I made every mistake possible when I started my CNC business. Overpaying for machines, underpricing my work, and missing deadlines. But through trial and error, I figured out what works—and what doesn’t.

Now, my CNC shop runs efficiently and profitably.

If you want to start a CNC business, you don’t have to go through the same struggles I did. The right knowledge upfront can save you time, money, and frustration.

This guide is based on firsthand experience and years of running a CNC operation. No fluff, no generic advice—just real steps you can take to build a successful business.

By the end of this article, you’ll have a clear, actionable plan to confidently start your CNC business. From choosing the right equipment to marketing your services, it’s all covered.

So, let’s begin!

Step#1 Analyzing the CNC Industry

Before you invest a single dollar into your CNC business, you need to understand the industry. The CNC machining market is growing rapidly, with increasing demand from aerospace, automotive, medical, and manufacturing sectors. But competition is tough.

Many CNC startups fail because they jump in without knowing their target audience. You need to identify:

- Who needs CNC machining services?

- What industries have high demand?

- Who are your competitors, and how can you stand out?

- Identifying Profitable Niches: Some CNC shops specialize in aerospace-grade machining, while others focus on prototyping or custom automotive parts. Finding a niche can help you avoid direct competition with large, established CNC businesses.

- Researching Competitors: Look at CNC businesses in your area and online. Check their pricing, services, and customer reviews. This helps you position your business strategically.

- Analyzing Industry Trends: Automation, precision machining, and 5-axis CNC technology are shaping the industry. Staying updated on trends helps future-proof your business.

Step#2 Creating a Business Plan

Starting a CNC business without a plan is like trying to machine a complex part without a blueprint. You might get something out of it, but it won’t be precise, efficient, or profitable. I learned this the hard way.

When I first started, I thought I could just buy a machine, take on jobs, and figure things out along the way. I wasted time. You don’t have to learn the hard way. Here’s how to build yours:

Define Your CNC Business Model

What kind of CNC business are you starting?

- Custom CNC Machining: Producing parts based on client designs.

- Prototyping: Working with engineers and product developers.

- Small-scale manufacturing: Producing batches of parts for businesses.

- Specialty machining: Aerospace, automotive, medical, or another high-precision niche.

Set Clear Goals

What do you want this business to become?

Do you want to stay small and focus on high-end, custom work? Or do you see yourself growing into a full-scale CNC production shop?

Write it down. Be specific.

- How much revenue do you want in year one?

- How many clients do you need to make that happen?

- Will you start solo, or will you hire a team?

Your business goals give you direction and help you make smart decisions from day one.

Know Your Costs

Let’s be real—running a CNC business is expensive. Machines, materials, rent, software, maintenance—it adds up fast.

You need to calculate your startup and ongoing costs so you don’t run out of cash before your business takes off.

Break it down:

- Startup Costs: Machines, tools, software, licenses, workshop setup

- Fixed Costs: Rent, insurance, maintenance, salaries (if hiring)

- Variable Costs: Materials, electricity, shipping, marketing

Once you know your costs, price your services accordingly. Don’t just undercut competitors—charge what your work is worth.

Identify Your Target Market

Not all CNC businesses serve the same customers. Some work with large industrial clients, while others focus on smaller businesses needing custom parts.

Who are you selling to?

- Manufacturers looking for production machining

- Engineers needing prototypes

- Automotive shops needing custom parts

- Local businesses need specialty machining

The more specific you get, the easier it is to market your business and close deals.

Plan Your Marketing Strategy

Even the best CNC shop in the world won’t succeed if nobody knows it exists. Your marketing plan should answer:

- How will you attract customers? (Website, social media, networking, referrals?)

- What makes your CNC shop different? (Faster turnaround? Specialized materials?)

- How will you build trust with potential clients? (Testimonials? Case studies?)

Step#3 Choosing a Business Structure

The structure you choose isn’t just a technicality—it affects your taxes, liability, and even your ability to grow. Choose the wrong one, and you could end up paying more in taxes, facing legal risks, or struggling to secure funding. Choose the right one, and you set yourself up for long-term success.

Let’s make sure you get it right from the start.

The 4 Main Business Structures

There’s no one-size-fits-all answer. Each business structure has pros and cons, depending on your goals, risk tolerance, and growth plans.

Sole Proprietorship (For Small, Low-Risk Startups)

Best for: A solo CNC machinist just getting started, taking small jobs.

