I remember standing in a workshop for the first time, surrounded by machines humming with precision. It was exciting—until I had to pick the right one for my project. Should I go with a CNC router? A milling machine? What about a lathe? Each machine had strengths, but I didn’t know which was best for the job.

If you’re here, you might be in the same situation. Choosing the right CNC machine can feel overwhelming. There are so many types, each designed for different tasks, materials, and industries. That’s where this guide comes in.

I’ve spent years working with CNC machines, testing their capabilities, and learning what makes them tick. Whether you’re a machine dealer, repair technician, or a furniture maker looking for precision, I’ve got insights to share.

By the end of this article, you’ll understand the 8 major types of CNC machines, what they do, and which one fits your needs.

So let’s get started!

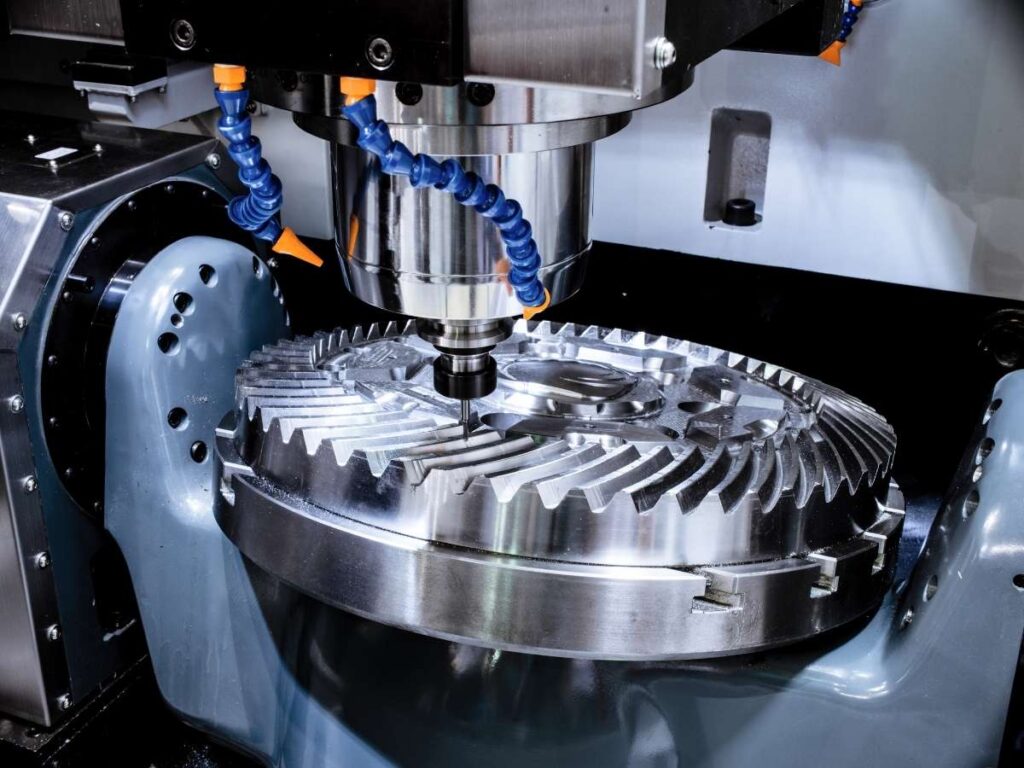

1. CNC Milling Machines

The first time I saw a CNC milling machine in action, I was hooked. The precision. The speed. The way it could cut through metal like butter. It was clear—this machine was a game-changer.

CNC (Computer Numerical Control) milling machines shape and cut solid materials with extreme accuracy. They use rotating cutting tools to remove material from a workpiece, following programmed instructions. Unlike manual mills, CNC mills run on software, reducing human error and improving consistency.

Applications and Industries

- Automotive: Creating engine parts and brackets.

- Aerospace: Machining lightweight, high-strength components.

- Mold Making: Producing injection molds and custom dies.

- Metal Fabrication: Shaping aluminum, steel, and titanium parts.

Advantages of CNC Milling Machines

- Precision: Cuts within microns of accuracy.

