Today, a client from England came to our factory.

Our factory had just bulit a new cnc machine which model is 1530.

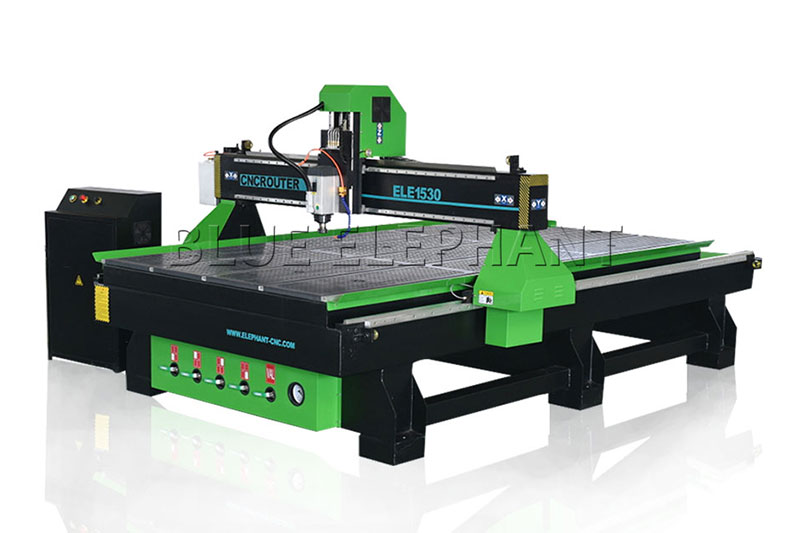

The official picture is:

The customer also liked the machine and he worked with our engineers to complete the machine commissioning.

And he learned how to use DSP A11 handle to control the 3 axis cnc routers.

The following is the technical parameters of this machine:

| Description | Parameter |

| X,Y,Z Working Area | 1500*3000*200mm |

| X,Y,Z Traveling Positioning Accuracy | ±0.03/300mm |

| Table Surface | T-slot and Vacuum Working Table |

| Frame | New type thicker and bigger heavy duty welded frame and gantry |

| X, Y Structure | Helical Rack gear, Taiwan PMI Rail Linear Rail |

| Z Structure | Taiwan TBI Ball Screw, Taiwan PMI Rail Linear Rail |

| Spindle | 4.5kw Italy HSD air cooling spindle |

| Spindle Speed | 0-18000RPM |

| Drive Motors | FL118 stepper motor and Yako 2811 big driver |

| Inverter | 5.5kw Delta Inverter |

| Lubrication system | Manual lubrication system |

| Working Voltage | AC380V, 3Ph, 50Hz (Option: 220V) |

| Operating System | DSP A11 Control System |

| Control box | Single-sided indenpended control box |

| Dust collector | 1.5kw double pockets dust collector, (AC380V, 3Ph, 50Hz) |

PS:All the working area and specifications can be customized according to your requests.