CNC Milling Machines

Blue Elephant: Your Reliable CNC Milling Machines Factory

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Customization Options

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

Croatia | Bathroom and Kitchen Furniture Manufacturing

Customer Challenges

- Expanding into kitchen and bathroom furniture

- Needs suitable CNC, considering bridge cutting saws

- Facing stock issues with local suppliers

- Price sensitive, comparing 4+1 and 5+1 Bridge Saws

- Seeks dependable suppliers for new operations

Our Solution

- Suggested the 4+1 Bridge Cutting Saw for its efficiency in bathroom and kitchen projects, suited to the budget.

- Detailed the benefits of 4+1 over 5+1 models, focusing on their cutting capabilities. Recommended 4+1 for its sufficiency.

- Explained galvanization of critical parts and use of antirust paint for others.

- Organized a visit for the customer’s agent to verify product quality and supplier reliability.

- Offered a timely discount to motivate quick decisions, emphasizing value and competitive pricing.

Final Results

- Customer chose the 4+1 Bridge Cutting Saw, suitable for their needs.

- Smooth process with clear communication.

- Customer confident in product quality and supplier partnership.

Ecuador | Personal Studio for 3D Model Creation

Customer Challenges

- Starting a new business in 3D model production

- Limited experience with CNC machines, worried about complexity

- Needs a budget-friendly, versatile, and easy-to-use solution

Our Solution

- Recommended the ELECNC-1530 ATC 4-Axis Router, featuring a spindle that swings ±90 degrees for complex tasks.

- Delivers ±0.03 mm precision, allowing high-quality 3D model creation.

- Confirmed the machine's user-friendliness, with ongoing free online support for a smooth transition to automated engraving.

- Discussed the growing 3D model industry, showing how this machine meets current and future needs, aiding market entry.

Final Results

- Shipped the ELECNC-1530 ATC 4-Axis Router to the customer’s studio in Ecuador.

- Provided comprehensive training and support, enhancing the customer’s confidence in using and maintaining the machine.

- Received positive feedback about the machine’s ease of use and precision, supporting future business expansion.

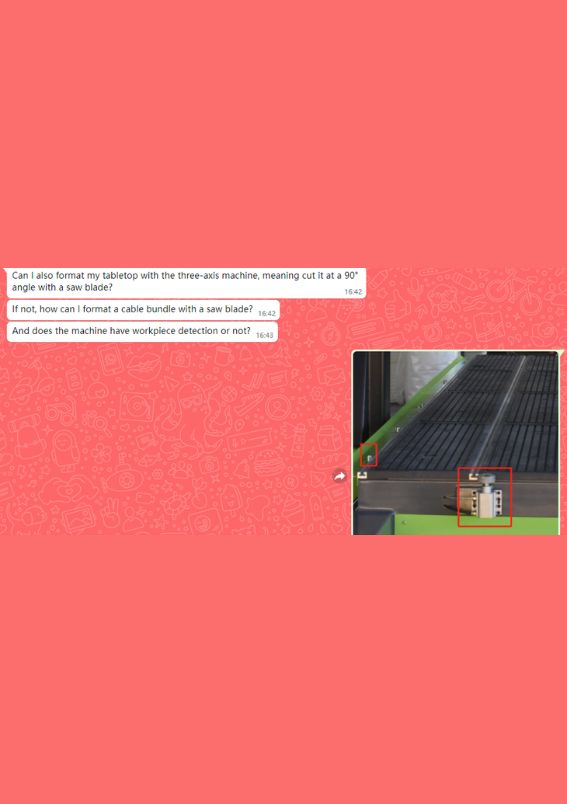

Austria | Wood Flooring Production

Customer Challenges

- Shifting from outsourcing to in-house wood flooring production

- Used a CNC machine with a right-angle head and saw blade, including an edge-seeking feature

- Uncertain about buying a similar machine or a cheaper option

- Budget capped at 15,000 USD for the initial machine purchase

Our Solution

- Recommended the standard ATC (Automatic Tool Changer) over the specialized right-angle head and saw blade, highlighting its efficiency for required tasks without the edge-seeking feature.