- Versatility: Works with metals, plastics, and composites.

- Complexity: Handles intricate designs and multi-sided machining.

Why Choose a CNC Milling Machine?

CNC milling machines are ideal for high-precision work, multi-sided machining, and automation. They handle a variety of materials and come with features like automatic tool changers and cooling systems. If you need speed, accuracy, and repeatability, a CNC mill is a solid choice.

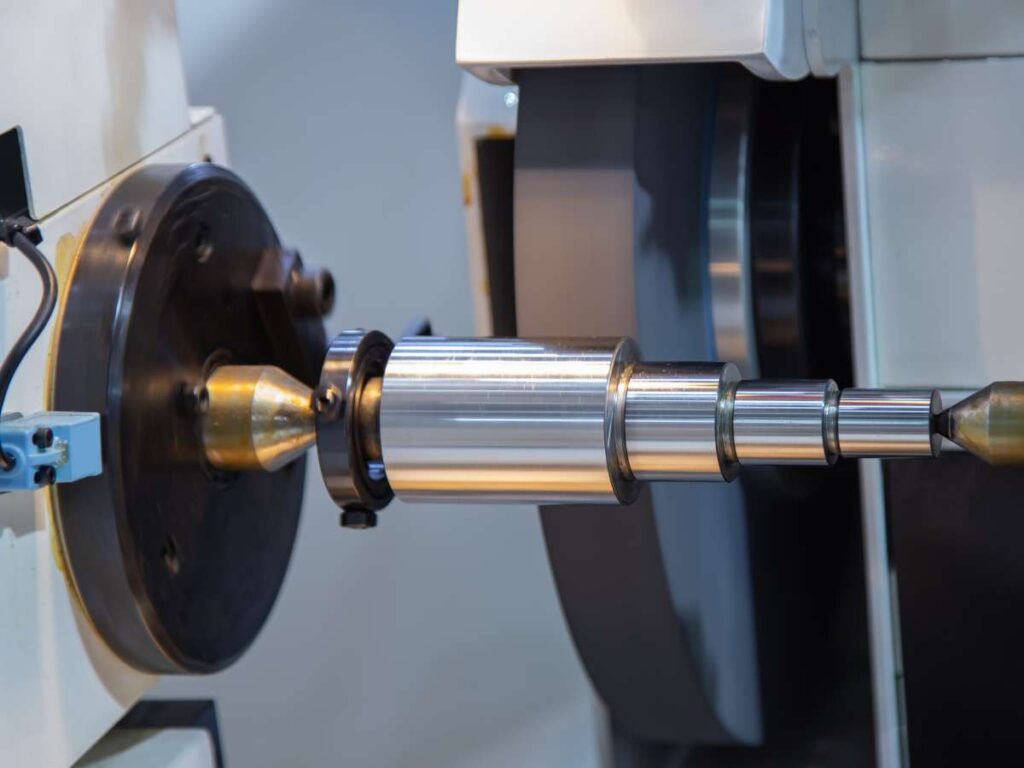

2. CNC Lathes

I once watched a machinist turn a simple metal rod into a perfectly threaded bolt in minutes. The precision was unbelievable. Every cut was smooth. Every detail was exact. That’s the power of a CNC lathe.

CNC (Computer Numerical Control) lathes rotate a workpiece while a cutting tool removes material. Unlike milling machines, which are cut from different angles, lathes specialize in shaping cylindrical parts. The workpiece spins at high speed while the tool carves, shaves, or drills into it.

Applications and Industries

- Automotive: Producing shafts, bushings, and pistons.

- Aerospace: Creating high-strength, lightweight components.

- Manufacturing: Making industrial fittings, rings, and custom hardware.

Advantages of CNC Lathes

- Speed: Produces parts quickly.

- Accuracy: Cuts within tight tolerances.

- Material Versatility: Works with metals, plastics, and ceramics.

- Automation: Runs continuously, improving efficiency.

Why Choose a CNC Lathe?

A CNC lathe is ideal if you need fast, precise machining for cylindrical parts. It allows for automation, reducing labor while increasing output. When selecting one, consider spindle speed, turret capacity, and workpiece size. If precision and efficiency are priorities, a CNC lathe is a strong investment.

