Years ago, I spent hours turning handwheels on a manual milling machine, measuring, adjusting, and hoping for a perfect cut. It was slow. It was tiring. And sometimes, mistakes were unavoidable.

Then I was introduced to CNC milling. The same tasks I struggled with manually were now handled with precision at the push of a button. It felt like stepping into the future.

If you’re wondering what a CNC milling machine is and how it differs from traditional methods, you’re in the right place.

Whether you’re new to machining or just curious about the technology, this article will explain it in clear, simple terms.

You’ll learn what a CNC milling machine does, how it operates, and why it’s essential in modern manufacturing.

By the end, you’ll have a solid understanding of CNC milling and why it’s revolutionizing industries worldwide.

So let’s start!

1. What is CNC Milling Machine?

Imagine trying to carve a complex shape into a block of metal using only your hands. Precision? Nearly impossible. Speed? Out of the question.

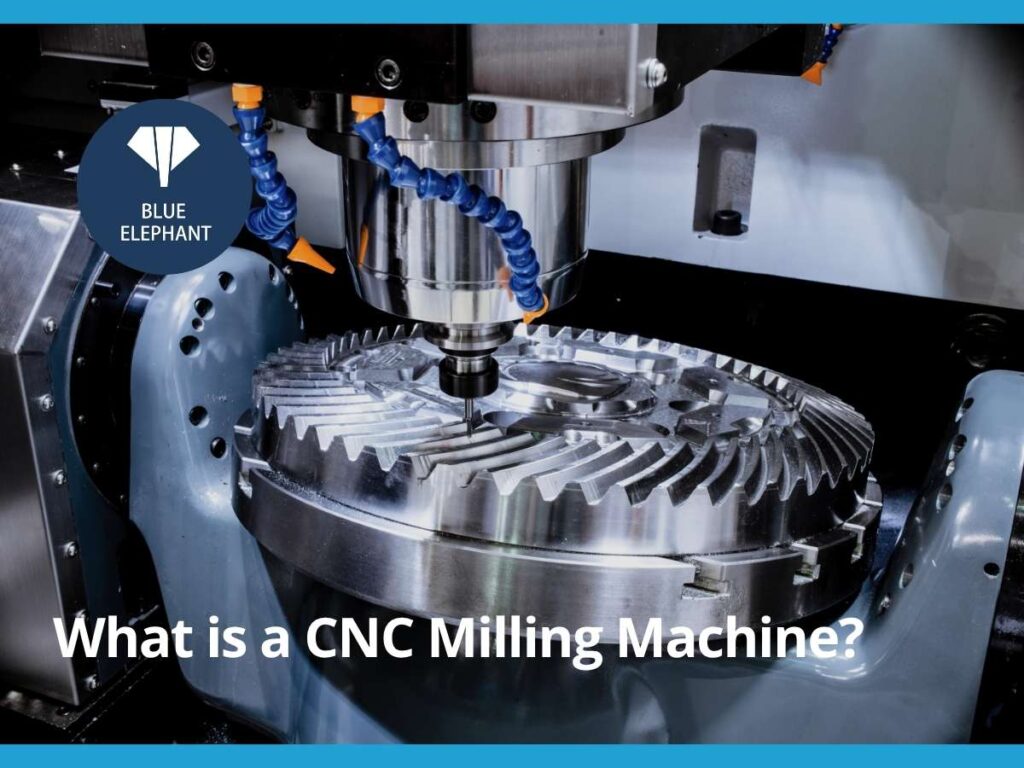

This is why CNC milling machines exist. They take raw materials—metal, plastic, wood—and shape them with precision, all controlled by computer programming.

But what exactly is a CNC milling machine, and why is it a game-changer in manufacturing?

Defining a CNC Milling Machine

A CNC (Computer Numerical Control) milling machine is a specialized machine that cuts, drills, and shapes materials with extreme accuracy. Unlike manual milling machines, which require hands-on operation, CNC milling machines follow programmed instructions to make precise cuts automatically.

Think of it as the difference between hand-carving a statue and using a 3D printer—one is manual, the other is automated and highly precise.

Why CNC Milling Machines Matter in Manufacturing

Before CNC milling, machining was a slow, hands-on process. Every cut had to be manually adjusted. Every mistake meant wasted material and time.

CNC milling changed everything. Now, industries can produce parts faster, with flawless accuracy and minimal waste.

Here’s why manufacturers rely on CNC milling:

- High Precision: CNC mills can achieve tolerances as tight as ±0.0001 inches.

