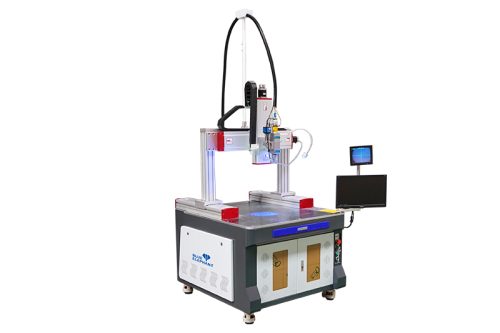

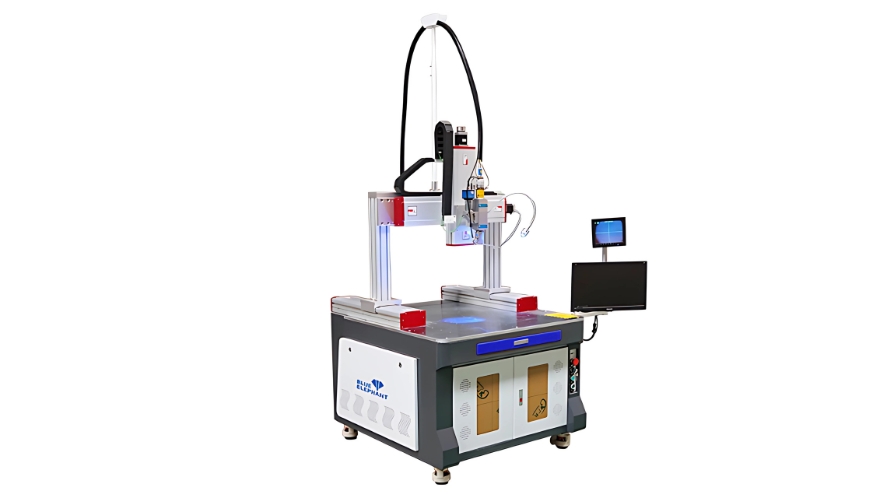

Laser Welding Machine

Blue Elephant: Your Reliable Laser Welding Machine Manufacturer

If you’re looking for a reliable laser welding machine, Blue Elephant offers machines that deliver clean results and steady output. Our models are built to handle daily demands—whether you’re working with stainless steel, aluminum, or other metals. From custom parts to repeat jobs, these machines give you tight, clean welds that save time and reduce waste.

As a trusted CNC company, we pay close attention to both performance and long-term value. We also offer custom builds to match your shop’s needs. Backed by skilled support and constant product updates, Blue Elephant helps businesses stay productive and accurate with every weld.

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Related Products

-

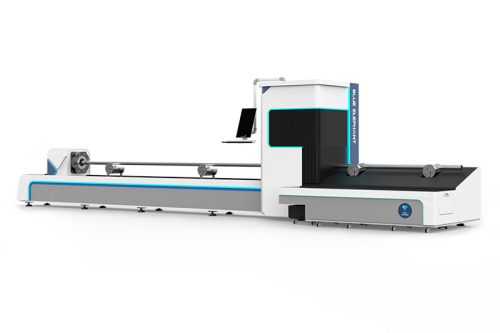

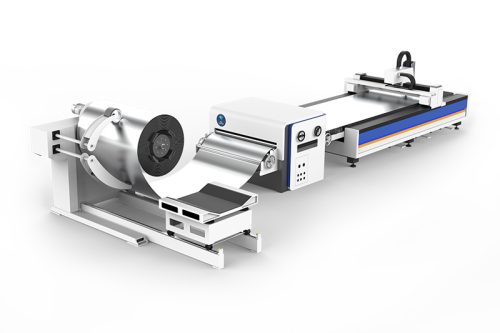

1530ET Metal Sheet and Pipe Fiber Laser Cutting Machine

Read more -

200F Fiber Laser Marking Machine for Sale

Read more -

1390 CO2 Laser Engraver with CO2 Laser Tube

Read more -

1325 CO2 Mixed Laser Cutting Machine or Metal & Non Metal

Read more -

100W Handheld Laser Cleaning Machine

Read more -

6160T Metal Tube Fiber Laser Cutting Machine

Read more -

1530E Fiber Laser Cutting Machine with Exchange Platform

Read more -

1530FC Coil Fed Fiber Laser Cutting Machine

Read more

Customization Options

Every laser CNC machine from Blue Elephant can be adjusted to fit your work style. You can upgrade performance, change the size, or even add your own brand logo. Whether you need faster output or a cleaner look, we can build the machine around your needs.

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

Mongolia

Aluminum and Steel Processing

Customer Challenges

- Unclear about the model and function of the fiber laser welding machine.

- Needed help choosing the right machine for aluminum and steel.

- Debated between a dedicated welder or a multi-functional machine.

Our Solution

- Evaluated customer’s material and thickness needs.

- Recommended a 1.5KW fiber optic welding machine.

- Explained the benefits of a three-in-one machine.

- Advised buying the three-in-one machine for its versatility and small price.

- Decided on the three-in-one machine and a woodworking machine .

