Years ago, I was confident in my CNC setup. My machines were reliable, my team was efficient, and we were delivering quality work.

Then a competitor showed up with newer technology. Faster cuts. Less material waste. Lower costs. Within months, they were winning bids I couldn’t touch.

I had a choice, update my approach or watch my business lose ground.

If you’ve ever worried about staying competitive, I get it. CNC technology moves fast. One year, a machine is top-tier. The next, it’s outdated. That’s why knowing what’s next isn’t just helpful, it’s necessary.

In this guide, you’ll find 8 CNC machine technologies that matter right now. I’ll break down what’s changing, why it’s important, and how it could impact your work. By the end, you won’t just know what’s new, you’ll know how to stay ahead and make smarter investment choices.

Let’s start!

1. Integration of Artificial Intelligence (AI) and Machine Learning in CNC Machining

I remember the frustration of losing an entire workday because a spindle motor failed unexpectedly. The machine had been running fine the day before. No warning signs, no strange noises. Just a sudden stop and a costly repair bill.

Back then, maintenance was reactive.

You waited for something to break, then scrambled to fix it. Or you followed a strict maintenance schedule, replacing parts that might have lasted much longer. Either way, it meant wasted time and money.

Now, AI and machine learning are changing that.

These technologies can now allow CNC machines to learn from data, make adjustments on the fly, and even predict issues before they happen. Instead of just executing commands, machines are starting to think ahead.

How AI Makes CNC Machines Smarter

Predictive Maintenance

A machine breaking down mid-project is every shop owner’s nightmare. It’s even worse when a big order is due. I once had to call a repair technician at 2 AM because a critical part snapped, leaving us behind schedule and scrambling.

AI prevents this by monitoring wear and tear in real time. Sensors track temperature, vibration, and cutting pressure. If the system detects an issue like a tool getting dull or a motor overheating—it alerts you before failure happens.

- Fewer surprise breakdowns

- Lower repair costs Less wasted time waiting on technicians

Process Optimization

Here’s a problem every machinist faces, you set up a job, the material cuts differently than expected, and suddenly your tool is chattering, or worse, breaking.

Machine learning fixes this in real time. It adjusts feed rates, spindle speeds, and cutting paths on the fly based on how the material reacts.

Instead of stopping the job, tweaking settings manually, and restarting, the machine learns and adapts.

What does this mean for you?

- Better surface finishes with fewer errors

- Less scrap material from mistakes

- Faster production without sacrificing accuracy

Where AI is Already Making an Impact

I used to think AI in CNC was just marketing hype. Then I saw how industries are using it today:

- Aerospace: Producing high-precision parts with minimal waste

- Automotive: Reducing cycle times while keeping tolerances tight

- Furniture & Woodworking: Perfecting intricate designs without excess material waste

- Medical Devices: Achieving extreme precision for implants and surgical tools

What to Consider Before Adopting AI in CNC

Before diving in, ask yourself these questions:

- Is my current CNC setup collecting real-time data? AI needs machine data to make smart adjustments. Without it, AI is like a pilot flying blind.

- Does my software support AI-driven machining? Some machines need upgrades or add-on software to enable machine learning.

- Am I prepared for a learning curve? AI helps, but you still need to understand its recommendations to make the most of it.

2. Advancements in Multi-Axis CNC Machining

Years ago, I worked with a standard 3-axis CNC machine. It got the job done, but some designs were impossible to produce without multiple setups.

Every time we repositioned a part, there was a risk of misalignment.

