When I bought my first laser engraver, I was on a tight budget. A brand-new one was out of reach, so I went with a used machine.

I was excited—until I turned it on. The cuts were weak, and the alignment was way off. I had no idea what I was doing, and it showed.

Over the years, I’ve bought and sold multiple laser engravers. I’ve learned what makes a second-hand machine worth the money and what to avoid at all costs.

If you’re in the market for one, you probably have the same questions I did: How do you know if it’s in good condition? What should you check before buying?

This article will walk you through the entire process, from evaluating the machine to making sure you don’t end up with a costly mistake.

By the time you’re done reading, you’ll have everything you need to buy with confidence.

So let’s start!

1. Why Buy a Second-Hand Laser Engraver?

You’ve probably seen the price tags on brand-new laser engravers. They’re not cheap. If you’re running a business, every dollar counts, and spending too much upfront can slow your growth. That’s why buying a second-hand laser engraver is an option worth considering.

But is it the right move for you? That depends on what you need, your budget, and how much risk you’re willing to take.

Let’s break it down.

You Get More Machine for Your Budget

With a new engraver, your budget limits your options. But with a used one, you might be able to afford a more powerful machine with better features.

For example:

- A used 100W CO2 laser might cost the same as a brand-new 60W model. That extra power means faster engraving and deeper cuts.

- A fiber laser, which is usually expensive, might suddenly be within reach, allowing you to engrave metal instead of just wood and acrylic.

I’ve seen people buy an entry-level new engraver, only to outgrow it within a year. Buying used lets you start with a better machine from day one.

No Long Wait Times

If you order a new machine, especially a high-quality one, you might have to wait weeks or even months for delivery. I’ve been there—placing an order, getting excited, and then realizing I won’t see my machine for three months.

With a second-hand engraver, you get it immediately. You can inspect it in person, test it, and take it home the same day. If time is money in your business, buying used could keep your workflow moving without delays.

You Avoid Depreciation

Just like a car, a laser engraver loses value fast. The moment a brand-new one is sold, its resale value drops. If you ever need to upgrade or sell your machine, you’ll take a bigger loss on a new one than a used one.

When you buy second-hand, you’re letting someone else take that initial hit. If you take care of the machine, you could even sell it later for almost what you paid.

2. Key Factors to Consider Before Buying

Buying a used laser engraver can be a smart way to save money, but only if you know what to look for. Some machines are in excellent condition, while others are more trouble than they’re worth. So how do you make the right choice?

Let’s go over the most important factors to check before making a purchase.

Machine Condition

A second-hand laser engraver may look fine on the outside, but the real question is how well it functions. Always inspect key components before making a decision.

- Laser Tube Life: CO₂ laser tubes have a limited lifespan, usually between 1,000 and 10,000 hours. If the tube is nearing the end of its life, replacing it could cost hundreds or even thousands of dollars. Ask the seller how many hours are left and if there’s a way to verify it.

