I still remember the first time I tried using a wood lathe, expecting it to handle a small metal part I needed to fix. Within seconds, I realized I had made a costly mistake.

The machine wasn’t built for it, and I nearly ruined both my project and the lathe itself.

That experience taught me that not all lathes are created equal. If you deal with machines, you need to know exactly what sets a wood lathe apart from a metal lathe.

This guide is built on real-world experience, not just theory. With years of working alongside machine dealers and repair professionals, I understand the key factors that affect purchase decisions, spare parts availability, and long-term maintenance costs.

By the end of this comparison, you’ll have clear answers on:

- How wood and metal lathes function differently

- Which one fits your business needs and why

- The market demand and resale value for each type

So, let’s dive in!

1. What is a Wood Lathe?

If you’re in the machine business, you know that not all lathes are built the same. And if you’ve ever tried using the wrong lathe for the wrong job, you’ve felt the frustration firsthand.

A wood lathe is designed specifically for shaping and carving wood. It’s a machine that brings raw wooden blocks to life—turning them into precisely sculpted furniture legs, decorative spindles, or handcrafted bowls. Unlike its metal counterpart, a wood lathe relies more on manual control and craftsmanship than strict precision engineering.

How a Wood Lathe Operates

Imagine a wooden cylinder spinning at high speed, while a skilled hand guides a chisel against it, shaving off layers until a smooth, symmetrical form emerges. That’s the essence of how a wood lathe works.

- Workpiece Placement: The wood is secured between the headstock and tailstock.

- Spindle Rotation: A motor-driven spindle spins the wood at adjustable speeds.

- Manual Shaping: The rest of the tool supports chisels, gouges, or parting tools—allowing the operator to carve, cut, and shape with precision.

Unlike a metal lathe, there’s no automatic cutting tool movement—you, or your workers, control the shaping manually. This gives a wood lathe flexibility, allowing for freehand designs and artistic curves, but it also means skill and experience play a huge role in the final outcome.

Common Uses

If your business deals with woodworking machinery, then you already know: wood lathes are the backbone of creative wood shaping.

- Furniture Production: Shaping table legs, chair spindles, bedposts, and other cylindrical wooden components.

- Artistic Carvings & Custom Work: Creating handcrafted wooden bowls, goblets, pens, and decorative columns.

- Architectural Woodworking: Producing intricate moldings, bannisters, and vintage-style wooden fixtures.

2. What is a Metal Lathe?

If you work with industrial machines, you know that precision matters. A metal lathe isn’t just another cutting tool—it’s the backbone of metal fabrication.

