I remember the first time I considered starting a CNC business. I had the skills, the connections, and access to machines, but I had no idea where to begin.

Was it profitable? How much would I need to invest? Where would I find clients? It felt overwhelming.

If you’re in the same boat, you’re not alone. Many machine dealers, spare parts suppliers, and repair businesses see the potential in CNC machining but struggle with the first steps.

This guide is built from real industry insights, not just theory. With years of experience in manufacturing, supply chains, and CNC business operations, I know what works—and what doesn’t.

In this article, you’ll get a clear, step-by-step roadmap to launching your CNC business. Whether you’re adding CNC services to your existing business or starting from zero, you’ll find practical advice that helps you move forward.

Let’s dive in!

Step#1 Identify Your Niche

When I first got into CNC machining, I thought I had to do everything—cutting, engraving, prototyping, mass production. The more I researched, the more I realized that trying to serve everyone would leave me with no real competitive edge.

And that’s the mistake I see many businesses make.

What’s the Right CNC Niche for Your Business?

The best niche for you depends on your existing strengths, network, and resources. Ask yourself:

- Do You Already Sell Machines or Spare Parts? You could focus on custom part production for your existing customers.

- Do You Have Experience With Machine Maintenance? Consider specializing in CNC repair services or even refurbishing used CNC machines.

- Are You Connected to Industries That Need CNC Work? Automotive, aerospace, and medical fields all have high-precision demands and low tolerance for errors, which means high margins for the right CNC business.

The key here: You don’t need to serve everyone. You need to serve the right customers.

CNC Niches Worth Considering:

- Precision Machining for Spare Parts

- CNC Prototyping for Manufacturers

- CNC Repair and Retrofitting

- CNC Rental and Leasing

- Custom Engraving and Marking

Choose the Right Niche

- Look at Your Current Business and Strengths: If you already sell machines, spare parts, or provide maintenance, build on that foundation instead of starting from zero.

- Check Market Demand: Are businesses in your area struggling to find reliable CNC services? If so, that’s a goldmine of opportunity.

- Analyze Profit Margins: Some CNC work, like mass production, is low-margin, while others, like prototyping and repairs, have higher markups and less competition.

- Think Long-Term: Don’t just chase trends—choose a CNC niche that can grow with your business over time.

Step#2 Create a Business Plan

Now that you’ve chosen your niche, you need a plan—a real strategy to turn your CNC business into a profitable operation. Without a plan, you’re guessing. And in this industry, guessing leads to wasted money, missed opportunities, and, worst of all, failure before you even start.

A business plan isn’t just something investors or banks want to see. It’s your roadmap. It keeps you focused, helps you avoid expensive mistakes, and ensures that every dollar you invest has a clear purpose.

Contents of Business Plan

- Your Business Model: Are you offering CNC machining services, custom part production, repair work, or machine rentals? Define exactly how you plan to make money.

- Your Target Market: Who are your ideal customers? Are you serving manufacturers, automotive companies, or industrial repair shops? The more specific, the better.

- Your Competitive Edge: Why should a customer choose you over another CNC shop? Speed? Precision? Cost efficiency? Specialization? Identify what makes you different.

- Your Pricing Strategy: How will you price your CNC services? Will you charge per part, per hour, or per project? You need a pricing model that covers your costs and ensures profitability.

- Your Startup Costs: Machines, tools, materials, software, and facility expenses all add up quickly. You need a clear breakdown of how much capital you need to get started.

- Your Growth Plan: CNC businesses can scale fast, but only if you plan for it. Will you expand by adding more machines, hiring staff, or offering new services?

How to Create a CNC Business

- Start With a One-Page Plan: Don’t overcomplicate things. Start with a simple outline of your business model, costs, and target market.

- Research Your Costs and Pricing: CNC machining has thin margins if you don’t price your services correctly. Study competitors, factor in your overhead, and set a pricing model that ensures profit.

- Define Your Customer Base: Who needs your CNC services the most? Identify industries, businesses, and decision-makers who will actually pay for your services.

- Outline Your First Year of Operations: What machines will you buy? How many customers do you need per month to break even? What’s your marketing plan? Put numbers behind your strategy.

- Plan for Growth: Your CNC business won’t stay the same forever. Will you invest in more machines? Offer additional services? Partner with suppliers? Map out a long-term vision.

Step#3 Determine Your CNC Business Startup Costs

You’ve identified your niche. You’ve created a business plan. Now, it’s time to face a critical question: How much will it cost to start your CNC business?

