Customer Stories

Discover real experiences and successes with Blue Elephant.

Factory& Quality Control in Action

At Blue Elephant, we welcome entrepreneurs from around the world to visit us and see our commitment to quality, precision, and service firsthand. Our machines undergo rigorous testing, our technology meets the highest standards, and our support is built to last, ensuring long-term reliability for every customer.

Beyond expanding markets, we build lasting partnerships. Customers worldwide trust Blue Elephant for reliable CNC solutions and exceptional service. Here are their experiences, sharing real feedback from industries across the globe.

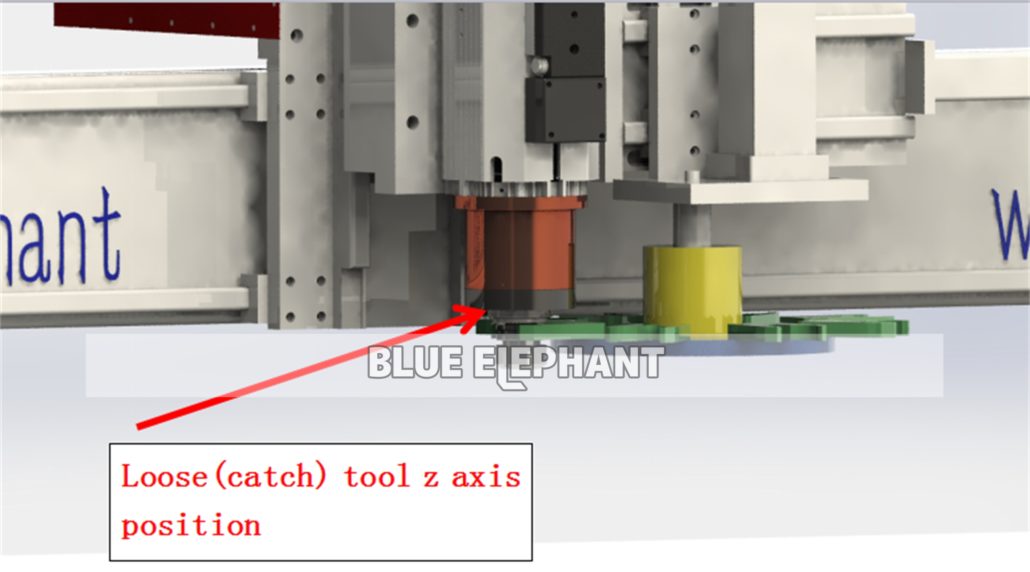

SYNTEC disk magazine parameters

Now we back to Syntec parameters seting Parameter meaning2803 Loose(catch) tool z axis position Accutlly the value is 8 tools z position average value2823 After Loose tool z axis move

SYNTEC disk tool setting tool parameters

SYNTEC disc changer 2841 x location 2842 y position 2843 z position The shortest knife 2846 z axis rapid positioning point When the customer uses a long knife, the following

How To Set Parameters Of Ball Screw CNC Router In DSP A11

The steps are as follows. The first part is “Pulse Equiv” 1.Press“MENU”button,then choose“MACHINE SETUP” 2.Press“OK”button,then choose“Pulse Equiv” 3.Press“OK”button, then Press“DELETE”button to clean the number 4.Input the data.The normal pulse of

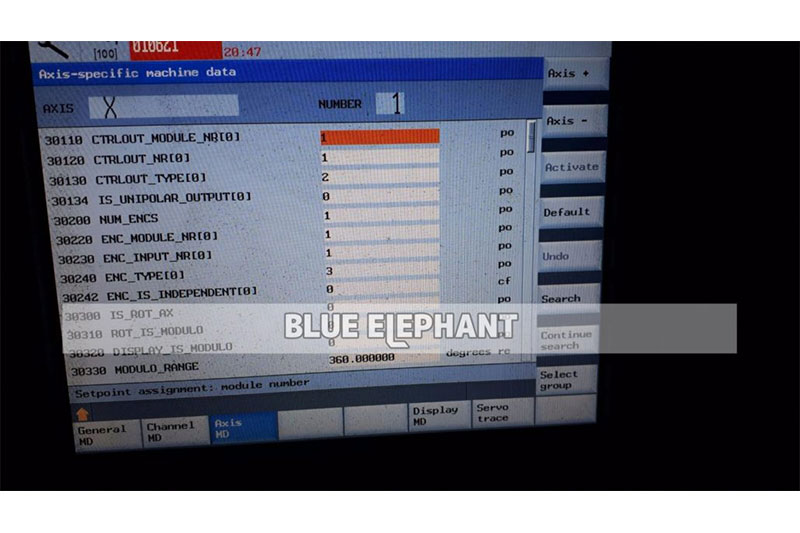

How to change rotary and real four axis in Syntec 6MB

After power on, have alarm:MLC 65 (R44.0)Rotation axis not back to orign alarm.(rotary)MLC 19 Z not yet back homeMLC 11 Y not yet back homeMLC 3 X not yet back

Common key change tool and knife

Carousel tool magazine Clockwise Carousel tool magazine Anticlockwise K7:Brush up and down K8:Measure tool K9:Oil-mist cooling K8:Measure tool How to change the tools of Carousel Tool Magazine. HRER ARE THE

How To Set Workpiece Zero Point In DSP A15 Handle Control System

The steps are as follows. The video is as follow.

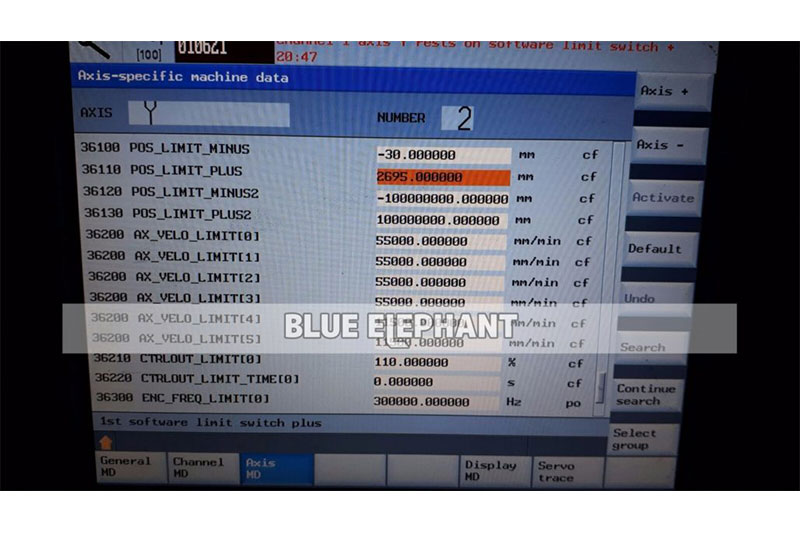

Siemens Disk Magazine

Press the key OFFSET ,you will see the windows ,like the picture . The mark. Press the key ④. You will see the R variable. R101 : 0 R102 :

How To Set The Zero Point Of Workpiece And Working In DSP B58

The steps are as follows. The first part is setting of workpiece zero point. 1.Move tool 2.When the tool is near workpiece,press”MODE”button,change “ContinueMode” to “StepMode”. 3.The Z axis will move

SIEMENS ITINERARY CHANGE

Press both buttons at the same time,the following interface will appear