel, Titanium, Plastics |

| Haas Mini Mill | 16″ x 12″ x 10″ | 6,000 RPM (15,000 RPM upgrade) | 7.5 HP | 36″ x 12″ | Haas CNC Control | 220V three-phase | Batch production, short-run | Aluminum, Stainless Steel, Mild Steel, Brass, Titanium |

| Blue Elephant ELECNC-1212ATC | 47” x 47” x 8” | 24,000 RPM | 6kW | N/A (CNC router) | Taiwan Syntec | 380V three-phase | High-mix, low-volume | Wood, Plastics, Composites, Soft Metals |

| Sherline 5400 | 9″ x 5″ x 6″ | 70–10,000 RPM | ¼ HP DC motor | 2.75″ x 13″ | LinuxCNC, Mach3 | 115V single-phase | One-off, short runs | Plastics, Soft Metals, Tooling Wax |

| Pocket NC V2-10 | 4.55″ x 5.00″ x 3.55″ | 2,000–10,000 RPM | 500W brushless DC motor | 4.275” diameter | Pocket NC proprietary | 110V | Small-batch, precision | Aluminum, Brass, Composites, Plastics, Soft Steels |

| Bantam Tools Desktop CNC | 9” x 7.5” x 3.5” | Up to 26,000 RPM | ⅝ HP (460W) brushless motor | 12” x 10” | Bantam Tools software | 120V | Low-to-mid volume | Aluminum, Brass, Composites, Wood |

| SainSmart Genmitsu 3018-PROVer | 11.8” x 7.1” x 1.8” | 10,000 RPM | 775 motor | 12” x 8” | GRBL-based | 24V | Low-volume, prototyping | Soft Metals, Plastics, Woods, PCB materials |

| Carbide 3D Shapeoko 4 XXL | 33” x 33” x 4” | Variable, up to 24,000 RPM | Compatible with Makita RT0701C | N/A (CNC router) | Carbide Motion | 120V | Large-scale projects, batch production | Hardwoods, Softwoods, Plastics, Acrylics, Aluminum, Brass |

1. Tormach 1100M CNC Mill

The Tormach 1100M is a compact yet powerful CNC mill designed for small businesses, machine shops, and production environments that need accuracy without the footprint of a full-size mill. It’s known for its rigid construction, upgradeable design, and ability to handle serious cutting tasks.

It’s not just a machine—it’s a workhorse that can grow with your business.

Specifications

- Travel (X/Y/Z): 18″ x 11″ x 16.25″

- Spindle Speed: 10,000 RPM

- Spindle Motor: 1.5 HP

- Table Size: 34″ x 9.5″

- Tool Changer (Optional Upgrade): 10-tool automatic changer

- Control System: PathPilot® (Tormach’s proprietary software)

Production Volume & Workload

How much work can this machine really handle? More than you’d expect.

The 1100M is ideal for low- to mid-volume production and prototyping. It’s not a full-scale industrial machine, but it’s leagues ahead of entry-level desktop CNC mills. Whether you’re machining aluminum, steel, or even harder alloys, this mill is ready.

Need to scale up? You can add an automatic tool changer, a power drawbar, and an enclosure to handle longer production runs.

Material Compatibility

Not every small CNC machine can handle tough materials. The Tormach 1100M does.

It cuts:

- Aluminum

- Brass

- Steel (including stainless)

- Titanium (with proper settings)

- Plastics and composites

I’ve run everything from stainless brackets to precision aluminum housings on the 1100M, and it handled each job like it belonged in a bigger shop. If you’re serious about small-scale production and want a mill that won’t limit your material choices—or your business growth—this one’s worth every inch of floor space.

2. Haas Mini Mill

I’ve worked with plenty of small CNC mills over the years, but few have the reputation of the Haas Mini Mill. I remember the first time I used one—it was compact, but when I fired it up, I realized it could handle serious machining. It didn’t just cut metal; it powered through it.

The Haas Mini Mill is a compact vertical CNC milling machine built for small-scale production, prototyping, and light manufacturing. Unlike many small mills, this one is designed and built in the U.S. with high-end components and industrial-grade engineering.

Specifications

- Travel (X/Y/Z): 16″ x 12″ x 10″

- Spindle Speed: 6,000 RPM (optional 15,000 RPM upgrade)

- Spindle Motor: 7.5 HP (far more powerful than most small CNC mills)

- Table Size: 36″ x 12″

- Tool Changer: 10-pocket automatic tool changer

- Control System: Haas CNC Control with intuitive interface

- Power Requirements: 220V three-phase

The cast-iron frame adds weight and stability, reducing vibrations for precise cuts. It’s built like a real industrial machine, not a hobbyist tool.

Production Volume & Workload

How much work can this machine handle? More than you’d expect from its size.

