I still remember the day I bought the wrong machine.

It looked like a good deal. It wasn’t.

I needed something for cutting aluminum parts, but I ended up with a CNC router that struggled from day one. It cost me time, money, and a lot of frustration. That’s why I’m writing this—to help you avoid the same mistake.

Over the years, I’ve worked with both CNC mills and routers. I’ve tested them, repaired them, and helped others choose the right one. I’ve made the mistakes, so you don’t have to.

If you’re asking, “what is the difference between CNC mill and CNC router?”, you’re already on the right path. In this article, I’ll break down:

- What each machine can do

- What materials they handle

- How they compare in precision and price

- And when to pick one over the other

By the end, you’ll know how to choose the right machine for your job—whether you’re buying, recommending, or using it yourself.

So let’s start!

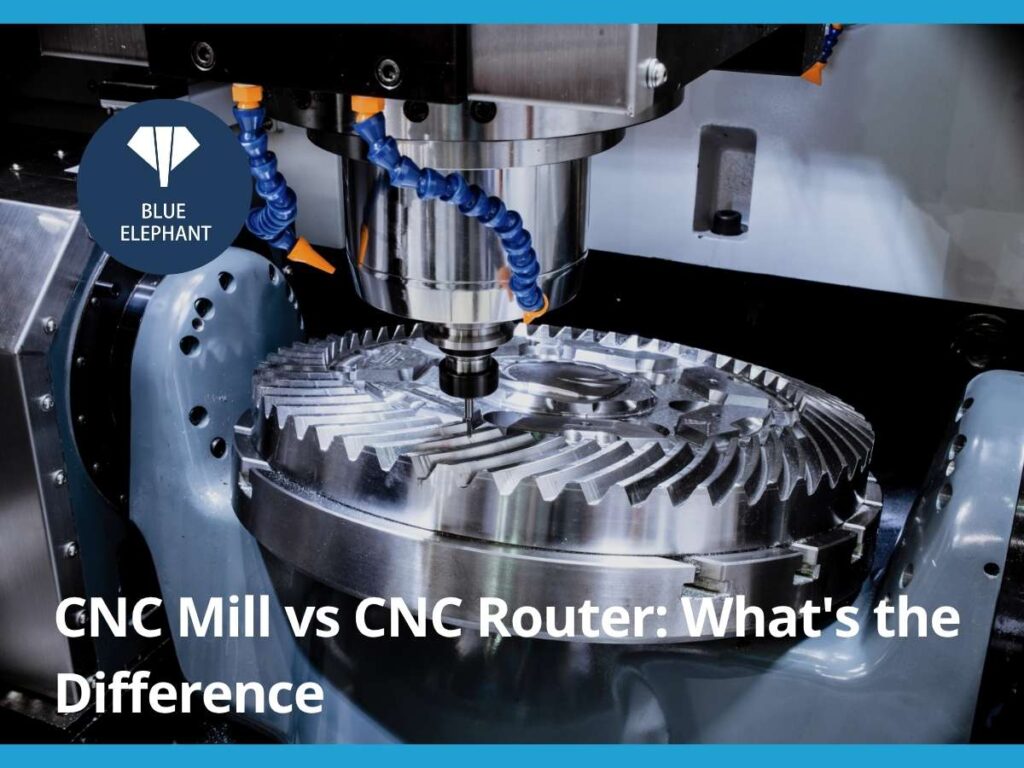

1. What is a CNC Mill?

When I first worked with a CNC mill, I was nervous. It looked big, heavy, and complicated. But once I understood what it did, things clicked.

A CNC mill is a machine that cuts, drills, or shapes materials using a spinning tool.

The letters CNC stand for Computer Numerical Control. That means the machine runs using computer commands, also called G-code.

You don’t guide it by hand. You program it. Then it does the job with accuracy.

It’s different from a manual mill, where the operator moves everything. CNC mills work faster. And they can do the same part over and over again without messing up.

CNC mills work best on:

- Aluminum

- Steel

- Brass

- High-density plastic

So ask yourself: Do I need to cut strong, hard materials? Do I need sharp detail?

If yes, a CNC mill could be a solid choice.