Final Results

- Prepared and ordered the machine for shipment.

- Customer pleased with the guidance and versatile machine choice.

- Enhanced production flexibility and efficiency with the three-in-one machine.

Saudi Arabia

Metal and Non-Metal Processing

Customer Challenges

- Needed tools for cutting both metal and non-metal.

- Limited budget, required affordable, high-quality equipment.

- Concerned about support for complex fiber laser systems.

- No experience in balancing the initial investment with the subsequent costs.

Our Solution

- Recommended the 1325 CO2 Laser and 1325 Fiber Laser .

- Agree to discounted prices and assured that the best machine quality.

- Committed to thorough after-sales service, including on-site training .

- Showed proven reliability through case studies and customer feedback.

Final Results

- Delivered machines to Saudi Arabia with comprehensive support.

- Customer pleased with the machine quality and cost.

- Established trust in our professional service, hinting at a lasting partnership.

Türkiye

Custom Parts Production

The client was a small sheet metal start-up cutting stainless and carbon steel for custom parts.

Customer Challenges

- Limited budget, but worried low-cost machines might be unreliable.

- No experience with laser cutting. Worried workers couldn’t operate the software.

- Remote location. Concerned about delayed after-sales service.

Our Solution

- Recommended a 1000W enclosed fiber laser machine.

- Gave a remote demo of real cutting to prove quality despite entry-level pricing.

- Sent a technician for on-site installation and training.

- Provided video tutorials and a support group for quick help from engineers.

- Connected the local technical partners to reduce maintenance costs.

Final Results

- Workers learned software basics in just two days. Fast layout, low error.

- Customer secured new orders and no longer worried about machine quality.

- Machine cost was 25% below budget. Extra funds used for material stock.

- Customer was very satisfied and plans to buy a higher-power machine next year.

What Our Customers Say about Edge Banding Machine

SAUDI ARABIA

E-70JDSR Edge Banding Machine

After unloading the machines, the staff also placed, organized, adjusted and set them up diligently until we finally completed the work.

The quality of the finished products I saw was also very good and satisfactory. Hopefully this is a good start.

AMERICA

E-80 Edge Banding Machine

The customers purchased our CNC machine two years ago. This time, they came to purchase another edge banding machine.

" Actually we are using that machine for two years and we have a very good experience with it. They have very professional salesteam and customer service. Definitely we will be their customers again."

MAURITIUS

E-80L Edge Banding Machine

We are from Mauritius and we came here to look at some work machines. We got an edge banding machine and a beam saw.

And we see that the factory is really good. They have very nice production, great engineer. And overall so far we' re very happy with what we've seen. And we look forward to having the machines and starting to use them.

Montenegro

E-60 Edge Banding Machine

Our after-sales technicians went to Montenegro to debug the machine and provide guidance on machine operation.

The customer said the machine was very good and was grateful for our service.

About Our Factory

15+ years in business as an industry leader

75000+㎡ High-level Production Base

25+ Dedicated Production Bays

10 technical service centers around the world

30+ locations worldwide

500+ emplovees for service you

8000+ client' Trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

Honest Reviews from Laser Welding Machine Users

TURKISH

The laser welding machine gave me clean welds on stainless steel with very little heat damage. Setup was simple, and it’s worked well for both repairs and light production jobs.

ZIMBABWE

I’ve used this laser welding machine on aluminum bike parts, and the results were great. Strong welds, smooth seams, and no need for extra grinding or post-cleaning afterward.

SAUDI ARABIAN

This laser welding machine helped speed up our custom tool repairs. It’s easy to operate and gives accurate welds every time. We’ve had no issues with overheating or warping so far.

25 Ways to Make Money with a Laser Welding Machine

- Automotive part repair

- Jewelry repair and fabrication

- Medical equipment welding

- Mold and die repair

- Custom metal art

- Bicycle frame repair

- Aerospace component welding

- Precision tool welding

- Small batch manufacturing

- Welding stainless steel kitchenware

- Engraving and welding combo services

- Watch and eyeglass frame repair

- Dental tool manufacturing

- Welding for electronic enclosures

- Metal furniture repair

- On-site welding services

- Prototype development support

- Metal signage welding

- Contract welding for factories

- Battery tab welding

- Micro welding for delicate parts

- Industrial blade repair

- Creating custom metal brackets

- Rewelding cracked aluminum parts

- Welding parts for 3D printed metal assemblies

Frequently Asked Questions

A laser welding machine can weld metals like stainless steel, carbon steel, aluminum, brass, and copper. Some machines also handle dissimilar metals, depending on your setup.

Most machines are easy to learn with some basic training. Once you understand the controls and safety steps, you can start welding clean seams without much trouble.

Laser welding uses a focused beam to join materials. It creates cleaner, smaller welds with less heat. This means less damage to surrounding areas and a neater finish.

Yes. Laser welding machines are great for both large projects and detailed work. Many shops use them for tool repairs, jewelry, electronics, and custom parts.

Pay attention to power output, supported materials, machine size, and how it fits with your current tools. You’ll also want to check support options and available spare parts.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371