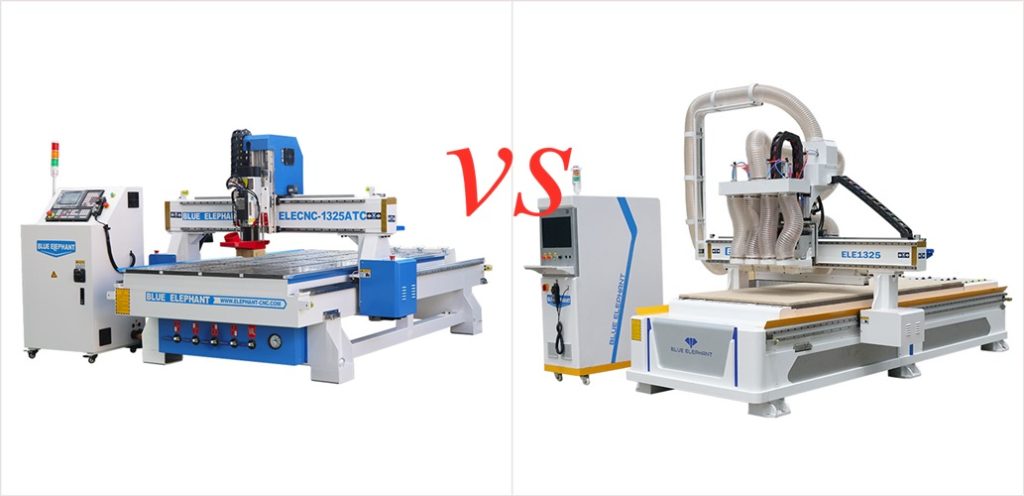

Both CNC router and nesting CNC machine are computer numerical controlled machines for woodworking and have wide applications in wood industries. Both two machines can cut, carve and mill wood materials, so what’s the difference? As a woodworking factory or furniture manufacturer, do you know how to choose between the CNC wood router and CNC nesting machine? In this article, I will make a simple comparison between the common CNC router machine and the nesting CNC machine by listing their similarities and differences. Hope it can provide you a little help to choose between the CNC engraving machine and the nesting machine.

What is a CNC router

CNC router is a kind of wood CNC machine controlled by a computer and is widely used for cutting, engraving, routering, pocketing of many materials. The CNC router we talk today is the wood CNC router, and often called wood CNC machine, CNC wood carving machine, CNC engraving machine, and wood router machine. It can process many materials, including hard and soft wood, MDF, particle board, acrylic, plastic, stone, soft metal etc.

For the working video of our CNC router machine, please visit:

What is a nesting CNC machine

Nesting CNC machine is also a kind of computer numerical controlled machine widely used in woodworking industry. It is also called nesting CNC router, CNC wood cutting machine and wood panel cutting machine. And it features with high cutting speed, long term processing, high precision and long service life. The CNC nesting machine is a type of dedicated equipment for flexible cutting, drilling, grooving and tenoning for panel furniture. The processing materials is mainly natural or artificial wood. Such as solid wood, MDF, plywood, particle wood, melamine board etc.

For the working video of our latest nesting CNC machine, you can click:

CNC router vs nesting CNC machine

As mentioned above, both the CNC router machine and the nesting CNC machine are capable for woodworking work. And both can cut, engrave, drill, mill grooves, etc. We often say that the CNC nesting machine is an upgraded model of the wood router machine. So what are the similarities and differences between these two machines?

Similarities

Similar appearance and configurations.

Both the wood CNC router and the nesting CNC machine mainly consist of mechanical parts and electrical parts. The mechanical parts include frame, worktable, gantry, etc. The electrical parts mainly include motor, driver, inverter, controller, spindle, control cabinet etc. So these two types of machines possess similar appearance.

Similar functions and applications.

Both the CNC wood router and the nesting CNC machine are capable for wood working and can cut, engrave, mill, drill and groove various wood materials. These two types of machines have wide applications in furniture industry. They are able to make panel furniture, cabinets, cabinet doors, doors, office furniture and customized furniture etc.

Similar with the multi-process or ATC CNC wood router, the nesting CNC machine also has multi-process or automatic tool charger models. Therefore, both the CNC engraving machine and the CNC nesting router can achieve multiple processes simultaneously without frequent showdown for changing tools manually. This greatly saves manpower, reduces the non-production time and increases processing efficiency.

