What is the ELECNC420 computer control wood panel saw?

It is often used in various woodworking applications, particularly in industries that require precision cutting and shaping of wood panels for furniture manufacturing, cabinetry, carpentry, and other woodworking tasks. It offers features such as automated cutting, accuracy, repeatability, and the ability to work with various wood panel sizes and thicknesses.

Features & Configurations of ELECNC420 computer control wood panel saw

Machine Bed

The machine size is about 7300*6530*1900mm. It uses high-quality steel to build up the body. And through the high-density process welding technology and annealing treatment, it effectively ensures the stability and service life of the main body.

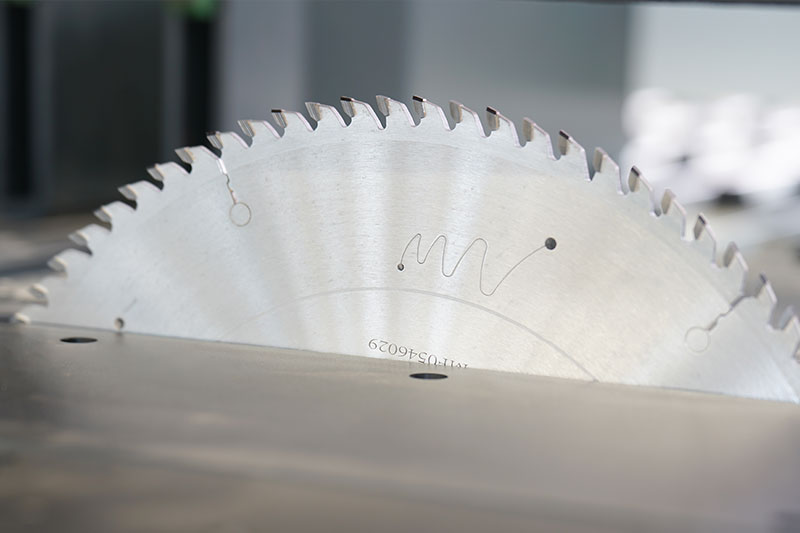

Saw

The saw base adopts double guide rail, which has the pros of straight sawing path, high precision and small load. It adopts gear and rack transmission and CNC sawing, which is suitable for dusty environment and has more stable precision.

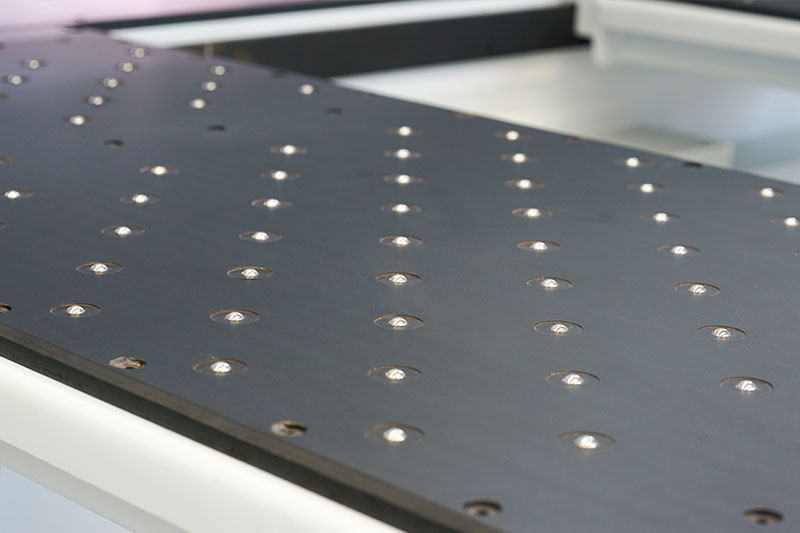

Air-floating workbench

The Blue Elephant 420 computer saw has four air floating workbenches, one more than ordinary computer saws. At the same time, it also makes panel feeding faster and easier, and also facilitates cutting of larger-sized wooden boards.

Failure alarm device

This high-end computerized panel saw is equipped with a fault alarm device, which automatically shuts down when a fault occurs. It also has an automatic fault detection function, making it easy to check the cause of the fault.

Friendly human-computer interaction

The panel display interface is simple and easy to operate. And the control method is safe and reliable. The required sawing plan can be edited and sawing can be simulated. It can be compatible and integrated with a variety of optimization software, barcode management software and automation software.

Electronic ruler magnetic induction device

The German electronic ruler is used for closed-loop precision compensation, with a compensation tolerance of ±0.02mm.

Remote docking service system

It can realize remote operating status monitoring and expand intelligent IoT docking.

Working process of ELECNC420 computer control wood panel saw

The ELECNC420 computer beam saw is capable of cutting whole panels, small panels, and batch panels. Its maximum cutting length is 420mm and maximum cutting thickness is 100mm.

Machine appearance – 0:04- 0:22

Whole panel processing – 0:24 – 1:40

Batch processing – 0:48 – 1:25

Small panel processing – 1:26 -1:36

What are the advantages of ELECNC420 computer control wood panel saw?

Precision and Accuracy: They are programmed to make exact cuts according to the specifications entered into the system, ensuring accuracy in dimensions and shapes.

Efficiency: CNC panel saws are highly efficient, capable of performing complex cutting tasks rapidly. They can handle a variety of cuts and designs without the need for manual adjustments between cuts, thus saving time and labor.

Customization and Flexibility: These machines can be programmed for various cuts and designs, allowing for customization and flexibility in production. They can handle different panel sizes and shapes according to the specific needs of a project.

Reduced Material Waste: The precision of these saws helps minimize material waste by making accurate cuts, optimizing the use of wood panels and reducing errors.

Quality Finishes: The precision of these machines leads to high-quality finishes on the cut wood panels, meeting high standards in the woodworking industry.