- Simple and inexpensive to set up

- All profits go to you (no complicated tax filings)

- You’re personally liable for business debts and lawsuits

- Harder to get business loans

If you’re testing the waters or starting small, a sole proprietorship can work. Just know that if something goes wrong—like a legal dispute or unpaid debt—you’re personally on the hook.

Limited Liability Company (LLC)

Best for: CNC businesses that want protection without corporate complexity.

- Personal assets are protected (your house, car, etc.)

- More credibility with clients and suppliers

- Flexible tax options (you can be taxed as an individual or corporation)

- Slightly more paperwork and costs than a sole proprietorship

An LLC is a great option for most CNC startups because it offers liability protection without too much red tape. It’s what I eventually switched to, and I wish I had done it sooner.

S Corporation (S-Corp)

Best for: CNC businesses making consistent profits, ready to scale.

- Lower self-employment taxes than an LLC

- Business income isn’t taxed twice (avoiding corporate tax)

- Easier to raise investment capital

- More paperwork, strict IRS requirements

If your CNC business is making over $50K in profit, an S-Corp can save you thousands in taxes. But it comes with extra rules and filing requirements, so it’s not ideal for beginners.

C Corporation (C-Corp)

Best for: Large-scale CNC businesses planning for investors and growth.

- Best for raising money from investors

- Strongest legal protection from liability

- No restrictions on number of owners

- Double taxation (business pays corporate tax, then you pay personal tax)

- Lots of paperwork and compliance requirements

A C-Corp is overkill for most CNC startups, but if you plan on building a multi-million-dollar operation, it might be worth considering.

Which One Should You Choose?

Ask yourself:

- Am I starting solo or with a team? (Solo = sole proprietorship or LLC, team = LLC or S-Corp)

- Do I want to protect my assets? (If yes, skip the sole proprietorship)

- Will I be making enough profit for tax savings to matter? (Over $50K profit? Consider an S-Corp)

- Do I plan to seek investors? (If yes, a C-Corp might be your best bet)

For most CNC startups, an LLC is the best choice. It protects your assets and gives you flexibility without corporate complexity.

Step#4 Selecting and Acquiring CNC Machines

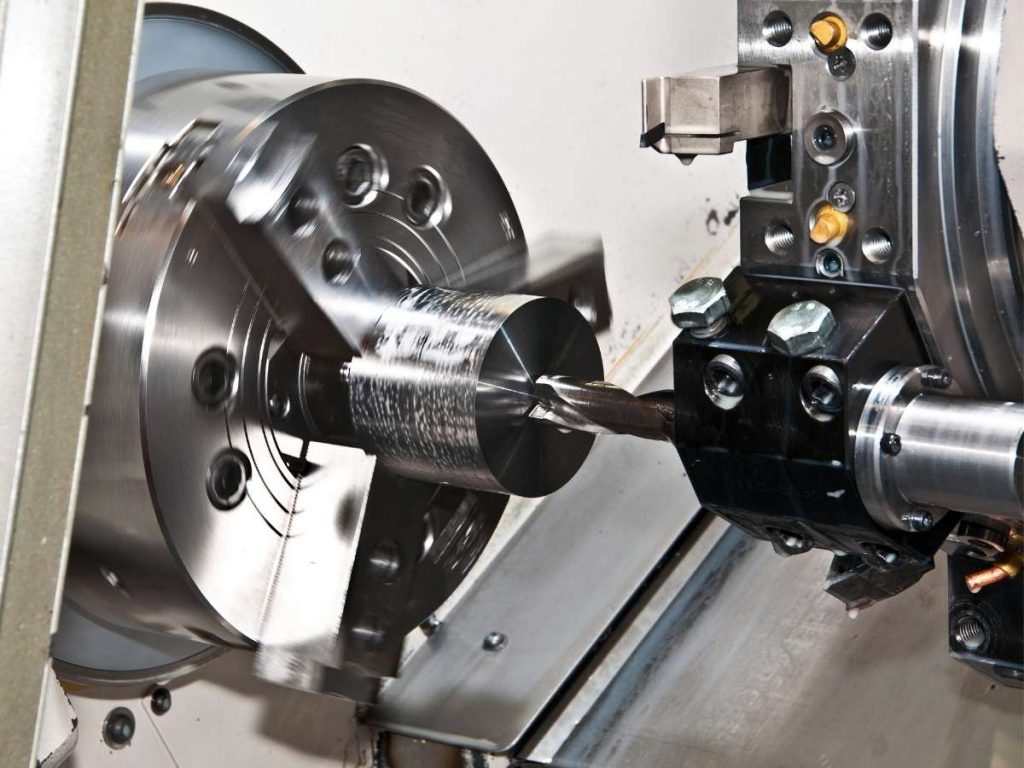

Your CNC machine is the heart of your business. It’s not just a tool—it’s the foundation of your success. Choose the wrong one, and you’ll be stuck with limitations, inefficiencies, and unnecessary expenses. Choose the right one, and you’ll have a reliable workhorse that drives profit, precision, and growth.