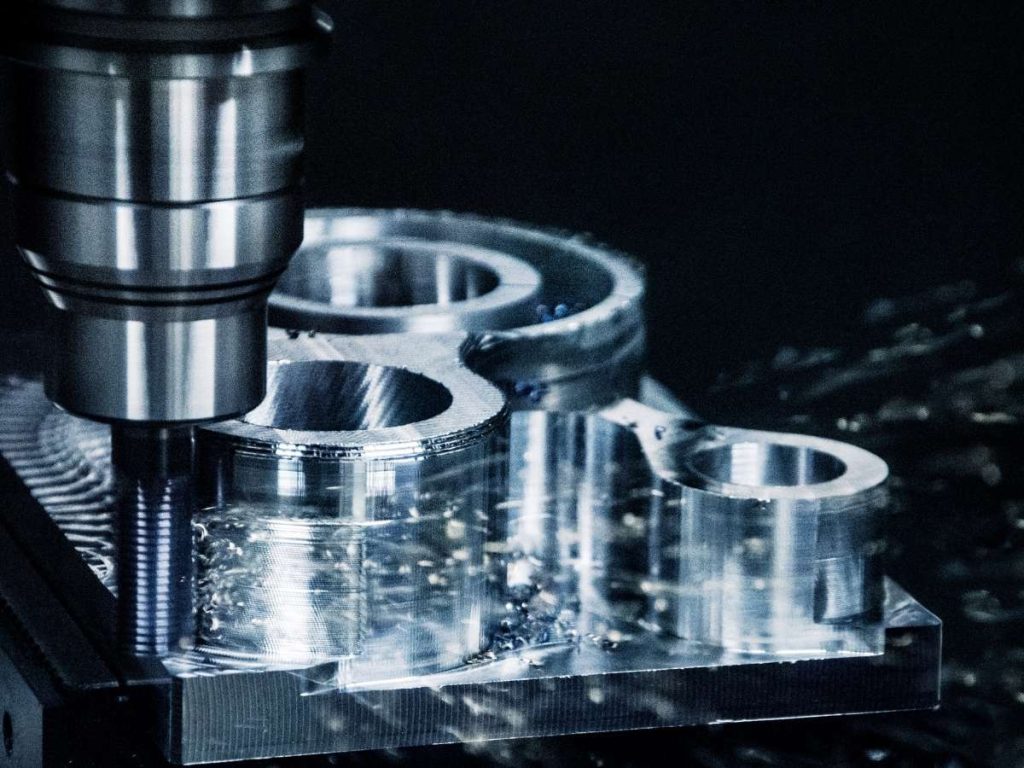

Then I saw a 5-axis CNC machine in action. One setup, no repositioning, and perfect cuts on all sides.

Multi-axis machining has come a long way.

Today, 5-axis and beyond machines are redefining precision manufacturing. If you’re working with complex parts, intricate designs, or tight tolerances, these machines can make your life easier.

5-Axis and Beyond

- Traditional CNC machines operate on 3 axes: X (left to right)

- Y (front to back)

- Z (up and down)

5-axis CNC machines add 2 more rotational axes, giving them far more flexibility.

- A-axis: Rotates around the X-axis

- B-axis: Rotates around the Y-axis

What does this mean for you?

- Fewer setups: Cut multiple sides of a part without stopping.

- Higher accuracy: No need to reposition the workpiece manually.

- Faster production: Reduced lead times and increased output.

And it doesn’t stop at 5 axes. 6-axis and 7-axis CNC machines are pushing the boundaries even further, allowing for even more complex machining in a single step.

Why Multi-Axis Machining Matters

If you work in industries like aerospace, automotive, or medical manufacturing, precision is everything. Multi-axis machines handle intricate designs with ease, making them ideal for:

- Aircraft components: Complex curves and lightweight structures

- Automotive molds: Seamless designs with fewer errors

- Medical implants: Precise shaping for custom-fit prosthetics

- Furniture and woodworking: Detailed carvings and 3D surfaces

What to Consider Before Upgrading

Before investing in a multi-axis CNC machine, think about:

- Software & Programming: Multi-axis machining requires advanced CAM software to generate precise toolpaths. Is your team ready for that learning curve?

- Cost & ROI: More axes mean higher costs. But for the right applications, the time and material savings can outweigh the investment.

- Machine Rigidity: More movement means more stress on components. High-quality machines are built to handle this, but lower-end models may struggle.

3. Hybrid Manufacturing: Combining Additive and Subtractive Processes

I used to think CNC machining and 3D printing were completely separate worlds. One removes material, the other adds it. Two different approaches, each with its strengths and weaknesses. Then I saw a hybrid CNC machine in action. It printed a complex metal part, then milled it to perfection, all in one setup.

That’s when it clicked.

Why choose between additive and subtractive when you can have both?

Hybrid manufacturing combines 3D printing (additive manufacturing) with CNC milling (subtractive manufacturing). Instead of working separately, these processes now work together in a single machine.

How Hybrid CNC Machines Enhance Manufacturing

Traditional CNC machining is great for precision and strength. 3D printing is great for complex geometries and internal structures. Hybrid machines let you take advantage of both.

- 3D printing builds up the part layer by layer, creating intricate shapes and hollow sections that would be impossible to mill.

- CNC milling refines the printed part, improving surface finish and ensuring precise dimensions.

The result? Stronger, more complex, and more efficient parts than either method alone could achieve.

Advantages of Hybrid CNC Machines

- Create complex parts with internal features: 3D printing allows for hollow structures, hidden channels, and lightweight designs that traditional machining struggles with.

- Reduce material waste: Instead of milling away large sections, you start with only the material needed.

- Streamline production: No need to switch between different machines, everything happens in one setup.

- Improve part strength: Additive processes can combine different materials in a single build, while subtractive machining refines the final product.

What to Consider Before Using Hybrid CNC Technology

Hybrid manufacturing is powerful, but it’s not for everyone. Before investing, think about:

- Cost: Hybrid machines are expensive and may not be worth it for simple parts.

