A few years ago, I watched a shop floor struggle with a milling machine that wasn’t right for their production line. Every job took longer than it should, and precision suffered. It turned out they had picked the wrong type of mill.

That mistake cost them time, money, and customers. And they’re not alone, many businesses make this error when they don’t fully understand the differences.

Over the years, I’ve worked with manufacturers, engineers, and CNC specialists who’ve faced the same issues. This guide is built on real-world experience, not just specs from a brochure.

By the end of this article, you’ll know exactly which milling machine fits your business needs. Whether it’s precision, speed, or material capability, this breakdown will make your decision easier.

So, let’s get started!

1. Fundamental Difference: Spindle Orientation

Let’s start with the one distinction that shapes everything else: spindle orientation. This is the primary design difference between horizontal and vertical milling machines, and it defines how the cutter interacts with the material. Even though it seems like a small change in axis, it completely changes machine behavior and ideal applications.

Vertical Milling Machines:

- The spindle is positioned vertically, facing downward over the workpiece. This setup is easy to visualize and familiar to most machinists.

- Tools move up and down into the material, similar to how a drill press operates. This motion makes it straightforward for top-facing jobs.

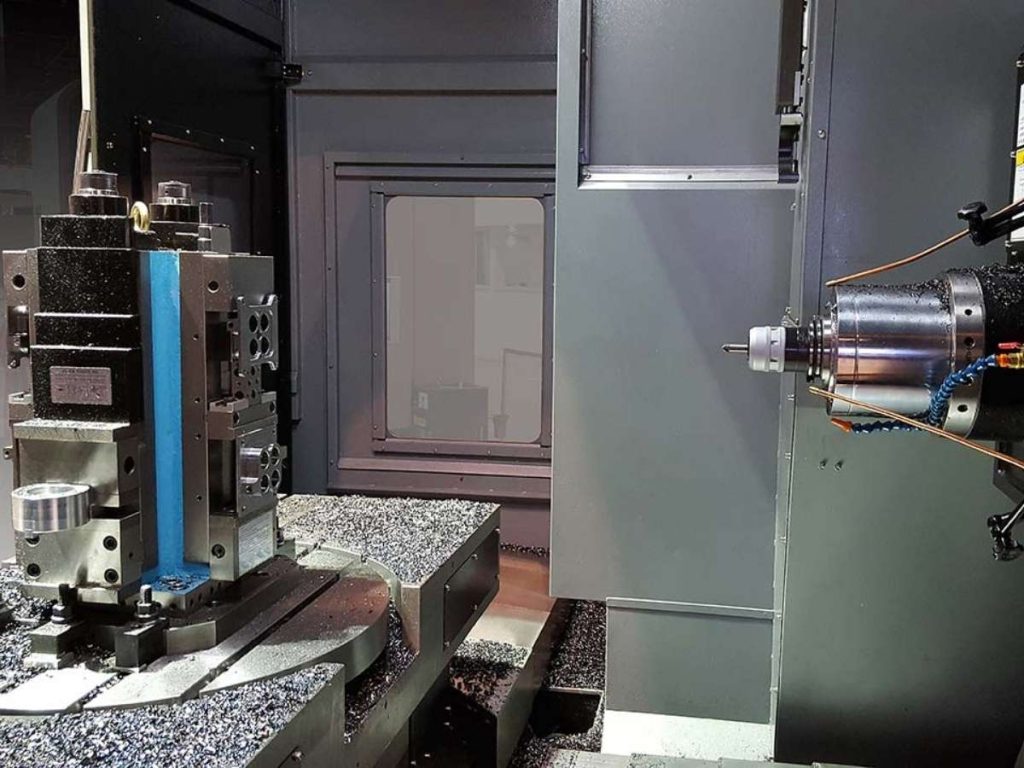

Horizontal Milling Machines:

- The spindle is oriented horizontally, parallel to the worktable surface. This allows cutters to approach the material from the side rather than above.

- Most horizontal mills use an arbor-supported spindle, which provides added strength for demanding cuts. This design works well for large or tough parts.

This basic orientation decision has a domino effect on tooling, setup, and job suitability. So, getting this part right from the beginning matters more than most people think.

2. Cutting Capabilities & Material Removal

Once you understand spindle direction, the next thing to look at is how each machine removes material. Some setups are better for precision finishing, while others are designed to plow through stock quickly. If your shop balances speed and surface finish, this is a make-or-break factor.

Vertical Mills: More Detail-Oriented

- They are great for lighter cuts and fine-detail work, such as pockets and contours. Vertical mills give you flexibility when working with varied part shapes.

- Their motion is ideal for finishing passes and surface detailing. You can use them efficiently for short-run and prototype work.

Horizontal Mills: Built for Bulk

- These machines are made for aggressive material removal and high-volume runs. Their rigidity and layout allow deeper and faster cuts.

- You can perform multiple operations in one pass using stacked tooling. This means fewer setups and faster turnaround times on large jobs.

If your business model relies on high-volume throughput or heavy-duty machining, horizontal wins this round. But for versatility and lighter-duty applications, vertical milling holds its own.