Main Components

- Heavy-duty frame: Made of cast iron or steel to keep the machine steady

- Spindle: Holds and spins the cutting tool, either vertically or horizontally

- Tool changer: Switches between tools automatically during a job

- Coolant system: Keeps tools cool so they don’t overheat or wear out too fast

- Precision rails: Guide the moving parts smoothly and accurately

When I worked on my first CNC mill, I was amazed by how smooth the rails felt. That smooth motion helps you get clean, sharp cuts—every time.

Best For

You’ll see them used in:

- Aerospace shops

- Automotive parts

- Mold-making for casting

- Custom parts and prototypes

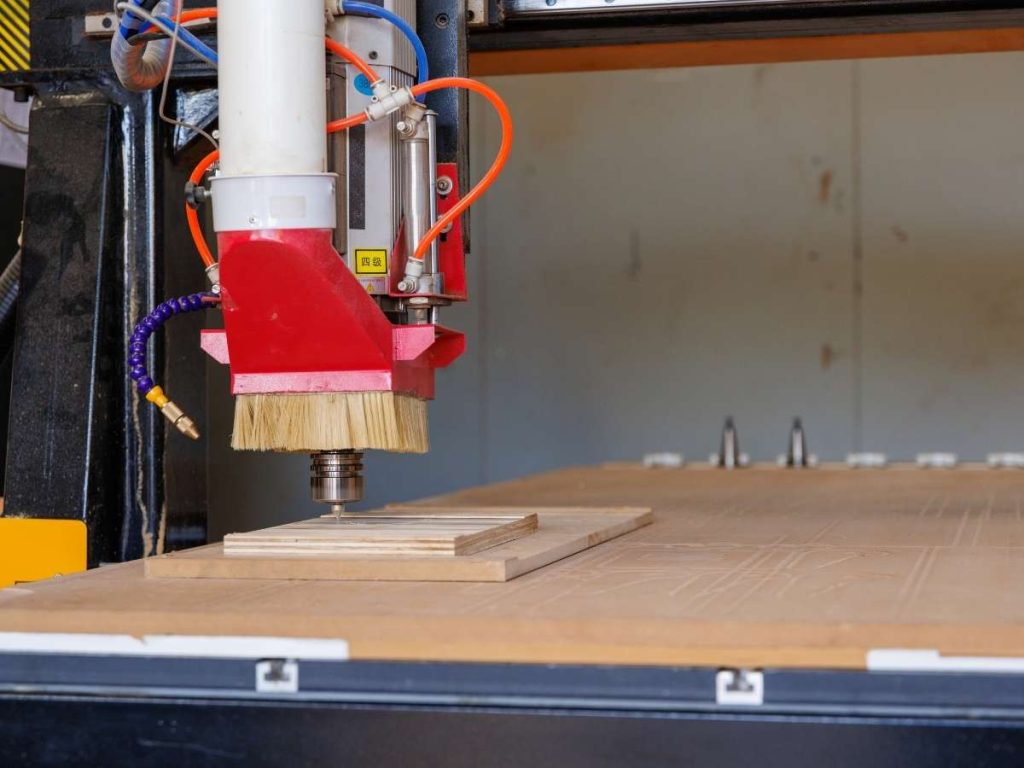

2. What is a CNC Router?

The first time I saw a CNC router in action, it was cutting cabinet panels in a small furniture shop. It moved fast—slicing through plywood like it was paper. The owner told me, “This machine changed how we work.”

If you’re wondering whether a CNC router might fit your needs, let’s break it down in plain terms.

A CNC router is a machine that cuts soft materials using a spinning tool.

CNC stands for Computer Numerical Control, which means the machine follows commands from a program (usually G-code). It doesn’t need a person to guide it by hand.

The router’s spindle moves along three directions, called X, Y, and Z axes. This lets it carve shapes, patterns, and parts from a flat sheet.

Compared to a CNC mill, routers are faster but less powerful. They shine when working with lighter materials.

