A CNC machine is more than just a tool, it’s a business waiting to happen. I’ve seen small shops grow into six-figure operations simply by focusing on the right products and customers.

If you’re exploring CNC business ideas, you’re on the right path. The market is growing, but profitability depends on choosing the right niche.

I’ve researched countless CNC businesses, spoken to industry experts, and identified the most profitable opportunities. The ideas in this article are based on real success stories and industry trends.

Here, you’ll find 7 high-profit CNC business ideas with solid market demand. Whether you’re just starting out or looking to expand, these insights will help you make a smart move.

Let’s get started!

1. CNC Machined Parts for Industrial Use

One of the most lucrative CNC business opportunities is manufacturing industrial parts. Industries like aerospace, medical, and automotive constantly require precision-machined components, and many companies prefer to outsource this work rather than invest in their own CNC equipment.

Why It’s Profitable:

- High demand exists across multiple industries, making it a stable and growing market. Companies are willing to pay a premium for precision and reliability, ensuring good profit margins.

- There is potential for long-term contracts and repeat orders, which can provide steady revenue. With the right quality control and customer service, businesses can secure high-value clients.

How to Get Started:

- Identify an industry niche (e.g., aerospace parts, medical implants, or custom fasteners) to differentiate yourself from competitors. Specializing in a specific sector helps you build expertise and attract targeted clients.

- Invest in a high-precision CNC milling or turning machine to meet the required industry standards. Reliable equipment ensures consistent quality and efficiency in production.

- Establish relationships with manufacturers and offer small-batch production to start. Many companies prefer working with trusted partners before scaling up orders.

If you focus on delivering consistent quality and fast turnaround times, word will spread, and you’ll start landing bigger contracts.

2. CNC Furniture Manufacturing

Gone are the days when furniture production was purely manual. Businesses are now leveraging CNC machines to create custom, high-end furniture that blends craftsmanship with efficiency.

Why It’s Profitable:

- High-end and custom furniture markets have strong demand, as more businesses and individuals seek unique pieces. With CNC machining, you can produce intricate designs that set your products apart.

- This business allows for scalable production while maintaining uniqueness. CNC machining reduces waste and increases efficiency, improving overall profitability.

How to Get Started:

- Choose a specialty, modern, minimalist, or even traditional CNC-carved designs. Focusing on a niche helps build a strong brand and attract a loyal customer base.

- Use a CNC router to cut and shape materials like wood, MDF, or plywood with high precision. Investing in the right software and tools ensures efficient production and design flexibility.

- Partner with interior designers, architects, and boutique furniture retailers to reach a wider audience. Establishing these connections can bring in consistent orders and referrals.

The key here is customization. Clients are willing to pay more for bespoke pieces that fit their exact needs.