- Material limitations: Some materials don’t bond well between additive and subtractive processes.

- Learning curve: Operating two manufacturing processes in one machine requires new skills and software.

4. Internet of Things (IoT) Connectivity in CNC Machines

A few years ago, if a CNC machine went down, you had to be on-site to notice. Maybe the spindle overheated. Maybe a tool broke. Either way, production stopped until someone caught the problem and fixed it.

Now, with IoT-connected CNC machines, you don’t have to guess.

Sensors track machine performance in real-time, sending alerts to your phone, computer, or even a control center. Instead of reacting after something breaks, you can spot issues before they cause downtime.

This shift is turning traditional machine shops into smart factories where everything is connected, monitored, and optimized.

How IoT is Changing CNC Operations

IoT, or the Internet of Things, refers to machines that collect, share, and analyze data through the internet. When applied to CNC machining, IoT allows machines to:

- Communicate with each other to optimize production flow.

- Monitor performance in real-time to detect inefficiencies.

- Send maintenance alerts before problems cause costly breakdowns.

With IoT, CNC shops are no longer operating in the dark. Every machine’s performance is visible, giving you complete control over production.

Benefits of IoT-Connected CNC Machines

- Better decision-making: Instead of relying on assumptions, you have real-time data to improve efficiency.

- Predictive analytics: Machine learning algorithms can detect trends and anticipate failures.

- Higher equipment effectiveness: By reducing downtime and optimizing workflows, machines stay productive longer.

- Remote monitoring: Check machine status from anywhere, reducing unnecessary trips to the shop floor.

What to Consider Before Using IoT in CNC Machining

Before upgrading to IoT-connected CNC machines, ask yourself:

- Is my shop ready for data integration? IoT requires a strong network infrastructure and software capable of handling data analytics.

- What security measures are in place? Connected machines increase cybersecurity risks, so protection against hacking is crucial.

- Does my team need training? Operators and technicians may need to learn how to interpret IoT data to maximize its benefits.

5. Development of Virtual Machining and Simulation Technologies

I once ran a new CNC program on an expensive workpiece, trusting my setup was perfect. It wasn’t. A slight miscalculation in the toolpath caused a deep gouge.

Hours of work, ruined. Materials, wasted.

That’s why virtual machining is a game-changer. Instead of testing programs on real machines, you can simulate every step digitally.

No wasted materials, no costly mistakes. Just a precise preview of how the machining will run.

Digital Twins

A digital twin is a virtual model of a CNC machine or an entire machining process. It mirrors the real-world machine, reacting exactly as it would during production. This lets manufacturers test, adjust, and optimize programs before cutting any material.

Here’s how it enhances cnc operations:

- Error detection: Catch programming mistakes before running a job.

- Process planning: Optimize toolpaths for better efficiency.

- Training without risk: Operators can learn and practice using a simulation instead of real equipment.

With digital twins, you see problems before they happen. Instead of guessing, you know exactly how the machine will behave under different conditions.

Where Virtual Machining is Making an Impact

Many industries already use digital twins to reduce waste and improve production:

- Aerospace: Simulating machining for complex, high-value parts.

- Automotive: Testing and optimizing designs before full-scale production.

- Medical: Ensuring precise cuts for implants and surgical tools.

What to Consider Before Using Virtual Machining

Before adopting digital twins, think about:

- Software compatibility: Does your current CAD/CAM system support virtual machining?

- Computing power: Simulations require high-performance processing to run smoothly.

- Training and adoption: Operators and programmers must understand how to interpret simulation data.

6. STEP-NC Implementation

If you’ve worked with CNC machines, you know how important G-code is. It tells the machine what to do, move here, cut there, change tools. But G-code has its limits. It’s rigid, lacks detailed part information, and requires manual programming adjustments.

Now, a new approach is changing how CNC machines process data. STEP-NC is replacing traditional G-codes with a smarter, more data-rich format.

Instead of just giving commands, it tells the machine exactly what it’s making and how to do it efficiently.

How STEP-NC Enhances CNC Operations

STEP-NC (Standard for the Exchange of Product model data for Numerical Control) uses object-oriented data models instead of simple command lines.

What does this mean for you?

- More detailed machining instructions: Machines understand full design intent, not just tool movements.

- Better interoperability: Different CNC machines can read the same file without needing manual reprogramming.

- Fewer errors: Reduced risk of incorrect toolpaths and misinterpretations.

With STEP-NC, the machine is no longer just following orders. It understands what it’s making.

Advantages of STEP-NC Over G-Code

- Higher precision: More detailed instructions lead to better machining accuracy.

- Easier modifications: Engineers can adjust machining parameters without rewriting entire programs.

- Supports complex parts: Ideal for aerospace, medical, and automotive industries where tolerances are critical.

