I once visited a factory where a single CNC machine replaced an entire team of manual operators. It wasn’t just about speed, it was about precision, consistency, and cost savings.

Businesses are always looking for ways to streamline production. CNC machines provide that edge, whether in small workshops or large-scale manufacturing plants.

With a background in industrial processes, I’ve worked closely with manufacturers who rely on CNC technology daily. This guide is based on real-world applications and industry insights.

You’ll find the top eight ways businesses use CNC machines to boost efficiency, accuracy, and scalability. If your goal is to improve production, this article will give you the information you need.

Let’s start!

1. Automotive Industry

The automotive industry relies on efficiency, precision, and scalability, three things CNC machines deliver exceptionally well. Whether it’s high-volume manufacturing or custom part production, these machines help manufacturers maintain consistency while meeting strict quality and performance standards. From machining engine components to crafting detailed interior elements, CNC technology keeps the industry moving forward.

Precision Manufacturing for Engine Components

- Cylinder Heads and Engine Blocks: CNC machines cut and shape engine components with extreme accuracy, ensuring they fit perfectly and function efficiently. Even minor inconsistencies can lead to performance issues, higher fuel consumption, or increased wear and tear.

- Transmission Components: Gears, shafts, and casings require precise tolerances for smooth performance. CNC machining enables the production of durable, high-precision parts that reduce friction and improve longevity.

- Brake System Parts: Discs, calipers, and brackets must be machined to exact specifications to ensure optimal braking performance. Any deviation can compromise vehicle safety, making precision manufacturing essential.

- Suspension and Steering Components: Parts like control arms, knuckles, and steering racks must meet tight tolerances for handling and ride quality. CNC machining allows manufacturers to produce these components with consistency across mass production.

Customization and Prototyping

- Custom Interior and Exterior Parts: Automakers use CNC machining to craft intricate dashboard panels, trims, and alloy wheels. This flexibility allows manufacturers to cater to different markets and premium vehicle segments.

- Rapid Prototyping for New Models: Before a vehicle goes into full production, engineers test multiple design variations. CNC machines help accelerate this process by producing functional prototypes with high accuracy.

- Aftermarket and Performance Parts: Performance enthusiasts and specialty manufacturers rely on CNC machining for custom exhaust systems, intake manifolds, and aerodynamic parts. These precision-made upgrades enhance vehicle performance and aesthetics.

- Electric Vehicle (EV) Component Production: The rise of EVs has increased the demand for lightweight and high-efficiency components. CNC machining plays a crucial role in manufacturing battery housings, electric motor casings, and cooling systems.

2. Aerospace Industry

When it comes to aerospace, precision isn’t just a requirement, it’s non-negotiable. Whether for commercial airplanes, military jets, or space exploration, every component must meet extreme accuracy and durability standards. CNC machining allows manufacturers to produce parts that can withstand high speeds, intense pressure, and extreme temperatures.

High-Precision Machining for Aircraft Components

- Turbine Blades and Engine Parts: Jet engines operate under extreme heat and pressure, requiring parts that are machined with microscopic accuracy. CNC machines ensure each turbine blade and engine component meets the necessary tolerances for efficiency and safety.

- Structural Components: Airframes, landing gear, and fuselage parts must be lightweight yet strong. CNC machining allows manufacturers to work with advanced materials like titanium and carbon composites without sacrificing strength.

- Fasteners and Connectors: The aerospace industry depends on thousands of bolts, rivets, and brackets that must hold up under stress. CNC machining ensures these components fit perfectly and maintain structural integrity.

- Avionics Housings and Instrumentation: Sensitive navigation and communication equipment require precision-machined housings to protect them from environmental factors. CNC machining provides the accuracy needed for these intricate components.

Innovation and Customization in Aerospace Engineering

- Prototyping for New Aircraft Designs: Before a new aircraft takes flight, manufacturers test multiple designs and materials. CNC machining accelerates this process by allowing engineers to quickly fabricate and refine complex prototypes.

- Satellite and Spacecraft Parts: From satellite brackets to propulsion system components, CNC machining plays a key role in space exploration. The ability to manufacture lightweight, high-durability parts ensures functionality in harsh space environments.

- Repair and Replacement Parts: Aircraft maintenance requires replacement parts that match the original specifications exactly. CNC machining allows aerospace companies to produce these parts quickly without compromising quality.

3. Medical and Healthcare Equipment

In the medical field, precision isn’t just about efficiency, it’s about saving lives. From surgical instruments to prosthetic implants, every component must meet exact specifications to function safely and effectively. CNC machining plays a critical role in producing these high-precision parts, ensuring they are reliable, durable, and biocompatible.