- Ideal for batch production and short-run manufacturing

- Handles high-speed prototyping without losing accuracy

- Works well for training environments and R&D departments

- Suitable for light production work in small shops

If you need a secondary machine to free up your larger CNC mills, this one does the job. It’s small enough to fit into tight spaces but powerful enough to handle real manufacturing.

Material Compatibility

Some compact CNC mills struggle with harder metals. The Haas Mini Mill doesn’t.

It can cut:

- Aluminum

- Stainless steel

- Mild steel

- Brass

- Titanium (with the right tooling and speeds)

But here’s where it stands out—it’s built to cut harder materials at production speeds. Some mills claim they can cut steel, but they slow down and wear out fast. The Haas Mini Mill handles steel like a full-sized mill, just in a smaller package.

3. Blue Elephant ELECNC-1212ATC

The ELECNC-1212ATC is a high-precision CNC router designed for demanding production environments. It’s built for businesses that need automation, speed, and flexibility in a compact footprint.

This machine stands out because of its automatic tool changer, allowing you to switch between cutting tools in seconds. No manual changes, no wasted time—just continuous machining.

Specifications

- Working Area (X/Y/Z): 1200mm x 1200mm x 200mm (47” x 47” x 8”)

- Spindle Speed: 24,000 RPM

- Spindle Motor: 6kW (powerful enough for high-speed cutting)

- Tool Changer: 8-position automatic tool changer

- Control System: Taiwan Syntec Control (user-friendly and reliable)

- Transmission: Helical rack and pinion for smooth, precise motion

- Power Requirements: 380V three-phase

With heavy-duty construction and industrial-grade components, this machine is designed to last.

Production Volume & Workload

How much work can this machine handle? A lot.

- Perfect for high-mix, low-volume production

- Handles continuous operation without overheating or wearing down

- Reduces downtime with its automatic tool changer

- Works well for batch production and custom orders

If you need a CNC machine that can cut multiple materials with different tools in a single setup, this one is a strong contender.

Material Compatibility

What materials can the ELECNC-1212ATC handle? The better question is—what can’t it cut?

- Wood: Plywood, MDF, hardwood, softwood

- Plastics: Acrylic, PVC, ABS, HDPE

- Composites: Fiberglass, carbon fiber panels

- Soft Metals: Aluminum, brass (with proper settings)

I’ve used machines that slow down the moment complexity kicks in—tool changes, re-fixturing, manual resets. The ELECNC-1212ATC removed all of that. If you’re building a business around efficient, multi-step production, this machine makes it feel like you’ve suddenly got a second set of hands in the shop.

4. Sherline 5400 CNC Mill

I remember working on my first small CNC mill. It wasn’t perfect, but it got the job done. Then I tried the Sherline 5400, and suddenly, everything felt smoother—precise cuts, a rigid frame, and an easy learning curve. It was compact, but it didn’t feel like a compromise.

If you need a small CNC mill that balances precision, affordability, and versatility, the Sherline 5400 is worth considering.

Specifications

- Travel (X/Y/Z): 9″ x 5″ x 6″

- Spindle Speed: 70–10,000 RPM (adjustable)

- Spindle Motor: ¼ HP DC motor

- Table Size: 2.75″ x 13″

- Control System: Compatible with LinuxCNC and Mach3

- Power Requirements: 115V single-phase

Its lightweight aluminum frame makes it easy to move, yet it’s sturdy enough to hold tight tolerances on small parts.

Production Volume & Workload

This machine isn’t made for mass production, but it excels in precision work.

- Ideal for one-off parts and short production runs

- Great for R&D, prototyping, and custom machining

- Used in education and training programs

- Perfect for businesses needing ultra-fine detail

If you manufacture small parts or need a secondary CNC mill for fine work, this machine delivers accuracy without taking up space.

Material Compatibility

Unlike larger CNC mills, the Sherline 5400 isn’t built for heavy metal cutting. But if you’re machining small parts, it’s a solid performer.

It cuts:

- Plastics: ABS, acrylic, nylon, and polycarbonate

- Soft metals: Aluminum, brass, and copper

- Tooling wax and composites

While it can cut steel, it’s not designed for aggressive machining. If your work requires precision over power, this machine is a great fit.

5. Pocket NC V2-10

The Pocket NC V2-10 is a desktop-sized five-axis CNC mill designed for precision machining in small-scale manufacturing, prototyping, and research labs. Unlike traditional three-axis mills, this machine lets you cut from multiple angles without manual repositioning, which means better accuracy and more complex part designs.

It’s a game-changer for businesses that need high-precision milling in a compact footprint.