This is where many businesses go wrong. They underestimate costs, overextend their budget, or spend money on the wrong things. If you don’t plan your finances carefully, you could run out of cash before your CNC shop even gets off the ground.

Let’s break it down.

Core Expenses

Your startup costs will depend on the size of your operation, the type of CNC work you’ll offer, and whether you’re buying new or used equipment. But in general, here’s where your money will go:

- CNC Machines and Tools: This is your biggest investment. A basic CNC mill or lathe can start at $10,000–$50,000, while high-end 5-axis machines can cost $100,000 or more.

- Software and Programming Tools: You’ll need CAD/CAM software to design and program parts. Expect to pay $2,000–$10,000 upfront, plus ongoing licensing fees.

- Facility and Workshop Setup: Whether you’re leasing a shop or converting a garage, you’ll need proper ventilation, electrical upgrades, and workbenches. Costs can range from $5,000 to $50,000, depending on the space.

- Raw Materials and Inventory: Steel, aluminum, plastics, materials vary by niche. A good starting budget is $5,000–$15,000 for initial stock.

- Business Registration and Legal Fees: Permits, licenses, and business formation (LLC, S-Corp, etc.) will typically cost $500–$3,000.

- Marketing and Branding: A professional website, logo design, and marketing campaigns will require at least $2,000–$10,000.

- Operational Expenses: Utilities, insurance, and payroll (if you’re hiring) can add another $3,000–$10,000 per month.

Hidden Costs

Beyond the big-ticket items, there are smaller expenses that can quickly add up:

- Machine Maintenance: CNC machines need regular servicing, and breakdowns can cost thousands in repairs.

- Tooling and Fixtures: Cutting tools, clamps, and fixtures can add up to $5,000+ in upfront costs.

- Software Updates and Training: Keeping your team up to date with software and machine operation costs time and money.

- Shipping and Logistics: If you’re handling large or heavy parts, shipping costs can eat into your profits.

Step#4 Register Your CNC Business & Get Legal Approvals

Now that you’ve calculated your startup costs, it’s time to make your business official. Without proper registration and legal approvals, you can’t open a business bank account, apply for financing, or legally operate.

This is where some businesses stall—not because it’s hard, but because the process feels overwhelming. The truth? It’s straightforward if you follow the right steps.

Choose a Business Structure

Your business structure determines how you pay taxes, handle liability, and even secure funding. Here are your main options:

- Sole Proprietorship: Simple to start, but you’re personally liable for all debts and lawsuits.

- Limited Liability Company (LLC): The best choice for most CNC businesses—provides liability protection and tax flexibility.

- S-Corp or C-Corp: Ideal for larger CNC operations that plan to scale and bring in investors.

Most CNC startups choose an LLC because it protects your personal assets if your business faces legal or financial trouble.

Register Your Business

Once you’ve chosen a structure, here’s what’s next:

- Register Your Business Name: Check your state’s business database to ensure your name is available.

- Apply for an EIN (Employer Identification Number): This is your business tax ID, required for banking and tax purposes.

- Obtain Business Licenses and Permits: Depending on your location, you may need local manufacturing permits or zoning approvals.

- Open a Business Bank Account: Never mix personal and business finances—this is key for tax and liability protection.

Industry-Specific Licenses and Compliance

CNC machining often involves industrial safety regulations, environmental considerations, and quality standards. Depending on your niche, you may need:

- OSHA Compliance: If you have employees, you’ll need workplace safety measures in place.

- EPA Permits: If your CNC processes involve hazardous materials or emissions, environmental regulations may apply.

- ISO Certifications: Not mandatory, but can help you secure contracts with large manufacturers.

Skipping compliance isn’t an option—penalties can shut down your business before it even gets traction.

Insurance

CNC machining involves high-value equipment, potential workplace injuries, and liability risks. The right business insurance protects you from costly lawsuits and damages. Consider:

- General Liability Insurance: Covers accidents, property damage, and legal fees.

- Equipment Insurance: Protects your CNC machines against theft, fire, or mechanical failure.

- Workers’ Compensation: Required if you hire employees, covering workplace injuries.

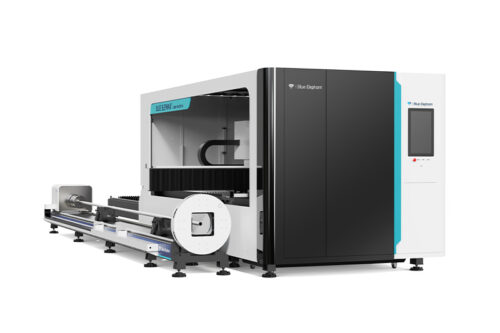

Step#5 Secure CNC Machines, Tools & Equipment

With your business legally registered, it’s time to invest in the heart of your CNC operation—your machines and tools. This step is where many businesses either set themselves up for success or make costly mistakes.