3. Blue Elephant CNC Routers

A friend of mine once struggled with cutting intricate wood designs by hand. He spent hours sanding and shaping, only to end up with uneven edges. Then, he discovered a Blue Elephant CNC router—and everything changed.

Blue Elephant is a well-known manufacturer of high-precision CNC routers. These machines cut, engrave, and carve materials with speed and accuracy. Unlike traditional methods, a CNC router follows programmed designs, making each cut identical to the last. Whether you’re working with wood, plastic, or metal, Our CNC router delivers smooth, detailed results.

Applications and Industries

- Furniture Making: Creating cabinets, doors, and custom pieces.

- Signage: Cutting and engraving letters, logos, and decorative panels.

- Woodworking: Crafting sculptures, frames, and moldings.

- Interior Decoration: Producing wall panels, ceiling patterns, and custom designs.

Advantages of Blue Elephant CNC Routers

- High-Speed Cutting: Advanced spindles allow for fast, smooth operation.

- User-Friendly Software: Compatible with popular design programs.

- Customizable Features: Machines can be tailored to fit different needs.

Why Choose a Blue Elephant CNC Router?

A Blue Elephant CNC router is a great option if you need precision, speed, and flexibility. Worktable size matters, especially for larger projects. Material compatibility is another factor since some models handle aluminum better than others. Software integration plays a role too, as an intuitive system can streamline your workflow.

4. CNC Plasma Cutters

If you work with metal, you know how tough it can be to cut thick steel or aluminum with precision. That’s where a CNC plasma cutter comes in. It’s fast, powerful, and cuts through metal with ease.

A CNC (Computer Numerical Control) plasma cutter uses an ionized gas jet to slice through metal. The gas heats up to extreme temperatures, turning into plasma that melts the material while a high-speed air jet blows the molten metal away. This creates clean, precise cuts without direct contact.

You’ll find 2 main types of CNC plasma cutters:

- Table-Type Systems: Large, stationary machines with a fixed cutting bed, perfect for high-volume production.

- Portable Plasma Cutters: Smaller, mobile units that allow you to work on-site or handle custom projects.

Applications and Industries

- Metal Fabrication: Cutting steel for machines, tools, and structures.

- Shipbuilding: Shaping large steel plates for hulls and frames.

- Construction: Producing metal reinforcements, beams, and panels.

- Automotive Repair: Modifying and restoring vehicle frames and parts.

Advantages of CNC Plasma Cutters

- Faster than oxy-fuel cutting, which means you save time.

- More affordable than laser cutting, making it a cost-effective option.

- Capable of automation, so you can produce identical parts with less waste.

Why Choose a CNC Plasma Cutter?

If you need a machine that cuts metal fast and doesn’t break the bank, a CNC plasma cutter is a great option. Cutting speed and thickness capacity are important factors—some models can handle half-inch steel, while others cut up to two inches. Table size matters too, especially if you work with large metal sheets. You’ll also need to consider ventilation, since plasma cutting creates heat, fumes, and smoke that require proper extraction.

