I. The Essential Role of the Edge Banding Machine

The Critical Finish

Edge banding machine is essential CNC equipment for modern panel furniture production, whose sole function is to apply a thin strip of material (PVC, ABS, wood veneer, etc.) to the raw, exposed edges of wood panels (MDF, Plywood, Particleboard).

Why Edge Banding Matters for Your Business?

Enhanced Aesthetics: Creates a seamless, polished, and professional final product (crucial for high-end cabinets and custom furniture).

Protection and Durability: Seals the panel core against moisture, impact, and warping, significantly extending the furniture’s lifespan.

Health and Safety: Covers sharp edges and seals in potential off-gassing from core materials.

Who Needs an Edge Banding Machine?

Furniture factories, cabinet makers, custom wood door manufacturers, and large-scale wardrobe producers in the USA and Europe who demand high precision and efficiency.

Tips for making money: 8 Ways to Make Money with An Edge Banding Machine for Plywood, MDF

II. Edge Banding Working Principle

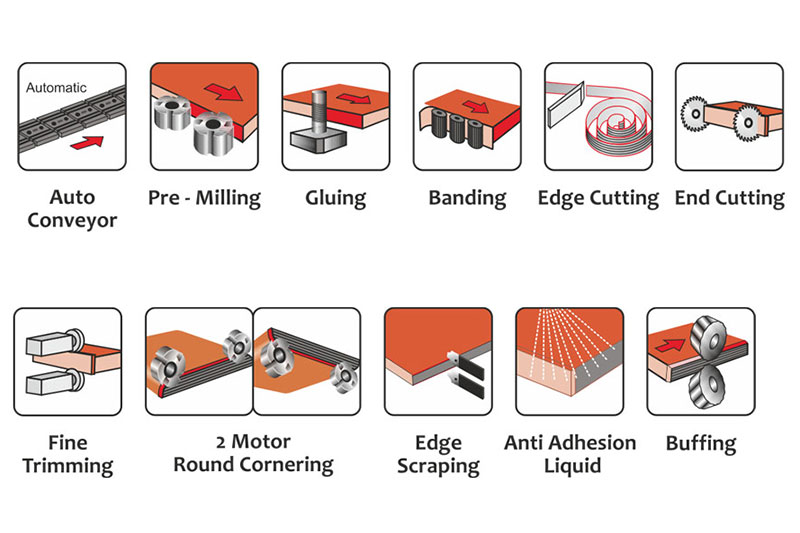

The edgebanding process is a smooth, automated workflow (often called a ‘through-feed’ system), where the panel is mechanically clamped and moved past various aggregate units, each performing a specialized task.

The 9 Essential Stations: A Deep Dive into the Processing Methods

| Station | Function | Critical for Factory Quality |

| 1. Pre-Milling | Two high-frequency diamond cutters refine the panel edge for a perfect 90° cut, removing defects from the sawing process. | Zero-Joint Appearance: Ensures no gap between the panel and the tape, crucial for aesthetic and moisture resistance. |

| 2. Gluing | Applies hot-melt adhesive (EVA or PUR) to the panel edge via a glue pot and roller. | Versatility: The ability to handle PUR glue is a competitive advantage for high-moisture applications. |

| 3. Band Feeding & Pressing | Feeds the edge tape from a coil and presses it firmly onto the glue using a large main roller and multiple secondary rollers. | Bond Strength: Ensures uniform pressure to eliminate air bubbles and maximize adhesion strength. |

| 4. End Trimming | Two high-speed motors snip the excess tape at the front and rear of the panel. | Precision: Clean, square cuts at high feed speeds. |

| 5. Rough Trimming | Removes the majority of the overhang on the top and bottom of the panel. | Speed: Prepares the edge for the final delicate work. |

| 6. Fine Trimming | Uses radius cutters to trim the tape flush and create the final, precise edge profile (e.g., R1, R2, R3 radius). | Aesthetics: Defines the final feel and look of the edge. |

| 7. Corner Rounding (Profiling) | (High-Value Unit) Automatically traces and rounds the four corners of a rectangular panel. | High-End Finish: Essential for cabinets and wardrobes; eliminates the need for manual work. |

| 8. Scraping (Flat & Profile) | Removes cutter marks (ripples) left by the trimming blades and scrapes any excess glue. | Ultra-Smoothness: Provides a hand-sanded feel that cannot be achieved with trimmers alone. |

| 9. Buffing/Polishing | Soft cloth wheels clean and buff the finished edge, restoring color and shine. | Final Luster: Removes minor scuffs for a flawless, final appearance. |

III. Machine Types: Matching Equipment to Production Scale

| Type of Edge Banding Machine | Production Volume & Target User | Core Advantages |

| 1. Fully Automatic CNC Edge Bander | Large-scale Industrial Factories (Your Main Target); High volume, complex panels (doors, cabinets, wardrobes). | High speed (18-30 m/min), maximum functionality (9+ stations), superior quality, minimal labor cost per panel. |

| 2. Semi-Automatic Edge Bander | Small to Medium Workshops; Straight edges only, lower throughput. | More affordable initial investment, a step up from manual, but lacks the precision of pre-milling and corner rounding. |

| 3. Portable/Manual Edge Bander | Hobbyists, on-site installation/repair. | Flexibility for curved/irregular shapes, but not a primary production tool for quality furniture. |

Jinan Blue Elephant’s offerings are positioned directly against the scale of US/European furniture production.

