A few years ago, I made a bad investment. I bought a CNC milling machine that seemed like a great deal. But after a few months, it couldn’t keep up, and I had to replace it.

That experience taught me how important it is to choose the right machine from the start. Small CNC milling machines aren’t cheap, so getting it right the first time matters.

I’ve spent years researching, using, and testing CNC machines. This review is based on hands-on experience, not just specs and sales pitches.

You’ll find a detailed breakdown of the best small CNC milling machines in this article. Whether you need precision, speed, or cost efficiency, there’s an option for you.

By the end, you’ll know which one is right for your shop.

Let’s get started!

Comparison Chart

Not all small CNC mills are created equal. This comparison table highlights the essential details—spindle speed, power, tooling, and usability—so you can make an informed choice quickly:

| Machine | Spindle Speed (RPM) | Spindle Power (HP) | Table Size (in) | Travel (X/Y/Z) (in) | Tooling | Control System | Capabilities | Software & Usability |

| Haas Mini Mill 2 | 10,000 | 1.5 | 34 × 9.5 | 18 × 11 × 16.25 | R8 Spindle | PathPilot® | General precision machining, expandable options | User-friendly, touchscreen, G-code support |

| Tormach 1100M | 10,000 | 1.5 | 34 × 9.5 | 18 × 11 × 16.25 | R8 Spindle | PathPilot® | High-precision jobs, small-batch manufacturing | Intuitive, customizable shortcuts, real-time adjustments |

| Blue Elephant CNC Mill | 24,000 | 3.2 – 9.6 | Varies | Configurable | ISO or HSK | SYNTEC or Siemens | Heavy-duty cutting, scalable automation | Multi-axis control, touchscreen, automation |

| SYIL X7 | 20,000 | 7.5 | 25.6 × 11.8 | 15.7 × 11.8 × 12.6 | 12-position auto tool changer | Siemens or LNC CNC | High-speed, tight-tolerance machining | High-speed processing, error detection |

| Pocket NC V2-50 | 50,000 | 0.28 | Compact | 4.55 × 5.00 × 3.55 | ER11 collet | Pocket NC Proprietary | Full 5-axis machining, micro-machining | G-code compatibility, cloud-based updates |

| TAIG 2019 CNC Micro Mill | 10,000 | 0.25 | 18 × 4.5 | 12 × 5.5 × 6 | ER16 collet | Mach3/LinuxCNC | Compact, detailed small-parts machining | Supports multiple control systems, hybrid manual operation |

| Genmitsu CNC 3018-PRO | 10,000 | N/A (24V motor) | 11.8 × 7.1 | 11.8 × 7.1 × 1.8 | ER11 collet | GRBL-based | Light-duty engraving, small-scale manufacturing | Easy setup, USB connectivity, offline control |

1. Haas Mini Mill 2

Ever struggled to find a CNC mill that balances power, precision, and affordability? I have. I’ve tested machines that looked promising but failed under real production conditions. The Tormach 1100M isn’t one of them.

The Tormach 1100M is a compact but powerful CNC mill designed for small businesses, machine shops, and prototyping labs. It’s built for those who need more than a hobby machine but don’t want to spend six figures on a high-end industrial mill.

Technical Parameters

- Spindle Speed: 10,000 RPM

- Spindle Power: 1.5 HP

- Table Size: 34″ × 9.5″

- Travel (X/Y/Z): 18″ × 11″ × 16.25″

- Tooling: R8 Spindle

- Control System: PathPilot®

These specs might not seem groundbreaking at first, but in real use, they make a difference. The high RPM spindle gives you flexibility, while the generous travel distances allow for larger workpieces.

Capabilities

What can the Tormach 1100M do for your business?

- Cut a Wide Range of Materials: From aluminum and steel to plastics, the 1100M handles them all with consistent performance.

- High Accuracy: Designed for tight tolerances, it’s ideal for producing precision components that meet exact specifications.

- Expandable Options: Add an automatic tool changer, 4th axis, or other upgrades as your production needs grow.

- Batch Production or One-Off Parts: Whether you’re prototyping or running short production jobs, the 1100M delivers reliable, repeatable results.

I’ve seen machine shops use the 1100M for aerospace components, custom automotive parts, and even medical device prototyping. It’s not just a machine—it’s a workhorse.

Software & Usability

How easy is it to use?

- Runs on PathPilot®: Tormach’s proprietary CNC control software is designed for ease of use—even for those without extensive machining experience.

- Intuitive Interface: The touchscreen system is simple to navigate, making setup and operation fast and straightforward.

