Beam Saw Cutting Machine

Blue Elephant: Your Trusted Beam Saw Cutting Machine Manufacturer

-

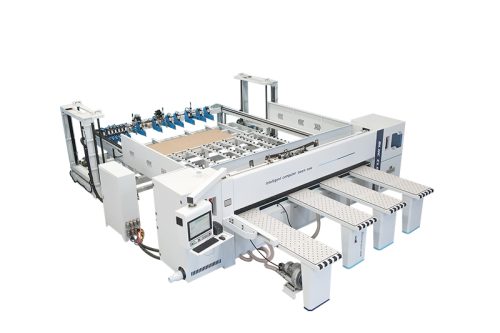

420 Computer Beam Saw Machine for Sale

-

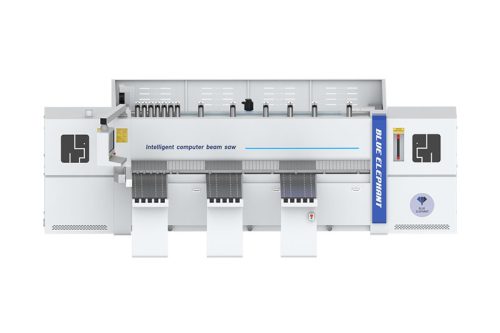

380 Computer Beam Saw for Sale

-

280 Computer Beam Saw with Groove Pulling Function

-

330C Rear Feeding Computer Beam Saw Machine

-

380 Computer Beam Saw Machine for Sale

-

280HG Automatic Loading Computer Beam Saw

-

280 Automatic Computer CNC Beam Saw

-

330 Computer Beam Saw Machine for Sale

Reduce Costs 30%, Increase Profits 42%

with Our CNC Machine.

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371

Explore More via Video

Related Products

-

EK2-1328 Double Head Linear CNC Machining Center

Read more -

E-70JR Auto Edge Banding Machine for Sale

Read more -

ET6 6 Sided CNC Drilling Machine with a Return Table

Read more -

ES4-3220 4 Axis CNC Bridge Saw Machine

Read more -

A6L Automatic Vacuum Press Machine

Read more -

E100 Single Head Side Hole Drilling Machine

Read more -

EM610 Cabinet and Door Wood Drilling Machine

Read more -

EM3.2-1126 Through-type Double-channel Keyhole Hinge Machine

Read more

Customization Options

Specs & Functions

CNC machines tailored in size, power, and system to meet your needs

Aesthetic Design

Custom colors and styling to enhance your brand identity

Branding Service

OEM solutions with your logo for market distinction

What Sets Blue Elephant Ahead

Superior Quality

100% inspection and 160 checks ensure precision and zero issues.

Cost Effectiveness

Efficient manufacturing meets ISO9001, SGS, CE, BV standards at competitive prices.

Precision Custom

Advanced CNC technology with yearly upgrades keeps products at the cutting edge.

Innovation Focus

Advanced CNC and annual upgrades ensure innovation and top performance.

Reliable Support

A dedicated 50+ team provides 24/7 pre-sales, installation, and maintenance support.

Global Reach

A 75,000㎡ modern factory supports direct sales, regional optimization, and fast delivery.

Certified Excellence

International certifications and over 8,000 satisfied users build trust and credibility.

Extended Warranty

A 12-month warranty, along with a 60-day trial, ensures lasting peace of mind.

Real-World CNC Solutions

Discover how businesses across industries overcome production challenges with Blue Elephant CNC solutions. From improving precision to enhancing efficiency, our machines help companies achieve their manufacturing goals.

Australia

Wooden Doors and Cabinets Production

Customer Challenges

- New to furniture, lacks machine operation skills.

- Knows needed machine specs, but unsure about operation and upkeep.

- Needs training and support after purchase.

Our Solution

- Quickly responded with price details and machine selection help.

- Suggested the 1325 Openers with automatic knife changes.

- Gave a thorough machine walkthrough via video.

- Demonstrated our factory's capabilities to gain trust.

- Addressed all issues directly through video chats.

- Applied a flexible pricing model and got a discount approved.

- Helped with contract, delivery scheduling, and training costs.

Final Results

- Machine set up and working at the customer's site.

