I remember the first time I bought a used CNC lathe. It felt like a great deal. The seller assured me it was in “perfect working condition.” But the minute I turned it on, the spindle started making an awful grinding noise. Turns out, the bearings were shot. I spent more on repairs than I did on the machine itself.

If you’re here, you’re likely looking for a high-quality, budget-friendly CNC lathe—one that won’t surprise you with hidden issues.

I’ve been there. After so many years , I experience working with used CNC machines. I know what to look for and what to avoid.

In this guide, you’ll learn:

- How to spot red flags before buying

- Which features matter most to your needs

- Where to find the best deals

By the end, you’ll have the tools to find a CNC lathe that fits your budget and performs like new. No wasted money. No regrets.

So let’s begin!

1. Key Considerations Before Buying a Used CNC Lathe

Buying a used CNC lathe can be a smart investment or a costly mistake. The difference? Knowing what to look for before you buy.

I’ve seen buyers jump at a low price, only to realize later that repairs cost more than the machine itself. I’ve also seen businesses find great machines that paid for themselves in no time.

So how do you make the right choice? Here’s what you need to consider.

#1 Budget

- Does the machine need repairs?: I once saw a shop buy a used lathe for a bargain—until they had to replace the spindle. The repair cost more than the machine.

- Are replacement parts expensive?: Some brands have affordable parts. Others? You might wait months and pay a fortune.

- Will it cost more to maintain over time?: A cheap machine with high maintenance costs isn’t really cheap.

#2 Machine Condition

- Maintenance records: A machine that was serviced regularly will last longer. If there are no records, assume the worst.

- Hours of operation: A machine running 24/7 for years? Expect wear and tear.

- Test runs: I once tested a lathe that “ran fine”—until I turned it on. The spindle made a grinding noise. Bad bearings. Huge repair bill.

#3 Does It Fit Your Production Needs?

- Precision: A high-end lathe with loose tolerances? Not worth it.

- Size: I’ve seen businesses buy lathes that couldn’t handle their materials. Then they had to resell. A waste of time.

- Speed: If a machine can’t keep up with demand, it will slow down your entire operation.

#4 Can You Get Spare Parts?

- Is the manufacturer still in business?: A discontinued brand means limited support.

- Are parts available and affordable?: I once saw a buyer wait 6 months for a single component. Their production line suffered.

- Will you need custom repairs?: If only a few experts can fix the machine, it’s a risky purchase.

#5 Who Are You Buying From?

- Inspections: Dealers test machines before selling. Private sellers? Not always.

- Limited warranties: Some dealers offer short-term protection. Private sales? You’re on your own.

- Support after purchase: A good dealer helps you troubleshoot issues. A private seller disappears once the deal is done.