3. Workpiece Handling & Setup Differences

Setup time affects productivity more than most people realize. The way a machine handles parts, how you secure them, rotate them, or reposition them, can either speed up your shop or cause bottlenecks. This section dives into how vertical and horizontal machines differ in the hands-on setup experience.

With Vertical Milling:

- Workpieces are typically secured to a flat table using clamps or vises. This setup is simple and intuitive, especially for operators newer to CNC work.

- Multi-face machining usually requires manual repositioning. That means added time for each setup if the part has more than one machined surface.

With Horizontal Milling:

- Tombstone fixtures allow for multiple workpieces or faces to be machined in a single setup. This increases throughput and reduces downtime between parts.

- Rotary tables can also be integrated for added flexibility. You can often machine all sides of a part without taking it off the fixture.

Horizontal machines take longer to set up initially, but they make up for it with massive time savings over longer runs. If your workload includes multi-face parts or repeated production, the payoff is hard to ignore.

4. Tooling & Cutter Differences

Tooling is more than just what spins on the spindle, it’s a real part of your investment. It determines cost per part, tool change frequency, and even machine compatibility. This section explores how vertical and horizontal machines differ in terms of cutters, arbor systems, and application fit.

Vertical Machines:

- They typically use end mills, face mills, and ball nose cutters. These are standard and widely available for most shop needs.

- Tool changes are fast and straightforward on vertical CNCs. This makes it easier to switch between different operations on one part.

Horizontal Machines:

- They often use arbor-mounted cutters, such as slab mills or side cutters. These are capable of handling deeper, wider cuts in fewer passes.

- You can stack multiple tools on one arbor to perform different operations in sequence. It’s efficient for high-volume production but takes longer to set up.

For most shops, vertical tooling is more accessible and flexible. But if your work requires stacked operations or high-output runs, horizontal tooling may justify the learning curve and extra spend.

5. Stability & Precision

This is where performance under pressure really comes into play. Whether you’re machining aerospace components or heavy-duty brackets, tool deflection and vibration can tank your results. Let’s take a closer look at how each machine holds up under cutting forces and precision demands.

Vertical Milling:

- These machines are stable enough for moderate cuts and most general-purpose work. However, you may experience deflection on deep or heavy passes.

- Shorter tool lengths help maintain accuracy. But harder materials and complex features can push verticals to their limits.

Horizontal Milling:

- The arbor provides additional tool support, which adds to the machine’s rigidity. This allows you to cut with greater force without sacrificing precision.

- Chip evacuation is more efficient since gravity pulls chips down and away. Cleaner cuts and less re-cutting help preserve your tooling and finish.

If surface finish or high-tolerance repeatability is a priority in your shop, horizontal machines offer stronger performance. But for lighter precision work, verticals are more than capable, especially with modern controls and toolpaths.

6. Speed & Efficiency

In a business context, time truly is money. Faster cycle times, reduced setups, and efficient chip clearing can all lead to a better bottom line. Here’s how each machine stacks up in real-world shop efficiency.

Vertical Machines: Quick to Set Up

- Setup is fast and doesn’t require much specialized fixturing. That makes them ideal for short-run jobs and shops with frequent changeovers.

- Operators can easily load, run, and unload parts in minutes. This suits businesses that handle varied work throughout the day.

Horizontal Machines: Faster Over Time

- Multi-side machining reduces tool changes and part repositioning. You save time over long production runs even if the initial setup takes longer.

- Chips clear quickly, keeping the tool path clean and reducing cycle time. That translates into more consistent output and fewer delays.

If you’re doing low-volume or custom work, verticals offer a quicker turnaround. But for ongoing production and repeat contracts, horizontals can be a game-changer in shop efficiency.

7. Cost & Investment Considerations

Let’s not beat around the bush, equipment costs can make or break your expansion plans. Beyond the price tag, you have to factor in maintenance, training, tooling, and potential ROI. This section looks at what each machine means for your financial planning and operational goals.

Vertical Machines:

- They’re typically more affordable upfront and easier to maintain. Lower cost makes them accessible to small shops or new operations.

- Training is simpler for vertical CNCs, and most machinists are already familiar with them. This reduces onboarding time and potential downtime.

Horizontal Machines:

- The purchase cost is higher, and tooling tends to cost more too. However, you’ll likely recoup that investment through greater output over time.

- These machines shine when doing repeat jobs in volume. Fewer setups, faster cycles, and better part consistency help with ROI.

Verticals give you flexibility at a lower cost, which is perfect for shops just getting started or managing diverse workloads. Horizontals are a bigger commitment, but one that can pay off fast with the right workflow.

Conclusion

You’ve seen the difference: vertical for versatility, horizontal for power.

Both machines have a place, but the best choice depends on your goals, your shop, and your future.

I remember when I was in your shoes, trying to pick the right machine. That decision changed everything for my business.

Don’t wait until you’re overwhelmed or behind.

Contact Blue Elephant today and let’s build your machining future together.

Explore More of Our Resources

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.