The first time I saw a CNC machine in action, I couldn’t believe how effortlessly it shaped raw materials. A block of aluminum went in, and minutes later, a flawless component emerged—no errors, no wasted material.

If you’ve ever wondered how manufacturers achieve such precision at scale, CNC is the answer.

I’ve compiled insights from machine operators, engineers, and industry experts to break down how CNC works. This article cuts through the jargon so you can make informed decisions about automation in your business.

You’ll discover the step-by-step process of CNC machining, the different types of machines, and why they matter for production efficiency. If precision and repeatability are priorities, this guide will give you the clarity you need.

Let’s dive in!

1. What is CNC Machining?

If you walk into a high-tech manufacturing facility, the sight of machines shaping metal with flawless precision is striking. Blocks of raw material transform into intricate parts without human intervention, showcasing the efficiency of CNC machining. The level of consistency and accuracy achieved is something manual processes simply cannot match.

CNC (Computer Numerical Control) machining is an automated manufacturing process controlled by pre-programmed software. Instead of relying on manual labor, CNC machines execute precise instructions to cut, shape, and drill materials with exceptional accuracy. This technology is widely used in industries such as aerospace, automotive, medical, and industrial manufacturing, where precision and repeatability are crucial.

For businesses focused on optimizing production, reducing errors, and maintaining uniformity across batches, CNC machining offers a reliable solution. The ability to automate complex tasks improves efficiency, lowers operational costs, and enhances product quality. Understanding how this process works is essential for companies considering CNC integration into their production lines.

2. How Does CNC Work? Step-by-Step Process

CNC machining might seem complex at first, but when broken down step by step, the process becomes much easier to understand. Whether producing a single prototype or running a full-scale production line, each step in the process plays a critical role in achieving accuracy and efficiency.

Step#1 Designing the Part (CAD Model Creation)

Everything starts with a design. Engineers and designers use Computer-Aided Design (CAD) software to create a detailed 2D or 3D model of the part. This digital blueprint includes all dimensions, shapes, and specifications required for production.

A well-crafted CAD file ensures that every detail is accounted for before machining begins. Even the slightest miscalculation at this stage can lead to costly errors later. Businesses rely on experienced designers who understand manufacturing constraints and material properties to ensure the design is both functional and manufacturable. Investing time here saves time and money down the line.

Step#2 Converting the Design into CNC Code (CAM Processing)

Once the design is complete, the next step is converting it into a language the CNC machine can understand. This is where Computer-Aided Manufacturing (CAM) software comes in. It translates the CAD model into G-code, a set of instructions that tells the CNC machine exactly how to move, cut, and shape the material.

Think of this step as creating a roadmap for the machine. It defines tool paths, cutting speeds, spindle rotation, and other critical settings. If a part requires multiple operations—like drilling, milling, or turning—the CAM software organizes them in the correct sequence. This automation reduces human error and ensures the machine executes each movement with precision.

Step#3 Machine Setup and Material Loading

Before production begins, the CNC machine must be properly set up. Operators install the necessary cutting tools, secure the raw material onto the machine’s worktable, and load the G-code into the system. Depending on the type of CNC machine, this step may also involve calibrating the tool offsets and double-checking alignment.

Even though CNC machining is largely automated, human expertise is essential here. Incorrectly mounted materials or misaligned tools can lead to scrapped parts, machine damage, or even safety hazards. Skilled operators ensure everything is secure and that the machine is ready for production. Once set up, the process runs with minimal supervision, producing identical parts with extreme precision.

Step#4 Executing the Machining Process

With everything in place, the CNC machine begins cutting, drilling, milling, or shaping the material according to the programmed instructions. The machine follows the G-code commands precisely, moving in multiple axes to achieve the desired shape.

Unlike manual machining, where each cut depends on the operator’s skill, CNC machining removes variability from the process. Whether producing ten parts or ten thousand, each one will be identical. The level of accuracy achieved is essential for industries like aerospace, automotive, and medical manufacturing, where even a fraction of a millimeter can make a difference.

Step#5 Quality Inspection and Finishing

Once machining is complete, the part is inspected for accuracy and quality. High-precision measuring tools, such as calipers, micrometers, or Coordinate Measuring Machines (CMMs), ensure that dimensions match the design specifications. If a part doesn’t meet the required tolerances, adjustments may be needed in the next production run.