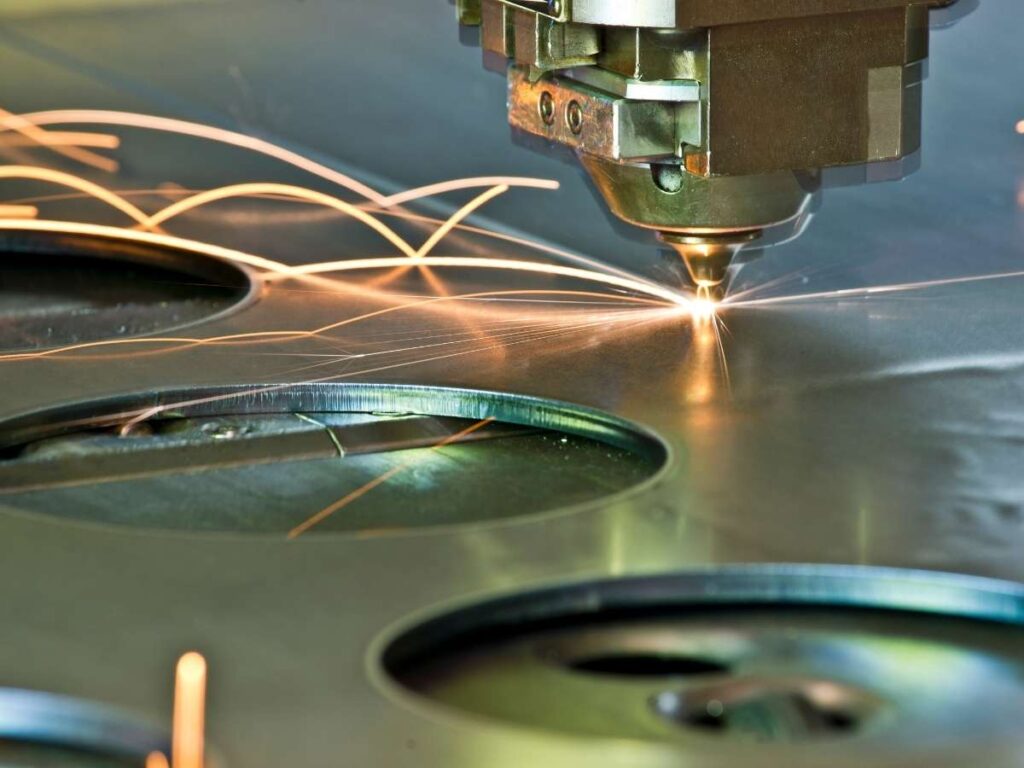

5. CNC Laser Cutters

Cutting detailed patterns into wood or metal by hand is slow and frustrating. The edges never come out as clean as expected, and mistakes waste material. A CNC laser cutter solves these problems by using a high-powered laser beam to cut, engrave, or etch materials with extreme accuracy.

Unlike traditional cutting tools, a laser cutter doesn’t rely on physical contact. Instead, it melts, burns, or vaporizes material, creating precise, smooth edges without the need for sanding or finishing.

There are 3 main types of CNC laser cutters:

- CO₂ Lasers: Best for wood, acrylic, plastic, glass, and leather. These are commonly used for signage and engraving.

- Fiber Lasers: Ideal for metals like steel, aluminum, and brass. They offer high-speed cutting and deep penetration.

- Diode Lasers: Smaller, less powerful, and mainly used for engraving and light cutting on wood, leather, and soft metals.

Applications and Industries

- Jewelry: Engraving fine details on rings, pendants, and watches.

- Signage: Cutting custom letters, logos, and decorative panels.

- Medical: Producing precise surgical tools and implants.

- Automotive: Cutting lightweight, high-strength parts for vehicles.

Advantages of CNC Laser Cutters

- Non-contact cutting reduces wear and tear on the machine.

- Extreme accuracy allows for engraving and fine detailing.

- Energy-efficient operation lowers running costs.

- Minimal maintenance compared to plasma or mechanical cutters.

Why Choose a CNC Laser Cutter?

If precision, efficiency, and versatility matter to you, a CNC laser cutter is a great choice. The power output determines what materials you can cut—higher wattage handles thick metals, while lower power is perfect for engraving. A cooling system is also important to prevent overheating during operation.

Software compatibility makes a difference too. Many CNC laser cutters work with popular CAD and design programs, allowing for smooth automation and mass production. If your projects require intricate cutting or engraving, a CNC laser cutter will help you create clean, professional results with minimal effort.

6. CNC Electric Discharge Machines (EDM)

Some metals are just too tough for traditional cutting tools. If you’ve ever struggled with machining hardened steel or intricate shapes, you know how frustrating it can be. That’s where CNC Electric Discharge Machines (EDM) come in.

CNC EDM machines use electrical discharges (sparks) to shape metal instead of cutting it with a blade. The process happens under a dielectric fluid, which helps control the sparks and prevent overheating.

There are 2 main types of EDM machines:

- Wire EDM: Uses a thin wire as an electrode to cut through metal with extreme precision.

- Sinker EDM: Uses a shaped electrode to press into the material and erode it into the desired form, perfect for deep cavities and molds.

