I still remember the first time I set up a CNC machine for a big production run. Everything was dialed in—so I thought. But as soon as the spindle started cutting, the tool dug too deep, ruining the entire workpiece.

The problem? My offsets were wrong. That mistake cost hours of rework and wasted material.

If you’ve ever faced a similar issue, you know how frustrating and costly it can be. I’ve seen machine shop owners struggle with misaligned cuts. It’s a common problem, but the good news is—it’s fixable.

You can trust this guide because it’s based on real-world experience, not just theory. With insights tailored for machine dealers, repair specialists, and rental companies, you’ll get practical, no-nonsense advice that works in the field.

Expect a deep dive into the types of offsets, how to set them correctly, troubleshooting tips, and best practices to improve efficiency. If you’re looking to master CNC offsets, you’re in the right place.

So, let’s get started!

1. What Is Offset in CNC Machine?

Imagine this—you’ve got a CNC machine, a high-value workpiece, and a tight production deadline. You hit start, expecting a flawless cut. But instead, the tool digs in too deep or doesn’t reach far enough. The part is ruined. Time is wasted. Money is lost.

What went wrong? Your offsets were off.

Offsets in a CNC machine are adjustments that tell the machine where to position its tools and workpieces. Think of them as calibrations that ensure every cut, hole, and contour is exactly where it should be. Without offsets, even the most advanced CNC machine is just a blind operator, guessing where to cut.

Offsets aren’t just numbers in a machine—they’re the difference between precision and disaster. They control:

- Tool Position: Ensures the cutting tool doesn’t dig too deep or miss the mark.

- Workpiece Alignment: Keeps the part in the exact right spot before machining begins.

- Wear Compensation: Adjusts for tool wear over time, maintaining accuracy.

Without correct offsets, you’re looking at misaligned parts, wasted materials, damaged tools, and frustrated customers.

2. Importance of Offsets in CNC Machining

Offsets aren’t just a technical detail—they are the foundation of precision machining. Without them, even the most advanced CNC machines will fail to produce accurate parts. Every tool, every workpiece, every cut relies on correct offset settings to ensure flawless execution and repeatable accuracy. Below are the reasons why offsets are critical in CNC machining:

- Precision and Accuracy: Offsets fine-tune the machine’s positioning, ensuring every cut, hole, and contour is exactly where it should be. Even a 0.1mm misalignment can lead to costly defects.

- Consistent Repeatability: Manufacturing isn’t about cutting a single perfect part—it’s about producing hundreds or thousands of identical pieces. Offsets ensure every part matches the blueprint, no matter how many are produced.

- Tool Protection: Without proper offsets, tools can collide with the workpiece or machine components, leading to premature wear, breakage, and costly replacements.

- Workpiece Protection: A small offset error can turn a high-value workpiece into expensive scrap. Proper offsets prevent material waste and ensure higher production efficiency.

- Reduced Machine Downtime: When offsets are correctly set, operators spend less time making manual adjustments, which means higher throughput and lower labor costs.

3. Types of CNC Offsets

Offsets in CNC machining are not a one-size-fits-all setting. Different types of offsets serve different purposes, each playing a crucial role in ensuring precision, reducing waste, and optimizing tool life. Understanding how these offsets work will help you set up, adjust, and troubleshoot your CNC machine efficiently.

Tool Offset

Think of tool offsets as the CNC machine’s way of recognizing each tool’s unique size and shape. Every cutting tool has a different length, and without the correct offset, the machine wouldn’t know where the cutting edge is.

- Adjusts Tool Position: Ensures proper cutting depth and accuracy based on the tool’s actual length.

- Compensates for Tool Length Differences: Each tool is different—offsets tell the machine exactly where the tip is relative to the spindle.

- Stored in the Tool Offset Table: This table holds values for multiple tools, allowing smooth tool changes during machining.

Why It Matters: Incorrect tool offsets lead to cuts that are too deep, too shallow, or completely misaligned, increasing scrap rates and damaging expensive tooling.