Buy the wrong machine, and you’ll struggle with inefficiencies. Skimp on tooling, and you’ll face downtime, scrap materials, and frustrated clients. But with the right setup, you can produce high-quality parts, maximize output, and grow your business profitably.

Let’s break down exactly what you need.

Choosing the Right CNC Machines

Your niche determines what type of CNC machines you need. Whether you’re manufacturing precision spare parts, doing custom prototyping, or offering repair services, your equipment needs to match your business goals.

- CNC Mills: Great for precise cutting, drilling, and shaping metal or plastic. Best for custom part production.

- CNC Lathes: Ideal for round or cylindrical parts, such as shafts and bushings.

- CNC Routers: Used for woodworking, plastic, and soft metal applications—great for signage or engraving businesses.

- CNC Plasma Cutters: Perfect for cutting through thick metal sheets, commonly used in industrial fabrication.

- 5-Axis CNC Machines: High-end, ultra-precise machines used for aerospace, medical, and complex manufacturing.

If you’re just starting out, focus on machines that align with your most profitable service offerings instead of trying to cover everything.

New vs. Used CNC Machines

Your budget will largely determine whether you buy new or used.

- New CNC Machines: Come with warranties, support, and the latest technology but require a high upfront investment.

- Used CNC Machines: More affordable, but you must inspect them carefully for wear, accuracy issues, and outdated software.

If you go the used route, buy from reputable dealers, and check the machine’s maintenance history before purchasing.

Essential Tools and Accessories

Your CNC machine is only as good as the tools and accessories supporting it. Here’s what you need to operate efficiently:

- Cutting Tools and Inserts: End mills, drill bits, lathe tools—invest in high-quality tooling to ensure precision and durability.

- Workholding Equipment: Vices, clamps, and fixtures to secure parts during machining.

- Coolant and Lubrication Systems: Prevents overheating and extends tool life.

- Measuring and Inspection Tools: Micrometers, calipers, and coordinate measuring machines (CMM) ensure precision and quality control.

- Dust and Chip Extraction System: Essential for keeping your workspace clean and preventing damage to your machine.

Skipping on tooling is a mistake. Poor-quality tools lead to inefficiency, rework, and wasted materials—which costs you money.

Financing Options

CNC machines aren’t cheap, and if you don’t have the cash to buy everything upfront, financing can be a smart option. Here’s how businesses typically fund their equipment:

- Equipment Leasing: Pay monthly instead of upfront; a good option if you need machines but want to preserve cash flow.

- Bank Loans and SBA Loans: Business loans with structured payment plans to help you spread the cost.

- Vendor Financing: Some CNC machine dealers offer in-house financing with flexible terms.

- Buying Used With Payment Plans: Some suppliers allow installment payments for pre-owned machines.

Step#6 Source Raw Materials

When I first helped set up a CNC shop, I thought the hardest part would be choosing the right machines. But I quickly realized something: Without quality materials, even the best machines are useless.

Raw materials determine everything—precision, durability, profitability. If you source cheap, inconsistent stock, you’ll waste hours adjusting settings, fixing defects, and dealing with frustrated customers. But if you find the right suppliers, your production runs smoothly, your parts meet industry standards, and your profits stay strong.

Here’s how to source materials the right way.

Raw Materials Needed

Your material choices depend on your niche and customers. Are you making aerospace-grade aluminum parts? High-strength steel components? Precision plastic molds? Each material has its own cost, machining properties, and sourcing challenges.

Here are some of the most commonly used CNC materials:

- Metals: Aluminum, steel, stainless steel, titanium, brass, copper.

- Plastics: ABS, polycarbonate, nylon, PEEK.

- Composites: Carbon fiber, fiberglass-reinforced plastics.

- Wood (for CNC Routers): Hardwood, plywood, MDF.

If your parts need to meet strict industry specs (aerospace, medical, automotive), your materials must be certified to specific standards.

Find Reliable Suppliers

The biggest mistake I see CNC businesses make is buying from the cheapest supplier available. Yes, you need to control costs—but cutting corners on material quality will lead to scrapped parts, production delays, and lost customers.

Here’s how to find trusted material suppliers:

- Local Metal Distributors: Fast delivery, better quality control, and the ability to inspect stock in person.

