Starting a CNC machining business sounded easy at first. Buy a machine, get some clients, make money. Right? But, you’re wrong!

When I first started, I underestimated everything—costs, time, even my own skills. I made mistakes, lost money, and almost quit. But I didn’t. Instead, I figured out what worked and what didn’t. And now, I’m here to help you skip the frustration.

If you’re reading this, you’re probably thinking about starting your own CNC shop. Maybe you’re worried about making the wrong choices. Maybe you don’t even know where to begin. Don’t worry—I’ve been there.

I’ll walk you through the first steps, from choosing equipment to landing your first customers.

By the time you’re done reading, you’ll have a clear, actionable plan to start your own CNc machining business.

Let’s get started.

Preview of Key Steps

Before we dive deep into each step, here’s a quick roadmap to guide you through starting and growing your CNC machining business. This table gives you a glimpse of the key steps, from setting up your shop to landing your first customers.

| Step | What to Do | Key Focus |

| Step #1 Understanding the CNC Machining Industry | Research trends and industries that need CNC services. | Find high-demand markets and business opportunities. |

| Step #2 Developing a Business Plan | Define your niche, calculate costs, and create a growth strategy. | Build a roadmap for sustainable success. |

| Step #3 Choosing the Right CNC Machines & Equipment | Select machines based on materials, part complexity, and production volume. | Buy the right equipment for your services. |

| Step #4 Legal & Compliance Requirements | Register your business and meet safety standards. | Avoid legal issues and protect your company. |

| Step #5 Setting Up Your CNC Workshop | Organize your shop for efficiency and safety. | Reduce wasted time and improve workflow. |

| Step #6 Sourcing Materials & Building a Supply Chain | Find reliable suppliers and track inventory. | Ensure material quality and avoid production delays. |

| Step #7 Marketing & Customer Acquisition | Build an online presence, network, and generate leads. | Attract long-term customers and grow your business. |

Now that you have the big picture, let’s dive deeper into each step.

Step#1 Understanding the CNC Machining Industry

When I first thought about starting a CNC machining business, I assumed it was all about getting the right machine and finding customers. But I quickly realized that understanding the industry itself was just as important.

Who needs CNC machining? What’s happening in the market? What challenges should I expect? I didn’t have all the answers at first, and that cost me time and money. If you’re thinking about starting, I want to help you avoid that mistake.

This section will give you a real-world look at the CNC machining industry—where the opportunities are, what obstacles to watch out for, and how you can position yourself for success.

Stay Updated on Key Market Trends

CNC machining is evolving, and keeping up with industry trends will help you stay competitive. Here’s how to keep your business future-proof:

- Research Automation and AI Integration: Look into CNC software that improves accuracy and reduces manual labor, such as Fusion 360 or Mastercam.

- Analyze Demand for On-Demand and Custom Manufacturing: Study how companies are shifting to low-volume, custom CNC parts instead of mass production

- Adopt Sustainable Practices: Reduce material waste by improving programming efficiency and recycling scrap metal.

- Expand into Advanced Materials: Consider machining composites, carbon fiber, and high-performance plastics to serve industries beyond traditional metalwork.

I ignored automation at first, thinking it was too expensive. Later, I realized even small investments in software saved hours of manual work.

Identify Where CNC Machining Is Used Most

To build a strong client base, you need to know which industries rely on CNC machining. Here’s how to find the right fit for your business:

- Evaluate Aerospace and Defense Needs: Research the precision requirements for aircraft parts and defense components.

- Understand Automotive Machining: Learn how CNC is used for engine parts, prototyping, and mass production in the car industry.

- Explore Medical and Healthcare Applications: Look into machining surgical tools, prosthetics, and medical implants, which require strict tolerances.

- Consider the Electronics Industry: CNC machining is used for circuit board housings, heat sinks, and high-precision electronic components.

- Connect With Industrial Machinery Manufacturers: These companies often need custom parts and specialized components on an ongoing basis.

I tried to serve everyone at first, which spread me too thin. Once I focused on industrial machinery parts, my business became more stable.

Step#2 Developing a Business Plan

Now that you understand the CNC machining industry, it’s time to build a solid business plan. Without a clear strategy, even the best machines and skills won’t guarantee success.

When I started, I thought knowing how to run a CNC machine was enough. But I quickly learned that a business without a plan is like a CNC machine without a program—completely useless. You need a roadmap that covers your target market, costs, and long-term growth strategy.

This step will help you define your niche, estimate startup costs, and create a strategy for scaling your CNC business over time.

Define Your Niche and Target Market

Trying to serve everyone is a mistake that can drain your time and resources. Instead, focus on a specific market where you can stand out. Here’s how to define your niche and attract the right customers:

- Identify High-Demand Industries: Research markets that require CNC machining, such as aerospace, medical, automotive, and industrial manufacturing. Which industry aligns with your expertise and resources?