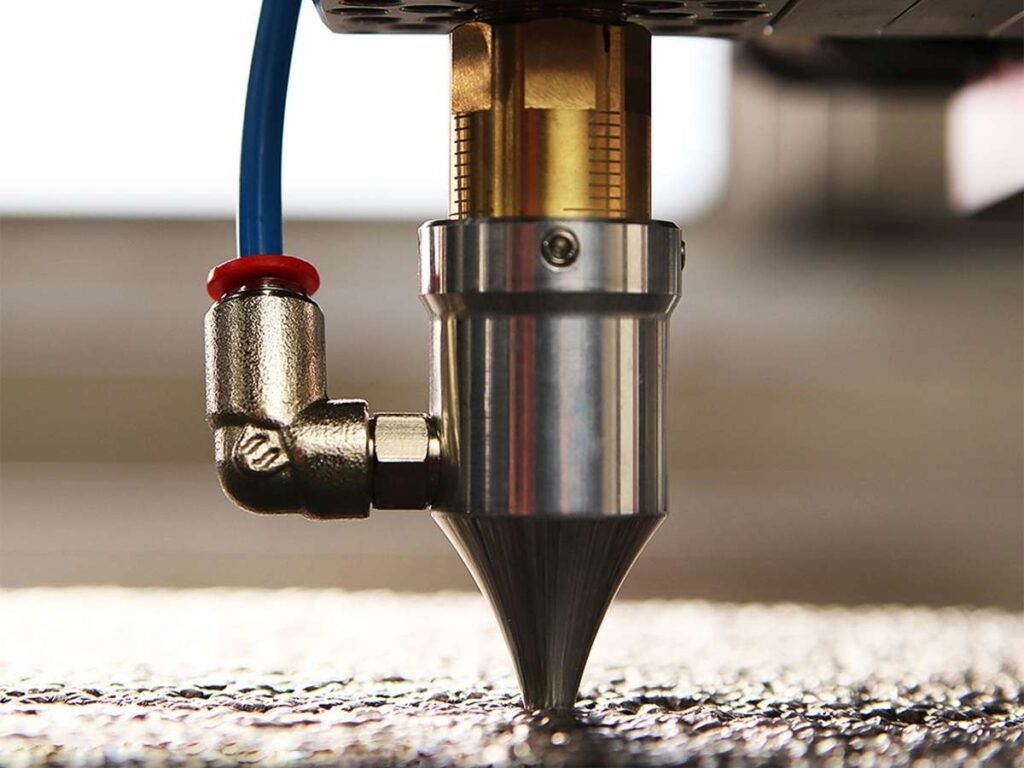

- Mirror and Lens Quality: Dirty, scratched, or misaligned optics can weaken laser power and ruin engraving accuracy. Take a close look at the mirrors and lenses. If they are foggy or have burn marks, they may need replacing.

- Engraving Bed and Rails: Check for wear and misalignment. Move the laser head by hand to see if it glides smoothly or feels rough. If the movement isn’t consistent, the machine may have mechanical issues.

- Cooling System: CO₂ laser tubes generate heat and need a working cooling system. Look for signs of leaks, corrosion, or mineral buildup in the water lines. If the engraver uses air cooling, make sure the fans are running properly.

- Electronics and Wiring: Frayed wires, loose connections, or exposed circuitry can cause serious problems. Open the control panel and inspect the wiring. If anything looks like a quick DIY fix, the machine may not have been properly maintained.

Brand and Model

Not all laser engravers are built the same. Some brands have a strong reputation for reliability, while others have limited support and hard-to-find parts.

- Reputation: Look for model that businesses trust. If a model has been widely used for years, chances are it’s reliable. I recommend choosing a machine from a reputable manufacturer like Blue Elephant—we can guarantee consistent quality, reliable performance, and strong after-sales support.

- Availability of Parts: Some laser engravers require brand-specific parts that aren’t easy to find. Before buying, check if replacement components like laser tubes, lenses, and motors are readily available.

- Software Compatibility: Many older engravers use outdated software. Make sure the machine works with modern programs like LightBurn, RDWorks, or EZCAD. Some engravers require a software license that may not transfer to a new owner.

Usage History

A machine’s past use can tell you a lot about its current condition. Some engravers run daily in high-production environments, while others are lightly used for hobby projects.

- Running Hours: Ask how many hours the machine has operated. The higher the number, the more wear and tear it has. If the seller can’t provide an estimate, assume it has been heavily used.

- Materials Engraved: Cutting and engraving metal puts more strain on a machine than working with wood or acrylic. If the engraver has been used primarily for thick materials, it may have more wear.

- Maintenance History: A well-maintained engraver lasts much longer. Ask if the machine has received regular mirror cleaning, belt adjustments, and cooling system maintenance. If the seller hasn’t kept records, there’s no way to know how well it has been cared for.

