I. Introduction: Why 4 Axis CNC Routers Matter

In today’s digital woodworking and furniture manufacturing, efficiency, precision, and repeatability are crucial. Traditional craftsmanship alone can’t meet modern production demands. That’s why a 4 axis CNC router has become a must-have for furniture manufacturers, woodworking professionals, and hobbyists across Europe and North America.

At Blue Elephant CNC, we specialize in high-end CNC routers that combine innovation, precision, and reliability. This guide will explain what a 4 axis CNC router is, how it works, and why it could be the smartest investment for your workshop.

In this guide, we’ll explore everything you need to know about 4 axis CNC routers, from how they work to why they could be the smartest investment for your workshop.

II. What Is a 4 Axis CNC Router?

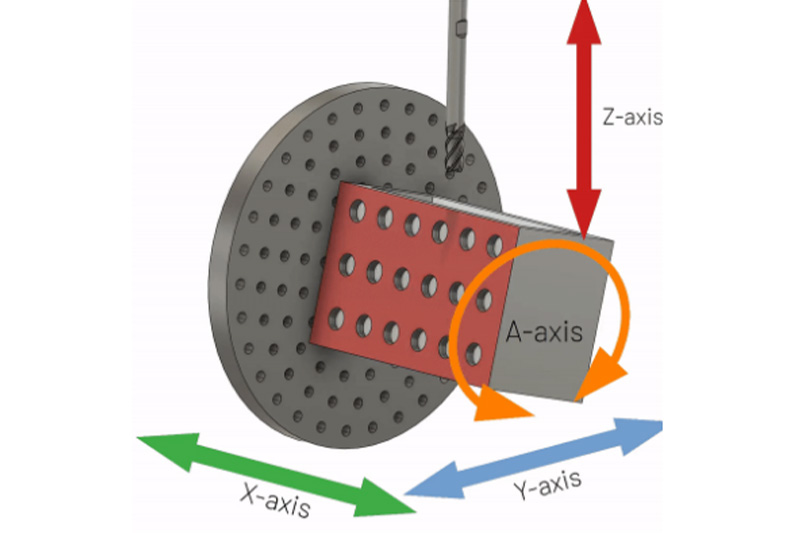

A 4 axis CNC router is a computer-controlled cutting machine that moves along four axes — X, Y, Z, and A. The first three axes control linear movement, while the A-axis introduces rotational motion, typically around the X-axis. This added flexibility allows the router to machine parts from multiple sides without manual repositioning.

In simple terms, a 4 axis CNC router is an enhanced version of the 3 axis router. While the 3 axis model is ideal for flat or shallow relief work, the 4 axis version can handle cylindrical, curved, and three-dimensional shapes. This makes it an essential tool for creating detailed furniture legs, sculptural art pieces, and intricate architectural elements.

III. How Does a 4 Axis CNC Router Work?

Like all CNC machines, a 4 axis router operates under the guidance of G-code, which is generated by CAM (Computer-Aided Manufacturing) software. The software converts a digital 3D model into a set of precise instructions for the machine to follow.

Here’s how the movement works:

- The X-axis moves the spindle horizontally.

- The Y-axis moves it vertically across the table.

- The Z-axis controls depth and height.

- The A-axis rotates the material or spindle, depending on the configuration.

This coordinated movement allows the router to sculpt complex 3D forms from a single block of material. Because of this, users can achieve multi-sided machining in one continuous process — without interrupting the workflow for repositioning.

IV. 3 Axis vs. 4 Axis CNC Router: What’s the Difference

If you’re familiar with CNC routers, you’ve probably encountered the standard 3 axis model. The main distinction between a 3 axis and 4 axis CNC router lies in the rotational motion.

| Feature | 3 Axis CNC Router | 4 Axis CNC Router |

| Axes of Movement | X, Y, Z | X, Y, Z + A rotary axis |

| Applications | Flat engraving, signage, cabinet doors, etc. | Cylindrical carving, 3D shapes, complex furniture components |

| Advantages | Lower cost, easy to operate | Continuous rotary machining, more complex shapes |

| Limitations | Can only machine one plane at a time | Can machine multiple angles and surfaces seamlessly |

With the extra degree of motion, the 4 axis router strikes the perfect balance between affordability and versatility — offering more power than 3 axis models while being simpler and more cost-effective than 5 axis CNC router machines.

V. Types of 4 Axis CNC Routers

There are two main configurations of 4 axis routers:

Rotary Type (A-axis table) – The workpiece is mounted on a rotary attachment, allowing it to spin while the spindle cuts from different angles. This setup is perfect for machining cylindrical objects such as chair legs, statues, and columns.