Applications and Industries

- Aerospace: Cutting heat-resistant alloys for engine components.

- Mold Manufacturing: Producing precise molds for plastic injection and die casting.

- Precision Tooling: Shaping small, intricate parts for electronics and medical devices.

Advantages of CNC EDM Machines

- High precision: Achieves detail that’s nearly impossible with traditional cutting tools.

- Works on heat-resistant materials: Ideal for hardened steel, titanium, and carbide.

- No direct contact: Reduces tool wear and eliminates mechanical stress on the part.

Why Choose a CNC EDM Machine?

If you work with hardened metals or need fine, detailed machining, a CNC EDM machine is worth considering. The type of material matters—EDM works best on conductive metals like steel, copper, and tungsten. The size and shape of your workpiece also play a role, as wire EDM is better for thin, precise cuts, while sinker EDM is ideal for deep cavities and mold-making.

Processing time is another factor. EDM is slower than traditional milling but makes up for it with unmatched accuracy. Power consumption can also be high, so you’ll want to factor that into your costs.

7. CNC Grinding Machines

There’s something satisfying about a perfectly smooth surface. No rough edges, no imperfections—just flawless precision. That’s exactly what CNC grinding machines are designed to achieve.

CNC (Computer Numerical Control) grinding machines use abrasive wheels to remove tiny amounts of material and create highly precise finishes. Unlike cutting machines that shape a part by removing large sections, grinding machines focus on refining the surface with extreme accuracy.

There are 3 main types of CNC grinding:

- Surface Grinding: Flattens and smooth surfaces, ideal for metal sheets and blocks.

- Cylindrical Grinding: Shapes the outer surface of round objects like shafts and rollers.

- Tool Grinding: Sharpens cutting tools, extending their lifespan and improving performance.

Applications and Industries

- Automotive: Refining engine components, gears, and brake parts.

- Aerospace: Perfecting turbine blades, landing gear, and structural components.

- Tool Manufacturing: Sharpening drills, milling cutters, and machine tools.

- Medical Equipment: Creating surgical tools and implantable medical devices.

- Metalworking: Producing smooth, durable parts for industrial machines.

Advantages of CNC Grinding Machines

A machinist once described CNC grinding as “the difference between good and perfect.” He had spent years trying to manually smooth out hardened steel, but even his best work couldn’t match the flawless precision of a CNC grinding machine.

- Incredible accuracy: Achieves tolerances within microns.

- Superior surface finish: Produces ultra-smooth results without imperfections.

- Works with tough materials: Handles hardened steel, tungsten carbide, and ceramics.

- Automated and repeatable: Ensures every part is identical with minimal operator effort.

Why Choose a CNC Grinding Machine?

If you need precision, smooth finishes, and reliability, a CNC grinding machine is an essential tool. The type of grinding machine matters—cylindrical grinding is best for round parts, surface grinding is ideal for flat components, and tool grinding is a must for sharpening cutting tools.

A CNC grinding machine isn’t just a tool—it’s the final step in creating parts that meet the highest standards.

