CNC router machine is a kind of high-tech automatic numerical control equipment. It came into being with the development of modern numerical control and the demand of the woodworking industry. When you buy a CNC router machine, you will find that there are several types of CNC router tables.

Generally, there are three types of CNC router tables. the aluminum T-slot CNC router table, the full vacuum CNC router table, and the T-slot vacuum table. So which one is the best CNC router table for you? What are the advantages and applications of each of these three CNC router tables? And how to choose the most suitable CNC table? Please read the following to find the right answer.

Classifications of CNC router tables

As above mentioned, the CNC router table is mainly divided into the aluminum T-slot table, and CNC vacuum table, and T-slot vacuum table.

For the CNC machine with the aluminum T-slot CNC router table, it needs to manually fix work pieces with clamps. And for the CNC vacuum table, you can directly place work pieces on the working table of the CNC router machine. And through a vacuum pump, work pieces the CNC machine will automatically and firmly absorb the work pieces. Comparatively speaking, the CNC vacuum table can save lots of time and its adsorption is more firm.

However, the vacuum adsorption table is not suitable for all kinds of CNC router processing. The choice of the specific CNC router table depends on the customer’s processing technology. Now we will introduce these three CNC router tables and their respective range of application.

Aluminum T-slot table

The aluminum CNC router table of the CNC router machine is also called the clamp CNC wood .

Its fixing method is to fix the workpiece on the T-slot CNC router table by manually tightening screws. So that work piece will not shake during engraving process.

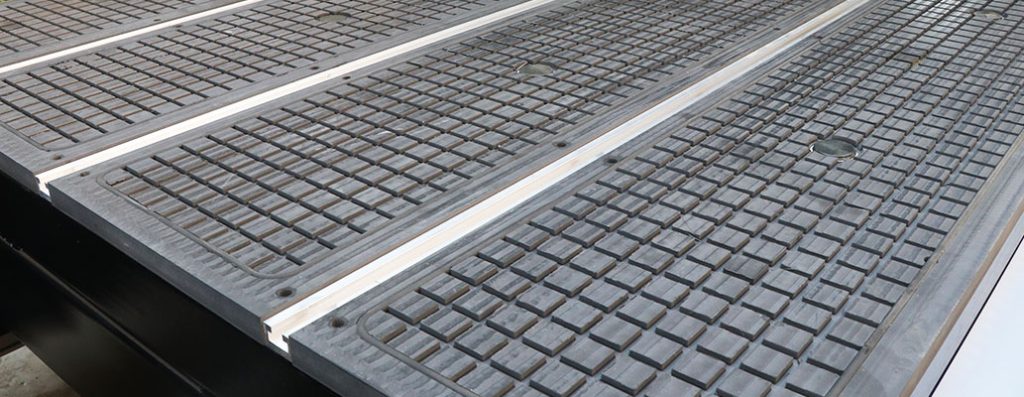

The T-slot CNC router table is made of an aluminum profile with a T-slot at the bottom and a layer of PVC material on the top. This CNC router table is suitable for the materials with irregular shape or vacuum adsorption not easy to fix. Especially when the processing technology is embossing, hollowing and cutting, it is more suitable to choose the T-slot CNC router table.

Applications

The engraving time of reliefs and woodblock painting by using CNC router kit is relatively long. Therefore, it doesn’t matter to spend the few minutes of manual fixing on the CNC router table. And the vacuum pump of CNC vacuum table cannot absorb 3D materials for hollowing and embossing. Therefore, the CNC router machine with T-slot CNC table is suitable for embossing handicrafts, hollowing partitions, screens and other decorations. The machine with T-slot CNC table is mostly used in advertising industry for cutting and engraving PVC, acrylic, two-color boards.

A dvantages of Aluminum T-slot CNC Table

The T-slot CNC table made of industrial aluminum profile is flat and beautiful, low cost, flexible and easy to disassemble. Such kind of aluminum T-slot CNC router table is also durable, anti-corrosive and wear-resistant, and easy to maintain. The aluminum CNC table kit with clamps adopts the technology of accessory connection. Therefore, it is also very convenient to modify and upgrade the CNC router machine in future. There is no need to disassemble and assemble the aluminum CNC router table. It just needs to use accessories to fix and install the new equipment on the CNC table. And there is no need for welding steps.

Full CNC vacuum table

The CNC router machine with a full vacuum table adopts a full piece of CNC vacuum table. The CNC vacuum table is connected with a vacuum pump through pipelines under the working table of CNC router machine. There are multiple adsorption holes on this CNC router table.

The users can put the wood board on the CNC vacuum table and open the vacuum valve. And then the wood is firmly absorbed by the negative pressure generated by a vacuum pump. At this time, the CNC router machine starts to work. And the entire loading and unloading process does not exceed ten seconds.

This kind of CNC vacuum table saves time of fixing workpieces and is efficient and fast. Therefore, the CNC machine with a full vacuum table is especially suitable for mass production and the wooden door processing industry.