1313 Rotary Axis CNC Router for Sale

1313 rotary axis CNC router has a small working area. With a small footprint and it is more flexible and convenient to use. Therefore, it is suitable for meeting the processing needs of the advertising industry, home use or small businesses.

Swing Spindle Type (Tilting head) – The spindle itself tilts along the A-axis, enabling angled cuts and curved surface machining. This configuration is more suitable for mold making, 3D sculptures, and components that require compound angles.

2137 Linear 4 Axis ATC CNC Router

2137 4 axis ATC CNC router for 3D wood carving adopts a linear tool magazine of 20 bits holders, which automatically chooses right bits to meet different working requirements. The 4 axis CNC machine is mainly used for 2D and 3D carving of wood, MDF, polywood. It is good at making cabinets, doors, molds, wood arts, wood crafts, etc.

Both designs are available from Blue Elephant CNC, ensuring you can choose the right solution for your specific production needs.

VI. Key Features of Blue Elephant 4 Axis CNC Router

At Blue Elephant CNC, our 4 axis cnc wood router are engineered for performance, stability, and reliability. Every model is designed with advanced components to ensure long-term precision and consistent output.

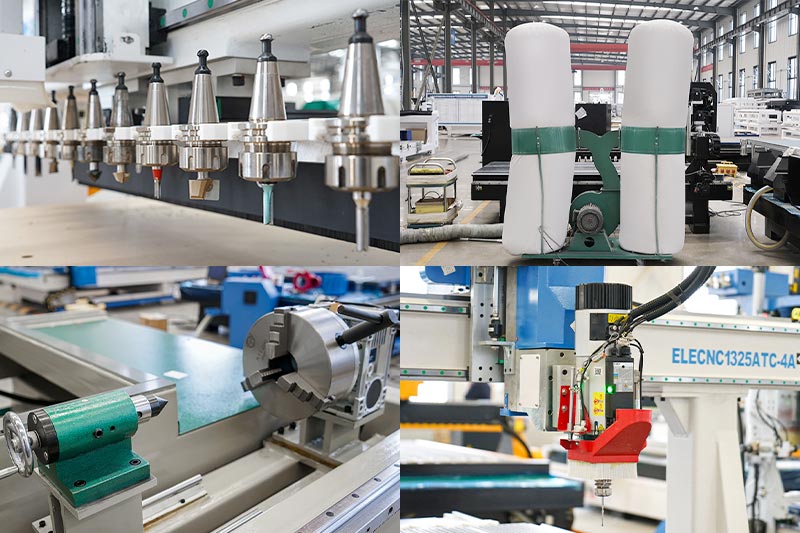

- Rigid Steel Frame: The heavy-duty welded structure minimizes vibration and guarantees accuracy even under continuous operation.

- High-Speed Spindle: We offer precision air-cooled or water-cooled spindles for clean, smooth cuts on any material.

- Automatic Tool Changer (ATC): Quickly switch between tools for different cutting, drilling, or carving operations without manual intervention.

- Advanced Control System: User-friendly interfaces like Syntec, OSAI, or Mach3 provide smooth motion control and precise programming.

- High-Precision Rotary Axis: Engineered with durable gears and bearings to ensure stable rotation during 3D carving.

- Dust Collection System: Keeps your workspace clean and extends tool life.

These features make Blue Elephant CNC wood routers ideal for furniture factories, woodworking studios, and custom design shops.

VII. Exploring the Versatility of a 4-Axis CNC Router

1. Advertising Industry

The 4 axis router is widely used in the advertising industry to precisely carve intricate signage, logos, and billboards. Its high efficiency and precision allow businesses to produce high-quality promotional materials, enhancing brand identity and meeting customized demands for unique designs and creative displays.

2. Furniture Manufacturing

In furniture manufacturing, 4 axis routers are used to carve detailed wooden components such as tabletops, chair backs, and cabinet doors. The machine’s fine carving capabilities ensure complex designs are produced with high accuracy, improving production efficiency while maintaining the unique aesthetic and quality of the products.

3. Art Creation

The 4 axis router plays a key role in art creation, especially for sculpting complex sculptures and intricate artistic pieces. Its precision enables artists to bring their creative visions to life, working with a variety of materials such as wood, stone, resulting in finely detailed three-dimensional works.

4. Mold Manufacturing

In mold manufacturing, the 4 axis CNC router is essential for creating complex curves and fine details. Its ability to work with high precision significantly improves mold production efficiency and quality. By automating the process, it reduces human error and ensures consistency and accuracy in the final mold designs.

Each of these applications benefits from the advanced motion control and efficiency offered by Blue Elephant’s 4-axis CNC routers, ensuring that businesses can meet the growing demands for innovation and high-quality production.