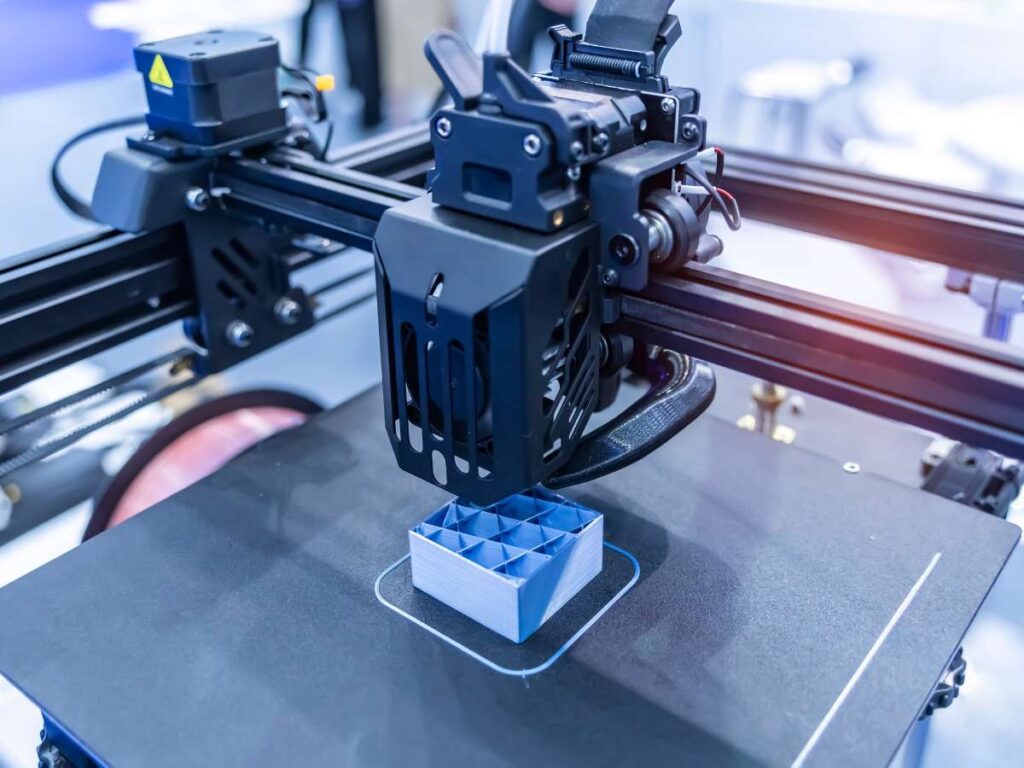

8. CNC 3D Printers

A machinist once told me how he spent weeks shaping a custom metal bracket by hand. The process was slow, costly, and frustrating. Then he switched to a CNC 3D printer. Within hours, he had a finished prototype—strong, precise, and ready for testing.

Unlike traditional CNC machines that cut away material, CNC 3D printers build objects layer by layer using a process called additive manufacturing. This method allows for complex geometries, reduced waste, and faster production times.

There are different types of 3D printing technologies, including:

- Fused Deposition Modeling (FDM): Uses a heated nozzle to extrude plastic layer by layer.

- Stereolithography (SLA): Uses a laser to cure liquid resin into a solid shape.

- Selective Laser Sintering (SLS): Fuses powdered materials into solid parts using a high-powered laser.

Applications and Industries

- Fashion & Jewelry: Creating custom rings, intricate watch parts, and even 3D-printed clothing.

- Dentistry: Producing crowns, bridges, and dental aligners tailored to individual patients.

- Education: Allowing students and engineers to create functional prototypes and test designs.

- Food Industry: Developing custom chocolate molds and 3D-printed edible decorations.

- Defense & Firearms: Prototyping weapon components and protective gear for military applications.

Advantages of CNC 3D Printers

- Unmatched complexity: Creates intricate designs that traditional machining can’t.

- Minimal material waste: Uses only what’s needed, reducing costs.

- Fast production: Makes functional parts in hours, not weeks.

- Custom manufacturing: Perfect for one-off designs and short-run production.

Why Choose a CNC 3D Printer?

If you need a machine that builds rather than cuts, a CNC 3D printer is a powerful tool. The type of material matters—plastics work well for rapid prototyping, while metals and ceramics provide industrial-grade durability. Print speed, resolution, and build volume also impact what you can produce.

CNC 3D printers come with a premium price, but their efficiency, speed, and ability to create intricate designs make them a smart investment for heavy-duty work. Whether you’re pushing the boundaries of design, testing new materials, or creating custom products, CNC 3D printing is revolutionizing manufacturing.

Conclusion

CNC machines are more than just tools. They are the backbone of modern manufacturing, shaping everything from aerospace components to jewelry. Whether you’re cutting, engraving, or printing, there’s a CNC machine for your needs.

Now that you know the differences, which machine suits your work best?

Don’t wait. The right CNC machine can transform your efficiency, precision, and creativity.

Contact us today and let’s find the perfect CNC machine for your needs!

Recommended Reads for You

Want to learn more? Here are some articles filled with valuable tips and information to guide you further:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.