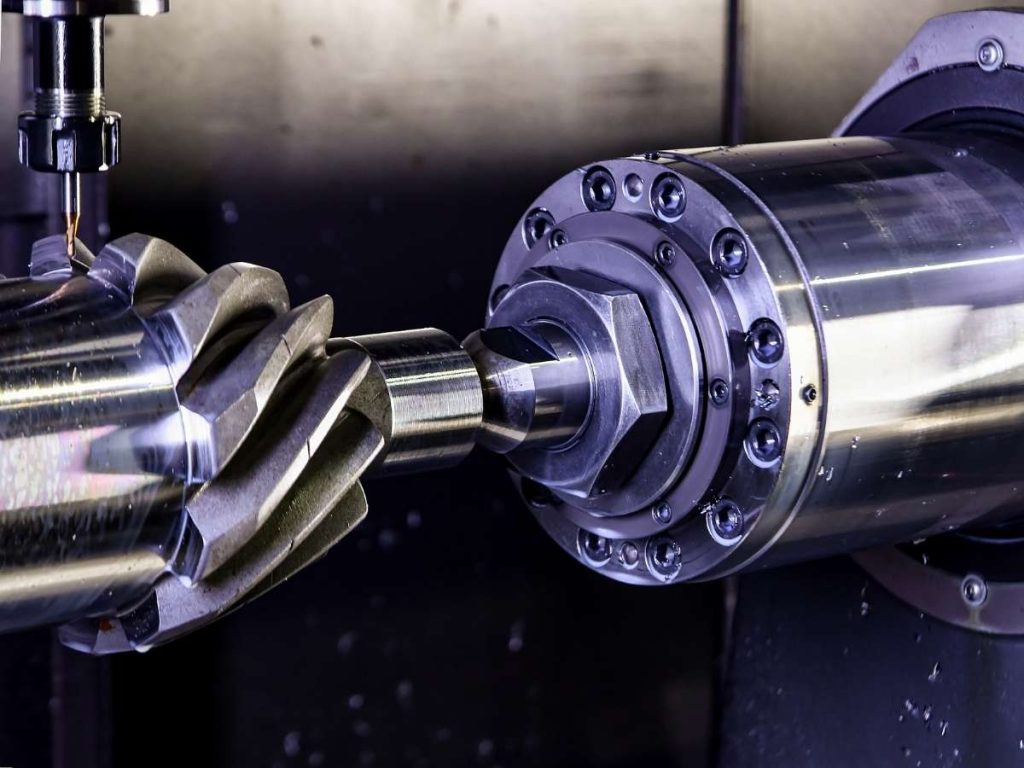

A metal lathe consists of a rigid, heavy-duty frame designed to handle the extreme forces required for shaping metals like steel, aluminum, and brass.

Its key feature? Automated Tool Movement. Instead of relying on manual carving, a metal lathe uses a motor-driven carriage that moves the cutting tool along the workpiece in a controlled, repeatable motion.

How a Metal Lathe Operates

Unlike wood lathes, where the operator manually shapes the material, metal lathes are built for precision and repeatability. Here’s how they work:

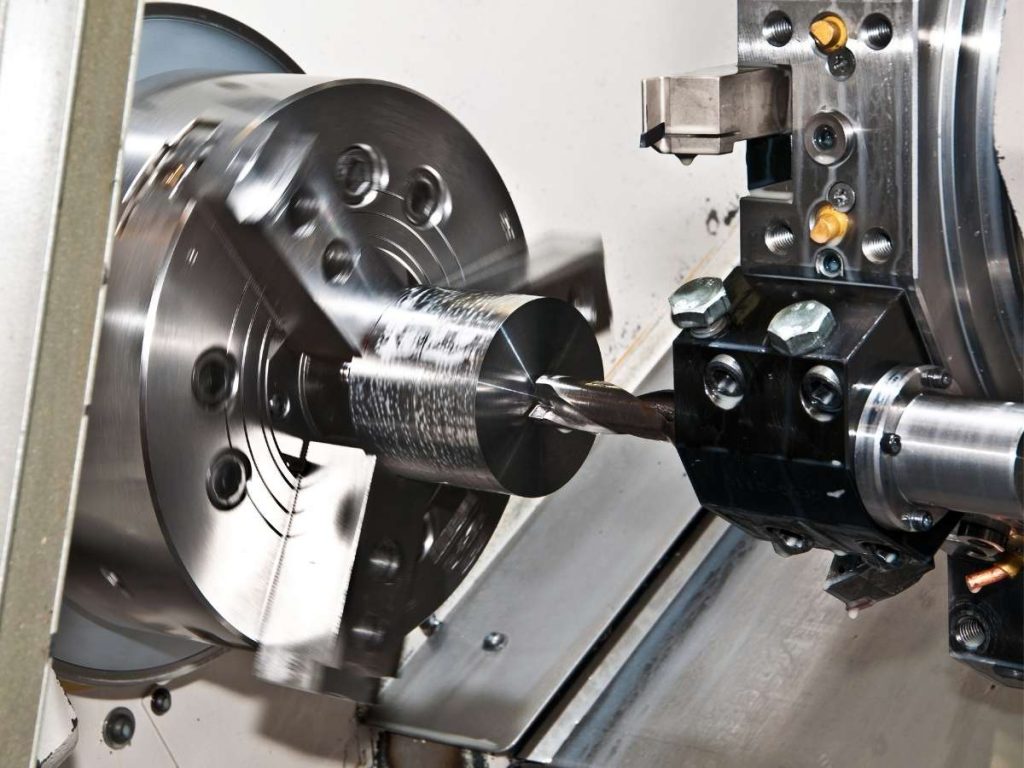

- Workpiece Mounting: The metal is clamped securely in a rotating chuck.

- Motorized Spindle Rotation: The spindle spins at a controlled speed, optimized for cutting metal.