Some parts require additional finishing processes, such as deburring, polishing, or coating, to improve aesthetics and functionality. Businesses aiming for high-quality standards incorporate thorough inspection protocols to minimize waste and maintain consistency. In industries where precision is non-negotiable, this final step ensures that every product meets the required performance criteria before it reaches the customer.

3. Key Components of a CNC Machine

A CNC machine isn’t just a tool—it’s a system where every part works together to deliver accuracy and efficiency. When one component is off, it can throw everything out of alignment, leading to wasted materials, lost time, and frustrated operators.

- Control Unit (The Brain of the Machine): Everything starts here. The control unit reads the G-code, translating it into precise movements that determine how smooth and accurate the machining process will be.

- Machine Bed and Frame (The Foundation): A strong, vibration-free foundation makes all the difference. If the frame isn’t sturdy enough, even the best programming and cutting tools won’t deliver consistent results.

- Spindle (The Powerhouse of Cutting Operations): The spindle is where the action happens. It spins at high speeds, cutting through metal, plastic, or wood with force and precision, but only if it’s powerful enough for the job.

- Cutting Tools (The Hands of the Machine): No matter how advanced the machine is, it’s only as good as its cutting tools. Dull or low-quality tools lead to rough finishes, wasted material, and unnecessary downtime for replacements.

- Tool Changer (For Speed and Efficiency): A well-functioning tool changer keeps production moving without unnecessary stops. Instead of waiting for an operator to swap tools manually, the machine does it in seconds, keeping efficiency high.

- Servo Motors and Drive System (Precision in Motion): Every tiny movement in CNC machining needs to be precise. Servo motors ensure the machine moves exactly as programmed, avoiding positioning errors that could ruin an entire batch of parts.

- Worktable and Workholding Devices (Keeping Materials Secure): If the material shifts even slightly, the entire part can be ruined. Secure workholding ensures the material stays exactly where it needs to be for precise, repeatable cuts.

- Coolant System (Keeping Things Running Smoothly): Heat is the enemy of precision. A good coolant system keeps temperatures under control, preventing tool wear and ensuring smooth, consistent cuts.

- Feedback and Sensors (The Machine’s Eyes and Ears): The best operators don’t rely on guesswork, and neither should a CNC machine. Sensors track everything from tool wear to overheating, catching issues before they become costly problems.

4. Types of CNC Machines & Their Uses

Not all CNC machines are built the same, and choosing the right one depends on the job at hand. The first time I stepped into a CNC shop, I was surprised at how many different types of machines were running at once—each one specialized for a specific task. Some were shaping metal with delicate precision, while others were cutting through thick materials with brute force.

- CNC Milling Machines: CNC milling machines use rotating cutting tools to remove material from a solid block, making them one of the most versatile CNC machines. They are widely used in industries like automotive, aerospace, and product manufacturing, where precision and complex geometries are required.