Similar operations.

The CNC router machine and the CNC nesting machine are numerical controlled machines and both of them have high automation level. They use corresponding computer software to make layouts and designs and the machines complete the subsequent processes automatically. No additional human intervention is needed. Both these two machines can significantly reduce human cost, improve production efficiency and reduce material loss.

Similar performance.

Both the CNC wood carving machine and the nesting machine have performance of high precision, high efficiency and high production. During the course of processing, the operators are able to see the whole process to the maximum extent. And at the same time the machine provides protection and reliable safety features for the operators.

Differences

Functions.

The CNC router machine is mainly used for simple cutting and 2D and 3D patterns engraving, such as relief and three-dimensional sculpture. And the CNC engraving machine with a rotary axis is also capable for 3D engraving on cylindrical workpieces.

The nesting CNC machine is mainly for cutting a wood panel into different sizes and is the dedicated equipment for flexible cutting, drilling and grooving of panel furniture. In addition, the CNC nesting machine can also engrave simple grooves and tenons on the board material.

So compared with each other, the CNC wood router has more functions, wider applications, and richer products. The CNC engraving machine can also cut materials, but its frame structure and mechanical parts determine that it is not capable for long-time cutting. And the cutting speed is relatively slow. Otherwise, it will cause frame deformation and increasingly low precision, which will affect the service life of the CNC router.

Applications.

Compared with the nesting CNC machine, the CNC wood carving machine has wider applications. Except for panel furniture, use of the wood CNC machine can also involve in such industries as advertising, crafts, artworks, molds, electronics, construction, packaging and printing, decoration etc. In addition, the wood CNC router can also cut and engraving acrylic, stone, plastics, foam, and soft metal.

However, the CNC nesting machine is mainly for the flexible cutting, drilling and grooving wooden panels for furniture. And it mainly manufactures the home & office custom panel furniture, such as household furniture and office furniture.

Dimensions.

The CNC engraving machine is available in a wide range of sizes, and different sizes are suitable for different projects. For example, the CNC router with worktable area of 600*900mm is able to make advertising signs and crafts. And the 4th axis wood router machine with worktable area of 2000*4000mm is capable for making complex wood furniture with 3D engraved legs.

The CNC wood cutting machine is mainly used to cut wood panels for cabinets, wardrobes, cupboards, shelves etc. So this type of machine is mainly available in large size, such as 1300*2500mm, 1600*3200mm, 2000*4000mm etc.

Configuration requirements.

As the CNC router is available in many types, the configuration requirements vary for different models. For instance, the mini or desktop wood CNC router with simple functions may not need too high configuration. While the ATC CNC engraving machine for 3D engraving or construction purpose may require ATC, rotary axis, high power spindle or other high level of configuration.

The average cutting speed of a nesting CNC router can reach 5m/min. And the panels cut out should be free of defects such as broken edges, gaps or wavy grain. Therefore, the nesting CNC machine needs high overall configuration requirements in order to accommodate the long-time, rapid, high precision and heavy load cutting work.

Frame.

The frame structure of the CNC wood router is not suitable for long term cutting work, because it may deform the frame, reduce the processing precision and wear the machine. However, the CNC panel cutting machine adopts heavy machine frame made of a welded steel construction and stable mobile gantry. It is more sturdy and endurable against large cutting force and impact. This ensures that the machine will not deform during long term and high speed operation.

Spindle.

The wood CNC router may be equipped with spindles of different power for different purposes. For example, for mini CNC router with simple cutting requirements, a 3kw spindle may be sufficient; while the ATC CNC wood carving machine of large working size may require a 9kw spindle.

The CNC nesting machine generally adopts high power spindles, such as 6kw, 9kw, 12kw etc. due to high cutting speed and long time work. Besides, the large power ATC spindle helps guarantee powerful functions, stable performance and excellent cutting results.

Worktable.

The CNC engraving machine can, if you require, be equipped with an aluminum T-slot working table, which is more cost-effective. For higher processing requirements, the vacuum T-slot working table is also available. However, most nesting CNC machines adopt the vacuum worktable to fix the panels to avoid movement during the cutting process. The vacuum worktable consists of several independent zones. Therefore, a single absorption zone can be switched on for cutting small size panels for the purpose of saving electricity.

Control system and nesting software.