- Supports Standard G-Code: Fully compatible with most CAM software, so there’s no need to adjust your existing workflow.

- Live Monitoring: Watch job progress in real-time and make on-the-fly adjustments as needed—ideal for prototyping and production flexibility.

2. Tormach 1100M

The Tormach 1100M is a small-footprint CNC milling machine built for professional shops, prototyping labs, and small-scale manufacturers. It’s designed for businesses that need precision machining without the cost of high-end industrial equipment.

This machine offers serious cutting power while staying compact. It’s easy to upgrade, making it a smart investment for growing shops.

Technical Parameters

- Spindle Speed: 10,000 RPM

- Spindle Power: 1.5 HP

- Table Size: 34″ × 9.5″

- Travel (X/Y/Z): 18″ × 11″ × 16.25″

- Tooling: R8 Spindle

- Weight: 1,220 lbs

- Control System: PathPilot®

The combination of power, precision, and flexibility makes this machine stand out. It’s designed to handle tough materials while maintaining accuracy.

Capabilities

What makes the Tormach 1100M a solid choice for your business?

- Handles High-Precision Jobs: Ideal for prototyping, small-batch manufacturing, and custom machining where accuracy is critical.

- Strong Frame Design: Built to reduce vibrations and improve cutting stability, resulting in cleaner, more precise finishes.

- Flexible Work Envelope: Offers a spacious cutting area for most small-to-medium parts while remaining compact enough for limited shop space.

- Expandable Features: Easily upgrade with a power drawbar, 4th axis, or automatic tool changer as production demands grow.

- Easy to Maintain: Designed for long-term reliability with accessible components, low maintenance requirements, and minimal downtime.

This machine isn’t just for light-duty work—it’s capable of serious production.

Software & Usability

How easy is it to use?

- PathPilot® Control System: Built for machinists—not programmers. Its intuitive layout makes it easy to learn and operate, even for first-time CNC users.

- Real-Time Adjustments: Make on-the-fly changes during a job without starting over—saving time and reducing material waste.

- Customizable Shortcuts: Personalize controls and workflows to match how you work, improving speed and comfort at the machine.

- Remote Monitoring: Check progress from a distance, so you don’t have to stay tethered to the control panel.

- Seamless CAM Integration: Compatible with Fusion 360, Mastercam, and other major CAM programs—no extra steps needed.

I’ve used the 1100M for everything from steel fixtures to aluminum prototypes, and it’s never felt out of its depth. If you need a reliable, professional-grade CNC mill that won’t overwhelm your team or your budget, the Tormach 1100M is one of the best steps a growing shop can take.

3. Blue Elephant CNC Milling Machine

I’ve used CNC machines that felt like a constant fight. Slow processing, rough finishes, and software that made even simple tasks frustrating. That’s why I pay attention to machines that offer real performance without the headaches.

The Blue Elephant CNC Milling Machine is one of those machines. It’s built for efficiency, precision, and power—without unnecessary complexity.

The Blue Elephant CNC Milling Machine is a heavy-duty, industrial-grade CNC mill designed for businesses that need precision and reliability. It’s not a hobbyist machine—it’s made for serious work.

Technical Parameters

- Spindle Speed: 24,000 RPM

- Spindle Power: 3.2 HP – 9.6 HP (varies by model)

- Table Size: Varies by configuration

- Travel (X/Y/Z): Configurable based on production needs

- Tooling: ISO or HSK spindle options

- Weight: Heavier than most compact CNCs for added stability

- Control System: SYNTEC or Siemens CNC

This machine is built for serious cutting power. High RPM means cleaner cuts, and a rigid frame ensures vibration-free operation.

Capabilities

Why do businesses choose the Blue Elephant CNC Mill?

- Heavy-Duty Cutting: Engineered to handle steel, aluminum, and other hard materials with precision and stability.

- High-Speed Operation: The 24,000 RPM spindle enables fast material removal while maintaining detail and accuracy.

- Advanced Automation: Compatible with tool changers and robotic integration—ideal for boosting efficiency and scaling operations.

- Scalable for Production: Equally effective for prototyping and high-volume manufacturing, making it a flexible long-term investment.

- Minimal Maintenance: Built with durable, industrial-grade components to reduce wear and limit downtime.

If you need a machine that can push through long production runs without sacrificing quality, this is a strong option.

Software & Usability

How easy is it to use in a real shop environment?

- Multiple Control System Options: Choose between SYNTEC or Siemens—whichever best fits your team’s workflow and existing setup.