- Choose the Right Services: Will you specialize in rapid prototyping, low-volume production, or high-precision machining? Each requires different machines and workflows.

- Analyze Local vs. National Demand: Are you targeting local manufacturers who need fast turnaround or larger clients across the country? Local businesses may offer repeat work, while national contracts could mean higher profits.

- Study Competitor Offerings: Research CNC shops in your area. What services do they provide? Can you offer better precision, faster lead times, or machining for special materials?

When I started, I tried to take on every job that came my way—big mistake. Once I specialized in machining parts for industrial machinery, I attracted repeat customers who needed consistent work.

Estimate Startup Costs and Explore Funding Options

Starting a CNC business requires a major investment. You need to plan your finances carefully to avoid running out of cash before you even start.

- Calculate Equipment Costs: CNC machines range from $20,000 for entry-level mills to $100,000+ for advanced multi-axis systems. Choose a machine that fits your niche and budget.

- Factor in Shop Setup Costs: You’ll need to budget for rent, utilities, tooling, raw materials, and software like Fusion 360 or Mastercam.

- Consider Labor Expenses: Will you start as a one-person operation, or will you hire machinists and programmers? Payroll adds a significant expense.

- Explore Funding Options: If you don’t have enough cash, consider:

- Equipment Loans: Financing through machine manufacturers or bank

- Small Business Grants: Some governments offer funding for manufacturing startups

- Investor Partnerships: Partnering with investors who can provide capital in exchange for a share of your business

I underestimated how much cash flow I needed for the first six months. When customers took longer to pay, I struggled to cover expenses. Having a financial cushion is critical.

Create a Growth Strategy for Your CNC Business

Once you’re up and running, how will you expand? Without a growth plan, your business may stall or get stuck at low-profit margins. Here’s how to scale effectively:

- Develop a Strong Marketing Plan:

- Build a website showcasing your capabilities, machine specs, and project examples

- Use LinkedIn and trade directories to connect with manufacturers

- Offer first-time customer discounts to attract new clients

- Invest in More Advanced Machines Over Time: Start with the basics, then upgrade to 5-axis machines or automated systems as demand increases.

• Build a Reliable Customer Base:

- Focus on long-term contracts with repeat clients rather than one-off jobs

- Offer fast turnaround times and precision machining to keep customers coming back

- Expand Into New Markets: Once you establish yourself, consider branching into high-precision aerospace parts, medical device machining, or custom prototyping services.

A strong business plan will keep your CNC shop on track for success. Now that you’ve defined your niche, budget, and growth strategy, you’re ready for the next step.

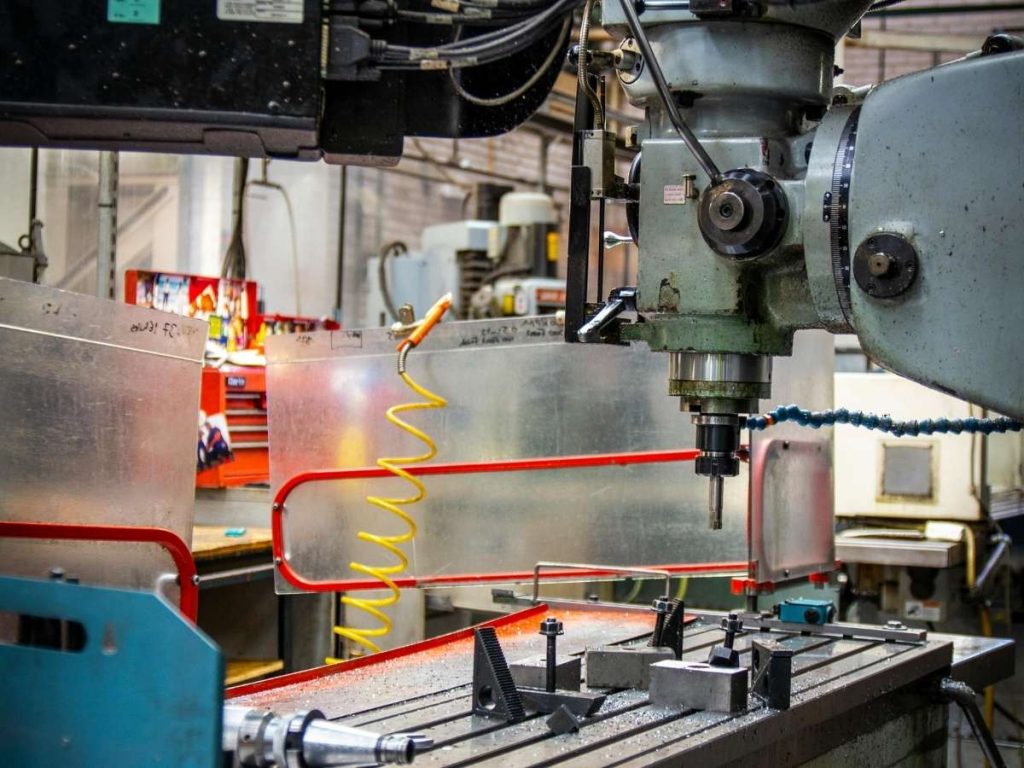

Step#3 Choosing the Right CNC Machines & Equipment

After develipong a business plan, it’s time to make one of the biggest investments—choosing your CNC machines. Your equipment will define the type of work you can take on, your efficiency, and your overall profitability.