Specifications

- Travel (X/Y/Z): 4.55″ x 5.00″ x 3.55″

- Rotary Axes (A & B): ±25° tilt, full 360° rotation

- Spindle Speed: 2,000–10,000 RPM

- Spindle Motor: 500W brushless DC motor

- Table Size: 4.275” diameter

- Control System: Pocket NC proprietary software (compatible with Fusion 360)

- Power Requirements: 110V

Its rigid aluminum frame and high-quality linear guides ensure smooth, repeatable movements—even on the smallest details.

Production Volume & Workload

This machine isn’t made for mass production, but it excels in small-batch, high-precision machining.

- Ideal for prototyping complex parts

- Great for medical, aerospace, and jewelry applications

- Perfect for research labs and training programs

- Designed for small-scale production with tight tolerances

If your business needs intricate, multi-axis machining but doesn’t have space for a full-size five-axis mill, the Pocket NC V2-10 fills that gap.

Material Compatibility

Despite its size, this machine is not just for soft materials. It can cut:

- Aluminum, brass, and copper

- Composites and carbon fiber

- Plastics, acrylic, and PEEK

- Soft steels (with careful speeds and feeds)

While it’s not built for heavy-duty steel machining, I can say that it’s one of the most capable small five-axis mills on the market for aluminum and precision parts.

6. Bantam Tools Desktop CNC Milling Machine

I’ve used a lot of small CNC mills, but most of them felt underpowered. Slow speeds, weak spindles, and limited material compatibility made them more of a hassle than a tool. Then I tried the Bantam Tools Desktop CNC Milling Machine, and everything changed.

If you’re looking for a desktop CNC mill that delivers precision without the frustration, this one might be exactly what your business needs.

Specifications

- Travel (X/Y/Z): 9” x 7.5” x 3.5”

- Spindle Speed: Up to 26,000 RPM

- Spindle Motor: ⅝ HP (460W) brushless motor

- Table Size: 12” x 10”

- Tool Changer: Manual

- Control System: Bantam Tools intuitive software (G-code compatible)

- Power Requirements: 120V

With its rigid aluminum frame and high-speed spindle, it cuts faster and more precisely than most desktop mills.

Production Volume & Workload

This machine is designed for high-speed, low-to-mid volume production.

- Perfect for prototyping and R&D

- Great for engineers and product developers

- Capable of running small-batch production

- Reduces turnaround time with rapid setup and cutting speeds

If you need to move fast and iterate designs quickly, this CNC mill helps you cut, test, and refine parts in-house.

Material Compatibility

Unlike most small desktop mills, the Bantam Tools CNC is built to handle tougher materials.

It cuts:

- Aluminum, brass, and copper

- Engineering plastics (Delrin, acrylic, HDPE, etc.)

- Carbon fiber sheets and composites

- Wood and MDF

It’s one of the few compact CNC machines that can cut aluminum effectively, making it a great option for precision metalworking.