- Touchscreen Interface: Streamlines navigation and speeds up setup by reducing the need for complex manual input.

- Multi-Axis Control: Supports 3-axis, 4-axis, and even 5-axis operations—ideal for machining complex or high-precision parts.

- Smart Error Detection: Proactively identifies issues like tool wear or code conflicts before they disrupt production.

- Custom Macro Programming: Automate routine processes to boost efficiency and minimize operator error.

I’ve seen plenty of machines that look good on paper but fall apart under pressure. The Blue Elephant didn’t flinch, even during extended aluminum runs with tight tolerances. If your shop is ready to step into real production without constant workarounds, this machine is built to deliver—day in, day out.

4. SYIL X7

The SYIL X7 is a compact, high-speed CNC milling machine designed for small to mid-sized manufacturers. It combines industrial-grade performance with affordability, making it a strong choice for precision machining.

With its rigid structure and fast spindle speeds, it delivers smooth, high-accuracy cuts across a wide range of materials. It’s a machine built for efficiency and reliability in demanding production environments.

Technical Parameters

- Spindle Speed: 20,000 RPM

- Spindle Power: 7.5 HP

- Table Size: 25.6″ × 11.8″

- Travel (X/Y/Z): 15.7″ × 11.8″ × 12.6″

- Tool Changer: 12-position automatic

- Control System: Siemens or LNC CNC

- Frame Material: Mineral casting for vibration dampening

With a high-speed spindle and a rigid frame, the SYIL X7 is optimized for precision and efficiency. It’s designed to reduce cycle times while maintaining tight tolerances.

Capabilities

How does the SYIL X7 perform under real production conditions?

- High-Speed Machining: The 20,000 RPM spindle enables rapid material removal, providing ultra-smooth surface finishes even on complex parts.

- Heavy-Duty Performance in a Compact Size: Packs industrial-grade power into a small footprint, perfect for shops with limited space but high demands.

- Precision Cutting: The mineral casting frame absorbs vibrations, ensuring high accuracy on tight-tolerance parts and reducing the need for rework.

- Automatic Tool Changing: The 12-position tool changer automates multi-step machining processes, reducing downtime and improving efficiency.

- Multi-Material Compatibility: Capable of handling a wide range of materials—from aluminum and steel to composites and plastics—giving you the flexibility to take on diverse jobs.

For businesses that need fast, repeatable accuracy, the SYIL X7 is built to handle the demands of modern production.

Software & Usability

What makes the SYIL X7 efficient in a shop environment?

- Dual Control Options: Choose between Siemens or LNC CNC, offering flexibility to match your shop’s existing workflow and control preferences.

- High-Speed Processing: Minimizes lag between toolpath calculations, ensuring smoother, faster cutting for greater throughput.

- Advanced Tool Path Optimization: Reduces unnecessary movement, cutting cycle times and improving overall machining efficiency.

- Built-In Error Detection: Proactively identifies issues like tool wear or misalignment before they result in defects or downtime, keeping your production on track.

- Seamless CAM Integration: Fully compatible with Fusion 360, Mastercam, and other industry-standard software, ensuring smooth design-to-machining workflows.

For shops that need serious speed, flexibility, and reliability in a small footprint, this machine earns its keep from day one.

5. Pocket NC V2-50

Not every CNC job requires a massive machine. I’ve worked on projects where a full-sized mill was overkill, and a compact, precise machine was the smarter choice.

That’s where the Pocket NC V2-50 stands out. It’s a small but powerful 5-axis CNC mill built for businesses that need high-precision machining in a compact footprint.

Technical Parameters

- Spindle Speed: 50,000 RPM

- Spindle Power: 0.28 HP

- Travel (X/Y/Z): 4.55″ × 5.00″ × 3.55″

- Rotary Axes (A/B): Continuous 5-axis motion

- Table Size: Compact footprint for desktop use

- Material Compatibility: Aluminum, wax, wood, plastics, and soft metals

- Control System: Pocket NC proprietary software

This machine is built for extreme precision. With a 50,000 RPM spindle, it’s designed to cut fine details without sacrificing accuracy.

Capabilities

What makes the Pocket NC V2-50 a unique tool for businesses?

- Full 5-Axis Machining: Enables complex part designs that traditional 3-axis mills can’t handle, giving you more design flexibility.

- Ultra-High Spindle Speed: The 50,000 RPM spindle is ideal for micro-machining and intricate cuts, perfect for detailed, small-scale parts.