- Cutting Tool Movement: A tool post holds the cutting tool, which moves automatically along the workpiece using a lead screw or carriage system.

- Adjustable Depth And Feed Rate: Operators can control the speed, depth, and direction of the cut to achieve micrometer-level precision.

This precision is why leading brands like Blue Elephant design their metal lathes with advanced automation features—ensuring efficiency and accuracy in large-scale production.

Common Uses

Metal lathes are not just workshop tools—they’re critical to industrial manufacturing. Businesses across different sectors rely on them for:

- Precision Cutting Of Metal Components: Producing gears, bushings, and high-tolerance parts for automotive and aerospace industries.

- Fabrication Of Industrial Parts: Shaping metal components for heavy machinery, oil rigs, and mechanical equipment.

- Threading, Drilling, And Knurling: Creating custom threads for bolts, drilling precise holes, and applying textured finishes for grip surfaces.

If your business supplies, repairs, or rents out metal lathes, understanding these applications is crucial. Metal lathes aren’t just tools—they are investments that drive industrial growth.

3. Design & Build Differences

If you’ve ever handled both a wood lathe and a metal lathe, you know right away—they feel different. One is light, straightforward, and built for smooth, flowing curves. The other is a powerhouse of steel and precision, designed to cut through tough metal like it’s nothing.

The difference isn’t just weight. It’s function, purpose, and the kind of work each machine was born to do.

Wood Lathes

A wood lathe is nimble. It doesn’t need a massive, reinforced frame because wood is soft and forgiving. These machines are built for freehand shaping, allowing operators to carve and mold wood with fluid movements and full control.

- Lightweight Construction: Easier to move, reposition, and set up.

- Minimalist Design: Fewer components, making them simpler to maintain and repair.

- Tool Rest Instead Of A Carriage: Unlike a metal lathe, a wood lathe doesn’t need an automated carriage system—you control the shaping process.

Metal Lathes

A metal lathe is a workhorse. It needs weight, power, and extreme rigidity to withstand the forces involved in metal cutting. Unlike wood, metal doesn’t yield easily. It fights back.

- Heavy-Duty Frame: Metal lathes are built from cast iron or steel to reduce vibrations and increase stability.

- Rigid Bed And Carriage System: These machines use a motorized carriage that moves the cutting tool with pinpoint accuracy.

- Gear-Driven Mechanisms: Unlike the simple belt systems in wood lathes, metal lathes have precision gears to control speed and feed rate with absolute consistency.

A metal lathe isn’t just a tool—it’s an engineering powerhouse. It cuts with micrometer precision, handling the toughest materials in the industry without compromise.

4. Material Handling

I remember the first time I saw someone try to turn a metal rod on a wood lathe. It was a disaster. Sparks flew, the chisel barely made a dent, and within seconds, the machine started vibrating like it was about to shake itself apart.

That moment made one thing clear: not all lathes are built to handle the same materials. If you or your customers don’t understand this difference, it’s only a matter of time before they burn out a motor, break a cutting tool, or destroy a perfectly good machine.

Wood Lathes

A wood lathe is designed to work with organic, lightweight materials. It spins the workpiece fast, allowing the operator to carve, shape, and smooth the surface with hand tools instead of fixed cutting bits.

- Softwood & Hardwood: Wood lathes can handle a variety of woods—oak, maple, walnut, and even softer materials like pine.

- Composite & Resin Materials: Many modern woodworkers use resin-infused blanks for artistic turning.

- Fast Material Removal: Since wood is soft, a sharp chisel can effortlessly shave off layers, shaping curves and contours in minutes.

A wood lathe is forgiving. If you make a mistake, you can adjust on the fly. But if you try to push it beyond what it was designed for—like using it on metal—you’ll quickly learn its limits.

Metal Lathes

Metal lathes don’t just cut metal—they dominate it. Unlike wood, which can be shaped by hand, metal requires force, precision, and the right cutting speeds to get the job done.

- Steel, Aluminum, Brass, & More: Metal lathes are built to handle tough, unyielding materials that require exact measurements.

- Coolant Systems: Cutting metal generates heat. Many metal lathes have built-in cooling systems to prevent tools from overheating.

- Slow, Controlled Cutting: Unlike wood lathes, which rely on high-speed chiseling, metal lathes use slow, controlled passes to remove tiny fractions of material with extreme precision.