Our edge banding machine is an ideal for furniture, cabinetry, and interior decoration, ensures clean, strong, and seamless edge finishes on a variety of board materials, and can be customized to fit specific production needs, including functions like gluing, scraping, and polishing.

Whether for PVC, ABS, wood veneer, or melamine, our edge banding solutions improve production efficiency and reduce manual labor.

Ⅳ. The Smart Buyer’s Checklist: 5 Crucial Purchasing Precautions

1. Functionality: Don’t Pay for What You Don’t Use

Must-Haves for US/EU Market: Prioritize machines with Pre-Milling and Corner Rounding. These are the two biggest quality differentiators.

Integration: Look for features like Slotting/Grooving (for wardrobe back panels) to reduce panel saw processes and streamline the workflow.

Tips for choosing edge banding machine: How to choose the edge bander?

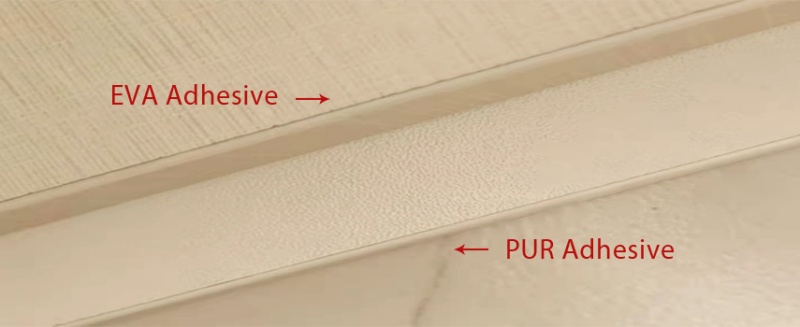

2. Glue Technology: The EVA vs. PUR Debate

EVA: Standard, affordable, easy to clean.

PUR (Polyurethane Reactive): The professional choice for premium, durable furniture. It forms a chemical bond that is virtually waterproof and has a much higher heat tolerance.

Actionable Tip: If you manufacture high-end kitchen or bathroom units, a PUR-capable machine is a non-negotiable investment for warranty and longevity.

3. Machine Components & Reliability

The Difference is in the Details: High-ranking machines use world-class components.

- Motors: High-frequency, independent motors for each unit (e.g., imported brands).

- Control System: User-friendly PLC control with a clear touchscreen interface.

- Frame: Heavy-duty, stress-relieved steel frame for vibration absorption and long-term stability.

4. Cost of Ownership & Support

Consider the Total Cost of Ownership (TCO). A cheaper machine with frequent downtime is more expensive than a reliable machine with a higher upfront cost.

Blue Elephant offers 24-hour response support, free lifetime technical support online, software upgrades and overseas parts service.

5. Panel Requirements

Ensure the machine’s specifications align with your production: Panel thickness (typically 10-60mm), minimum/maximum panel length/width, and feed speed range (look for high variable speeds).

Ⅴ. Conclusion

Investing in an advanced CNC Edge Banding Machine is the single most effective way to guarantee the quality and efficiency needed to compete in the high-demand US and European markets for cabinets, doors, and wardrobes.

Jinan Blue Elephant’s Promise: As a leading manufacturer of comprehensive woodworking CNC solutions (Cutting, Drilling, Edge Banding), we build machines engineered for the precision, durability, and high throughput your factory demands.

Ⅵ. Unlock the Power of Blue Elephant CNC Edge Banding

Ready to upgrade your production to achieve the industry-leading, seamless, zero-joint finish your clients demand?

Instead of guessing which model fits your needs, let our experts provide a clear, customized path forward.

Request Your Free, Personalized Edge Banding Machine Consultation

Click below to tell us:

- Your Production Goal: (e.g., 50 panels per day, high-gloss cabinets)

- Required Features: (e.g., must have PUR and Corner Rounding)

- Your Budget Range

A dedicated Blue Elephant CNC consultant will contact you within one business day with a detailed comparison of the best-suited models (including specifications and pricing) designed to minimize labor and maximize the profitability of your woodworking shop.