VIII. Choosing the Right 4 Axis CNC Router for Your Business

Selecting the ideal CNC router depends on your materials, production volume, and budget. Here are some factors to consider:

- Material Type: Will you work mainly with wood, MDF, acrylic, or soft metals? Blue Elephant routers handle them all.

- Work Area Size: Choose a table size that accommodates your largest projects comfortably.

- Power and Spindle Speed: Higher horsepower and RPMs mean faster, cleaner cuts.

- Control System: Look for a system that suits your workflow – we offer intuitive interfaces for all experience levels.

- Support and Training: Reliable after-sales support and guidance are critical. Blue Elephant offers both local and online assistance.

If you’re unsure which model fits your needs, our expert team can recommend the best configuration based on your specific production goals.

IX. Maintenance Tips to Keep Your 4 Axis Router in Top Shape

Routine maintenance ensures consistent performance and extends the lifespan of your investment.

- Clean the Machine Daily: Remove sawdust, chips, and residue to prevent buildup.

- Lubricate Moving Parts: Apply grease or oil to rails, screws, and bearings regularly.

- Inspect the Rotary Axis: Check for smooth rotation and tighten components if needed.

- Monitor the Spindle: Ensure cooling systems are working and replace bearings when worn.

- Software Updates: Keep your control system updated for improved performance and compatibility.

Blue Elephant also provides a detailed maintenance guide and remote support to help you handle routine checks and adjustments.

X. Why Choose Blue Elephant CNC?

For over a decade, Blue Elephant CNC has been recognized as one of China’s leading CNC router manufacturers, serving clients in more than 180 countries. Our reputation is built on precision engineering, reliable performance, and exceptional service.

When you buy a Blue Elephant CNC router, you’re not just purchasing a machine — you’re gaining a trusted production partner. Our advantages include:

1. Premium Components for Long-Lasting Performance

A CNC machine’s performance is directly tied to its components. At Blue Elephant CNC, we never cut corners. Our 3-axis routers are built with the best, globally trusted parts to keep your business running efficiently and without interruptions.

- Industrial-Grade Spindles:

Our spindles are designed to run continuously for long hours without overheating, ensuring consistent high-performance cutting. - Durable Frame:

Our routers feature heavy, welded, heat-treated steel frames that prevent vibrations and ensure precision for every cut. - Reliable Motors:

We use servo or stepper motors from renowned brands like Yaskawa and Leadshine, delivering the power and speed needed to handle tough materials without lag.

2. Trusted Global Quality Standards

Our machines are designed to meet the highest international standards, making them ideal for markets in the US and Europe.

- CE Certified:

Our machines meet stringent European safety, health, and environmental standards. - ISO Certified:

Our factory adheres to strict quality management protocols, ensuring each machine is consistently built with precision. - Pre-Delivery Testing:

Every machine undergoes a comprehensive testing process before it leaves our factory to ensure flawless performance when it reaches you.

3. Always Available Support

We understand the concerns about support when purchasing from overseas. Blue Elephant CNC offers comprehensive solutions for your peace of mind.

- 24/7 Technical Assistance:

Our expert support team is available 24/7 via phone, video calls, or remote access to assist with any issues or questions you may have.

- Installation & Training:

We don’t just ship machines; we provide detailed installation guidance and hands-on training to ensure you’re up and running on day one. - Dependable Warranty:

Our robust warranty backs every machine. Should a part fail, we quickly send a replacement and assist with installation to minimize downtime.

XI. Testimonials from Blue Elephant Users

Our clients around the world have transformed their production with Blue Elephant routers:

- “The Blue Elephant 4 axis router completely changed how we produce furniture components. We’ve cut production time in half while improving quality.”

— David M., Furniture Manufacturer, USA

- “As a sculptor, precision is everything. The 4 axis CNC router allows me to carve intricate designs with ease. It’s an incredible tool.”

— Emma R., Artist, UK

- “Excellent support and machine quality. The rotary axis runs perfectly smooth — highly recommended!”

— Lukas P., Workshop Owner, Germany

These testimonials reflect our ongoing commitment to customer satisfaction and performance excellence.

XII. Ready to Upgrade Your Workshop?

A 4 axis CNC router isn’t just an upgrade — it’s a transformation. With the ability to create intricate designs faster and with greater precision, you’ll gain a competitive edge in the woodworking and manufacturing industries.

Contact Blue Elephant CNC today to get a personalized quote or a free consultation with our experts.

Order your 4 Axis CNC Router now and experience unmatched precision and productivity.

Don’t settle for average. Invest in excellence. Invest in Blue Elephant.

Read more recent news: