Customer Stories

Discover real experiences and successes with Blue Elephant.

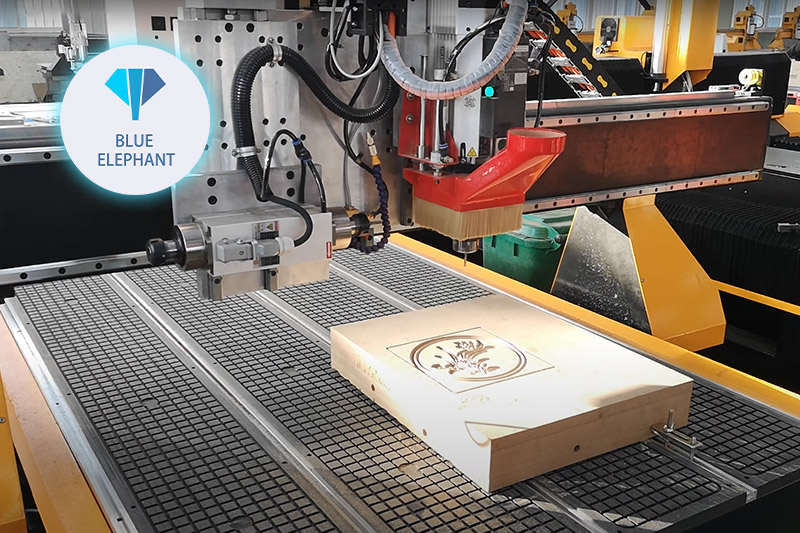

Factory& Quality Control in Action

At Blue Elephant, we welcome entrepreneurs from around the world to visit us and see our commitment to quality, precision, and service firsthand. Our machines undergo rigorous testing, our technology meets the highest standards, and our support is built to last, ensuring long-term reliability for every customer.

Beyond expanding markets, we build lasting partnerships. Customers worldwide trust Blue Elephant for reliable CNC solutions and exceptional service. Here are their experiences, sharing real feedback from industries across the globe.

How To Set Coordinate System Of Z Axis Gap In LNC MW5800A

The steps are as follows. Press “JOG” Move spindle by press “X”、“Y”、“Z” Press “MPG”,then turn handwheel Choose “SETUP”,then choose “ATM” Choose “Z SET” Choose “SETUP”,then choose “TEACHIN”,choose “SETX”、“SETY” Press “JOG”

How To Set The Position Of Tool Calibration In LNC MW5800A

The steps are as follows. Choose “MAINTE”,then input “5”to User and “2222” to Password Choose “SETUP”,then choose “ATM” Press “MPG”,then turn the handwheel Choose “TEACH IN YX” The video is as

How To Set The Position Of Tool Magazine In LNC MW5800A

The steps are as follows. Choose “MAINTE”,then input “5”to User and“2222” to Password Choose “SETUP”,then choose “ROW TOOL” Please notice “XCOORD、YCOORD、ZCOORD” Press “MPG”,then turn handwheel Choose “TECHIN”,then choose “SETX” Choose “YCOORD”,then

Rotary Device Machining Example In LNC MW5800A

The steps are as follows. Press “JOG” Move spindle by press “X”、“Z” Press “MPG”,then turn handwheel Choose “SETUP”,then choose G54 Choose “TEACHIN”,then choose “SETX”、“SETY”、“SETZ”、“SETA” Press “JOG”,then move spindle by press

Slotting And Side Hole Machining Example In LNC MW5800A

The steps are as follows. Part1 Slotting Machining Press “MPG DRN”until the green light is on Press “MEM”until the green light is on Press “CYCLE START”,then turn handwheel Press “F%-”,then

Fiber vs co2 laser cutting machine

Fiber laser vs Co2 laser is a frequent asked question, it includes cost, speed, maintenance and other issues. Fiber laser & Co2 laser are two important laser sources of laser

MW2200 Horizontal spindle ATC teaching videos

1. Establishing the workpiece coordinate system 2. Automatic tool setting and measuring tool length 3. How to put two spindles into one program and run 4. Handwheel movement 5. Start

How To Set The Workpiece Zero Point In NK105 G3

The steps are as follows. The video is as follow.

How To Set The Workpiece Zero Point In NK260 Control System

The steps are as follows. Press “Handle”,then turn the handwheel to adjust position When tool touch surface of workpiece Press “F6”,then press “F5”,for all axes go back to zero Press