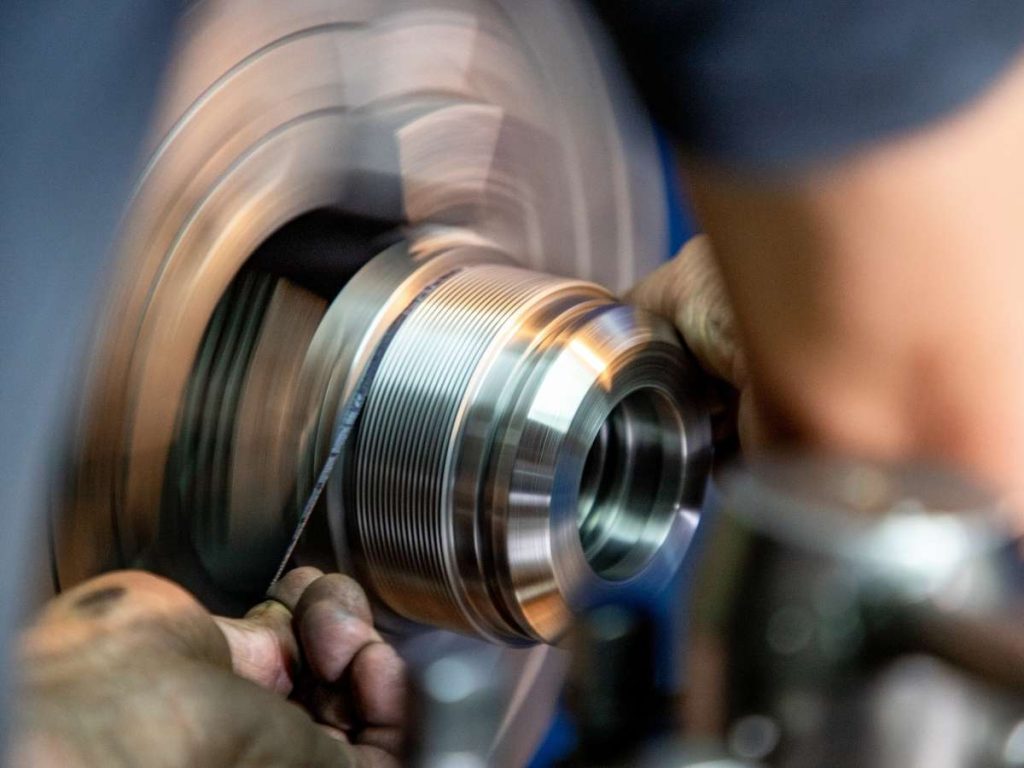

- CNC Lathes: CNC lathes spin the workpiece while a cutting tool shapes it, making them ideal for cylindrical and symmetrical parts. They are commonly used to produce shafts, bushings, and threaded components in industries such as automotive, medical, and industrial manufacturing.

- CNC Routers: CNC routers work similarly to milling machines but are designed for cutting wood, plastics, and soft metals at high speeds. They are widely used in furniture production, cabinetry, and sign making, where smooth finishes and fast processing times are essential.

- CNC Plasma Cutters: CNC plasma cutters use a high-temperature plasma arc to cut through conductive metals like steel and aluminum. They are commonly found in fabrication shops and automotive repair facilities where speed and efficiency in cutting sheet metal are a priority.

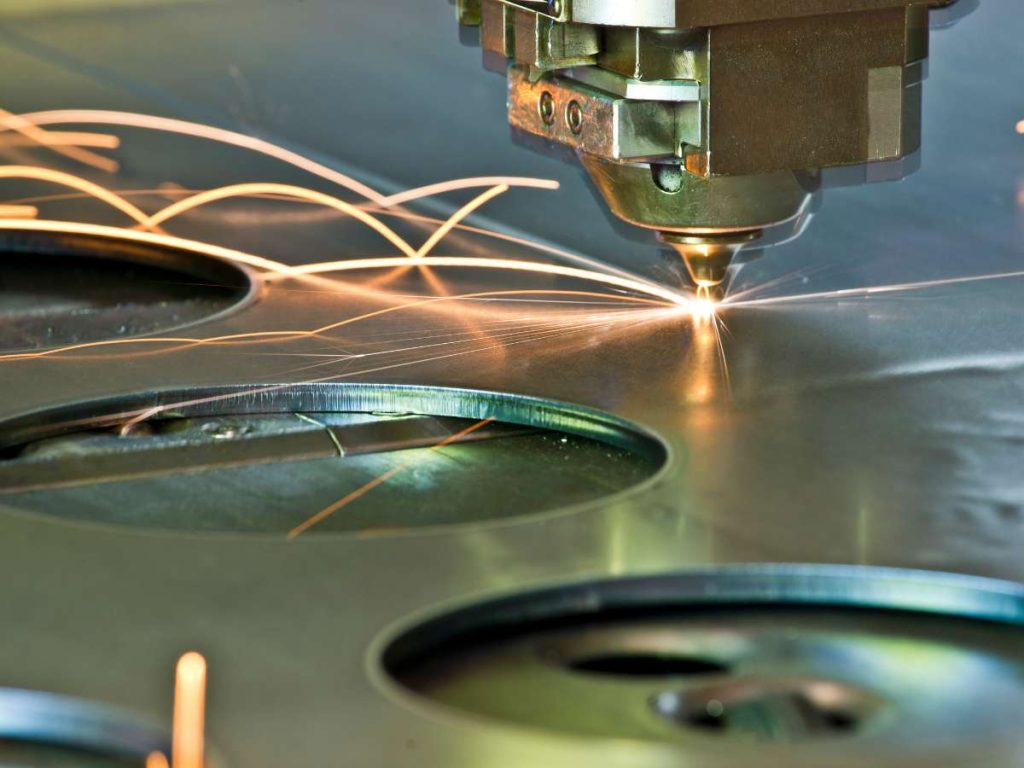

- CNC Laser Cutters: CNC laser cutters use a high-powered laser beam to cut or engrave materials with extreme precision. Industries like jewelry making, custom signage, and precision fabrication rely on them for clean cuts and intricate designs.