Work Offset (Fixture Offset)

A CNC machine needs a reference point for every job, which is where work offsets come in. Work offsets define the workpiece’s position relative to the machine’s coordinate system.

- Adjusts Workpiece Position: Ensures the machine knows exactly where the part is located on the table.

- Uses G-code Commands: G54 – G59 store multiple work offsets, allowing quick part changes without resetting everything.

- Essential for Multi-Part Machining: Eliminates the need for constant repositioning, reducing setup time and improving efficiency.

Why It Matters: Imagine machining a batch of parts—without proper work offsets, every single piece would be misaligned, leading to wasted material and time.

Wear Offset

Even the best cutting tools don’t stay perfect forever. Over time, tools wear down, affecting precision. Wear offsets allow you to make fine adjustments to compensate for this gradual wear.

- Compensates for Tool Wear Over Time: Keeps parts within tolerance even as the tool wears down.

- Allows Fine Adjustments: Instead of replacing tools too early, operators can make small offset changes to maintain accuracy.

- Prevents Excessive Tool Replacement Costs: Extends tool life while maintaining precision.

Why It Matters: Without wear offsets, parts slowly drift out of tolerance, leading to subtle but costly quality issues over time.

Cutter Radius Compensation (CRC) Offset

When using end mills, ball nose cutters, or other tools with a defined diameter, the CNC machine must account for the tool’s size to follow the correct path. That’s where Cutter Radius Compensation (CRC) offsets come in.

- Adjusts for Tool Diameter: Ensures the machine understands how wide the cutting tool is.

- Uses G-code Commands:

- G41: Cutter compensation left.

- G42: Cutter compensation right.

- G40: Cancels cutter compensation.

- Prevents Gouging or Incorrect Paths: Ensures the programmed toolpath aligns correctly with the actual cutting edge.

Why It Matters: Without CRC offsets, the machine cuts either too far inside or too far outside the intended path, ruining precision-critical parts.

Machine Zero Offset (G92 Offset)

Machine zero offsets temporarily shift the machine’s coordinate system, allowing flexibility in how a job is set up.

- Temporarily Shifts the Zero Position: Used when a different zero point is needed for a specific setup.

- Used for Temporary Part Setups: Ideal for situations where the standard work offset (G54-G59) doesn’t apply.

Why It Matters: Machine zero offsets give operators more flexibility when setting up parts, especially in unique machining scenarios.

4. CNC Offset Commands in G-Code

Offsets are controlled through G-code commands, which tell the CNC machine how to position tools, compensate for tool length, and adjust for cutter diameter. Using the right offset commands is critical for precision, repeatability, and avoiding costly mistakes. Below, we break down the essential G-code offset commands and how they work.

Tool Offset Commands

Tool offsets help the CNC machine understand the actual length of each tool. Since different tools have different lengths, the machine must adjust accordingly to ensure accurate cutting depths.

- G43: Tool Length Compensation (Positive)

- Increases the tool length offset.

- Used when the tool is longer than the default reference point.

- Commonly used with an H-value to define specific tool lengths (e.g., G43 H01).

- G44: Tool Length Compensation (Negative)

- Decreases the tool length offset.

- Less common than G43 but used when shorter tools need offset adjustment.

- G49: Cancels Tool Length Offset

- Resets any tool length compensation, returning the machine to default settings.

Work Offset Commands

Work offsets define the starting position of the workpiece, ensuring that the CNC machine knows exactly where the material is located.

- G54 – G59: Stores Different Workpiece Positions

- These commands store multiple work offsets, allowing quick setup changes without manual repositioning.

- Example: G54 sets the first workpiece position, G55 sets a second position, and so on up to G59.

- Ideal for batch production, where multiple fixtures hold parts in different positions.

- G92: Temporarily Shifts the Coordinate System

- Overrides the current work offset, setting a new temporary zero point.

- Useful for one-time setups or when working with irregularly positioned parts.

Cutter Compensation Commands

Cutter compensation (CRC) offsets adjust for the diameter of the cutting tool, ensuring the toolpath matches the programmed design.

- G41: Cutter Compensation Left

- Offsets the tool to the left of the programmed path.