- Efficiency: Automated operation speeds up production and cuts down labor costs.

- Scalability: Once programmed, the machine can produce one part or thousands—all with the same level of accuracy.

- Versatility: Works with metals, plastics, composites, and even ceramics.

- Reduced Waste: Optimized programming means less wasted material, lowering costs.

I once spoke with a machinist who told me, “Before CNC, every part had to be checked and rechecked. Now, we trust the machine to get it right the first time.” That’s the difference CNC milling makes.

So if you are considering investing in CNC milling machines, choose Blue Elephant as your provider. All our machines undergo rigorous testing and use high-quality materials for long-term precision.

2. How CNC Milling Machines Work

I remember the first time I tried programming a CNC machine. It felt intimidating—lines of code, numbers, and movements I had never seen before. But once I understood the basics, it all made sense.

Here’s what makes a CNC milling machine work:

- Computer Programming: The machine follows a set of instructions (usually written in G-code) to control movement and cutting operations.

- Rotating Cutting Tools: High-speed cutting tools move in multiple directions, shaping the material with precision.

- Worktable: The material is clamped down, staying perfectly still while the cutting tool moves around it.

- Multiple Axes: Standard machines move on three axes (X, Y, and Z), but advanced CNC mills can have five or more for complex cuts from different angles.

Some industries use 7-axis CNC milling machines, especially in aerospace and medical manufacturing, where extreme precision is non-negotiable.

3. Types of CNC Milling Machines

CNC milling machines come in different designs, each built for specific tasks. Whether you’re machining a simple part or creating complex components for aerospace, the right machine makes all the difference.

But how do you choose the best one for your needs?

Let’s break down the different types:

Vertical CNC Mills

A vertical CNC mill has its cutting tool positioned vertically, moving up and down along the Z-axis. This is the most common type, widely used in workshops and industrial settings.

Advantages:

- Easy to Use: Operators have a clear view of the cutting area, making it simpler to set up and adjust.

- Cost-Effective: Generally more affordable than horizontal mills.

- Great for Prototyping: Ideal for small to medium production runs.

Best Use Cases:

- Creating flat surfaces, slots, and holes.

- General-purpose machining across industries.

- Small to mid-sized parts in automotive and aerospace.

My first CNC machine was a vertical mill. It was simple to operate, and I could visually inspect every step of the process. If you’re starting out, a vertical CNC mill is a solid choice.

Horizontal CNC Mills

A horizontal CNC mill has its cutting tool positioned horizontally, meaning the spindle moves side to side rather than up and down.

Key Benefits:

- Faster Material Removal: Gravity helps with chip evacuation, reducing heat buildup.

- Better for Large Parts: Can handle bigger, heavier workpieces.

- More Efficient on Complex Cuts: Supports multi-sided machining without repositioning.

Ideal Applications:

- High-production machining in automotive and heavy industry.

- Large metal components that require deep cuts.

- Molds, gears, and aerospace parts with multiple features.

I once watched a horizontal CNC mill carve a large aluminum mold in half the time it would take a vertical mill. The efficiency was impressive, but the machine came with a hefty price tag—something to consider when budgeting.

3-Axis CNC Milling

A 3-axis CNC mill moves in three directions:

- X-axis (left to right)

- Y-axis (front to back)

- Z-axis (up and down)

Best Use Cases:

- Flat parts with drilled holes.

- Standard machining in general fabrication.

- Entry-level CNC operations.

A 3-axis CNC mill is great for everyday jobs, but if you’re working on more intricate parts, you’ll hit its limits quickly.

4-Axis and 5-Axis CNC Milling

When more complex shapes are required, 4-axis and 5-axis CNC mills step in.

- 4-Axis CNC Mills: Adds rotation along the X or Y-axis, allowing the workpiece to be rotated during machining.

- 5-Axis CNC Mills: Adds two rotational axes, giving full 3D machining capabilities.

Best Use Cases:

- Medical implants that require intricate contours.

- Aerospace components with multiple angles.

- High-performance automotive parts.

4. Key Features To Look for in CNC Milling Machines

Choosing the right CNC milling machine isn’t just about price—it’s about performance, efficiency, and long-term reliability. The right features can reduce production time, improve part quality, and lower operating costs.

But what features truly matter? Let’s go through the must-have elements that make a CNC mill worth the investment.

Precision and Accuracy

Precision is what separates an average CNC machine from a great one. Tolerances—the allowable variation in a part’s dimensions—play a critical role in quality control.