Precision Manufacturing for Medical Devices

- Surgical Instruments: Scalpels, forceps, and orthopedic tools must be crafted with exact dimensions to ensure precision in medical procedures. CNC machining allows manufacturers to produce these instruments with sharp edges and smooth finishes for safe use.

- Prosthetics and Implants: Artificial joints, dental implants, and bone plates require a perfect fit for patient comfort and long-term success. CNC machining ensures these components match a patient’s unique anatomy while using biocompatible materials like titanium.

- Diagnostic Equipment Components: MRI machines, CT scanners, and ultrasound devices require complex metal and plastic parts. CNC machining enables the production of intricate housings and support structures that maintain accuracy in medical imaging.

- Microfluidic Devices and Lab Equipment: Many modern diagnostic tools rely on tiny channels and precise fluid movement. CNC machining allows for the creation of these highly detailed components, ensuring accuracy in lab tests and research applications.

Customization and Advancements in Healthcare Technology

- Patient-Specific Medical Solutions: With advancements in medical technology, CNC machining now enables the creation of patient-specific implants and devices. This personalized approach improves patient outcomes by ensuring a perfect fit and function.

- Rapid Prototyping for New Medical Devices: Medical innovation moves quickly, requiring constant testing of new device designs. CNC machining allows researchers and manufacturers to create and refine prototypes rapidly, bringing new solutions to market faster.

- Sterile and Corrosion-Resistant Manufacturing: Medical components must withstand repeated sterilization and resist corrosion. CNC machining supports the use of stainless steel, titanium, and other medical-grade materials that meet these demanding requirements.

- Robotic Surgery and Automated Equipment Parts: The rise of robotic-assisted surgeries has increased the need for ultra-precise components. CNC machining produces the intricate gears, joints, and housings that allow these robotic systems to operate with accuracy.

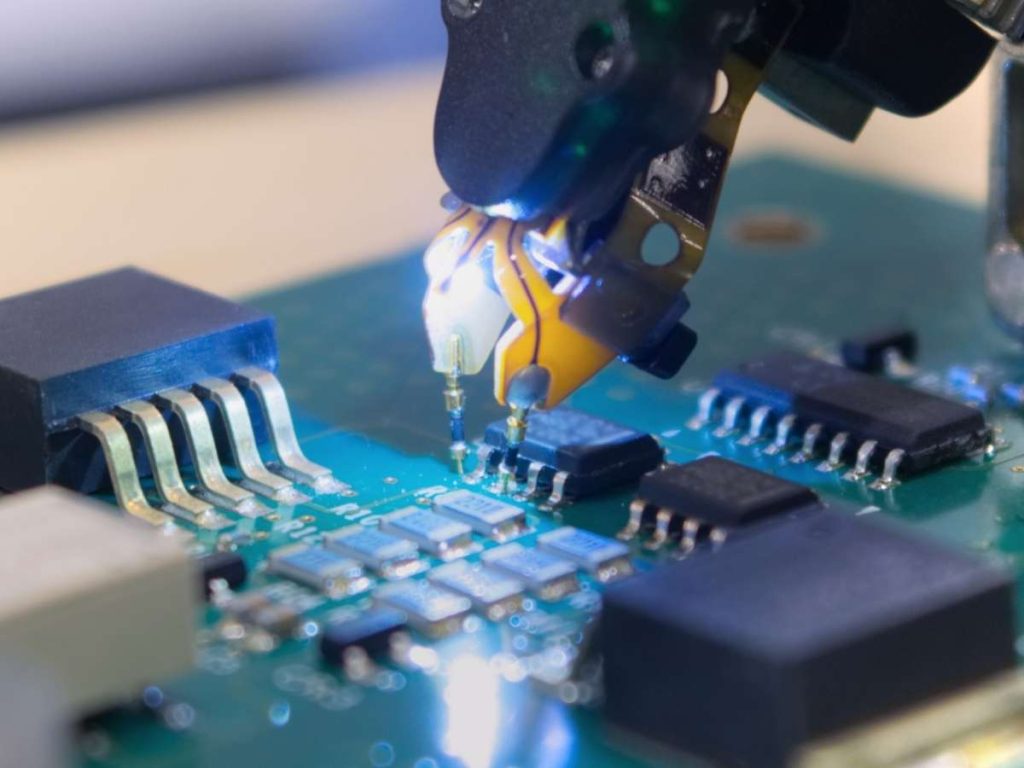

4. Electronics and Semiconductor Manufacturing

If you’ve ever opened up a computer or smartphone, you know how small and intricate the components are. Now imagine manufacturing those parts at an industrial scale with absolute precision. That’s where CNC machining comes in. Electronics and semiconductor manufacturing demand extreme accuracy, down to the micrometer level, to keep up with the increasing complexity of modern technology.

