CNC laser tube cutting is a common processing method. It uses laser cutting technology, which cuts the pipe into various shapes and sizes. This process has the advantages of high precision, high efficiency, high quality and environmental protection, so it is widely used in manufacturing. Why is CNC laser tube cutting machine so important? What are the advantages of CNC laser tube cutting machine? What are the use processes of CNC laser tube cutting machine? Today we will talk about these things about CNC laser tube cutting machine.

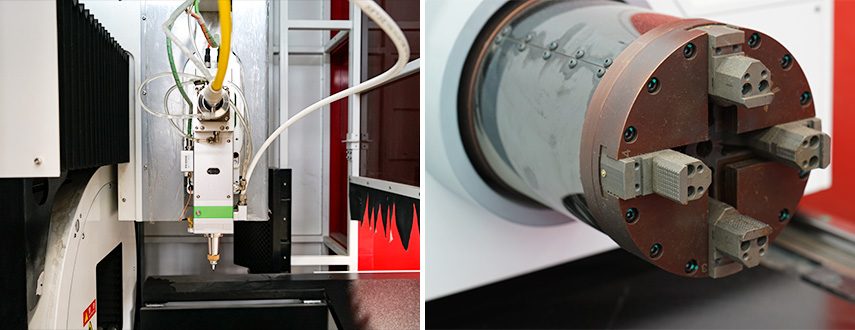

Principle of CNC laser tube cutting machine

CNC laser tube cutting machine uses a high-energy laser beam to create a high-temperature area on a metal tube. The high temperature causes physical changes such as melting and vaporization of the pipe to achieve precise cutting and processing of the pipe. The principle can be described in the following steps:

1. The laser beam is focused into an extremely bright spot and irradiated on the surface of the metal pipe.

2. After the surface of the metal pipe is irradiated by the laser beam, the high temperature area will cause the melting and vaporization of the pipe. And a tiny incision is made here.

3. The machine moves the laser cutting head axially. And after many times of cutting, the cutting of the pipe is finally completed.

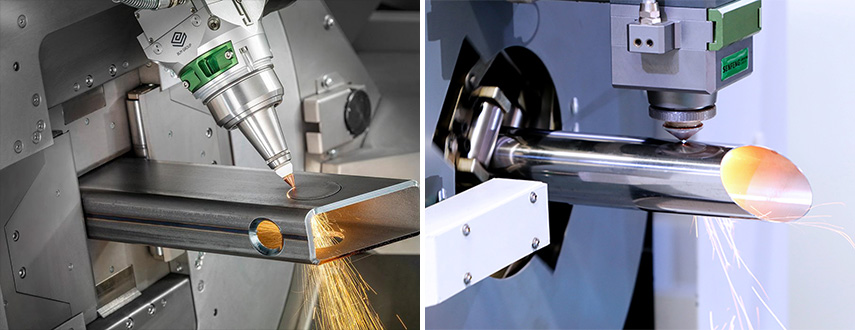

Application of CNC laser tube cutting machine

In the field of mechanical engineering, metal pipe laser cutting machines are mainly used for cutting and processing metal parts on construction machinery. These metal parts often need to be precisely cut to ensure that the size and shape of the part meet specifications. Laser cutting technology has the advantages of high precision, high efficiency and high quality. It is often used in the construction industry, decoration industry and furniture industry. The use of laser cutting technology ensures the quality and performance of the product.

Why choose a CNC laser tube cutting machine?

In addition to laser cutting, traditional cutting methods for pipe processing include hand cutting, rolling, cutting, and gas welding. But compared to these methods, laser cutting offers significant advantages in terms of quality and efficiency. It saves labor by machining strength and reduce smudging. Professional CNC laser tube cutting machine, single tube processing has a higher degree of automation.

CNC laser tube cutting machine is controlled by CNC system. The axial movement of the tube is called the X axis. The rotation of the tubing is called the A/B axis. The horizontal movement of the cutting head is called the Y axis. The cutting head is called the Z axis. If your processing requirements change, you can simply change the program. Equipped with an automatic loading and unloading system, the machine can complete complex operations in one step.