- Compact and Lightweight: Fits on a standard workbench, offering industrial-level precision while saving valuable floor space.

- Ideal for Prototyping: Quickly test designs and produce highly detailed, small-scale parts with precision.

- Multi-Material Compatibility: Easily handles soft metals, plastics, wax, and composites—making it a versatile tool for diverse applications.

For businesses that need extreme precision in a small package, the Pocket NC V2-50 is one of the best options available.

Software & Usability

How does this machine fit into your workflow?

- Proprietary Pocket NC Software: Specifically designed for 5-axis machining, this software ensures seamless control and maximum precision.

- G-Code Compatible: Works with standard CAM software, so it easily integrates into your existing machining setup without additional software investments.

- Touchscreen Interface: The intuitive touchscreen simplifies operation, reduces setup time, and shortens the learning curve for operators.

- Live Job Monitoring: Track the progress of your cuts in real time, allowing you to make adjustments on the fly and avoid errors.

- Cloud-Based Updates: Ensures that the machine’s software is always up-to-date, keeping the system optimized for smooth, efficient operation.

I’ve used the V2-50 for tight-tolerance prototype parts where every thousandth mattered—and it delivered without hesitation. If you need full 5-axis precision in a footprint that won’t crowd your bench or your budget, this machine punches far above its size.

6. TAIG 2019 CNC Micro Mill

The TAIG 2019 CNC Micro Mill is a compact yet capable milling machine designed for precision machining. It’s built for small workshops, prototyping, and specialty manufacturing where space and budget are limited.

Despite its size, this machine delivers professional-grade accuracy, making it a strong choice for detailed machining work on metals, plastics, and composites.

Technical Parameters

- Spindle Speed: 10,000 RPM

- Spindle Power: 1/4 HP

- Table Size: 18″ × 4.5″

- Travel (X/Y/Z): 12″ × 5.5″ × 6″

- Tooling: ER16 collet system

- Machine Weight: 105 lbs

- Control System: Mach3, LinuxCNC, or custom G-code controllers

With its high-speed spindle and compact size, the TAIG 2019 is perfect for high-precision small parts manufacturing.

Capabilities

What makes the TAIG 2019 CNC Micro Mill a smart choice?

- Precision Machining: Holds tight tolerances, making it ideal for producing small, detailed parts with high accuracy.

- Compact and Lightweight: Perfect for small shop spaces, yet still delivers industrial-grade performance and reliability.

- Smooth Motion Control: High-quality leadscrews and stepper motors ensure consistent, repeatable accuracy for every job.

- Flexible Material Compatibility: Can handle a wide range of materials, including metals, plastics, and composite materials.

- Customizable Setup: Offers options for upgrades such as ball screws and high-speed spindles, enhancing machining capabilities for advanced projects.

For businesses needing a compact yet highly accurate milling solution, this machine delivers exceptional value.

Software & Usability

How well does it integrate into your workflow?

- Supports Multiple Control Systems: Compatible with Mach3, LinuxCNC, and other G-code-based software for flexibility in your machining process.

- Simple User Interface: Works seamlessly with standard CAM software, ensuring an easy and efficient programming experience.

- Manual and CNC Hybrid Operation: Provides the flexibility of hand-cranked movement for setup adjustments, giving operators control during initial setup.

- Customizable Motion Profiles: Allows machinists to fine-tune speeds and feed rates, optimizing cutting efficiency based on the specific job.

- Easy Maintenance: Designed for easy upkeep with readily available parts, minimizing downtime and keeping operations smooth.

It may be small, but it’s consistently reliable—perfect for businesses that need precision without the size or spend of a full industrial mill.

