Nowadays, a lot of acrylic product manufacturers often choose the CNC Acrylic Laser Cutter Machine or CNC Router acrylic cutting machine for the processing of acrylics. Acrylics, as a plastic polymer material, has a wide range of application. People often use it to produce advertising signboards, lamp boxes, direction boards, shop windows, and display racks, etc.

Both the CNC Acrylic Laser Cutter Machine and CNC Router acrylic cutting machine have their own advantages for processing acrylic. While choosing to purchase, the users need to understand the machines and choose the right one based on their demands. Otherwise, if the users choose the unsuitable machine, it will affect the processing effect, and also cause economic loss.

This article mainly focuses on the brief introduction, working principles, and the comparison of processing features of the two machines. And the following also gives suggestions on how to choose a suitable machine.

What are CNC Acrylic Laser Cutter Machine and CNC Router acrylic cutting machine?

·Similarities:

Both the laser acrylic cutting machine and the CNC Router acrylic cutting machine are computer-controlled ones. And they both need a computer to design cutting graphics and control the cutting process. The users use the software to design the picture file or cutting route and import it into the cutting machine. Later, the machine automatically completes the cutting process.

·Difference

However, in comparison, the “cutting tool” of a laser cutting machine is a complete set of optical components. It uses the high energy of the laser to complete the cutting or engraving of materials.

But the tool of the CNC acrylic cutting machine is a real cutting tool. It uses a cutting head with high-speed rotation to cut and engrave acrylic material.

Working principles of the laser cutting machine and CNC cutting machine:

The laser acrylic cutting machine emits laser and makes it form a high-power density laser beam through the optical system. The laser beam irradiates on the surface of the acrylic work-piece. And such a work-piece will reach the melting point or boiling point. At the same time, the compressed air coaxial with the beam blows away the molten or vaporized acrylic materials. As the laser beam and the work-piece moves, the cutting graphics appear on the acrylic material eventually. In this way, the laser acrylic cutting machine completes the cutting processing.

CNC acrylic cutting machine relies on the high-speed rotation of the cutting head driven by the motor spindle. It cuts and engraves the acrylic material fixed on the worktable through the tool according to the processing material. And the machine can also engrave various plane materials or 3D embossing graphics according to the designs on the computer. And it can realize automatic cutting operation.

Processing characteristics:

Laser acrylic cutting machine:

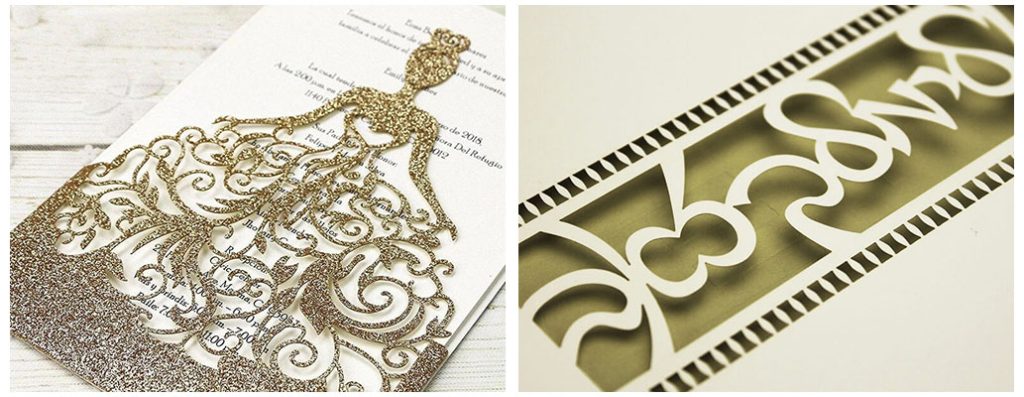

Laser acrylic cutting machine belongs to non-contact processing and does not need to fix the work-piece. It can protect the surface of thin or soft materials from being scratched or deformed. In addition, the laser beam is very thin, so the cutting marks or engraving graphics can be very small.

Therefore, It is suitable for cutting thin acrylic boards (generally less than 20 mm), especially for the processing of small details. And it can meet high precision marking requirements.

·CNC acrylic cutting machine:

It uses mechanical means and has larger power. As it uses the mechanical tool and directly contact the work-piece during processing, it may not achieve high precision. But for the thicker acrylic plates, this machine can complete cutting or embossing processing easily. Especially for the acrylic reliefs and 3D sculptures with different depths, the CNC acrylic cutting machine has more advantages.

How to choose a suitable acrylic cutting machine?

Choosing a suitable acrylic cutting machine is very important for the users. Before purchasing the machine, they’d better consider the following aspects:

Acrylic processing requirements

When choosing the acrylic cutting machine, the users should consider the size, thickness, and processing requirements at first.

·Thin acrylic board cutting and marking:

When cutting acrylic boards, if it is a thin sheet, less than 20 mm, the users choose an acrylic laser cutting machine. If you need to engrave letters, LOGO, and other graphics on the surface of acrylic or PMMA, it’s better to choose a laser cutting machine.

·Thick acrylic board cutting and embossing

If the thickness of acrylic boards exceeds 20 mm, it is recommended to choose a CNC cutting machine for acrylic processing. When the users need to groove and emboss their designs on the acrylic materials, a CNC cutting machine is the optimal.

They can also consult with the suppliers of laser engraving or CNC Router machine to obtain professional opinions and suggestions.

Sizes of the acrylic materials

The users may also consider the size of the materials for laser processing. It is about the choice of the size of the working table of the laser engraving machine. But the users should notice that the large size of the machine is not necessarily good. Because the large-size equipment is of course more expensive.

Factory visit

We recommend that users visit the manufacturer’s factory of the laser engraving machine before procurement. The buyers visit the manufacturing factory, communicate with the manufacturer as much as possible. In this way, they can get an in-depth understanding of the manufacturer’s strength and test the operation performance. They can also see the actual processing effect and discuss the after-sales service. After knowing the acrylic cutting machine well, they can make the best choice.

Other applications

Absolutely, in addition to acrylic processing, the laser cutting machine and the CNC cutting machine can also process many other materials in practical application.

·Laser acrylic cutting machine:

The laser cutting machines are also suitable for cutting and engraving many non-metallic materials. These materials include double-color boards, PVC, MDF, and leather, paper, resin and plastic, bamboo and wood, and cloth. The machine is widely used in the advertising processing, and handicrafts, printing and packaging, and leather industry and other fields.

·CNC router acrylic cutting machine:

In addition to the processing of acrylics, the CNC cutting machine can also cut and engrave various wood, stone, PMMA, plastic, copper, and aluminum, and other soft metal sheets. The typical application industries include woodworking, furniture and decoration, the musical instrument industry, mold industry, wooden crafts industry, and so on.

Therefore, if you plan to process other materials besides the acrylic materials, you may take the above as a reference.

In summary, the CNC Acrylic Laser Cutter Machine can mainly cut thinner acrylic plates, or engrave and mark on the acrylic surface. While CNC cutting machine can cut thicker acrylic, process reliefs, and three-dimensional acrylic engraving, etc. Blue Elephant can produce both the laser cutting machine and the CNC cutting machine. We can also provide the best machine and processing solution according to the specific demand of customers.

If you would like to know more about the cutting machine, please leave us a message.