- Standard Tolerance (±0.001″): Suitable for general machining.

- Tight Tolerance (±0.0005″): Required for aerospace, medical, and high-performance parts.

- Ultra-Precision (±0.0001″): Used in optics, scientific equipment, and advanced engineering.

I’ve seen companies buy cheap CNC mills, thinking they got a deal—until they struggled with inconsistent tolerances. In precision machining, consistency is everything.

Spindle Power and Speed

The spindle is the heart of a CNC milling machine. It determines how well the machine can cut through different materials. Here are things to consider:

- Power (Horsepower or kW):

- 3-5 HP: Suitable for aluminum and plastics.

- 10-15 HP: Handles mild steels and alloys.

- 20+ HP: Required for hardened steel, titanium, and aerospace-grade materials.

- Speed (RPM Range):

- High-speed spindles (10,000+ RPM): Best for light materials like aluminum and composites.

- Low-speed spindles (<3,000 RPM): Needed for tough metals like titanium and Inconel.

- Direct-Drive vs. Belt-Driven Spindles:

- Direct-drive offers higher precision and faster acceleration.

- Belt-driven spindles handle heavier loads but may have some vibration.

Number of Axes

A CNC milling machine’s axis configuration determines its versatility.

- 3-Axis Mills: Move in X, Y, and Z directions. Good for basic machining, drilling, and contouring.

- 4-Axis Mills: Add rotational movement around the X or Y-axis. Useful for machining cylindrical parts.

- 5-Axis Mills: Offer two rotational axes, allowing for simultaneous multi-angle machining—ideal for aerospace and medical components.

A shop I worked with bought a 5-axis mill, thinking they needed it—but they barely used the extra axes. If most of your parts are flat or simple shapes, 3-axis might be all you need.

Tooling System and Automatic Tool Changer (ATC)

Switching tools manually wastes time. An Automatic Tool Changer (ATC) speeds up production and reduces human error.

Key Tooling Features to Look For:

- Tool Capacity:

- 10-20 tools: Small shops or low-production environments.

- 30-60 tools: Mid-to-high production with frequent tool changes.

- 100+ tools: Large-scale manufacturing with complex setups.

- Tool Holders:

- CAT & BT Holders: Standard for industrial CNC mills.

- HSK Holders: Better precision and rigidity for high-speed machining.

Every feature adds value, but not every feature is necessary for your specific work. Which of these features matter most to you? That’s the real question.

5. Applications of CNC Milling Machines across Industries

CNC milling machines aren’t just for high-tech manufacturing plants—they’re used in industries ranging from automotive and aerospace to furniture and custom signage. Whether you’re a machine dealer, parts supplier, repair service, or manufacturer, CNC milling plays a crucial role in your operations.

So, where do these machines make the biggest impact? Let’s explore the key applications in industrial and business sectors.

Industrial Applications (B2B Use Cases)

- Machine Dealers and Resellers: The demand for CNC machines is growing as businesses upgrade to newer models. Selling new or used machines and offering leasing options are profitable business models.

- Spare Parts Suppliers: CNC machines require regular maintenance, creating a steady market for parts like ball screws, spindle bearings, and coolant pumps. Suppliers benefit from ongoing demand.

- Machine Repair Services: Frequent breakdowns lead to high demand for repair services. Common issues include spindle failures, axis misalignment, and software errors that impact production.

- CNC Machine Rentals: Many businesses prefer leasing CNC machines instead of buying them. Rental companies serve startups, manufacturers with short-term projects, and those testing new technology.

Consumer and Business Applications (B2C Use Cases)

- Furniture Manufacturing: CNC mills streamline furniture production, making it easy to create cabinet doors, table frames, and decorative engravings with precision.

- Advertising and Signage: Businesses use CNC milling for custom signage, engraving logos, and crafting branding elements on materials like acrylic, wood, and aluminum.

- Mold and Die Production: CNC milling is essential for manufacturing high-precision molds used in automotive, medical, and consumer goods industries.

- Hobbyists and Small Businesses: Entrepreneurs and hobbyists use CNC mills for custom projects, prototyping, and engraving, turning creative ideas into finished products.

6. Common Problems in CNC Milling Machine and How To Solve It

CNC milling machines are incredible tools, but they aren’t perfect. I’ve seen machines that ran flawlessly one day and then struggled with precision the next. Sometimes it’s a small issue—a worn-out tool or a misaligned axis—but if left unchecked, even minor problems can waste time, ruin materials, and throw off production schedules.