- Clarified cost benefits, showing the standard ATC fits the budget while meeting production needs.

- Compared both machine options, emphasizing functionality and clear differences.

- Kept communication clear and direct to aid the customer's decision-making.

Final Results

- Chose the standard ATC for its value and functionality.

- Installed successfully; performs well in production.

- Customer satisfied with guidance and support, considering a long-term partnership.

- Valued the budget-friendly, functional solution.

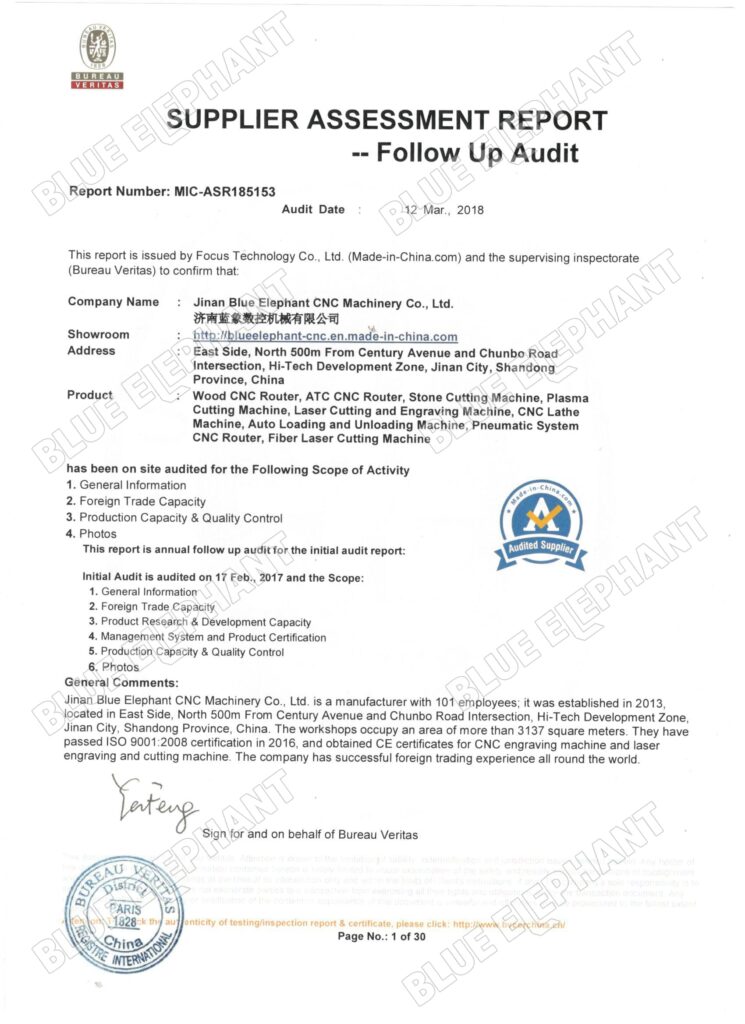

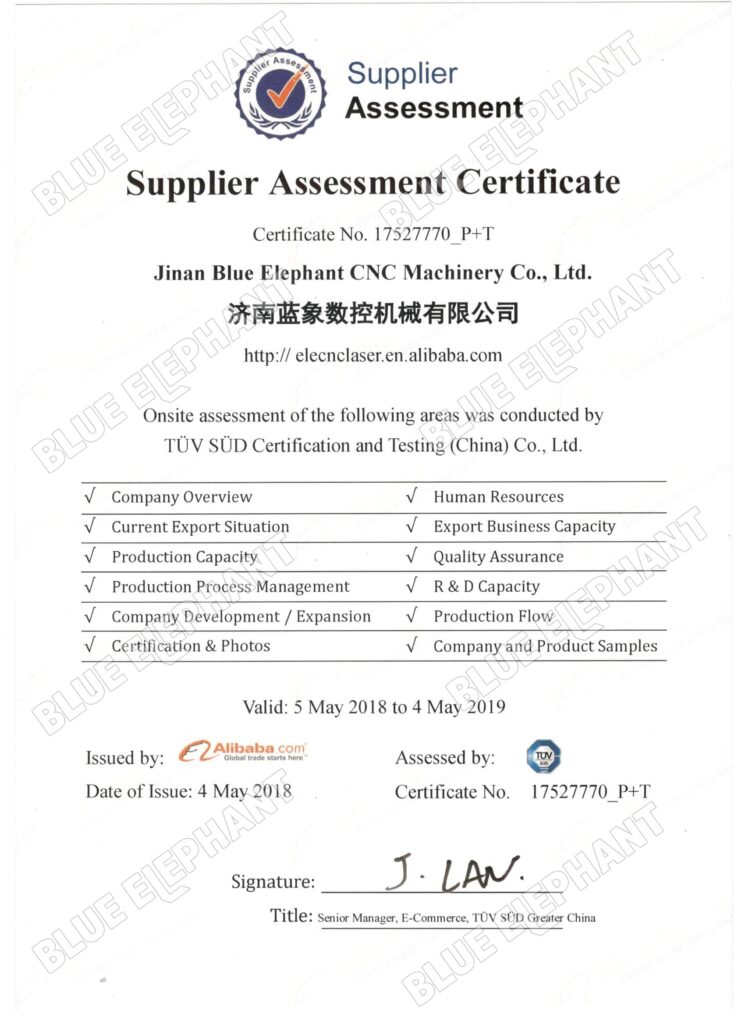

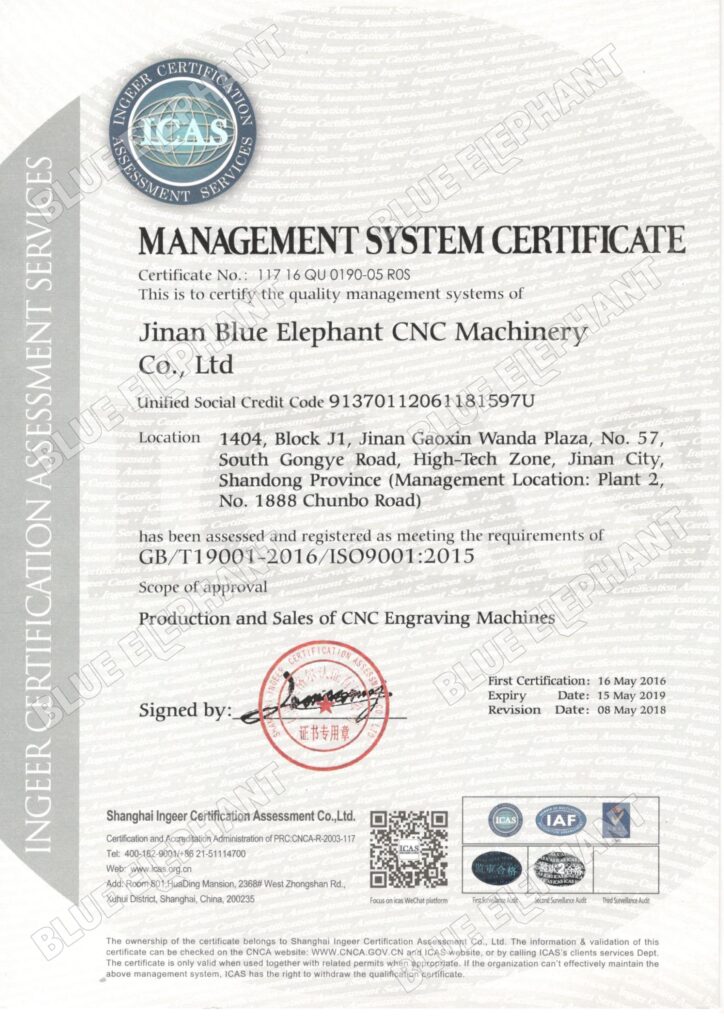

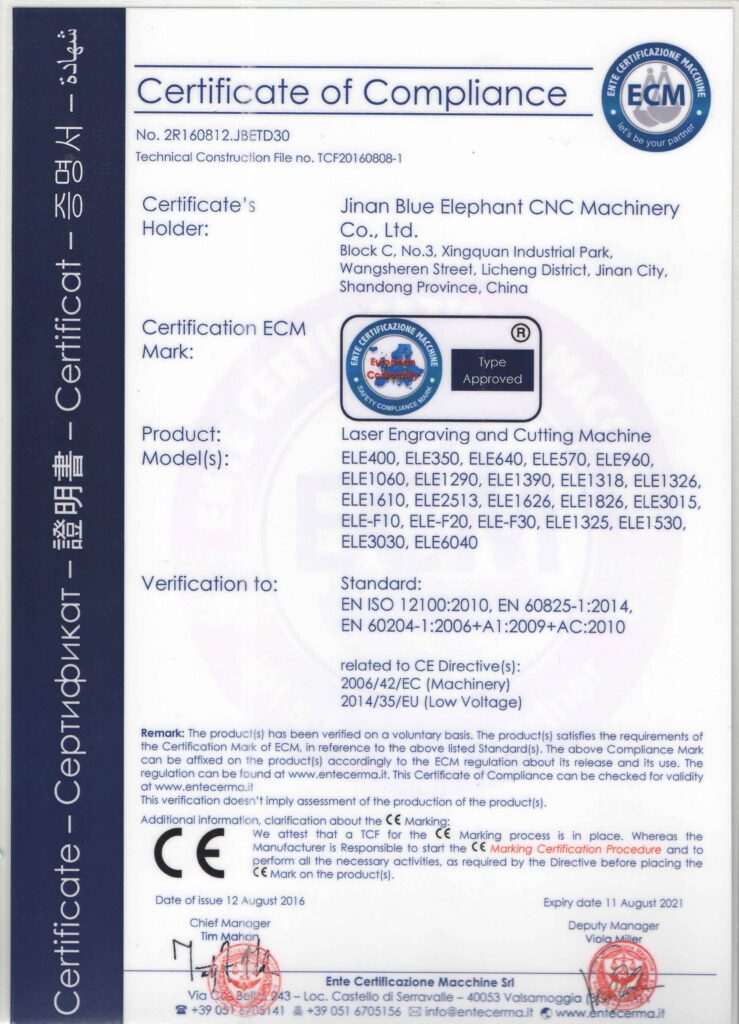

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

Real Stories from Our CNC Milling Machine Clients

INDONESIAN

Highly Efficient and Accurate, Perfect for Metal Milling