I once watched a metalworker try to turn a steel rod on a cheap, lightweight lathe. Within minutes, the motor overheated, the tool bit dulled, and the machine struggled to make a single clean pass. The right lathe makes all the difference.

5. Operational Precision

I’ll never forget watching a skilled woodturner at work for the first time. His hands moved with absolute control, guiding the chisel along the spinning wood, making delicate adjustments with nothing but instinct and experience. The result? A beautifully shaped table leg—smooth, symmetrical, and handcrafted to perfection.

Then, in another shop, I watched a metal lathe in action. No human hands guided the tool—it moved on its own, following precise, pre-set measurements. With each pass, it shaved off thin layers of metal, creating a flawlessly machined part, identical to the one before it.

No guesswork. No freehand adjustments. Just pure precision.

Precision by Hand

A wood lathe is all about manual skill. The operator controls the cutting tools directly, relying on experience and technique rather than automation.

- Hand-Guided Shaping: The tool rest provides support, but it’s up to the operator to control depth, angle, and speed.

- Adjustments in Real-Time: If a cut isn’t quite right, the operator can shift pressure or change direction on the fly.

- Variation in Output: No two pieces will be 100% identical unless the operator has mastered the craft.

Wood lathes give freedom and flexibility, but that comes with a tradeoff—they rely entirely on human precision.

Precision by Automation

A metal lathe is built for repeatability. Every cut follows an exact path, controlled by gears, lead screws, and automated feed systems.

- Automatic Feed System: The tool post moves the cutting bit in a controlled, measured motion—ensuring consistency across every pass.

- Micrometer-Level Precision: Adjustments can be made in fractions of a millimeter, something impossible with hand-controlled tools.

- Perfect Repeatability: Need 500 identical metal parts? A metal lathe will produce them with zero variation.

This is why metal lathes dominate industrial production. There’s no room for guesswork—only precision, accuracy, and absolute control.

6. Maintenance & Spare Parts Availability

The first time I had to troubleshoot a lathe issue, I thought it was a simple fix. A wood lathe had started vibrating too much, and the operator assumed it was a motor problem. Turns out, the tool rest was loose, and the bearings were worn down from months of use without maintenance. A quick adjustment and some fresh bearings solved the problem.

On the other hand, when a metal lathe comes in for repair, it’s rarely that simple. Precision is everything, and even a small misalignment in the gears or lead screw can throw off an entire production run.

That’s the key difference—wood lathes need frequent but straightforward upkeep, while metal lathes demand precision maintenance to keep operations running smoothly.

Wood Lathe Maintenance

At Blue Elephant, w offer wood lathes that endure constant dust, friction, and wear, but they don’t have the complex internal mechanisms of a metal lathe. Most maintenance tasks are quick and manageable.

- Regular Sharpening of Tools: Wood chisels and gouges dull quickly—keeping them sharp ensures clean cuts and reduces strain on the machine.

- Cleaning Wood Dust and Debris: Sawdust accumulates fast and can clog moving parts. Regular cleaning prevents overheating and mechanical issues.

- Checking the Tool Rest and Bearings: Loose tool rests lead to inconsistent cuts, while worn-out bearings cause excessive vibration. Both should be checked frequently.

Metal Lathe Maintenance

Metal lathes can’t afford even the slightest misalignment. A fraction of a millimeter off, and the entire part is ruined. This makes maintenance more technical and critical than with wood lathes.

- Lubrication of Gears and Lead Screws: Metal-on-metal contact generates heat and wear. Proper lubrication extends the life of key components and prevents costly repairs.

- Alignment Calibration for Accuracy: Over time, vibrations and heavy use can shift components slightly out of alignment. Regular calibration ensures the lathe continues cutting with micrometer precision.

- Checking for Wear and Tear on Cutting Tools: Dull or chipped cutting bits leads to inconsistent finishes and wasted material. Operators must inspect and replace worn tools before precision is compromised.

Unlike wood lathes, metal lathe parts are specialized and harder to replace. Lead screws, gears, and motor components must be sourced carefully to maintain machine accuracy. A single misfitted part can ruin performance—which is why experienced dealers and repair professionals are crucial in this industry.