This isn’t a decision you can afford to get wrong. The market is filled with options—milling machines, lathes, routers, plasma cutters, laser engravers. Each has its strengths. But which one is right for your business?

Let’s break it down step by step.

Define Your Business Needs

Before you even look at machines, ask yourself:

- What type of parts will you be machining?: Metals, plastics, composites?

- What industries will you serve?: Aerospace, automotive, medical, prototyping?

- What level of precision is required?: Are tolerances tight or flexible?

- What’s your expected production volume?: Custom one-offs or mass production?

Your machine must align with your business model, not the other way around.

Types of CNC Machines

Each CNC machine serves a different purpose. Choosing the wrong one can cripple your efficiency and profitability.

- CNC Milling Machines: Best for precision cutting and shaping of metals, plastics, and composites. Ideal for aerospace, automotive, and industrial manufacturing.

- CNC Lathes: Designed for high-precision cylindrical parts. Perfect for automotive, medical, and mechanical components.

- CNC Routers: Best for cutting and engraving wood, plastics, and soft metals. Common in signage, cabinetry, and artistic applications.

- CNC Plasma Cutters: Used for cutting thick metal sheets. Mostly used in metal fabrication and industrial applications.

- CNC Laser Cutters: Provides high-precision cutting on thin metals, plastics, and other materials. Great for fine detailing and engraving.

Each machine has its place. Choose the one that matches your workload and long-term goals.

New vs. Used

CNC machines aren’t cheap, and this decision can significantly impact your cash flow. Should you invest in a brand-new machine or look for a quality used one?

| Option | Pros | Cons |

| Buying New | – Comes with manufacturer warranty – Latest technology and features – Lower maintenance costs – Long-term reliability | – High upfront cost – Potential lead times for delivery |

| Buying Used | – Lower purchase price – Faster availability – Great for tight budgets and startups | – Higher risk of wear and tear – May not include warranty or support |

If reliability is critical to your operation, go new. If you’re working with a limited budget, used can work—just inspect thoroughly before buying.

Where to Buy a CNC Machine

Buying a CNC machine is a big investment and where you buy it matters just as much as what you buy. The right source can offer better support, longer machine life, and faster results. Here are your top options:

- Direct from Manufacturers: This is often the smartest route for startups and growing shops. Trusted names like Blue Elephant specialize in manufacturing high-performance CNC machines for businesses of all sizes, and they’re known for their reliability and service.

- Authorized Dealers: A solid middle ground. You can find both new and certified pre-owned machines, often with limited warranties and installation support. Make sure the dealer is reputable and knowledgeable about your industry’s needs.

- Used CNC Marketplaces: If you’re on a tight budget, used machines can work—but they come with risk. Without detailed service records or inspection guarantees, you might inherit someone else’s problems. Always bring in a technician to evaluate the machine before you buy.

- Industrial Auctions: Sometimes you can score a deal here, but understand that auctions are “as-is.” No guarantees. No support. Only go this route if you’re experienced and know what to look for.

Step#5 Sourcing Materials

Your CNC machine is only as good as the materials you feed it. The right materials ensure precision, durability, and consistency. The wrong ones lead to poor-quality parts, wasted money, and frustrated clients.

Sourcing materials isn’t just about finding the cheapest supplier—it’s about balancing cost, quality, and availability. If your materials are inconsistent, your business will be too.

Let’s break down how to source the right materials for your CNC business and ensure you’re never stuck without what you need.

Identify the Materials You Need

The materials you choose depend on your niche. Before sourcing, ask yourself:

- What industries do I serve? Aerospace, medical, automotive, prototyping?

- What properties do my parts require? Strength, weight, heat resistance, conductivity?

- What’s my budget for raw materials? Can I afford high-end alloys, or should I start with budget-friendly options?