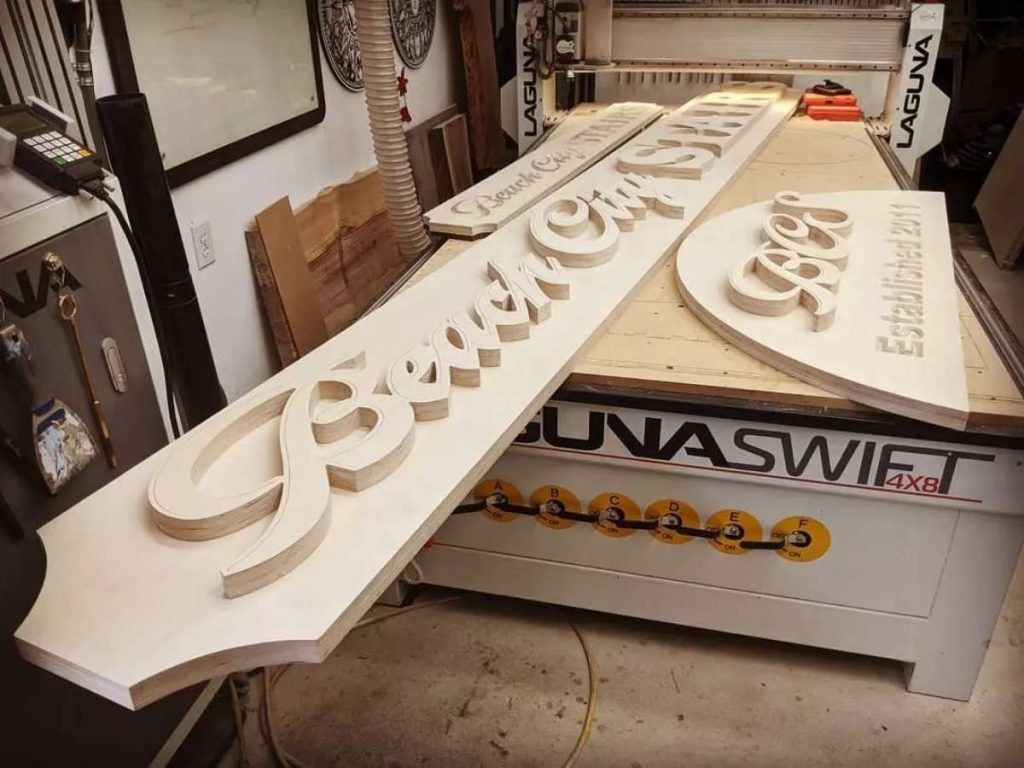

3. CNC Signage and Advertising Products

Businesses always need signage, whether for branding, navigation, or advertising. CNC machines can create stunning 3D signs, illuminated letters, and intricate advertising materials.

Why It’s Profitable:

- There is constant demand from businesses, retail stores, and event organizers looking to enhance their visibility. Custom signage often commands high prices due to its design and material quality.

- Low material costs compared to the selling price make this a profitable venture. With CNC technology, you can efficiently produce high-quality signs with intricate details.

How to Get Started:

- Offer custom signage for storefronts, office spaces, and exhibitions, catering to different business needs. Creating a diverse portfolio can help attract more clients.

- Use CNC routers to cut and engrave acrylic, metal, or wood with precise detailing. Advanced CNC technology enables you to offer unique and visually appealing products.

- Develop partnerships with marketing agencies and event planners who regularly need custom signage. Strong industry connections can lead to bulk orders and recurring business.

With the right marketing, this business can generate consistent income since businesses frequently refresh their branding.

4. CNC Jewelry and Accessories Production

Jewelry making has evolved beyond handcrafting. CNC machines can produce intricate rings, pendants, and accessories with high precision, making this a profitable niche.

Why It’s Profitable:

- High profit margins exist due to the value of materials used, such as gold, silver, and titanium. Precision machining allows for unique and high-quality designs that customers are willing to pay a premium for.

- Custom and personalized jewelry is in demand, as consumers seek one-of-a-kind pieces. CNC machining enables mass customization, helping businesses cater to niche markets.

How to Get Started:

- Specialize in a niche (e.g., engagement rings, watches, or custom name pendants) to create a strong brand identity. Focusing on a particular segment ensures better market positioning.

- Use a CNC milling machine for metals or a laser CNC for engraving designs to achieve intricate detailing. Investing in quality materials and finishing techniques enhances the overall product appeal.

- Sell to jewelry stores or directly through an online platform to expand your reach. Leveraging e-commerce and social media marketing can help drive sales and brand awareness.

This business thrives on creativity and precision. The more unique your designs, the more clients you’ll attract.