Here are some of the most common CNC milling problems, their causes, and how you can get your machine back on track.

| Common Problem | Causes | Solutions |

| Inaccurate Cuts and Poor Tolerances | Loose ball screws, tool wear, thermal expansion | Tighten ball screws, replace worn tools, use temperature compensation |

| Tool Breakage and Excessive Wear | Incorrect feed rate, wrong tool for material, poor chip evacuation | Adjust feed rate, use correct tooling, optimize coolant flow |

| Machine Vibration and Chatter | Loose workpieces, incorrect spindle speed, worn machine components | Secure workpiece, adjust spindle speed, replace worn components |

| Spindle Overheating and Failure | Improper lubrication, spindle overload, coolant system failure | Check lubrication, use step-down cuts, inspect coolant system |

| Software and Programming Errors | Incorrect G-code, zero-point misalignment, outdated software | Run CAM simulation, check zero-point, update control software |

| Poor Surface Finish | Dull cutting tools, improper feed rates, machine vibration | Replace dull tools, increase spindle speed, stabilize machine |

| Coolant System Failures | Clogged filters, coolant contamination, insufficient coolant flow | Clean filters, replace coolant, ensure proper coolant delivery |

| Axis Misalignment | Worn guideways, improper homing, temperature fluctuations | Realign axis, recalibrate machine, control shop temperature |

If your CNC machine is acting up, don’t panic. Most of the time, a simple adjustment—tightening a loose screw, tweaking the feed rate, or replacing a worn tool—can save hours of troubleshooting and lost production.

7. Tips To Consider Before Investing in CNC Milling Machine

Buying a CNC milling machine is a big investment, and choosing the wrong one can lead to wasted money, downtime, and frustration. I’ve seen businesses rush into a purchase, only to realize later that the machine didn’t fit their production needs.

Before you sign that purchase order, here are some key tips to help you make the right decision.

Tip #1 Check the Machine’s Precision and Tolerance Levels

Not all CNC machines offer the same accuracy. If your parts require tight tolerances (±0.0001″), you need a machine with high-rigidity construction and precision ball screws.

- For standard machining: A tolerance of ±0.001″ is usually enough.

- For aerospace or medical parts: You may need ±0.0005″ or better.

A manufacturer I worked with tried to cut high-precision aerospace parts on a lower-end CNC mill. They spent more time fixing errors than producing parts. Don’t make that mistake—match the machine’s accuracy to your work requirements.

Tip #2 Consider Spindle Power and Speed

The spindle determines cutting power, speed, and material compatibility. A weak spindle will struggle with hard materials, while an overly powerful spindle may be overkill for light-duty work.

- For aluminum and plastics: Look for 10,000+ RPM spindles.

- For steel and titanium: Choose a high-torque spindle (10-20 HP).

Tip #3 Evaluate the Machine’s Automation Features

CNC machines with automatic tool changers (ATC), pallet changers, and advanced software can dramatically improve productivity.

- If you run high-volume production, an ATC with 30+ tool slots will minimize downtime.

- If you need flexibility, consider a machine with multi-axis automation for reduced manual intervention.

Tip #4 Look at the Manufacturer’s Support and Reputation

Not all CNC brands offer reliable support and spare parts availability. Look for manufacturers with good customer service, easy-to-find parts, and strong user communities.

- Ask other machinists which brands they trust.

- Read reviews on customer service response times.

Consider Blue Elephant as your CNC milling machine provider. We offer 24/7 online support, spare parts supply, and on-site servicing when needed.

Conclusion

Buying a CNC milling machine is a big decision. The right one can boost efficiency, cut costs, and take your production to the next level. But the wrong one? It can be a costly mistake.

We covered key factors—precision, spindle power, software, automation, and support. Now, it’s your turn.

At Blue Elephant, we help businesses like yours find the perfect CNC solution. Whether you need a 3-axis, 5-axis, or custom-built machine, we’ve got you covered.

Contact us today and let’s build something great together!

Explore More Helpful Resources

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

If you’re looking for more insights, we’ve put together a list of helpful articles that you might enjoy:

Milling Basics

- CNC Mill vs CNC Router: What’s the Difference

- Horizontal vs Vertical Milling: What’s the Difference?

- Milling Machine Vs Lathe: Key Differences Explained

Technical Comparisons

- Bed Mills Vs. Knee Mills: What’s The Difference?

- CNC Milling Machine Process: A Step-by-Step Guide

- Your Guide to Choosing a Used CNC Milling Machine

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.