- Used when the tool follows the outer contour of a workpiece.

- G42: Cutter Compensation Right

- Offsets the tool to the right of the programmed path.

- Used when machining inside pockets or inner contours.

- G40: Cancels Cutter Compensation

- Turns off cutter compensation and resets to the default toolpath.

5. How to Set Offsets in a CNC Machine

Setting offsets correctly is one of the most important steps in CNC machining. Without proper offsets, even the most precise G-code program can result in misaligned cuts, tool crashes, or poor part quality.

Whether you’re setting tool offsets, work offsets, or wear adjustments, accuracy is key. Below, we’ll walk through the step-by-step process for each type of offset:

Setting Tool Offsets

Every cutting tool has a unique length, and the CNC machine needs to know exactly where the tip of each tool is. Tool offsets ensure the machine compensates for different tool sizes, preventing cutting errors.

Steps to Input Tool Offset Values in the Machine Control Panel:

- Load the Tool: Insert the tool into the spindle and secure it properly.

- Access the Tool Offset Table: Open the CNC control panel and navigate to the offset settings.

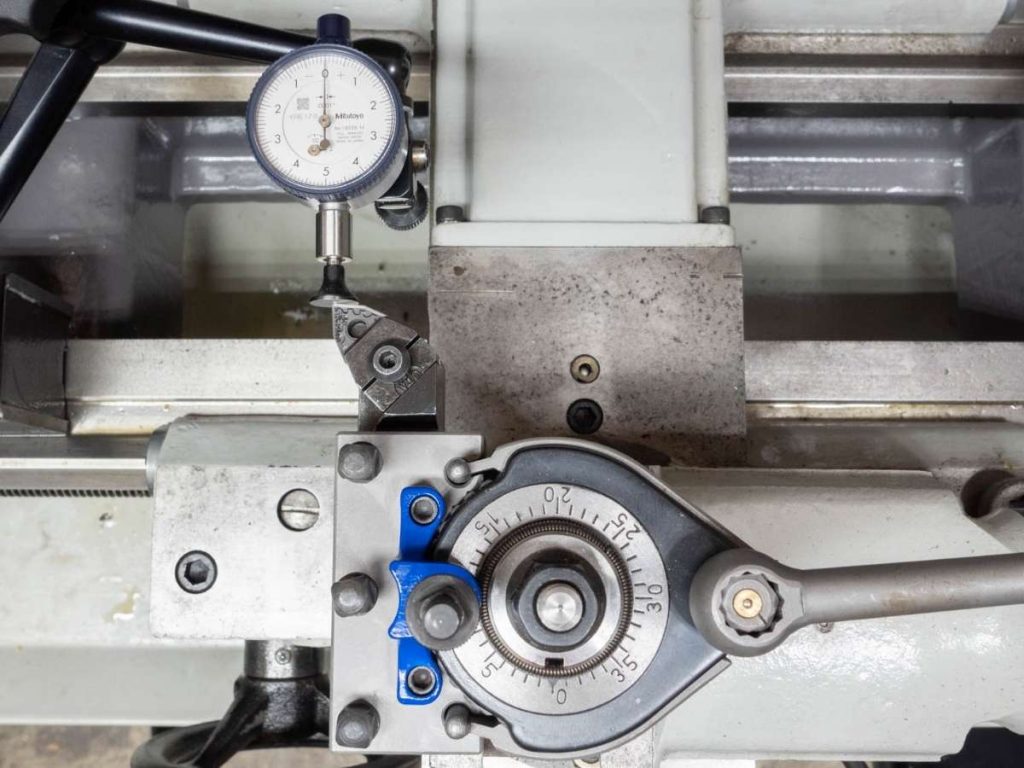

- Measure the Tool Length:

- Using a Touch Probe (Recommended): The machine automatically measures the tool and updates the offset table.

- Manual Method: Lower the tool to a fixed reference point, record the measurement, and input the value manually.

- Save the Offset Value: Enter the measured tool length into the tool offset table.

- Verify by Running a Test Cut: Make a small test cut to confirm the tool position is correct.