Common CNC materials include:

- Metals: Aluminum, steel, stainless steel, brass, titanium

- Plastics: ABS, acrylic, nylon, polycarbonate, PEEK

- Composites: Carbon fiber, fiberglass, kevlar

- Wood: MDF, plywood, hardwoods (if using a CNC router)

Finding Reliable Suppliers

A bad supplier can cost you time, money, and your reputation. Late shipments, poor-quality materials, or inconsistent stock can cripple your business. Here’s how to find the right suppliers:

- Local Distributors: Faster shipping, easy communication, lower freight costs.

- Online Industrial Suppliers: McMaster-Carr, Online Metals, Grainger, Xometry. Good for specialty orders.

- Direct from Manufacturers: Best for bulk orders and long-term contracts. Companies like Blue Elephant, known not only for their CNC machines but also for reliable material partnerships, offer a seamless experience for sourcing equipment and compatible supplies at scale.

- Metal Scrap Yards/Recyclers: A budget-friendly option for certain metals.

- Networking & Trade Shows: Connect with trusted industry suppliers.

When vetting a supplier, look for:

- Consistency in quality (request material certifications)

- Reasonable lead times (delays cost you money)

- Scalability (can they handle larger orders as you grow?)

- Fair pricing (cheapest isn’t always best)

Step#6 Setting Up Your CNC Workshop

Your CNC workshop isn’t just a workspace—it’s the engine that drives your entire business. A well-designed shop boosts efficiency and keeps production running smoothly. A poorly planned one? It leads to wasted time, frustration, and costly mistakes.

Let’s build a workshop that works for you, not against you.

Choosing the Right Location

Your workshop needs to support your machines, workflow, and future growth. Whether you’re starting in a garage, renting a commercial space, or building a dedicated shop, consider:

- Space Requirements: Can your shop fit your CNC machines, workbenches, and material storage without feeling cramped?

- Power Supply: CNC machines need stable power. 3-phase power is ideal for industrial machines.

- Ventilation & Air Quality: Cutting metals, plastics, and composites generates dust, fumes, and debris. Invest in proper ventilation and air filtration.

- Noise & Vibration Control: CNC machines are loud. If you’re in a shared or residential space, soundproofing and vibration dampening will be crucial.

- Expansion Potential: Your business will grow. Will you have space for additional machines, employees, and storage?

Layout Optimization

A CNC shop should run like a well-oiled machine. Every step in the process—from raw material intake to final inspection—should flow seamlessly.

Essential Zones in Your Workshop:

- Machine Area: Dedicated space for CNC machines with proper clearance and access.

- Material Storage: Keep raw materials organized and easily accessible.

- Workbenches & Assembly: Space for secondary operations, inspections, and assembly.

- Tooling & Maintenance: A designated area for tool changes, maintenance, and calibration.

- Office & Programming Space: A quiet, clean area for CAD/CAM programming and business operations.

Essential CNC Safety Measures

- Emergency Stop Buttons: Every machine should have accessible emergency stop controls.

- Proper Ventilation: Coolants, dust, and fumes require air filtration systems.

- Fire Safety: CNC machines can overheat and keep fire extinguishers and suppression systems nearby.

- Personal Protective Equipment (PPE): Safety glasses, ear protection, gloves, and steel-toe boots are non-negotiable.

- Machine Guards & Shields: Protect operators from moving parts and flying debris.

Step#7 Investing in CNC Software

A CNC machine is only as good as the person programming it. Without the right software and training, even the most expensive machine is just an expensive paperweight.

Many CNC businesses fail not because of bad machines—but because they don’t invest in software and training. Poor programming leads to slow production, mistakes, wasted materials, and lost profits.

If you want your CNC business to thrive, you need to master the right tools and the right skills. Let’s break it down:

Choosing the Right CNC Software

- CAD (Computer-Aided Design) – Designing Parts

CAD software allows you to create precise 2D and 3D models before machining.

- Fusion 360: Affordable, beginner-friendly, cloud-based.

- SolidWorks: Industry standard for complex designs.

- AutoCAD: Great for 2D drafting, used in many industries.

Without solid CAD skills, you can’t design parts that meet your client’s specifications.

- CAM (Computer-Aided Manufacturing) – Generating Toolpaths

CAM software converts CAD designs into machine-readable toolpaths that tell the CNC machine how to cut.

- Fusion 360 CAM: Integrated with Fusion 360, ideal for beginners.

- Mastercam: Industry standard, powerful toolpath creation.

- HSMWorks: Best for those already using SolidWorks.

A bad toolpath can break tools, waste materials, and destroy parts. Mastering CAM is critical.