- CNC Waterjet Cutters: CNC waterjet cutters use a high-pressure stream of water, often mixed with abrasives, to cut materials without generating heat. This makes them ideal for aerospace, architecture, and custom fabrication projects that involve heat-sensitive materials.

- 5-Axis CNC Machines: 5-axis CNC machines allow multi-directional machining, reducing the need for multiple setups and improving efficiency. They are crucial in aerospace, medical, and engineering industries where complex shapes and tight tolerances are required.

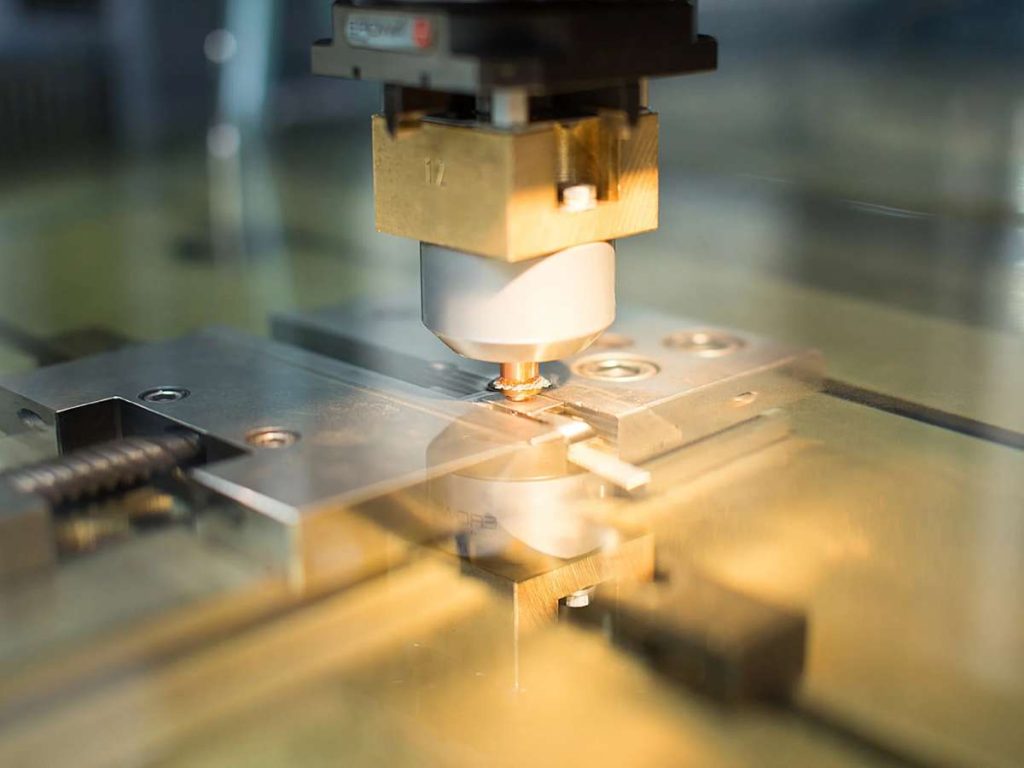

- CNC EDM: CNC EDM machines use electrical sparks to erode material, allowing for precise machining of hard metals and intricate details. They are often used in mold-making, tool production, and industries requiring high-precision parts that traditional cutting tools struggle with.

5. Applications of CNC Machining in Different Industries

From tiny medical implants to massive aerospace components, CNC machining has become a backbone of modern production. Businesses that rely on precision, repeatability, and efficiency turn to CNC machining because it eliminates human error and speeds up production.

Aerospace: Precision at Every Altitude

Every component, from engine parts to structural elements, must meet strict tolerances because even the smallest deviation can lead to failure. CNC machining produces lightweight, high-strength parts that can withstand extreme conditions, whether it’s the high pressure of space or the turbulence of commercial flights.

Without CNC technology, making complex geometries like turbine blades or aircraft landing gear would take far longer and require significantly more manual labor.

Automotive: Speeding Up Production

The automotive industry thrives on efficiency, and CNC machining plays a crucial role in keeping assembly lines moving. From engine blocks to custom interior components, CNC machines ensure that every part is identical, durable, and perfectly fitted.