7. Safety Considerations for Each Type

I once watched a new operator turn a piece of wood on a lathe without wearing a face shield. It took just one second—a splinter flew off at high speed, missing his eye by inches. That was a close call, but I’ve seen worse. In metal shops, I’ve witnessed cutting tools snap under pressure, sending shards of metal flying across the room.

Safety isn’t just a checklist. It’s the difference between a productive day and a serious injury. And when it comes to lathes, wood and metal machines come with very different risks.

Protecting Against Flying Debris

Wood lathes may seem less dangerous, but they come with their own set of hazards—splinters, dust inhalation, and tool kickbacks. The key to safety is protecting the operator from airborne debris and ensuring proper tool handling.

- Wear a Face Shield or Safety Glasses: Wood chips and splinters fly unpredictably. Eye protection is a must.

- Keep Hands Clear of the Spinning Workpiece: It’s easy to get too close when making manual adjustments—one slip, and fingers can get pulled in.

- Use Sharp Tools to Avoid Kickback: Dull chisels cause the tool to catch, leading to violent jerks that can throw the chisel out of the operator’s hands.

- Secure the Workpiece Properly: Loose wood can spin off at high speeds, turning into a dangerous projectile.

Preventing High-Force Injuries

Metal lathes operate under high torque and extreme precision—which means that when something goes wrong, it happens fast and with serious consequences.

- Always Wear Safety Glasses and Protective Gloves: Metal shards can be razor-sharp and unpredictable.

- Keep Hands Away from Moving Parts: Unlike a wood lathe, where manual shaping is normal, a metal lathe uses automatic feeds. One moment of carelessness, and hands can get caught.

- Ensure Proper Lubrication to Prevent Overheating: Friction builds up fast in metal cutting. Without proper lubrication, tools can snap, workpieces can jam, and motors can overheat.

- Never Leave a Running Lathe Unattended: If a tool bit breaks or a piece of metal shifts unexpectedly, damage happens in seconds. A machine should never be left cutting without supervision.

8. What to Choose Between Wood and Metal Lathe

I once had a machine dealer tell me about a customer who insisted on using a wood lathe for small metal parts. “It should work fine,” the customer said. 2 weeks later, the motor burned out, the rest of the tool was wrecked, and the machine was unusable. He ended up buying a metal lathe anyway—after losing both time and money.

That’s why choosing the right lathe isn’t just about preference. It’s about function, efficiency, and making the right investment from the start. Let’s break down the key factors that determine whether a wood lathe or a metal lathe is the best choice for your business.

Work Type

The first question: What material will your customers be working with?

- Wood Lathe: Best for shaping wood, crafting furniture, and making decorative pieces. Allows for freehand carving and artistic flexibility.

- Metal Lathe: Essential for precision cutting, machining industrial parts, and working with metal. Built for high accuracy and repeatable cuts.

Choosing the wrong lathe means inefficiency, damage, and wasted investment.

Precision vs. Flexibility

Wood lathe requires manual control. Cuts and shapes are guided by hand, offering custom designs but less consistency. While metal lathe uses automatic feed systems and calibrated movements. Ideal for identical, repeatable parts with extreme precision. For artistic woodworking, choose a wood lathe. For manufacturing and industrial use, go with a metal lathe.

Budget & Value

- Wood Lathe: Cheaper upfront with minimal maintenance. Great for businesses that don’t need extreme precision.

- Metal Lathe: Larger investment but holds value longer. Essential for machining industries and high-end production.

For tight budgets and basic needs, a wood lathe works. For long-term, industrial investment, a metal lathe is the smarter choice.

Conclusion

2 weeks. That’s how long it took for that wood lathe to burn out under metalwork. The lesson? Using the wrong machine for the job is a costly mistake.

If you need manual flexibility, a wood lathe is the answer. If you require automated precision, a metal lathe is your best bet.

One is built for craftsmanship, the other for industry. Which one fits your business?

Don’t let a bad decision slow you down.

Contact us now, and let’s find the best lathe for your needs.

Explore More Helpful Resources

Want to see more products? We’ve got plenty of options that might just be the perfect fit for you:

Still haven’t found what you’re looking for? Don’t hesitate to contact us. We’re available around the clock to assist you.