3. How to Inspect and Test a Second-Hand Laser Engraver Before Buying

I’ve bought my share of used laser engravers—some great, some a complete waste of money. The worst one? It looked perfect in photos, but when I turned it on, the laser barely cut through paper. The mirrors were foggy, and the software refused to connect. I ended up spending more on repairs than the machine itself.

I don’t want you to make the same mistake. Here’s a straightforward way to inspect and test a second-hand laser engraver before buying.

Look at the Machine Before Turning It On

- Frame and Structure: Run your hand over the machine. Are there dents, cracks, or loose bolts? If the frame is damaged, engraving accuracy will suffer.

- Laser Tube Condition: CO₂ laser tubes don’t last forever. Look for burn marks, discoloration, or bubbles inside the tube. If the seller can’t confirm how many hours are left, that’s a red flag.

- Mirrors and Lenses: Hold a light to the mirrors and lenses. If they look foggy, scratched, or burnt, they won’t reflect the laser properly. A dirty mirror is an easy fix; a damaged one is not.

- Rails and Motion System: Manually slide the laser head. It should move smoothly, without stiffness. If it’s rough or wobbly, the rails may be misaligned or worn out.

- Cooling System: Touch the cooling tubes (if it’s water-cooled). Any leaks? Mineral buildup? A bad cooling system leads to overheating, which can destroy the laser tube fast.

Test the Machine in Action

- Power It On: Does it boot up quickly? Any strange noises? A slow startup or buzzing sounds could mean a failing power supply.

- Run a Sample Engraving: Ask the seller to engrave on wood or acrylic. Watch for:

- Clean, even engraving (no faded spots)

- Smooth edges (not jagged or rough)

- Consistent depth across the engraving area

- Check Laser Power: Set the machine to different speeds and power levels. Does the engraving stay strong, or does it weaken at higher speeds? A weak laser means a failing tube.

- Software and Connectivity: Bring your laptop if you can. Does the engraver connect properly? Some older machines don’t work with modern software like LightBurn or RDWorks. If the software license isn’t included, you might need to buy a new one, which can be expensive.

If the machine passes all the tests, it’s a great buy. If something feels off—walk away. I’ve learned the hard way that it’s better to wait for the right machine than to deal with costly surprises later.

4. Where to Buy Second-Hand Laser Engraver?

Finding a good used laser engraver isn’t just about price—it’s about trust. The last thing you want is to pay for a machine that arrives damaged, missing parts, or worse, doesn’t arrive at all.

So, where should you buy from? And how do you make sure the seller is reliable? Let’s go over your options.

Buying from Certified Dealers

If you want less risk, a certified dealer is the safest option. These sellers inspect, refurbish, and sometimes offer short-term warranties on used machines.

- Machines are tested before resale, so you know what you’re getting.

- Some dealers offer warranties, though they may be limited.

- Customer support is usually available, which helps if you run into problems.

The downside? Prices are higher than buying directly from an owner, but you’re paying for peace of mind.

I once bought from a dealer who replaced a worn-out laser tube before selling the machine. I paid a little more, but it saved me from dealing with costly repairs later.

Buying Direct from Previous Owners

Buying straight from another business can save money, but it’s riskier. Sellers may not disclose everything, and there are no refunds if something goes wrong.

- Prices are lower since you’re skipping the middleman.

- You can negotiate the price if the seller wants to sell quickly.

- There’s no warranty, and the machine could have hidden problems.

Buying from Online Marketplaces

Platforms like eBay, Alibaba, and Facebook Marketplace have plenty of listings, but not all sellers are honest. Some machines are overpriced, damaged, or even scams.

- Huge selection of machines from different sellers.

- Prices vary, but some listings are way too cheap (red flag).

- Buyer protection may apply, depending on the platform.

Watch Out for These Red Flags:

- Too-good-to-be-true prices—they often mean the seller is hiding something.

- Stock photos instead of real images—ask for pictures of the actual machine.

- No willingness to provide a video demo—a working machine should be easy to show.