The CNC router machine and the nesting CNC machine may use different control system and software. The CNC nesting router has dedicated nesting software for designing the cutting path, which maximizes the utilization of the panels. Besides the nesting software can automatically break up an order and carry out auto cutting process with simple operations.

Degree of automation.

Compared with the common CNC router machine, the CNC nesting machine has a higher degree of automation and intelligence to meet the high efficiency and high production requirements.

The common CNC wood carving machine may not have an automatic loading and unloading platform or device. So there is a need to feed and discharge materials manually. While most nesting CNC machine is equipped with automatic loading and unloading mechanism. The large panel on the lifting platform is automatically pulled to the position with a positioning device by the suction cup of the machine for cutting. And the finished panel is also automatically pushed to the discharge platform.

Some nesting CNC machines are also equipped with two working platforms, a drilling unit, an automatic labeling device or other automatic systems. All these automatic mechanisms guarantee the high efficiency and high output of the nesting CNC router.

How to choose between CNC router and nesting CNC machine

After knowing the similarities and differences between the CNC wood router and the CNC nesting machine, do you have a preliminary understanding of how to choose between the two? Let me help you sort it out again.

When to choose a CNC router machine?

The wood router machine is available in many types and can process a wide range of materials. In addition to cutting function, the CNC wood router can also realize 2D carving, 3D engraving, cylindrical workpiece engraving, surface milling, pocketing and side drilling processes. The common CNC engraving machine models include but not limited to 3 axis or 4 axis wood CNC router, multi-process or multi-spindle CNC wood router, ATC CNC router etc.

Therefore, if you are a:

Craft-making hobbyist, or a gift, souvenir and wall artwork workshop;

Maker of wooden or acrylic advertising signs, 3D letters, logos, or nameplates;

Furniture manufacturer, and your business includes not only panel cutting and 2D patterns engraving, but also three-dimensional engraving, such as engraving on chair or table legs or on columns and pillars;

Service provider in decoration industry, and your work involves wall decoration, indoor decoration, relief carving, ornament making etc.;

Manufacturer of wood wainscoting wall or stairs and handrails;

Or, except for wood, you need to process other materials, such as acrylic, ABS, epoxy resin, stone, foam etc.

The CNC router is your ideal choice.

When to choose a nesting CNC machine?

The nesting CNC machine is mainly used for cutting wood panels for making cabinet furniture. For example, customized furniture, doors, cabinets, cabinet doors, wardrobes, cupboards, shelves, racks, screens etc. With the matched nesting software, the nesting machine can realize online nesting design and optimized layout. And it is able to complete the drilling, grooving and cutting three processes in one feeding. What’s more, the CNC wood cutting machine can cut irregular shapes from the panels with a high speed.

Therefore, if you are:

A panel furniture manufacturer, requiring to cut panels, drill holes and cut irregular shapes rapidly; and

Inclined to choose automatic and optimized layout, precise and fast cutting and automatic loading and unloading of panel materials

Don’t hesitate to choose the nesting CNC machine.

Conclusion

| Item | CNC router | Nesting CNC machine |

| Features | Multiple functions Various processing materials High automation Excellent precision | Rapid cutting speed excellent precision High automation Long service life |

| Major functions | Cutting 2D and 3D engraving Drilling Milling | Cutting Drilling Grooving Milling |

| Processing materials | Wood, MDF, plywood, particle board, melamine board Plastics Acrylic Soft metal Stone | Mainly wood, MDF, plywood, particle board, melamine board |

| Applied industry | Furniture Advertising Crafts & artworks Mold Construction Decoration Musical instrument Automobile Aerospace | Panel furniture Home & office custom furniture |

| Applications | Simple and complex furniture Advertising signs, 3D letters, logos Crafts, artworks, gifts Molds Decorative ornaments Guitars, speakers, stringed instruments Automobile inside decoration | Panel furniture: Cabinets, doors, cabinet doors, wardrobes, cupboards, shelves etc. |

he above table lists the respective major functions, processing materials, applied industries and applications of the CNC engraving machine and the nesting CNC machine. Both of them are suitable for woodworking, but they have a distinctive difference in their major functions, which leads to the difference in the applications. Therefore, before choose a CNC router or a nesting CNC machine, you need to carefully consider your work demands to see which machine can best suit your needs. Choosing the right and suitable machine can surely increase the production efficiency, save manpower and bring more profits.