- National/Global Suppliers: Companies like Ryerson, OnlineMetals, and McMaster-Carr offer bulk pricing and a wide selection.

- Direct from Mills or Manufacturers: Best for high-volume orders, but requires larger purchases.

- Industrial Scrap and Surplus Suppliers: Great for small batches or prototyping, but quality varies.

When choosing a supplier, don’t just compare prices—ask about:

- Consistency: Do they provide the same material grade every time?

- Lead Times: Can they deliver materials when you need them?

- Minimum Order Quantities: Are you locked into buying more than you need?

- Certifications: Can they provide material certificates if your industry requires them?

Step#7 Learn CNC Programming & Machining Techniques

The first time I watched a CNC machine in action, I was blown away. A raw block of metal transformed into a precision part, cut with perfect accuracy. It looked effortless—until I tried programming a machine myself.

That’s when I realized: CNC machining is only as good as the person operating it. Even the most expensive machine won’t produce quality work if the programming is wrong or the machining techniques are sloppy.

If you want a profitable CNC business, you (or your team) need to master both programming and machining skills. Here’s how to do it.

Learn the Language

CNC machines don’t just “know” what to do—you have to tell them through programming. The 2 core languages in CNC are:

- G-Code: Controls the movement of the machine (where to cut, how fast, and at what depth).

- M-Code: Handles auxiliary functions (tool changes, coolant, spindle on/off).

Most modern CAD/CAM software generates G-code automatically, but you still need to understand it. A single programming error can ruin a part—or worse, damage your machine.

Master CAD/CAM Software

Gone are the days of writing G-code line by line. Today, most CNC businesses use CAD/CAM software to design parts and generate toolpaths.

The most widely used programs include:

- Fusion 360: Affordable and powerful, great for small businesses.

- Mastercam: Industry standard for advanced machining.

- SolidWorks + CAMWorks: Best for complex part design and manufacturing integration.

- AutoCAD: Used in many industries for technical drawings.

If you’re not comfortable with CAD/CAM yet, invest time in online courses, tutorials, or hands-on training. The better you understand the software, the faster and more accurately you can produce parts.

Machining Techniques

CNC programming gets the machine moving, but machining techniques determine part quality, efficiency, and profitability. Here’s what you need to focus on:

- Feeds and Speeds: Setting the right cutting speed and feed rate for different materials. Too slow? Wasted time. Too fast? Tool breakage.

- Workholding and Fixturing: Securing the material properly to avoid vibrations, shifting, or inaccuracies.

- Tool Selection: Using the right cutting tools for the material and job type (end mills, drills, inserts, etc.).

- Coolant and Lubrication: Preventing overheating, extending tool life, and improving surface finish.

- Surface Finishing: Understanding roughing vs. finishing passes to achieve the desired quality.

Step#8 Set Up Your CNC Workshop or Facility

When I helped set up my first CNC workshop, I made a crucial mistake—I focused only on the machines. I thought, “If I have the right equipment, I’m good to go.” But soon, I realized workflow, layout, and organization matter just as much as the machines themselves.

A poorly designed shop slows you down, increases errors, and eats away at profits. But a well-planned facility boosts efficiency, reduces waste, and creates a smoother production process.

Here’s how to set up a CNC workshop that works.

Choose the Right Location

Your CNC facility should match your business size, production needs, and future growth. Ask yourself:

- Are you starting from a home garage or renting an industrial space?

- Do you need space for large machines and heavy material handling?

- Will you need room for future expansion?

If you’re starting small, a well-organized garage or small shop may be enough. But if you’re aiming for high production volumes, you’ll need a larger, industrial space with proper infrastructure.

Plan Your Shop Layout

A CNC workshop isn’t just a room with machines—it’s a production system. The way you set up your machines, workstations, and storage affects how fast and accurately you produce parts.

Follow these key principles:

- Create a Logical Workflow: Arrange machines in a way that minimizes unnecessary movement. Materials should flow from storage to machining to finishing, to shipping.

- Allow Enough Space Around Machines: Operators need room to load materials, change tools, and access control panels. Crowded work areas slow you down.

- Separate Dirty and Clean Areas: Keep machining separate from programming, inspection, and packaging to avoid contamination.

- Make Safety a Priority: Clear emergency exits, fire extinguishers, and safety signage are non-negotiable.

Set Up Essential Infrastructure

CNC machines need more than just a power outlet—you’ll need to set up the right infrastructure to keep your shop running smoothly.

- Electrical Supply: CNC machines require 3-phase power and dedicated circuits. Make sure your facility can handle the load.