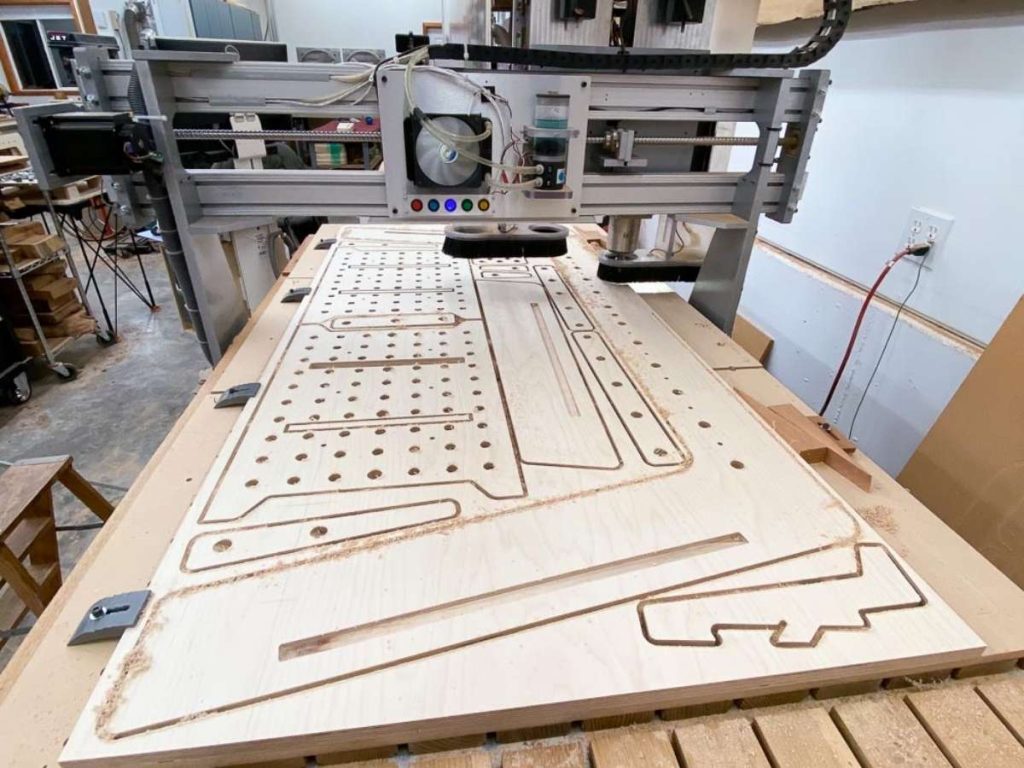

5. CNC Router-Based Woodworking Business

If you have a passion for woodworking, CNC routers can help you scale a profitable business. From cabinetry and home decor to intricate wooden carvings, the possibilities are endless.

Why It’s Profitable:

- Custom wood products sell well in the premium market, as customers seek unique designs. CNC routers make it easier to produce high-quality, detailed wooden pieces efficiently.

- Low material costs and high markup potential make this an attractive business. Since CNC routers minimize waste, they help maximize profit margins.

How to Get Started:

- Invest in a CNC router capable of handling various wood types to create diverse products. The right machine ensures precision and quality in every piece.

- Offer specialized products like personalized cutting boards, wall art, or furniture components. Focusing on custom-made items can attract a niche customer base.

- Partner with interior designers and home renovation businesses to secure larger projects. Establishing these relationships can provide steady work and long-term collaborations.

With the growing trend of unique home decor and personalized wooden gifts, this CNC business has strong earning potential.

6. CNC-Based Prototyping Services

Creating new products requires testing and refinement, and that’s where CNC-based prototyping services come in. Businesses in industries like medical, automotive, and consumer electronics need high-precision prototypes before committing to full-scale production.

Why It’s Profitable:

- Many industries require rapid prototyping, including medical, automotive, and product design. CNC machining allows businesses to test designs before committing to large-scale production.

- Companies pay well for precision prototypes with quick turnaround times. The ability to produce accurate, functional prototypes ensures high demand.

How to Get Started:

- Invest in versatile CNC machines that can handle multiple materials, such as metal, plastic, and composites. Offering a broad range of materials increases your client base.

- Partner with product developers and engineers who need rapid prototyping services. Establishing relationships with R&D departments can lead to recurring contracts.

- Develop an efficient workflow to quickly iterate on prototype designs. Faster turnaround times can give you a competitive edge and attract more clients. Offering a broad range of materials increases your client base.

7. CNC Automotive Parts and Customization

The automotive industry is a goldmine for CNC machining businesses, with countless opportunities in customization and performance upgrades. Car enthusiasts and mechanics are always looking for precision-engineered parts to enhance vehicle performance and aesthetics.

Why It’s Profitable:

- The automotive aftermarket is growing, with high demand for custom parts and modifications. Car enthusiasts and professional tuners are willing to pay premium prices for unique designs.

- CNC machining allows for precision-engineered parts that improve vehicle performance and aesthetics. High-quality custom parts can command strong profit margins.

How to Get Started:

- Focus on a niche, such as engine components, performance upgrades, or restoration parts. Specializing in a segment helps build a reputation and attract loyal customers.

- Establish relationships with auto repair shops and performance-tuning businesses. Partnering with industry professionals ensures a steady stream of customers.

- Offer customization services for individual clients or automotive brands. Unique, high-quality CNC parts can help build a loyal customer base and generate word-of-mouth referrals. Specializing in a segment helps build a reputation and attract loyal customers.

Conclusion

That day in the workshop? It was more than just cool to watch. It showed me what’s possible with CNC machines, and now, you’ve seen it too.

Need machines you can trust?

Blue Elephant, based in China, offers reliable CNC systems for businesses like yours.

Are you ready to take that leap?

Contact us today. Let’s build something incredible.

Explore More of Our Resources

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.