Furthermore, the CNC vacuum table has improved the engraving accuracy, especially for thinner, lighter or irregular plates. After these plates are fixed with clamps, they may cause slight displacement due to machine vibration during the engraving process, which affects the engraving accuracy. The CNC vacuum table solves this problem well.

When using a CNC router with a vacuum table, it is better to place a layer of MDF board between the CNC vacuum table and the workpiece. This board prevents scraps from being sucked into the vacuum pump and also protects the CNC vacuum table from damage.

A dvantages of full CNC vacuum table

Large-size plane board cutting and engraving

In terms of use, the CNC vacuum table is suitable for quickly engraving patterns on a big-size wooden boards. Because the big-size board is easier to suck firmly and not easy to move.

And the CNC router vacuum table is very suitable for the line and pattern engraving of solid wood doors, wardrobe boards, cabinet boards and other panel furniture.

Higher work efficiency and accuracy

The full vacuum table can save clamping and positioning time and improve work efficiency. The CNC vacuum table also improves the engraving accuracy, especially for thinner, lighter or irregular plates.

As these plates are fixed with clamps, there may be slight displacement due to machine vibration during the engraving process. This vibration will affect the engraving accuracy of CNC router machine. But the CNC vacuum table has very adsorption capacity and strong solves this problem well.

T-slot and vacuum table

The T-slot and vacuum table is the CNC router table that combines T-slot clamp and vacuum CNC table. This kind of CNC router table usually can be divided into several sections for vacuum adsorption.

The feature of this CNC table structure is adding T-slot on the basis of the CNC vacuum table. According to customer needs, the aluminum profile of the T-slot is embedded in this CNC router table. So that it can meet the processing requirements of special workpieces. And this T-slot and vacuum CNC router table is designed for the CNC woodworking of irregular workpieces. The machine with T-slot and vacuum CNC table belongs to the customized engraving machine model.

The T-slot and vacuum CNC table can not only be used to process the entire board of panel furniture. And it can also clamp and process special workpieces. The T-slot divides this CNC router table into several zones, and each control valve controls a small zone.

Advantages of T-slot and vacuum CNC table

Fix both regular and irregular workpieces effectively

This design of combining T-slot and vacuum adsorption on the same CNC table has advantages. If the workpiece is relatively small, it is not necessary to open all vacuum control valves, which can save electricity. The T-slot and vacuum CNC table can effectively adsorb plates with various sizes.

Applicable for the processing of precise mechanical parts

Because the clamping force of the clamp is uniform and adjustable, there is no clamping mark. And as being easy to install and unload workpieces, this CNC router table can be used in various mechanical processing. Especially in the processing of thin-wall and complex precision mechanical parts, the T-slot and vacuum CNC table is optimal.

How to protect the CNC router table during the CNC woodworking process?

In the engraving process of the CNC router machine, the CNC router table may be damaged due to incorrect use of clamp or non-standard tool positioning. And the tool may hit the CNC table sometimes during the CNC cutting process.

Then, how to set up the CNC router machine to avoid damaging the CNC router table?

We provide several practical methods here for your reference :

1. Parameter setting of CNC router machine

When calculating the cutting path, not set according to the material thickness as before, but set to: 0MM. Before generating the G code file, the value of the “knife lift distance” item should be: previously set the sum of the lifting height plus the thickness of the cutting material;

For example: when cutting acrylic, the original height of the knife is 8MM when the tool is set on the surface of the material, and the thickness of the material to be cut is 15MM, then the value of “knife lift distance” at this time is: 8+15=23MM; Outside the CNC router machine table, other operations remain unchanged.

2. Add a protective board on the table of the furniture CNC router machine

For example, a furniture CNC router machine with a vacuum suction table can put a thin loose board on the table. The loose and breathable loose board itself will not affect the vacuum adsorption capacity, and it also avoids the problem of tool damage and table top caused by inaccurate origin setting.

3. Milling table

Even if the countertop of the furniture CNC router machine is in use, even if the above treatment is done, it will inevitably have accidental scratches during long-term use. At this time, it is necessary to remill the countertop. When the bakelite or PVC on the countertop is too thin Then, you can re-lay a layer. In addition, it should be noted that when the furniture and CNC router machine leaves the factory, in order to prevent damage to the table surface due to bumps in logistics transportation, it is generally necessary for after-sales personnel to remill the table surface when installing and debugging.

Conclusion

In the above, we talk about three types of CNC router table. They are respectively the aluminum T-slot CNC table, the full vacuum table and the T-slot and vacuum CNC table.

Aluminum T-slot CNC table is more economic and suitable for hollowing, embossing and carving of 3D materials.

Full vacuum table has higher efficiency, and is suitable for cutting and engraving large-size plane boards for panel furniture.

T-slot and vacuum CNC table has more flexible fixing methods, and is suitable for the processing of workpieces with irregular shape.

CNC Router machine is widely used in furniture industry, home improvement industry, woodworking industry, musical instruments and wooden crafts industries. Choosing a right CNC router table will greatly improve production efficiency, and also improves the quality of production.

When choosing the CNC router table, you must select the appropriate one according to your own processing demands. It is not advanced engraving equipment that can increase the processing speed.