When I started, I thought I needed the most advanced machine. I quickly learned that the right machine isn’t about price—it’s about matching the equipment to your business goals.

This step will help you choose the right CNC machine and equipment by following a clear, step-by-step process.

Identify the Type of CNC Machine You Need

CNC machines vary based on the work they can handle. Choosing the wrong type can limit your services. Follow these steps to determine which one suits your business best.

Identify Your Core Machining Needs: List the types of parts you plan to produce, including size, material, and complexity.

Match a Machine to Your Needs:

- If making general parts: Choose a CNC mill for versatility.

- If working with round parts: Choose a CNC lathe for precision turning.

- If cutting sheet metal: Choose a plasma or laser cutter based on material thickness.

Check Material Compatibility: Make sure the machine can handle the metals, plastics, or composites your customers require.

Decide on Production Volume:

- For low-volume work: Get a manual tool change machine.

- For high-volume production: Get a machine with automatic tool changers and robotic loading.

I initially bought a 3-axis CNC mill without considering the demand for lathe work in my area. If I had analyzed customer needs first, I would have started with a lathe.

Arrange Machine Delivery, Setup, and Installation

Once you’ve selected your machine, the next step is getting it installed and running smoothly.

Confirm Delivery Logistics: Check lead times and shipping requirements to avoid production delays.

Prepare Your Shop Space:

- Allocate enough floor space for machine movement and operator access.

- Install necessary electrical connections (some machines require 3-phase power).

- Set up ventilation and dust extraction if machining composites or wood.

Level and Anchor the Machine: Use a precision level to avoid vibration and machining errors.

Run Initial Calibration: Perform test cuts and spindle runouts to ensure accuracy.

Train Operators on Setup and Safety: Ensure your team understands tooling changes, maintenance, and emergency procedures before running production.

I didn’t check my shop’s power capacity before buying my first CNC machine. Upgrading my electrical system costs more than expected. Always verify power requirements before installation.

Step#4 Legal & Compliance Requirements

Now that you’ve selected your CNC machines and equipment, it’s time to make your business official. Registering your company and complying with industry regulations protects you from legal issues, ensures smooth operations, and builds trust with customers.

When I started, I thought paperwork was just a formality. But I quickly learned that missing even one legal requirement can delay projects or shut down operations. This step will guide you through the legal and compliance processes so you can operate without unnecessary risks.

Register Your CNC Machining Business

Before you start machining parts for customers, you need to legally establish your business. Here’s how to do it step by step.

Choose a Business Structure:

- Sole Proprietorship: Simple setup but leaves you personally liable for business debts.

- Limited Liability Company (LLC): Protects personal assets while keeping taxes flexible.

- Corporation (C-Corp or S-Corp): Best for larger businesses or those planning to attract investors.

Register Your Business Name:

- Check name availability through your state’s business registry.

- File a Doing Business As (DBA) if using a different trade name.

Obtain an Employer Identification Number (EIN):

- Required for taxes, opening a business bank account, and hiring employees.

- Apply online through the IRS website (for U.S. businesses).

Understand Industry Regulations & Safety Standards

CNC machining comes with strict safety, environmental, and industry regulations. Failing to comply can lead to fines, legal action, or even forced shutdowns. Follow these steps to stay compliant.

Follow Occupational Safety Standards:

- OSHA (U.S.) or Local Safety Authorities: CNC shops must meet workplace safety standards to protect employees.

- Train employees on machine safety: Requires lockout/tagout (LOTO) procedures, PPE (Personal Protective Equipment), and emergency stop training.

- Install proper ventilation: Essential when machining materials that produce dust or fumes.

Comply With Industry-Specific Regulations:

- Aerospace (AS9100 Certification): Required if making parts for aerospace clients.

- Medical (ISO 13485): Needed for manufacturing medical devices and implants.

- Automotive (IATF 16949): Ensures compliance with automotive part manufacturing standards.

Maintain Proper Documentation:

- Keep records of employee safety training and machine maintenance.

- Document waste disposal logs if required by local authorities.

- Stay updated with regulatory changes that may impact CNC machining.