Advantages of using laser cut tubes:

- 1. The thermal effect of cutting is very low, and the parts are almost not deformed

- 2. It is a non-contact processing method. This method does not apply pressure to the workpiece, so the part will not deform or wear

- 3. The control of the laser beam has greater adaptability and flexibility

- 4. Cutting efficiency can be increased by 8-20 times, and material waste can be saved by 15-30%.

Workflow of using CNC laser tube cutting machine

Prepare materials

First, select and purchase pipe materials. Usually, considering factors such as cost and performance, metal materials such as steel, stainless steel, aluminum alloy, and copper are generally selected. When purchasing pipes, we need to pay attention to their size and quality to ensure that they meet production requirements.

Cut pips

Cutting is the core link of CNC laser tube cutting machine production process. Before cutting, the operator should set and adjust parameters according to the drawing design and other requirements. Then, the tubing is placed, secured and the cutting process started. When cutting, it is necessary to control parameters such as laser output power and moving speed.

Process details

After finishing the pipe cutting, we need to do secondary processing. These mainly include the removal of burrs and marks caused by cutting. Usually, it can be processed by grinding, gas cutting, polishing, cleaning and other methods.

Check quality

Finally, quality testing of the pipes is required. The inspection items mainly include appearance, size, shape, surface finish, etc. During the inspection, we need to operate in strict accordance with relevant standards and requirements to ensure that the quality of the pipes meets the requirements.

CNC laser tube cutting machine recommendation

Features

- One machine with dual functions, saving cost It can cut both metal sheets and pipes. Besides, the two-in-one design saves a lot of floor area and improve work efficiency greatly.

- Aircraft-grade aluminum beam Aircraft-grade aluminum is corrosion resistant, lightweight and highly rigid, guaranteeing high speed laser cutting. Besides, it also guarantee the excellent cutting precision due to the perfect dynamic performance such as anti-twisting, anti-tilting and anti-deformation.

- High quality thick wall carbon steel sheet welded bed High strength machine bed is more stable and durable. After 600℃ stress relief annealing treatment, the machine bed has strong structural rigidity. The overall mechanical structure of the machine has small deformation, low vibration, ensure cutting accuracy.

- Independent control cabinet All electrical components and laser sources are built into a separate control cabinet to prevent dust buildup. Besides, the control cabinet is equipped with automatic thermostatic air conditioning. This prevents damage to components from high summer temperatures.

Parameters

| Model | ELECNC-1530FT | ELECNC-1560FT | ELECNC-2060FT |

| Working area (mm) | 1515*3030 | 1515*6050 | 2020*6050 |

| Worktable bearing capacity | 900kg | 1500kg | 2000kg |

| Positioning accuracy | ±0.03mm | ±0.03mm | ±0.03mm |

| Repositioning accuracy | ±0.02mm | ±0.02mm | ±0.02mm |

| Pipe section shape | Round/square/rectangular | Round/square/rectangular | Round/square/rectangular |

| Max length of pipe | 3m/6m | 3m/6m | 3m/6m |

| Laser power | 1kW – 6kW | 1kW – 6kW | 1kW – 6kW |

| Laser Multiple options | Multiple options | Multiple options | Multiple options |

| Max. acceleration | 1.5G | 1.5G | 1.5G |

| Max. running speed | 140m/min | 140m/min | 140m/min |

Conclusion

The CNC laser tube cutting machine production process has the advantages of high efficiency, high precision, and environmental protection. In production, we need to pay attention to the above aspects, so as to produce pipes that meet the requirements. A CNC laser tube cutting machine uses a laser beam to cut or engrave metal tubing. Its flexibility allows it to achieve a variety of complex processing. When choosing a machine, we should look for a suitable machine according to the thickness and length of the material to be processed. Professional manufacturers will also provide advice and technical assistance to customers.

Blue Elephant will provide you with technical services, technical consultation, modern logistics, and other professional services. We not only provide customers with cost-effective products but also provide all-around service support. In the future, we will, as always, provide you with scientific design schemes and serve you with high-quality products!