What’s the difference between the automatic tool changing six sides CNC drilling machine and common six sides CNC drilling machine?

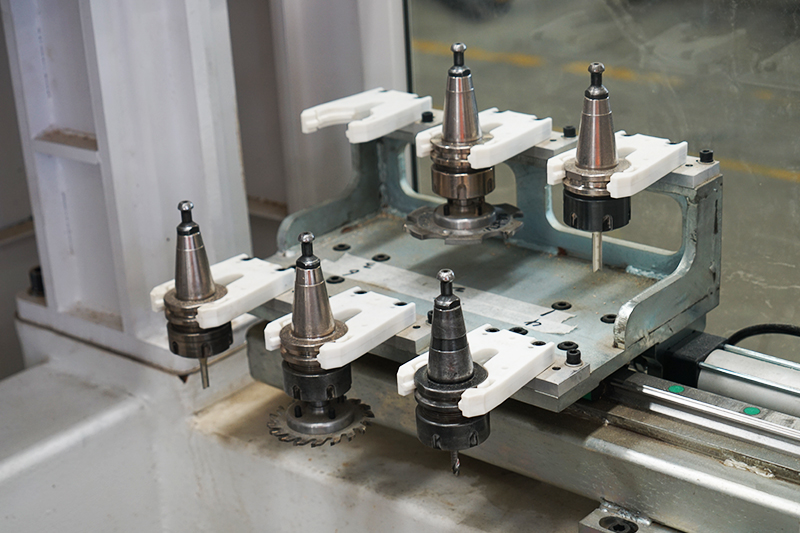

Automatic tool changing

Ordinary six-sided CNC drilling machine: Usually require manual tool replacement. When a different type or size of drill bit is required, operators need to shut down the machine to manually replace the drill bit, which can lead to production stagnation and reduced productivity.

Automatic tool changing six-sided CNC drilling machine: This equipment is equipped with an automated tool changing system. It is able to accommodate multiple tools and automatically replaces the required tool during machining without manual intervention. This significantly increases productivity and reduces downtime.

Side drilling

Ordinary six-sided CNC drilling machine: only upper and lower drill packages, not including four milling heads.

Automatic tool changing six-sided CNC drilling machine: Equipped with Changchuan four-sided milling head, it can complete multi-sided processing in one operation. It can mill, cut or cut on the front, rear, left and right sides of the workpiece at the same time, thus saving processing time. In addition, the four milling heads help maintain consistency and precision in machining. This can reduce workpiece positioning deviations caused by multiple clamping or adjustments.

Work efficiency

Ordinary six-sided CNC drilling machine: Due to the need to manually change tools, frequent shutdowns are required during the production process, which will lead to a decrease in work efficiency.

Automatic tool changing six-sided CNC drilling machine: Due to the existence of the automatic tool changing system, the equipment can continue processing without frequent shutdowns to replace tools, thus improving work efficiency.

In general, automatic tool changing six-sided drill equipment improves production efficiency and reduces downtime through an automated tool changing system, while ordinary six-sided drills require manual intervention to change tools, which will lead to a decrease in production efficiency. Which equipment to choose depends on production needs and budgetary considerations.

Features of ET6T automatic tool changing six sides CNC drilling machine

1. Automatic tool changing

This machine is equipped with an automatic tool changer, enabling it to switch between different tools without manual intervention. This feature enhances efficiency and reduces downtime during production.

2. Four direction drilling

Specifically, the machine is capable of drilling in four different directions. This versatility allows for a wider range of hole placements and configurations on the workpiece.

3. Customized control system

Independently developed Blue Elephant customized intelligent control system, with high effect speed, high communication speed, response upgrade, action integration, and linked execution.

Applications of ET6T automatic tool changing six sides CNC drilling machine

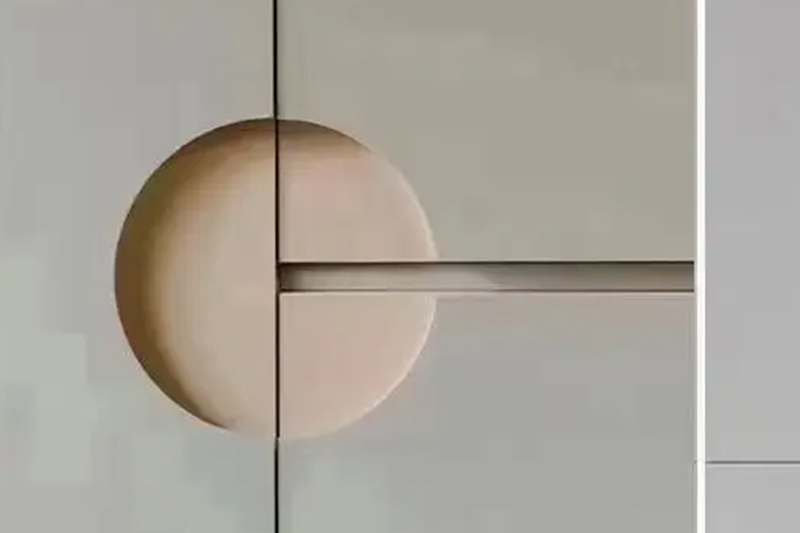

Pull Free Handle Processing

It can easily process various invisible handles such as horn handles, rocket handles, outer rectangular handles, inner rectangular handles, semi-circle handles, inner circle handles, full-body handles, U-shaped handles, etc.

Cabinet Processing

Using automatic tool changing + four-sided side milling, one machine can realize various door and wall cabinet processes such as light ducting, closing strips, and crabapple corners.

High-end crafts processing

It can complete high-end craftsmanship such as Lamino, Mudeyi, Lock, pressed invisible door locks/door handles, sky-to-ground hinges, door closers, etc.

Advantages of ET6T automatic tool changing six sides CNC drilling machine

Automated Tool Changes: This machine is equipped with an automatic tool changing system. It can hold multiple tools and switch between them autonomously during the machining process. This feature significantly reduces downtime between tool changes, enhancing overall productivity.

Versatile Six-Sided Drilling: ET6T is specifically designed for six-sided drilling operations. It can efficiently drill holes and perform various operations on all six sides of a workpiece without manual intervention, ensuring comprehensive and precise machining.

High Precision and Accuracy: The machine’s automated operations contribute to consistent precision in drilling and machining tasks. Accurate positioning and tool changes help maintain the desired tolerances and dimensions across multiple surfaces.

Enhanced Efficiency: By eliminating the need for manual tool changes, the ET6T boosts operational efficiency. It reduces human error, speeds up production cycles, and allows for continuous machining without frequent interruptions.

Customization and Programming: These machines often come with user-friendly software interfaces that allow for easy programming and customization. Operators can set specific drilling patterns, sequences, and tool paths, enabling a high degree of flexibility in machining operations.

Reduced Labor Dependency: Automation in tool changing and drilling processes minimizes the need for constant human intervention. Operators can oversee the machine’s operations and handle more complex tasks, reducing labor dependency on routine operations.

Increased Production Capacity: With its automated tool changing system and efficiency in six-sided drilling, the ET6T can significantly increase the production capacity of a manufacturing unit, meeting higher demand within shorter timeframes.

Cost Efficiency: Despite the initial investment, the efficiency gains and reduced downtime from automated tool changes often result in long-term cost savings. The machine’s ability to perform multiple operations without constant supervision optimizes resource utilization and maximizes output.