I once skipped a required hazardous waste disposal permit for used coolant. A surprise inspection led to a hefty fine. Always check local environmental laws before disposing of machining waste.

Step#5 Setting Up Your CNC Workshop

When I first set up my shop, I placed machines based on available space instead of workflow. Big mistake. Operators wasted time moving between stations, and material handling was a mess. Optimizing your shop layout saves time, increases productivity, and reduces unnecessary movement.

This step will help you design an efficient workshop layout so you can get the most out of your CNC machines.

Plan Your Workshop Layout for Efficiency

Your workshop layout should be designed to minimize movement, maximize productivity, and keep workers safe. Follow these steps to create an efficient setup.

Define Your Workflow: Arrange machines and workstations based on the natural flow of production. A common order is raw material storage → cutting → machining → finishing → inspection → shipping.

Allocate Enough Space for Each Work Area:

- CNC Machine Area: Keep enough clearance around machines for tool changes and maintenance.

- Material Storage: Place racks or shelves near the cutting and machining area to reduce handling time.

- Workbenches for Assembly and Finishing: Position these close to the CNC machines for easy access.

- Inspection and Quality Control Station: Should be separate from machining to avoid contamination and distractions.

Set Up a Logical Path for Movement: Minimize unnecessary walking by placing workstations near each other in a U-shaped or linear flow.

Keep Safety a Priority:

- Maintain clear pathways for forklifts and workers.

- Install proper lighting to reduce errors and accidents.

- Use floor markings to indicate hazardous zones and movement lanes.

Step#6 Sourcing Materials & Building a Supply Chain

Now that your CNC workshop is set up, it’s time to focus on sourcing raw materials and establishing a reliable supply chain. Without quality materials and dependable suppliers, your production can suffer from delays, defects, and unexpected cost increases.

A CNC business is only as good as its materials. Inconsistent quality or late deliveries can ruin production. A strong supply chain keeps operations smooth and customers happy.

Choose the Right Materials

Match material properties to your machining needs:

- Aluminum: Lightweight, fast machining (aerospace, automotive).

- Steel & Stainless Steel: High strength, corrosion-resistant (industrial, medical).

- Titanium: Tough, heat-resistant (aerospace, medical implants).

- Plastics (ABS, PEEK, Delrin): Electrical and medical applications.

- Composites: Strong but tricky to machine (carbon fiber, fiberglass).

Check for certifications (AMS, ISO 10993, ASTM) if required by clients.

Cheap materials can warp or fail under stress—always test before bulk orders.

Find Reliable Suppliers

- Use industry directories (ThomasNet, Xometry) and trade shows to vet vendors.

- Test sample materials before committing to a supplier.

- Negotiate pricing and terms (bulk discounts, net-30 payments).

- Keep at least two suppliers for critical materials to prevent shortages.

Consider Blue Elephant as a reliable supplier of CNC machines. We offer customization in size, configuration, functionality, and aesthetics to meet diverse client needs.

Streamline Your Supply Chain

- Track inventory with MRP or QuickBooks to avoid shortages.

- Set reorder points to prevent last-minute delays.

- Diversify sourcing to protect against disruptions.

- Monitor material prices and lock in contracts during low-cost periods.

Relying on one supplier stopped my entire production when they delayed a shipment.

Step#7 Marketing & Customer Acquisition

With your CNC shop set up and materials secured, it’s time to get customers. Without a strong marketing strategy, even the best machine shop won’t survive. You need a system to attract, convert, and retain clients.

Build an Online Presence

Your website is your digital storefront. Make it clear, professional, and focused on conversions.

- List your capabilities (machines, tolerances, industries served).

- Showcase past projects with high-quality images.

- Offer instant quotes or an easy contact form.

- Use LinkedIn & directories to connect with decision-makers.

Adding before-and-after machining photos helped me win clients who needed proof of quality.

Generate Leads & Close Sales

Inbound leads don’t happen overnight. Take proactive steps to land jobs.

- Cold outreach: Contact manufacturers directly with tailored proposals.

- Partner with larger shops: Offer overflow capacity or niche services.

- Join trade shows: Meet potential clients face-to-face.

- Leverage referrals: Satisfied customers bring new business.

Marketing isn’t about luck—it’s about building relationships and showing value. With a strong strategy, your CNC shop will attract the right customers and grow consistently.

Conclusion

Starting a CNC machining business isn’t just about machines—it’s about strategy, planning, and persistence. You now know how to set up your shop, source materials, and get customers.

Success won’t happen overnight, but with the right steps, you’ll get there.

Are you ready to take action and turn your vision into reality? Partner with reliable CNC suppliers like Blue Elephant.

We offer high-performance machines at competitive prices, often delivering better durability and stability than competitors in the same price range.

Explore More of Our Resources

We’ve gathered a few more articles that could help you out. Check them out for more great advice:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.