2. Advantages of Buying Used CNC Lathe Machines

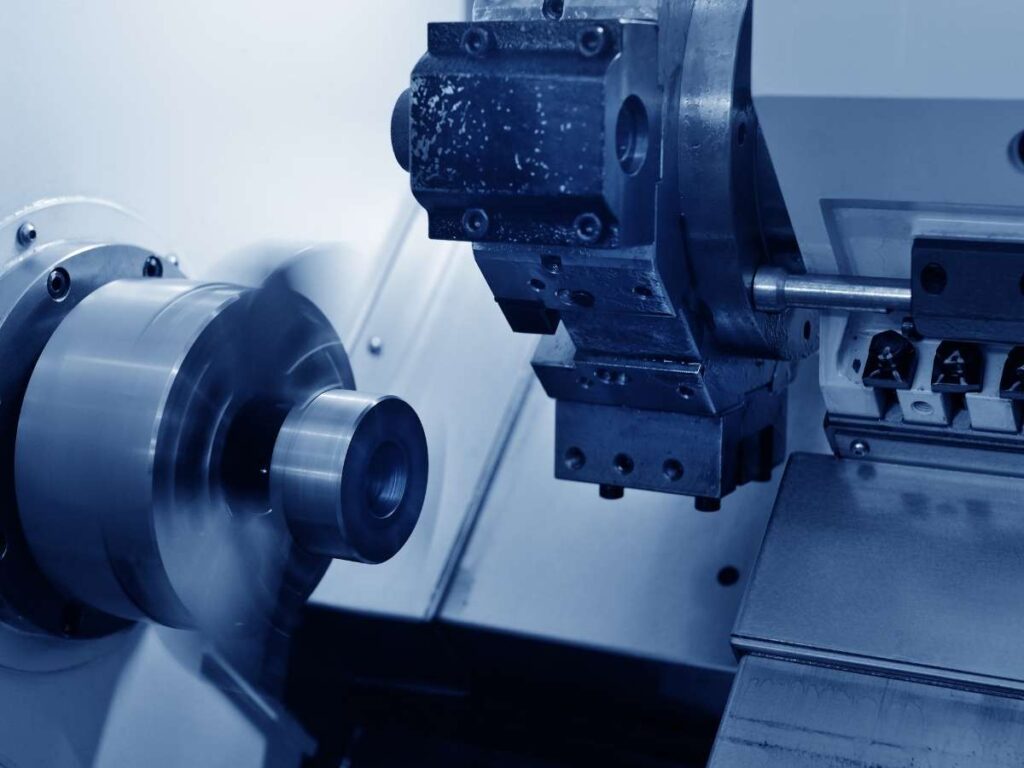

A CNC lathe is a big investment. Buying used can save money and open doors to better machines—if you choose wisely. Let’s talk about why a used CNC lathe might be the best decision for your business.

I remember standing in front of 2 machines—one brand new, one used. The new one had all the latest features, but the price was painful. The used one? Well-maintained, half the cost, and already proven in production. “Do I really need brand new?” I asked myself. That day, I learned that smart buyers look beyond the shine of new equipment. They focus on value, reliability, and performance.

Lower Cost, Bigger Savings

A used CNC lathe can cost 30% to 60% less, making it a smart financial move. Instead of draining capital on equipment, businesses can put those savings into tooling, upgrades, or expanding production. The right machine will pay for itself faster without adding unnecessary debt.

However, a low price alone doesn’t mean a good deal. Machines with poor maintenance histories or worn-out components can lead to unexpected repair costs. That’s why checking service records and inspecting wear points is critical before buying.

No Waiting—Buy & Start Using It

Time is money, and downtime is expensive. Used CNC lathes are typically ready for purchase and installation without waiting. Businesses needing to replace a machine or expand operations can get up and running quickly.

Availability also means more flexibility in choosing a machine that fits specific needs. Instead of being limited by production schedules, buyers can focus on finding a machine that’s ready to work right away. This reduces delays and helps maintain steady production.

Proven Reliability & Performance

Used CNC lathes have a track record. Buyers can check how well a machine has performed, how often it has been serviced, and whether it has had any major breakdowns. This eliminates guesswork.

A machine with a strong maintenance history and reliable performance data is a safer investment. Unlike an untested piece of equipment, a well-maintained machine has already proven it can handle real production demands.

Access to High-End Machines at a Fraction of the Cost

Buying used opens the door to higher-quality machines that might have been too expensive when new. Instead of compromising on features, buyers can invest in models that offer better precision, greater durability, and more advanced capabilities.

A well-built, high-performance CNC lathe will continue to deliver results for years. Investing in a used premium model can provide longer service life and better machining output, giving businesses a competitive edge.

3. Disadvantages of Buying Used CNC Lathe Machines

Buying a used CNC lathe can be a smart decision, but it’s not without risks. Machines that have been in service for years come with history—both good and bad. If you don’t do your homework, you could end up with unexpected repair costs, outdated features, or performance issues.

I once saw a business pick up a used CNC lathe at an unbelievably low price. The seller said it “worked fine.” At first, it did. But within weeks, small issues started piling up. The spindle needed adjustments. The lubrication system wasn’t working properly. A few months in, they were spending more on repairs than they had saved on the purchase.

Higher Maintenance & Repair Costs

Older machines require more upkeep. Components wear down, and parts need replacement. Even a well-maintained CNC lathe will eventually need servicing more often than a new one.

The cost of repairs adds up, especially if critical parts like the spindle or motor start failing. A simple breakdown can mean days or weeks of downtime while waiting for repairs. This not only affects production but also increases costs.

A machine with an unclear maintenance history is even riskier. Without records, there’s no way to know how much wear and tear it has already endured.

No Warranty

Most used CNC lathes come without a warranty. If something breaks, you’re responsible for the repairs. Unlike new machines, which often come with service contracts and support, a used machine is sold as-is.

Some dealers offer short-term warranties or service agreements, but private sellers usually don’t. If a major component fails, repair costs could be thousands of dollars. For some businesses, that risk is too high.

Outdated Technology & Features

CNC technology is constantly evolving. Older machines lack modern automation, advanced software, and efficiency improvements that newer models have. This can slow down production, increase labor costs, and limit the types of jobs the machine can handle.

Certain features, like touchscreen interfaces, faster tool changers, and improved energy efficiency, may not be available on an older machine. If you need the latest tech for precision work or high-speed production, a used CNC lathe may not be the best option.