- Customer trained on machine use and upkeep.

- Ongoing support provided to reduce operational issues.

United Arab Emirates

Tables Mass Production

Customer Challenges

- Customer owns a small furniture factory that mass produces furniture such as tables and cabinets. He needs an edge banding machine.

- Small factory, needs a versatile machine within budget.

- Worried that the equipment is complicated to operate and training is difficult.

Our Solution

- No need for batch processing and the budget is limited. Entry-level E50 edge bander is sufficient to meet the needs.

- Confirm with the technicians wants be achieved on one machine.

- Provide itemized costs including freight and machine configuration.

- After-sales team provide online guidance and door-to-door service.

Final Results

- Customer's questions and requests were responded to on the same day.

- Customer was very satisfied with the discount price.

- Machine was installed, debugged and operated smoothly.

- Customer was very satisfied with the machine and after-sales service.

New Zealand

Cabinets Production

Customer Challenges

- Limited CNC and software experience.

- Small studio, needs a versatile machine within budget.

- Concerns about software costs and ongoing support.

Our Solution

- Suggested 1530 CNC and W1 Edge Banding Machine for their versatility.

- Offered 1530ATC with a vacuum and a curve automatic edge bander.

- Set up a dedicated after-sales group for guidance and potential on-site service.

- Provided itemized costs including shipping and machine configurations.

- Discussed software cost solutions and training options.

- Contact via email, phone, and WeChat for any queries or changes.

Final Results

- Customer bought 1530ATC CNC, E-50J Edge Bander , and Cold Press .

- Clear and proactive communication ensured a smooth transaction.

- Customer happy with machine quality and after-sales service.

What Our Customers Say about Panel Saw

Turkey

330 Computer Beam Saw

This machine is a sawing machine that I bought from Blue Elephant factory. I am very satisfied, I have been using it for 3 months,

they provide immediate service with technical support. I am very satisfied with the machine in terms of cutting and sizing, I plan to buy other machines in the future. I would like to thank the blue elephant staff and engineers very much.

UK

540 Computer Beam Saw

We come to have a look at some machineries, this is an effective message. It's a really big factory,

very nice quality and we hope to have some visits in the future.

SAUDI ARABIAN

280C Computer Beam Saw

This beam saw cutting machine fits right into our workshop. We use it for cabinet parts and custom panels.

Accurate cuts and steady performance. It’s helped us speed up jobs and cut down on waste. No big issues so far.

Kyrgyzstan

280 Computer Beam Saw

I have visited the Blue Elephant factory, and the machine tools there are really good. I bought a 280 computer beam saw machine and it is great.

Intends to use it to do all the work, and it’s all set. Thank you very much for the warm reception from Blue Elephant, their machines are really good, l also bought a double station cutting machine, and many other different types of machines, the quality is really very good.

About Our Factory

15+ years in business as an industry leader

75000+㎡ high-level production base

25+ dedicated production bays

10+ technical service centers around the world

30+ locations worldwide

500+ employees for service you

8000+ clients' trust and recognition

Exported to 180+ countries and regions

Our Valued Certifications

Blue Elephant CNC machines comply with internationally recognized standards, holding certifications such as CE, ISO9001, BV, SGS, and TUV. Our strict quality control processes and precision engineering ensure high-performance, durable, and reliable solutions that meet the demands of global industries.

25 Ways to Make Money with a Beam Saw Cutting Machine

- Furniture production

- Kitchen cabinet making

- Wardrobe manufacturing

- Office desk cutting

- Custom wood paneling

- Interior decoration services

- Wooden door manufacturing

- Window frame cutting

- MDF board processing

- Plywood sheet cutting

- Bulk cutting for carpenters

- Shopfitting projects

- Wooden crate production

- DIY furniture kits

- Signboard cutting

- Exhibition stand building

- Packaging material cutting

- Acoustic panel cutting

- Wood flooring cutting

- Art panel production

- Toy making with wood sheets

- School furniture production

- Hotel furniture supply

- Contract work for factories

- Renting the machine for local jobs

Frequently Asked Questions

Explore More of Our Resources

Connect With Us

For any inquiries, don’t hesitate to contact us at:

- manager@elephant-cnc.com

- +86 186 6899 1371