- CNC Machine Control Software – Running the Machine

This software sends G-code (machine instructions) to the CNC machine.

- Mach3 & Mach4: Popular for small CNC businesses.

- LinuxCNC: Open-source and customizable.

- GRBL: Common for smaller CNC routers and hobby machines.

The right software depends on your machine type and level of automation.

Step#8 Marketing Your Business

A great CNC shop with no marketing is like a high-performance machine with no power—it won’t run. You can have the best equipment, the most skilled operators, and the highest precision machining, but if no one knows your business exists, you won’t get clients.

The CNC industry is competitive, and simply relying on word-of-mouth isn’t enough. You need a marketing strategy that positions your business as the go-to solution for high-quality CNC machining.

Let’s break it down step by step.

Build a Professional Website

In today’s world, if your CNC business isn’t online, you don’t exist. Your website should showcase:

- Your Services: What industries do you serve? What parts can you produce?

- Your Capabilities: List your machines, materials, and tolerances.

- Your Portfolio: Show real examples of your work.

- Your Contact Information: Make it easy for potential clients to reach you.

SEO Optimization

Most buyers search for CNC services online. If your website doesn’t rank in search engines, your competitors will get the business instead. To improve visibility:

- Use keywords like “custom CNC machining” and “precision metal fabrication.”

- Create content (blogs, case studies) that answers client questions.

- Add location-based SEO (e.g., “CNC machining in [your city]”).

Leverage LinkedIn and Industry Networking

Unlike retail businesses, CNC clients don’t come from Instagram or TikTok. They’re on LinkedIn, industry forums, and trade shows.

- Connect with engineers, manufacturers, and procurement managers.

- Post valuable content like machining tips, project showcases, and industry insights.

- Engage in industry discussions and position yourself as an expert.

Create a Lead Generation System

Marketing isn’t just about visibility—it’s about turning visitors into paying clients. Here’s how to generate leads for your CNC business:

- Offer a free quote request on your website.

- Use Google Ads to target businesses searching for CNC services.

- Send cold emails to manufacturers who might need your services.

- Set up referral partnerships with engineers and design firms.

Step#9 Maintaining Quality Control

In CNC machining, precision is everything. A single miscalculation, a dull cutting tool, or a programming error can turn a perfect part into scrap. Scrap means wasted materials, wasted time, and lost money.

Your clients expect absolute accuracy, repeatability, and reliability. If you can’t consistently meet their standards, they’ll find another shop that can. Let’s break down how to maintain flawless quality control in your CNC shop.

Set Clear Quality Standards

What defines a “good part” in your shop? If you can’t answer this, you’re already at risk. Your quality control (QC) standards should cover:

- Tolerances: What’s acceptable, and what’s not?

- Surface Finish: What’s the required roughness or polish level?

- Material Specifications: Does each part meet the client’s requested material properties?

- Dimensional Accuracy: How will you measure and verify each cut?

- Inspection Procedures: Who checks for defects, and how often?

Invest in Precision Measuring Tools

If you can’t measure it, you can’t guarantee quality.

- Calipers & Micrometers: For quick and accurate measurements.

- Dial Indicators: To check part alignment and runout.

- CMM (Coordinate Measuring Machine): For high-precision inspections.

- Height Gauges & Surface Plates: For measuring part flatness and height accuracy.

- Optical Comparators: For inspecting detailed part profiles.

Implement In-Process Inspection

Catching defects after production is too late. In-process inspection ensures you identify problems before they become expensive mistakes.

When to Inspect:

- Before Machining: Check material specs, dimensions, and setup.

- During Machining: Use probing systems and manual spot-checks to verify dimensions.

- After Machining: Perform a final quality control check before shipping to the client.

Inspection Methods:

- First Article Inspection (FAI): Check the first part produced before running a full batch.

- Random Sampling: Inspect a set percentage of parts in each production run.

- 100% Inspection: If tolerances are tight, inspect every single part.

Conclusion

Starting my CNC business wasn’t easy, but looking back, every struggle was worth it. From that first machine in my garage to a fully operational shop, the journey has been incredible.

Now, it’s your turn.

You’ve got the roadmap—how to set up, find clients, and scale. The only thing left? Taking action. The best time to start was yesterday; the next best time is now.

What’s stopping you from launching your CNC business today? Let’s make it happen.

Recommended Reads for You

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

- How to Start a CNC Machine Business Successfully

- How Profitable Is a CNC Business?

- Top 9 Fiber Laser Cutting Machine Manufacturers

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.