7. Genmitsu CNC 3018-PRO

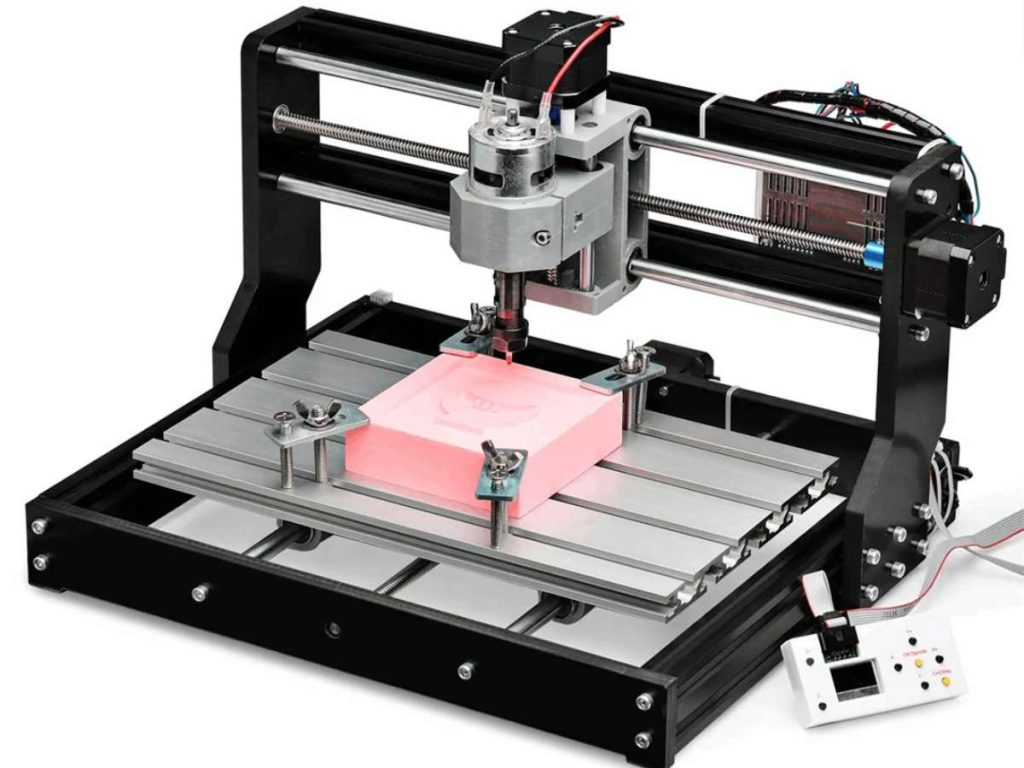

The Genmitsu CNC 3018-PRO is a desktop CNC milling machine designed for small-scale manufacturing, prototyping, and engraving. It’s built for businesses that don’t need a heavy-duty CNC mill but still require accuracy and reliability.

With its easy setup and versatile material compatibility, this machine is a cost-effective choice for light machining and engraving projects.

Technical Parameters

- Spindle Speed: 10,000 RPM

- Spindle Power: 775 motor (24V)

- Table Size: 11.8″ × 7.1″

- Travel (X/Y/Z): 11.8″ × 7.1″ × 1.8″

- Tooling: ER11 collet

- Frame Material: Aluminum & plastic composite

- Control System: GRBL-based controller

This machine is built for precision on a small scale. It’s not for heavy-duty metal cutting, but for engraving, circuit board milling, and light-duty machining, it delivers excellent results.

Capabilities

What can the Genmitsu CNC 3018-PRO handle?

- Engraving and Light Cutting: Perfect for wood, acrylic, PCB boards, and soft metals like aluminum, ideal for detailed work.

- Easy Customization: Modify the machine with laser modules or upgraded spindles to expand its capabilities.

- Compact and Lightweight: Small enough to fit on a workbench, but still delivers precision cutting for a variety of materials.

- Low-Cost Production: An excellent choice for small businesses, custom shops, and prototyping labs looking for an affordable CNC milling solution.

- User-Friendly Operation: Designed for businesses that need a straightforward CNC solution with minimal setup and easy operation.

For businesses that don’t need industrial-scale power but still require precision, the Genmitsu CNC 3018-PRO is a practical choice.

Software & Usability

How easy is it to use in a business setting?

- GRBL-Based Control System: Runs on open-source software, making it easy to integrate with various CAM programs for seamless workflow.

- Simple Setup: Pre-assembled parts reduce installation time, allowing you to start projects quickly.

- USB Connectivity: Easily connects to most computers without the need for expensive controllers, making it accessible to a wide range of users.

- Supports Offline Control: Can run jobs without a constant PC connection, offering flexibility in your production environment.

- Expandable Features: Upgradeable with laser engraving modules or more powerful spindle motors to meet evolving production needs.

I started using the 3018-PRO when I needed a low-risk CNC solution for prototyping small parts—and it’s stayed in my lineup ever since.

Conclusion

We just walked you through 7 small CNC milling machines that prove size doesn’t limit performance. They’re compact, capable, and designed for makers, engineers, and small business owners.

Whether you’re machining metal parts or fine details, these machines deliver precision that pays off.

But, if you’re aiming for long-term wins, the Blue Elephant CNC Mill delivers the speed, strength, and scale your business needs.

Contact us today to learn how we can power up your business.

Explore More of Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.