Precision Machining for Electronics Components

- Circuit Board Housings and Frames: Whether for consumer electronics or industrial machinery, circuit boards need protective casings. CNC machining ensures these enclosures are made with precise dimensions to allow proper airflow, cooling, and secure fitting.

- Heat Sinks and Thermal Management Components: Electronics generate heat, and without proper cooling, they won’t last. CNC machines create finely detailed heat sinks and thermal components that dissipate heat efficiently and extend the lifespan of devices.

- Connector Pins and Micro Components: CNC machining allows manufacturers to produce tiny, high-precision parts like connector pins and micro-screws. These parts are essential for maintaining stable connections in circuit boards and processors.

- Touchscreen and Display Casings: The smooth metal and plastic casings for tablets, laptops, and industrial touchscreens require flawless machining. CNC technology ensures consistent quality and a sleek finish that enhances both function and aesthetics.

Advancing Semiconductor Manufacturing with CNC Technology

- Wafer Processing and Silicon Components: The semiconductor industry depends on ultra-precise machining to manufacture silicon wafers and microchips. CNC machines help produce the high-tolerance tools used in the wafer-cutting and etching process.

- Prototyping for New Tech Innovations: Before a new semiconductor chip or device hits the market, engineers go through multiple iterations. CNC machining allows for rapid prototyping, helping tech companies stay ahead in innovation.

- Custom Fixtures and Test Equipment: Semiconductor testing requires specialized jigs and fixtures to hold microchips in place. CNC machining enables manufacturers to create these tools with extreme accuracy for reliable testing and calibration.

5. Metal Fabrication and Tooling

Walk into any manufacturing facility, and you’ll see metal parts everywhere, frames, enclosures, brackets, and custom tools. What you might not see is how these parts are made with exact precision, time after time. Whether for large-scale industrial applications or specialized tooling, CNC machines help businesses create high-quality metal components with minimal waste and maximum efficiency.

High-Precision Metal Fabrication

- Sheet Metal Cutting and Shaping: CNC machines cut, bend, and shape sheet metal with pinpoint accuracy. This ensures consistency across large production runs, reducing the risk of material waste and rework.

- Welding Fixtures and Assembly Jigs: Manufacturing often requires holding parts in perfect alignment before welding or assembly. CNC-machined fixtures keep everything in place, improving efficiency and final product quality.

- Custom Metal Brackets and Supports: Structural integrity matters in every industry, and CNC machining allows for the production of precise brackets and support structures. This ensures that metal components fit seamlessly into larger systems.

- Surface Finishing and Engraving: CNC machining doesn’t just shape metal, it also refines it. Businesses use it for engraving serial numbers, logos, or instructions directly onto metal parts without sacrificing durability.

Precision Tooling for Manufacturing

- Mold and Die Making: Injection molding and stamping processes rely on high-precision molds and dies. CNC machining creates these tools with fine detail, ensuring that every molded or stamped part is identical.

- Cutting and Drilling Tools: Industrial drills, cutters, and reamers must be manufactured to exact specifications. CNC machining ensures these tools maintain sharp edges and durability for high-performance applications.

- Replacement Parts and Wear Components: Over time, factory tools wear out, but CNC machining makes it easy to produce replacements. Instead of waiting for expensive imports, businesses can machine custom parts in-house.

- Prototyping for New Metal Designs: Before committing to mass production, businesses often test new metal designs. CNC machining allows companies to prototype parts quickly, making adjustments before scaling up production.

6. Furniture and Woodworking Industry

There’s something satisfying about a perfectly crafted piece of furniture, clean cuts, smooth finishes, and precise joints that fit together effortlessly. While traditional woodworking still has its place, CNC machines have transformed the industry, allowing businesses to produce high-quality furniture at scale without sacrificing craftsmanship.

Precision Cutting and Shaping for Furniture Manufacturing

- Custom Cabinetry and Wood Panels: CNC routers cut detailed designs into wood panels with a level of accuracy that’s hard to achieve by hand. This ensures seamless assembly, reducing the time and labor required for finishing work.

- Intricate Carvings and Decorative Elements: Ornate furniture designs that once took skilled artisans days to complete can now be machined in hours. CNC technology allows businesses to replicate detailed carvings consistently, even on large production runs.

- Seamless Joinery and Assembly: Mortise and tenon joints, dovetails, and other complex joinery methods are easier to produce with CNC machining. This improves structural integrity while maintaining the elegance of traditional craftsmanship.

- Textured and 3D Surface Engraving: CNC machines can create textured wood surfaces for modern furniture designs. From subtle grain enhancements to deep 3D carvings, this technology opens new design possibilities.

Efficiency and Customization in Woodworking

- Mass Production with Consistency: Whether producing a hundred dining tables or a thousand chair legs, CNC machines deliver precise cuts every time. This level of consistency minimizes waste and speeds up the production process.