Uncertain Machine Condition

Every used machine has a past. Some have been well taken care of, while others have been pushed to their limits. The problem? It’s not always easy to tell which one you’re getting.

A CNC lathe might look fine on the surface but have hidden issues that aren’t obvious until you start running it. Bearings might be worn. Electronics could be unreliable. The bed could have slight damage that affects precision.

Without a full inspection or test run, you’re taking a risk. If the seller is unwilling to provide maintenance records or let you test the machine, that’s a red flag.

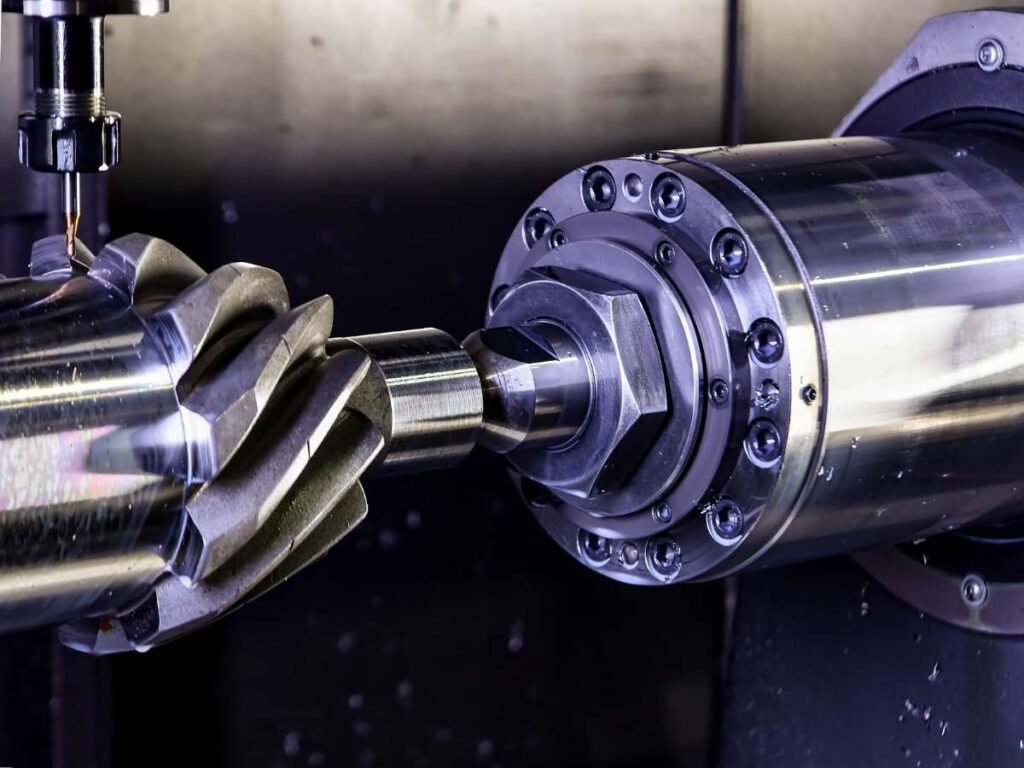

4. How to Inspect a Used CNC Lathe Before Buying

Buying a used CNC lathe can save you money, but only if you choose the right machine. The wrong one could lead to constant repairs, lost production time, and unexpected costs. Before making a purchase, you need to inspect the machine thoroughly to make sure it’s in good condition.

Skipping this step could leave you with a machine that breaks down days after you start using it. Here’s what you need to check.

Check Physical Condition

Start with a visual inspection. Look for rust, cracks, worn-out parts, and oil leaks. Surface wear is normal, but deep cracks or corrosion can be signs of serious problems.

Pay close attention to the guideways, ball screws, and tool turret. These parts should be clean and free of excessive wear. If a machine looks poorly maintained on the outside, it’s likely worse on the inside.

Review Spindle Hours & Usage History

A CNC lathe’s spindle hours tell you how much work it has done. Machines that have run nonstop for years may have worn-out bearings, loose components, and hidden issues.

Ask for maintenance records. A well-maintained machine with high hours can still perform well, but a neglected machine with fewer hours can be a disaster.

If the seller won’t provide service history, that’s a red flag.

Test Machine Performance

Never buy a used CNC lathe without testing it first. Ask the seller to run a sample operation. Listen to unusual noises, watch how smoothly it moves, and check for vibrations or lag.

Make sure it holds tolerance. If the machine can’t cut accurately, it’s not worth the risk.