Setting Work Offsets (G54-G59)

Work offsets tell the CNC machine where the workpiece is positioned on the machine table. Without them, the machine wouldn’t know where to start cutting.

- Mount the Workpiece Securely: Make sure the workpiece is clamped properly to avoid movement.

- Select the Desired Work Offset (G54 – G59): Choose an available offset in the CNC control.

- Find the Workpiece Zero Point:

- Using a Probe (Best for Accuracy): The machine automatically detects the workpiece edges.

- Using an Edge Finder (Manual Method): Slowly move the tool until it touches the edge of the workpiece, then set the zero position.

- Enter the Work Offset Values: Input the X, Y, and Z coordinates of the zero position into the CNC control panel.

- Verify the Offset Before Running a Program: Jog the machine to the zero position and confirm alignment.

Adjusting Wear Offsets for Precision

Even the best tools wear down over time, causing minor but critical deviations in cutting accuracy. Wear offsets allow small corrections without stopping production. Steps to adjust wear offsets:

- Monitor Tool Wear Using Digital Readouts: Check for changes in cutting accuracy using a micrometer or laser measurement system.

- Make Small Adjustments: If the tool is cutting too deep, decrease the offset. If the tool is cutting too shallow, increase the offset.

- Update the Wear Offset in the CNC Control: Enter the correction value in the wear offset table.

- Continue Monitoring Throughout Production: Regularly check tool performance and adjust wear offsets as needed.

6. Advanced Offset Techniques for Precision Machining

In high-precision CNC machining, standard offset settings aren’t always enough. To achieve maximum accuracy, reduce setup time, and minimize errors, advanced offset techniques are essential. These techniques help operators automate adjustments and maintain precision across multiple production runs.

Below are 3 powerful offset optimization strategies that will take your CNC machining to the next level:

Using Automatic Tool Setters

Manually measuring tool lengths can be time-consuming and prone to human error. Automatic tool setters eliminate these issues by measuring tool lengths and updating offsets in real time.

How It Works:

- The machine lowers the tool onto a touch-sensitive probe or laser-based sensor.

- The system measures the exact length of the tool and automatically updates the tool offset table.

- If the tool wears down, breaks, or is replaced, the setter recalibrates the offsets without requiring manual input.

Benefits:

- Reduces human error by eliminating manual tool length measurement.

- Saves time by automating tool offset entry.

- Prevents tool crashes by ensuring the CNC machine always has the correct tool data.

Probe-Based Work Offset Setting

Traditional work offset settings using manual methods like edge finders can be slow and inaccurate. Probe-based systems allow the CNC machine to automatically detect the workpiece location with extreme precision.

How It Works:

- A touch probe or laser scanning probe is mounted on the spindle.

- The CNC machine moves the probe to touch the workpiece edges.

- The system automatically records the exact X, Y, and Z coordinates, setting the work offsets accurately.

Benefits:

- Eliminates human error from manual offset setting.

- Reduces setup time by quickly determining workpiece zero points.

- Improves repeatability, ensuring every part starts from the correct position.

CNC Software for Corrections

Modern CNC software can automatically adjust offsets in response to tool wear, temperature changes, and material variations—without operator intervention.

How It Works:

- Real-time sensors monitor factors like tool wear, spindle heat, and material shifts.

- The software calculates necessary offset adjustments and updates them dynamically.

- Machine learning algorithms can predict when offsets need to be corrected, improving long-term accuracy.

Benefits:

- Improves long-term consistency by adapting to changes in real-time.

- Reduces manual adjustments, freeing up operators for other tasks.

- Enhances productivity by reducing errors and rework.

When to Use: If your production runs involve long machining cycles, high volumes, or sensitive materials, automatic offset correction will drastically improve efficiency.

7. Common CNC Offset Mistakes and How to Avoid Them

Even a small offset error can turn a perfectly good CNC operation into a costly failure. Whether it’s a tool crashing, parts being scrapped, or production delays, improper offset management is a leading cause of machining issues. Below are three of the most common CNC offset mistakes—and how to prevent them.