No matter where you buy, always ask questions, request a demo, and take your time. A little caution now can save you from big regrets later.

5. Common Mistakes to Avoid When Buying a Used Laser Engraver

Buying a used laser engraver can be a great investment, but small mistakes can lead to big regrets. Here’s a quick guide to the most common pitfalls and how to avoid them.

| Common Mistakes | Solution |

| Skipping a proper inspection | Always inspect in person or request a live video demo. Test the machine on different materials. |

| Ignoring the laser tube’s condition | Ask about the laser tube’s remaining hours. Check for burn marks or discoloration. Verify replacement costs before buying. |

| Buying the wrong type of machine | Ensure the machine matches your business needs. CO₂ lasers for wood/acrylic, fiber lasers for metal, diode lasers for light engraving. |

| Not checking software compatibility | Confirm software compatibility with LightBurn, RDWorks, or EZCAD. Check for required licenses. Verify the connection type. |

| Falling for unrealistic prices | Compare prices with similar models. Research the seller’s background. Avoid deals that seem too cheap. |

| Overlooking after-sales support | Check if the manufacturer still provides support. Ensure replacement parts are available. Look for user communities for troubleshooting. |

| Not testing the engraving quality | Run a sample engraving to check for smoothness, depth, and power consistency. Watch for fading or uneven lines. |

| Ignoring signs of poor maintenance | Check belts, rails, mirrors, and cooling systems for wear or dirt. Poor maintenance leads to expensive repairs. |

| Forgetting about shipping costs | Laser engravers are heavy. Factor in shipping fees, handling costs, and potential import taxes if buying internationally. |

| Rushing into a deal | Take your time. Ask questions. If a seller pressures you to decide fast, it could be a red flag. |

| Assuming spare parts are easy to find | Check the availability of replacement parts before buying. Some models have discontinued parts, making future repairs costly. |

6. Tips To Consider When Buying Second-Hand Laser Engraver

I’ve been in your shoes—excited to find a good deal on a used laser engraver, but also nervous about getting stuck with a bad machine. The first time I bought one second-hand, I thought I was saving money, but I ended up with a worn-out laser tube and software that wouldn’t even connect to my computer. Lesson learned.

If you’re considering buying a used laser engraver, here are some hard-earned tips to help you avoid costly mistakes and get a machine that actually works for your needs.

Tip #1 Know What You Need Before You Start Looking

Not all laser engravers are built for the same jobs. CO₂ lasers are best for wood, acrylic, and plastic, while fiber lasers are needed for metal engraving. If you buy the wrong type, you won’t get the results you need, and reselling it later may be difficult.

Tip #2 Check the Laser Tube’s Condition

The laser tube is the heart of the machine, and replacing it can be expensive. CO₂ laser tubes have a lifespan of 1,000 to 10,000 hours, depending on quality and usage. Ask the seller about its current hours and look for burn marks or discoloration, which may indicate that it’s near the end of its life.

Tip #3 Run a Test Engraving Before Paying

A functional test should be non-negotiable. Have the seller run a job on wood, acrylic, or metal, depending on your material needs. Evaluate edge sharpness, consistency, and depth. If the engraving shows uneven lines, weak contrast, or fading in certain areas, the optics or power system may fail.

Tip #4 Make Sure the Software Works on Your Computer

Outdated software can be a major bottleneck, especially if it’s no longer supported. Confirm that the engraver is compatible with mainstream platforms like LightBurn, RDWorks, or EZCAD. Also, clarify whether the software license is transferable or if you’ll need to purchase a new one.

Conclusion

Buying used isn’t about luck—it’s about knowledge. I learned that after my first bad engraver. You don’t have to repeat that mistake.

From tube lifespan to software compatibility, this article gave you everything you need to make a confident decision.

If you still have questions or want help finding a reliable seller, Blue Elephant has your back.

Contact us today—we’ll help you avoid hidden costs and find the right machine for your needs!

Recommended Reads for You

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.