Examine Electrical & Control Systems

Check the CNC control panel, wiring, and connections. Look for frayed wires, damaged connectors, or outdated software. Older machines may not be compatible with modern programs or tool paths.

If the control system is obsolete or difficult to repair, it could be costly to upgrade later.

Verify Availability of Spare Parts

Some older CNC lathes are difficult to repair because parts are discontinued. Check if essential components like spindles, drives, and circuit boards are still available.

If parts are expensive or hard to find, you could end up with a machine you can’t fix.

5. Comparing New vs. Used CNC Lathe Machines

A small machining shop needed a CNC lathe. Business was growing, and demand was increasing. The owner had a decision to make: buy a used machine, or invest in a brand-new model.

The right choice came down to cost, performance, and long-term needs. Here’s how the 3 options compared.

| Factor | Used CNC Lathe | New CNC Lathe |

| Initial Cost | Lower purchase price, typically 30%–60% cheaper than new machines. | High initial investment, often requiring significant capital. |

| Long-Term Cost | Higher maintenance expenses due to wear and possible part replacements. | Lower maintenance costs in the first few years, covered by warranty support. |

| Availability | Ready for immediate purchase and installation. | Longer lead times due to manufacturing and shipping delays. |

| Machine Condition | Condition varies; wear and tear depends on previous usage and maintenance history. | Brand new, in perfect condition, with zero operating hours. |

| Technology & Features | May lack modern automation, software updates, and energy efficiency improvements. | Includes latest CNC control systems, automation, and precision features. |

| Performance & Precision | Performance depends on machine age; accuracy may decline over time. | Higher precision, better efficiency, and improved speed. |

| Warranty & Support | No or limited warranty; buyer takes full responsibility for repairs. | Manufacturer warranty provides coverage for defects and support. |

| Customization | Limited; older models may not support software upgrades or modifications. | Fully customizable to fit specific production needs and automation setups. |

| Spare Parts Availability | May be difficult to find discontinued parts, increasing downtime risk. | Spare parts readily available, often stocked by the manufacturer. |

| Operational Downtime | Higher risk of unexpected breakdowns leading to production delays. | Lower risk of major failures due to new components and warranty protection. |

| Resale Value | Lower resale value; machines depreciate faster after heavy use. | Holds value longer, especially premium brands with strong demand. |

| Best For | Businesses looking for cost savings and have in-house maintenance expertise. | Companies that need long-term reliability, high precision, and modern features. |

Buying used saves money upfront but comes with maintenance risks and potential downtime. Buying new means higher costs but fewer surprises in the long run. At Blue Elephant, we help businesses find CNC lathes that match their production needs, budget, and ability to handle machine repairs.

6. Making the Best Choice for Your Needs

Choosing the right CNC lathe is more than just comparing prices. It’s about finding a machine that fits your business needs, budget, and long-term goals. A low-cost machine isn’t a good deal if it constantly breaks down, and an expensive one isn’t worth it if it puts too much pressure on your finances. Understanding when to buy used ones and when to invest in a new CNC lathe will help you make the right decision.

When to Buy a Used CNC Lathe

A used CNC lathe is a good option when keeping costs low is a priority. Many businesses choose this route when they need to expand production without spending too much upfront. If you have experienced technicians who can handle repairs and maintenance, a well-maintained used machine can still provide reliable performance.

Buying used also works if you don’t need the latest automation or efficiency improvements. Some businesses only require basic machining capabilities, and an older lathe can still handle the job. However, the risks include higher maintenance costs, outdated software, and limited access to spare parts. Without a proper inspection, you could end up with a machine that needs expensive repairs shortly after purchase.

When to Buy a New CNC Lathe

A new CNC lathe is the best choice when long-term reliability is more important than short-term savings. Businesses that depend on high-precision machining and uninterrupted production benefit from a modern machine that runs efficiently with minimal breakdowns.

At Blue Elephant, we offer new CNC lathes designed for maximum productivity, precision, and automation. Investing in a new machine means fewer unexpected repair costs and better support from the manufacturer. Newer models also provide faster machining speeds, enhanced precision, and easier programming, making them a valuable asset for long-term growth.

Conclusion

Your CNC lathe isn’t just a machine—it’s the heart of your production. Choosing the wrong one can lead to downtime, high costs, and frustration. The right one can boost efficiency, quality, and profits.

Used machines work well for budget-conscious buyers who can handle maintenance. New machines give peace of mind with reliability and the latest technology.

What does your business need most right now? Cost savings or long-term growth?

Don’t wait until you’re stuck with the wrong machine. Let’s find the right fit today.

Contact us now to get started.

Explore More Helpful Resources

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.