Whether a company is mass-producing vehicles or crafting high-performance racing parts, CNC technology provides the speed and accuracy needed to meet tight production deadlines. Custom car manufacturers also rely on CNC machining to create one-of-a-kind parts that wouldn’t be possible with traditional methods.

Medical: Life-Saving Precision

Medical device manufacturers can’t afford errors when machining implants, prosthetics, or surgical tools. A single defect in a joint replacement or a medical instrument can lead to serious complications for a patient. CNC machining allows for extreme precision in the production of stainless steel, titanium, and plastic medical components.

Electronics: Tiny Parts, Big Impact

Modern electronics require complex, miniature components that must be produced with extreme accuracy. CNC machining plays a key role in manufacturing circuit boards, heat sinks, and casings for devices like smartphones and laptops.

The demand for smaller, more powerful devices continues to grow, and CNC machines make it possible to cut, drill, and shape materials at a microscopic level. Without CNC technology, producing high-quality, high-volume electronic parts with such consistency would be nearly impossible.

6. Common CNC Machining Challenges & Solutions

When one thing goes wrong, it can lead to defective parts, wasted materials, and costly downtime. Businesses that understand these common challenges and how to fix them can keep operations running smoothly and avoid expensive mistakes.

| Challenge | What Happens | How to Solve It |

| Inconsistent Tolerances | Machines occasionally produce parts that don’t meet required tolerances due to temperature changes, tool wear, or calibration issues. | Regular maintenance, proper machine calibration, and investing in quality cutting tools help maintain consistent accuracy. |

| Tool Wear and Breakage | Worn-out tools lead to rough finishes, slow machining times, and more rejected parts, especially when cutting harder materials. | Use the right feed rates and coolant systems, and apply tool coatings to extend tool life and reduce costly interruptions. |

| Programming Errors | A small G-code mistake can cause incorrect tool paths, damaged parts, or even machine crashes, all of which can stop production cold. | Double-check code, run simulations, and rely on trusted CAM software to catch mistakes before they hit the machine. |

| Material Issues | Materials respond differently to machining; improper speeds or feeds can cause chipping, warping, or overheating. | Match settings to each material type and keep a shared database of tested parameters to avoid starting from scratch each time. |

| Machine Downtime | Unexpected failures halt production and lead to missed deadlines, especially when there’s no warning. | Preventive maintenance and real-time monitoring help detect issues early, so machines stay running when you need them most. |

| Surface Finish Problems | Poor surface finishes result from dull tools, incorrect speeds, or unstable setups—especially on sensitive parts or aesthetic products. | Keep tools sharp, ensure stable workholding, and fine-tune speed/feed settings based on the finish quality you need. |

7. How to Choose the Right CNC Machine for Your Needs

With so many options available, businesses need to consider several factors before making a purchase. The right CNC machine should align with production goals, material requirements, and long-term business needs. Here are 6 key factors to keep in mind when choosing the right CNC machine.

- Material Compatibility: Different CNC machines are designed for specific materials, from soft plastics to hardened metals. Choosing a machine that can handle the materials your business works with ensures better performance and tool longevity.

- Machine Size and Work Area: The physical size of the machine and its cutting area should match your production needs. A machine that’s too small limits the size of parts you can produce, while an oversized machine can take up unnecessary space and increase costs.

- Precision and Tolerance Requirements: If your industry demands high-precision machining, look for machines with advanced control systems and tight tolerance capabilities. Aerospace, medical, and automotive industries often require machines that can maintain accuracy within microns.

- Automation and Tool Changing Features: Businesses with high production volumes benefit from automatic tool changers and robotic integration. These features reduce downtime, improve efficiency, and allow for unattended operation, increasing overall productivity.

- Software and Compatibility: The CNC machine should support the CAD/CAM software your business uses to ensure smooth programming and execution. Some machines come with proprietary software, while others offer more flexibility in integrating with different systems.

- Cost and Long-Term Investment: Beyond the initial purchase price, consider maintenance costs, tooling expenses, and training requirements. A cheaper machine might save money upfront but could lead to higher operational costs in the long run.

Conclusion

That moment in the factory, watching a block turn into a finished part, makes more sense now, right?

CNC machining is powerful, precise, and built for modern business.

You now know what it is, how it works, and why it matters.

So, what’s next for your business?

If you’re ready to automate with confidence, Blue Elephant offers machines trusted around the world.

Ready to get started? Contact us today!

Explore More Helpful Resources

Want to learn more? Here are some articles filled with valuable tips and information to guide you further:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.