- MDF (medium-density fiberboard)

- Plywood

- Plastics

- Foam

- Light aluminum (for simple jobs only)

Main Components

Most CNC routers come with:

- Lighter frame: Often made from aluminum or welded steel for easier movement

- High-RPM spindle: Spins fast to cut quickly through soft materials

- Vacuum bed or clamping system: Holds the material steady while cutting

- Large working area: Great for full-sized boards and wide panels

Common Uses

You’ll often find CNC routers used for:

- Furniture production (like cabinet doors or table tops)

- Sign making and shop displays

- Decorative wood panels

- Acrylic and foam carving

3. CNC Mill vs CNC Router: Key Differences

When people ask me what machine they should choose, I always say—it depends on what you’re making.

A CNC mill and a CNC router may look similar at first glance. But under the surface, they’re built for totally different jobs. I’ve seen beginners buy the wrong one and regret it fast.

To make it easier for you, here’s a simple side-by-side comparison:

| Category | CNC Mill | CNC Router |

| Machine Structure | Heavy and rigid frame (cast iron or steel) | Lightweight frame (aluminum or welded steel) |

| Material Fit | Best for hard materials: steel, aluminum, brass | Best for soft materials: MDF, plywood, plastic, foam, light aluminum |

| Precision | High accuracy (up to ±0.01 mm) | Moderate precision, better for shapes and curves |

| Spindle Type | Low-speed, high-torque for heavy cutting | High-speed, low-torque for fast carving |

| Common Uses | Mold making, metal parts, aerospace, prototyping | Furniture, signs, decorative panels, 3D carving in wood |

| Software Used | Fusion 360, Mastercam, SolidCAM | VCarve, ArtCAM, Aspire |

| Cost & Maintenance | Higher cost, complex maintenance, long tool life | Lower cost, easy maintenance, shorter tool life |

4. Factors to Consider When Choosing Between CNC Mill and CNC Router

I’ve helped many buyers, from dealers to repair techs, decide between a CNC mill and a router. It’s not always about specs—it’s about fit. Here’s how you can guide your decision based on what really matters.

#1 Your Primary Application

Think about what the machine will be used for. A CNC router is ideal for cutting large sheets of wood, plastic, and foam, making it the preferred choice for furniture production, signage, and decorative work. A CNC mill is better suited for machining metal parts, molds, and high-precision components, commonly used in aerospace, automotive, and industrial manufacturing.

#2 Material Type

At Blue Elephant, both CNC routers and CNC mills are built to handle specific materials efficiently. A CNC router is designed for soft materials like MDF, plywood, plastics, and composites, allowing for fast and precise cutting in woodworking, advertising, and decorative applications. A CNC mill, on the other hand, is engineered for harder materials such as steel, aluminum, and brass, providing the power and stability needed for industrial machining and precision manufacturing.

#3 Desired Precision

Assess the level of accuracy needed. A CNC mill delivers extreme precision, maintaining tolerances as tight as ±0.01 mm, which is crucial for engineering, mold-making, and metal fabrication. A CNC router provides sufficient accuracy for artistic work, furniture design, and signage, where small variations are acceptable.

#4 Budget Constraints

Factor in total investment. A CNC router is more affordable, with lower initial costs and minimal maintenance, making it accessible for startups and businesses needing high-speed production. A CNC mill requires a higher upfront cost but offers long-term reliability, making it a valuable investment for industries focused on precision machining.

#5 User Skill Level

At Blue Elephant, CNC routers and mills are designed to match different skill levels. A CNC router is easier to operate, with user-friendly software that simplifies setup and production, making it ideal for beginners and small businesses. A CNC mill requires advanced CNC knowledge, including programming, tooling selection, and cutting strategies, making it better suited for experienced operators who need greater control and precision in machining. Whether looking for an entry-level machine or high-end precision equipment, our machines provide solutions tailored to different experience levels.

Conclusion

A CNC machine is more than just a tool—it’s the foundation of efficient production. A router delivers speed and flexibility, while a mill offers precision and power. Choosing the right one depends on the materials, accuracy, and workflow you need.

The best machine is the one that helps you create without limits. Whether it’s furniture, signs, or metal components, the right decision will shape your success.

What matters most to you—speed or precision? Now’s the time to take action.

Contact us today and find the CNC machine that fits your needs.

Recommended Reads for You

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.