- Ventilation and Dust Collection: Metal chips, wood dust, and coolant fumes can be hazardous. Install proper exhaust fans and filtration systems.

- Compressed Air System: Many CNC machines use air-powered tool changers and coolant misting systems. A good air compressor is essential.

- Workbenches and Tool Storage: Organize cutting tools, measuring equipment, and fixtures to reduce setup time and improve efficiency.

- Inspection and Quality Control Area: Set up a station with calipers, micrometers, and surface gauges to check part accuracy before shipping.

Step#9 Develop a Marketing Strategy

You’ve got your CNC machines. Your workshop is set up. Now, there’s just one problem: Without customers, your machines are just expensive paperweights.

I’ve seen CNC businesses struggle—not because they lacked skill or quality machines, but because they didn’t know how to attract customers. You can have the best CNC shop in the world, but if no one knows about it, you won’t make a dime.

Here’s how to market your CNC business effectively and consistently bring in clients.

Build a Strong Online Presence

In today’s world, if you’re not online, you don’t exist. Many CNC businesses rely on word of mouth and local connections, but the most successful ones dominate online. Here’s what you need:

- A Professional Website: Your site should clearly explain what CNC services you offer, what industries you serve, and how to get a quote.

- Search Engine Optimization (SEO): Optimize your site, so businesses looking for CNC services find you on Google. Focus on keywords like “custom CNC machining” or “precision CNC parts supplier.”

- Google My Business Listing: Show up in local searches when nearby businesses look for CNC services.

- LinkedIn Networking: Connect with manufacturers, engineers, and business owners who might need your services.

- YouTube or Instagram Content: Share videos of your CNC process, showcasing precision cuts, engraving, or prototype work.

Use Direct Outreach to Land Clients Fast

If you’re just starting, don’t sit around waiting for customers to find you. Go after them.

- Cold Emailing & Calls: Identify businesses that use CNC machining and send them a simple, direct offer.

- Networking With Machine Dealers & Manufacturers: Partner with existing businesses that need reliable CNC services.

- Industry Trade Shows & Events: Attend manufacturing expos to connect with buyers looking for CNC partners.

Offer Competitive Pricing & Discounts for First-Time Clients

When you’re new, it’s hard to win customers over big, established CNC shops. A smart way to build trust and get your foot at the door is to:

- Offer discounts on the first order to encourage businesses to try your services.

- Provide fast turnaround times to beat competitors who are slow.

- Highlight quality assurance by offering sample parts or prototype machining.

Build a Referral Network

One of the best ways to grow your CNC business without spending a fortune on ads is through referrals.

- Ask satisfied customers to refer you. Many business owners trust recommendations from other companies.

- Offer incentives for referrals. Give a discount or small bonus to businesses that send new clients your way.

- Partner with related businesses. Machine dealers, metal suppliers, and engineering firms can refer work to you when their clients need machining services.

Step#10 Expand Your CNC Business

Once your CNC business is running successfully, the next step is scaling and expanding to increase profitability and market reach. Growth requires strategic planning, investment in resources, and process optimization to handle more clients and larger projects.

Here’s how to expand your CNC business the right way.

Increase Production Capacity

As demand for your CNC services grows, you may need to increase output without compromising quality or efficiency. Consider:

- Investing in Additional CNC Machines: Expanding your machine fleet allows you to take on higher-volume orders and diversify services.

- Automating Processes: Implement robotic loading systems, tool changers, and software automation to reduce manual labor and increase efficiency.

- Hiring Skilled Operators: Bringing in experienced machinists and CNC programmers ensures consistent production quality.

Offer New CNC Services

Expanding your capabilities can open new revenue streams. Consider adding:

- 5-Axis Machining: Allows for more complex and high-precision part production.

- Laser Cutting and Engraving: A profitable add-on for industries needing marking and custom engraving.

- CNC Prototyping: Working with engineers and manufacturers to produce low-volume, high-precision prototypes.

- CNC Repair and Maintenance Services: Providing repair, retrofitting, and maintenance for other CNC businesses.

Conclusion

Starting a CNC business can feel overwhelming. But when you break it down—choosing a niche, setting up your workshop, learning the skills, and marketing your services—it becomes a clear, step-by-step process.

I remember when I first got into CNC, unsure where to start. But taking that first step changed everything. Now, it’s your turn.

The best time to start? Now.

The only thing standing between you and a profitable CNC business is action.

Let’s talk about your next step.

Contact us today—we’re here to help you get started.

Explore Related Resources

For more helpful content, explore our collection of recommended reads:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.