- Future-proof technology: Designed to integrate with AI and IoT-connected machines.

What to Consider Before Adopting STEP-NC

Before switching to STEP-NC, think about:

- Software compatibility: Not all CNC software supports STEP-NC yet. You may need upgrades or plugins.

- Training requirements: Programmers and machinists may need to learn how to work with richer data models.

- Industry adoption: While gaining popularity, some manufacturers still rely on traditional G-code workflows.

Adopting new CNC technologies can feel overwhelming, but you don’t have to do it alone. At Blue Elephant, we don’t just manufacture CNC machines, we work with businesses to find the right solutions for their specific needs.

If you’re looking for a powerful, adaptable CNC system with expert support, explore what Blue Elephant has to offer.

7. Energy-Efficient CNC Machining Solutions

A few years ago, energy efficiency wasn’t a top concern in CNC machining.

Shops focused on speed, precision, and output. But as electricity costs rise and sustainability regulations tighten, more manufacturers are paying attention to how much power their machines consume.

Energy-efficient CNC machines are now designed to reduce waste, lower power consumption, and operate with greater efficiency. Whether you run a small shop or a large production facility, cutting down on energy use can save money and reduce environmental impact.

How Energy-Efficient CNC Machines Work

Modern CNC machines are built with smarter energy use in mind. New features help reduce unnecessary power consumption without sacrificing performance.

- Regenerative braking: Captures excess energy from motor braking and reuses it.

- Low-power standby modes: Machines automatically switch to energy-saving modes when idle.

- Optimized cutting strategies: New software helps reduce cutting time and tool wear, lowering energy usage.

- Smart cooling systems: Sensors adjust coolant flow based on real-time cutting conditions, minimizing waste.

Benefits of Energy-Efficient CNC Machines

- Lower electricity costs: Machines that consume less power lead to noticeable savings over time.

- Compliance with regulations: Many industries face stricter environmental laws, making energy-efficient equipment a smart investment.

- Longer machine lifespan: Less heat and strain on components lead to reduced maintenance needs.

- Reduced carbon footprint: A more sustainable operation helps businesses meet corporate social responsibility (CSR) goals.

If you’re running a CNC shop, energy costs add up fast. Switching to an energy-efficient system helps protect your bottom line.

What to Consider Before Investing in Energy-Efficient CNC Machines

Before upgrading, think about:

- Machine specifications: Some energy-saving features work best in specific applications.

- Initial investment: While energy-efficient machines save money in the long run, upfront costs can be higher.

- Training and adjustments: Operators may need to learn how to optimize machine settings for the best energy savings.

8. Innovations in CNC Tooling and Materials

I once struggled with a job that required cutting a tough alloy. My standard end mills wore down quickly, forcing me to stop, replace tools, and adjust settings constantly. It was frustrating, time-consuming, and expensive.

Now, CNC tooling has advanced significantly. Modern cutting tools are built to last longer, cut harder materials, and achieve smoother finishes. If you’re machining complex parts, using the right tools can make all the difference.

How Advanced CNC Tooling is Changing Machining

Cutting tools are no longer just hardened steel. New materials and coatings have extended tool life and improved performance.

- Carbide tools: More durable than high-speed steel, perfect for tough materials.

- Diamond-coated tools: Ideal for machining composites and abrasive materials.

- Ceramic inserts: Handle high temperatures, great for high-speed machining.

- Coatings like TiAlN (Titanium Aluminum Nitride): Reduce heat buildup, making tools last longer.

With these innovations, you can push your machines harder without sacrificing quality.

Where These Tools Are Making an Impact

New CNC tooling expands what’s possible across industries:

- Aerospace: Cutting heat-resistant alloys with minimal wear.

- Automotive: Producing smoother, more precise components.

- Medical: Achieving ultra-fine details in titanium and stainless steel.

- Woodworking: Creating intricate designs with sharper, longer-lasting router bits.

What to Consider Before Upgrading Your CNC Tools

Before investing in new cutting tools, think about:

- Material compatibility: Does the tool match the materials you work with?

- Machine capability: Some high-end tools require machines with higher spindle speeds or rigidity.

- Cost vs. longevity: Premium tools cost more but often last longer, saving money over time.

Conclusion

I’ve been there, watching competitors win jobs I couldn’t, all because they had better technology. It’s frustrating, but it’s also fixable.

CNC machines are getting smarter, faster, and more efficient. The businesses that adopt new tech cut costs, improve precision, and stay ahead.

What about you? Are you ready to upgrade?

Don’t wait until it’s too late. Start now.

Contact us today and see how the right CNC machine can transform your production.

Explore More Helpful Resources

For more in-depth knowledge, take a look at these recommended reads. We think you’ll find them useful:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.