CNC Milling Machine is ideal for precise and automated cutting on materials like aluminum, copper, brass, mild steel, stainless steel, and plastic. Delivers smooth finishes and consistent accuracy on complex parts.

SAUDI ARABIAN

We Use It Daily for Custom Parts, Very Reliable Machine

The horizontal panel saw machine is mainly for cutting various wooden panels and sheets. It takes more space but easier to use than vertical ones. The panel sizing machine mainly includes the computer beam saw (computer CNC panel saw) and the sliding table saw.

25 Ways to Make Money with CNC Milling Machines

- Precision metal part prototyping for engineers

- Aluminum nameplate and tag engraving

- Production of custom automotive parts

- Mold making for plastic injection

- Engraving custom metal tools and dies

- Jewelry mold and wax model production

- Machining of mechanical spare parts

- Small-batch industrial part manufacturing

- Engraved branding plates for equipment

- Production of motorbike and bicycle components

- Medical device prototyping and parts

- Heat sink and electronic casing fabrication

- Hobbyist-grade firearm part customization

- Machining of aerospace-grade components

- Engraving of industrial control panels

- Steel and alloy sample making for R&D

- Training and workshops for CNC operation

- Local contract milling services

- Repair and remanufacturing of old machinery parts

- Custom enclosure machining for electronics

- Production of engraved architectural models

- CNC design and G-code programming services

- Flipping or leasing CNC machines

- Online sales of custom machined products

- Custom knife and tool handle machining

Frequently Asked Questions

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371