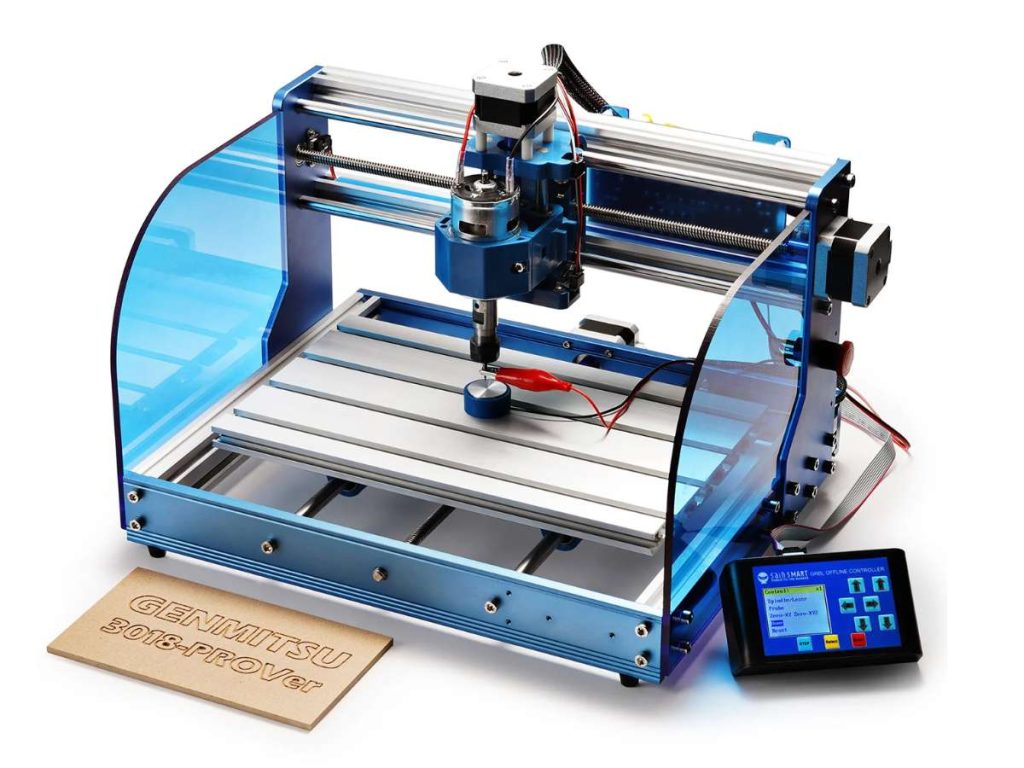

7. SainSmart Genmitsu 3018-PROVer

The 3018-PROVer is a desktop CNC milling machine designed for small-scale production, prototyping, and light machining work. Unlike many entry-level CNC machines, it’s built with an aluminum frame, safety features, and a pre-assembled design, making it one of the easiest to get up and running.

It’s a great option for businesses looking to test CNC machining without a huge upfront investment.

Specifications

- Travel (X/Y/Z): 11.8” x 7.1” x 1.8”

- Spindle Speed: 10,000 RPM

- Spindle Motor: 775 motor (powerful for its class)

- Table Size: 12” x 8”

- Control System: GRBL-based software (compatible with open-source CNC programs)

- Frame: Full aluminum body for stability

- Power Requirements: 24V

It’s not a powerhouse, but for precision engraving and light milling, it gets the job done.

Production Volume & Workload

This CNC mill is best for low-volume work and prototyping.

- Great for engraving and small-scale production

- Works well for prototyping before scaling up to larger machines

- Ideal for testing out new designs with minimal material waste

- Reliable for light-duty manufacturing

If you need a machine for precision engraving, circuit boards, or intricate milling, the 3018-PROVer is a cost-effective option.

Material Compatibility

Despite its size, the 3018-PROVer handles a surprising range of materials.

It cuts:

- Soft metals (aluminum, brass, and copper in thin sheets)

- Plastics (acrylic, ABS, and polycarbonate)

- Woods (MDF, hardwoods, and softwoods)

- PCB materials for circuit board prototyping

I’ve used the 3018-PROVer to prototype everything from PCB designs to hardwood engravings, and it’s never let me down. If you’re just stepping into CNC or need a low-risk way to test ideas before scaling up, this machine is one of the most dependable starters out there.

8. Carbide 3D Shapeoko 4 XXL

The Shapeoko 4 XXL is a large-format CNC router designed for businesses that need precision, speed, and a big work area without the complexity of an industrial CNC.

Unlike many budget CNC routers, this machine is built for real production work. It features a heavy-duty aluminum and steel frame, upgraded motion control, and a powerful spindle system, making it ideal for small manufacturers and workshops.

Specifications

- Travel (X/Y/Z): 33” x 33” x 4”

- Spindle Speed: Variable, supports up to 24,000 RPM (with optional spindle)

- Spindle Motor: Compatible with routers like the Makita RT0701C or Carbide Compact Router

- Frame: Aluminum extrusions with steel reinforcements for stability

- Motion System: Linear rails and V-wheels for smooth operation

- Control System: Carbide Motion (user-friendly and simple)

- Power Requirements: 120V

It’s built to handle bigger jobs with accuracy and consistency.

Production Volume & Workload

This CNC router is perfect for businesses that need a mix of size, precision, and affordability.

- Handles large-scale projects and batch production

- Great for sign-making, cabinetry, and furniture production

- Works well for prototyping oversized parts

- Reliable for cutting multiple parts in one run

If you need a CNC machine that can handle production work but don’t want to spend six figures on an industrial router, this one is a solid alternative.

Material Compatibility

The Shapeoko 4 XXL isn’t just for wood—it handles a variety of materials with ease.

It cuts:

- Hardwoods and softwoods

- Plastics and acrylics

- Aluminum and brass (with the right feeds and speeds)

- Composite materials like carbon fiber and HDPE

I’ve pushed the Shapeoko 4 XXL through hardwoods, plastics, and aluminum—and it’s taken everything in stride. If you need a CNC router that feels like it belongs in a professional shop but won’t bury you in overhead, this one hits that sweet spot between capability and cost.

Conclusion

I started this CNC journey in a cramped garage with more doubts than answers. Now? I’ve tested machines that actually work for real businesses—big or small.

You’ve just seen 8 reliable small CNC machines. Some are great for beginners. Some are built for power.

And Blue Elephant? It’s the game-changer for anyone serious about speed and scale.

Don’t wait for the “perfect time.”

Start building smarter, faster—today.

Contact us today and take the next step toward growing your workshop!

Recommended Reads for You

If you enjoyed this read, here are a few more articles packed with helpful information:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.