Incorrect Tool Length Compensation

Every tool in a CNC machine has a different length, and if the offset isn’t set correctly, it can lead to:

- Cutting too deep or too shallow, affecting part accuracy.

- Poor surface finish due to incorrect tool engagement.

- Potential tool crashes, damaging both the tool and the workpiece.

How to Avoid It:

- Always measure tool length properly using a touch probe or manual method.

- Enter the correct tool length offset in the machine’s tool offset table.

- Run a test cut or a dry run to verify the tool’s position before machining high-value parts.

Failure to Set Work Offsets Correctly

Work offsets tell the CNC machine where the workpiece is located. If set incorrectly, you may experience:

- Misaligned cuts, causing holes or features to be in the wrong position.

- Tool collisions with fixtures, leading to broken tools or machine damage.

- Scrapped parts, increasing production costs.

How to Avoid It:

- Use a probe or edge finder to accurately determine the workpiece zero position.

- Double-check work offsets (G54-G59) in the CNC controller before starting the program.

- Verify alignment with a dry run, ensuring the tool moves to the correct starting position.

Overcompensating for Wear Offsets

Wear offsets allow for small adjustments to maintain accuracy as tools wear down. However, excessive adjustments can lead to:

- Overcorrection, causing parts to be out of tolerance.

- Unnecessary tool replacements, increasing operational costs.

- Unexpected dimensional drift, making it difficult to maintain consistency in production.

How to Avoid It:

- Make small wear offset changes—typically no more than 0.001” at a time.

- Use digital readouts, probes, or micrometers to track tool wear instead of guessing.

- Replace tools when necessary rather than trying to compensate for excessive wear with offsets.

8. Best Practices for Managing CNC Offsets

CNC offsets are the foundation of machining precision, but they require careful management to ensure accuracy, efficiency, and repeatability. Poor offset management can lead to scrapped parts, tool crashes, and costly production delays. By following best practices, you can minimize errors and maximize machine performance.

Regularly Verify and Update Offsets

Offsets are not a set-it-and-forget-it parameter. Over time, tool wear, temperature changes, and fixture adjustments affect machining accuracy, requiring frequent updates.

- Check tool offsets at the start of each shift to ensure accurate length measurements.

- The monitor wears offsets and adjusts in small increments rather than making large changes.

- Use digital measuring tools (touch probes, micrometers) to verify tools and work offsets.

Use Probing Systems

Manual offset adjustments are prone to human error. Probing systems eliminate guesswork by automatically detecting tool length, workpiece position, and wear conditions.

- Tool probes measure tool length and update offsets dynamically.

- Workpiece probes find zero point with precision, reducing setup time.

- Wear monitoring sensors adjust offsets in real-time, compensating for tool degradation.

Maintain a Centralized Offset Log

Tracking offset adjustments over time helps operators identify trends, troubleshoot issues, and optimize machining performance. Record all offset changes in a logbook or digital system. Monitor tool wear patterns to predict when offsets need updating. Use historical data to refine future offset adjustments for repeat jobs.

- Best Practice: Train operators to document offset adjustments after every major tool change or calibration.

Perform Test Runs Before Full Production

A small error in offsets can ruin an entire batch of parts. Running a test cycle before production prevents costly mistakes.

- Use a dry run (without cutting) to verify tool movements.

- Check tool engagement in scrap material before machining high-value parts.

- Confirm all offsets are correct before starting full production.

Conclusion

I still remember that frustrating day when my CNC machine ruined an entire batch because my offsets were wrong. But once I understood how to set and manage offsets correctly, everything changed—fewer mistakes, higher precision, and smoother production runs.

Now, you have everything you need to master CNC offsets—from tool length and work offsets to advanced techniques that boost efficiency. The next step is yours. Start fine-tuning your offsets, eliminate costly errors, and take control of your machining process.

Have you faced challenges with CNC offsets before?

Let’s talk. Contact us today, and let’s get your machines running perfectly.

Recommended Reads for You

Interested in more? Here are some additional articles with insights and tips to keep you informed:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.