- Rapid Prototyping for New Designs: Furniture designers can test and refine concepts quickly with CNC machining. This allows businesses to adjust dimensions, experiment with materials, and finalize designs before committing to full-scale production.

- Personalized and Custom Furniture Pieces: CNC technology makes it easier to create unique, made-to-order pieces for high-end clients. Whether it’s a company logo carved into a conference table or a custom bookshelf with exact specifications, businesses can offer personalized designs without slowing down production.

- Material Versatility for Modern Woodworking: CNC machines can handle solid wood, MDF, plywood, and even acrylic or aluminum accents. This gives furniture manufacturers the flexibility to create innovative designs that blend different materials.

7. Defense and Military Applications

Military and defense manufacturing demands absolute precision. Whether it’s aerospace components, firearm parts, or armored vehicle components, every piece must perform under extreme conditions. In this industry, there’s no margin for error, CNC machining plays a crucial role in ensuring every part meets exact specifications.

Precision Manufacturing for Military Equipment

- Firearm Components and Weapon Systems: Rifles, handguns, and heavy artillery require finely machined parts for accuracy and durability. CNC machining ensures each barrel, trigger mechanism, and sighting system is crafted with exact tolerances to maintain peak performance.

- Armored Vehicle and Tank Components: Military vehicles must withstand extreme impact, rough terrain, and combat conditions. CNC machines cut and shape armor plating, structural components, and mounting systems with high-strength materials.

- Aircraft and Drone Parts: Military aircraft and drones depend on CNC-machined parts for both internal mechanisms and external structures. Whether it’s an engine casing or a lightweight UAV frame, CNC machining ensures reliability in the field.

- Ammunition and Ballistic Equipment: Precision is critical when manufacturing ammunition, casings, and ballistic components. CNC machining allows for repeatable accuracy, ensuring consistency across large production runs.

Advanced Tactical Gear and Defense Prototyping

- Communication and Surveillance Equipment Housings: Tactical radios, surveillance drones, and night vision devices require protective casings. CNC machining produces lightweight, durable enclosures that protect sensitive electronics in the field.

- Rapid Prototyping for Defense Technology: The military is constantly testing new technology for improved defense strategies. CNC machining allows for quick prototyping and iteration, helping defense contractors refine new weaponry, armor, and equipment.

- Missile and Guidance System Components: High-speed projectiles and missile guidance systems rely on precisely machined parts. CNC technology ensures these critical components function flawlessly under extreme conditions.

8. Jewelry and Luxury Goods Manufacturing

While traditional handcrafting still holds value, CNC machining has revolutionized how luxury goods are produced. From high-end watches to custom engagement rings, CNC technology allows businesses to create intricate, flawless designs at a level of precision that was once impossible.

Precision Crafting for Luxury Jewelry

- Custom Engraving and Filigree Work: Whether it’s intricate patterns on a gold bracelet or initials on a wedding band, CNC machines can engrave with unmatched accuracy. This ensures every piece maintains sharp details, even on the smallest surfaces.

- Stone Settings and Mounts: Diamonds and other gemstones need perfectly machined settings to hold them securely. CNC machining creates symmetrical and durable mounts, enhancing both the aesthetic and structural integrity of the jewelry.

- Watchmaking and Micro-Machining: Luxury watches require incredibly small, highly precise parts. CNC machines produce the internal gears, dials, and casings with micrometer-level accuracy, ensuring smooth operation and long-lasting quality.

- Replicating Handcrafted Quality at Scale: While handcrafting is an art, CNC machining allows businesses to replicate detailed designs consistently. This means customers get artisan-level craftsmanship without the limitations of slow, manual production.

Efficiency and Innovation in Luxury Manufacturing

- Prototyping and Custom Designs: High-end jewelry brands often create prototypes before finalizing designs. CNC machining enables fast, precise prototyping, allowing designers to refine details before moving to production.

- High-End Metal and Material Processing: Gold, platinum, titanium, CNC machines handle all of them with precision. This ensures that luxury pieces are not only beautiful but also structurally sound and made from the finest materials.

- Consistency Across Large Production Runs: Whether producing ten rings or a thousand, CNC technology ensures uniformity. This is crucial for maintaining brand reputation and meeting the high expectations of luxury buyers.

- Personalized and One-of-a-Kind Creations: Customization is a major trend in luxury goods, and CNC machining makes it possible. From engraving personal messages to designing one-of-a-kind patterns, brands can offer unique experiences without sacrificing precision.

Conclusion

You’ve now seen the top 8 ways CNC machines are used, from building airplanes to crafting jewelry.

What CNC offers isn’t just speed.

It’s freedom, from mistakes, rework, and lost time.

Where could you go if your machines kept up with your vision?

Contact Blue Elephant today. Let’s find the right fit for your future.

Recommended Reads for You

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.