What is beam saw machine?

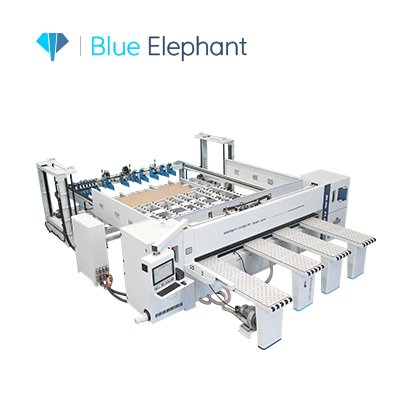

A beam saw is a professional industrial sawing machine (sizing machine) for cutting wood and panels. It gets its name from its special beam structure. Its strength lies in its ability to handle larger dimensions of lumber and panels, suitable for large-scale production and custom cutting. It is often used in industries such as making furniture, doors and windows, cabinets and building materials. The automated features and high efficiency of beam saw make the cutting process more precise, fast and reliable.

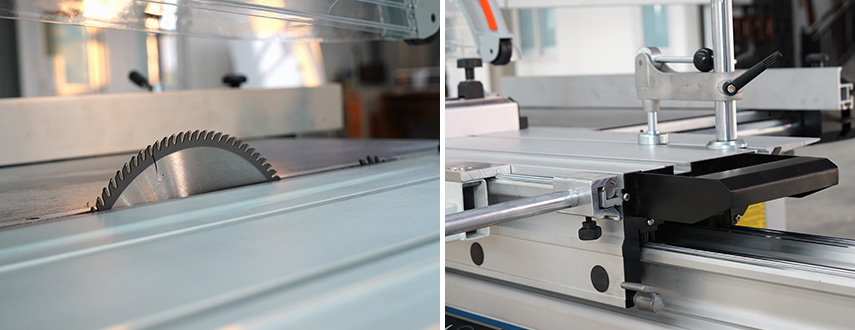

Beam saw is mainly composed of beams, saw blades, workbench and control system. Among them, the beam is one of the most notable features of Beam saw. It is a large transverse beam that sits on top of the sawing machine. The saw blade is attached to the bottom of the beam and cuts along the length of the beam. The table is located under the beam to support and position the lumber or board to be cut. There is usually a set of adjustable clamps on the workbench to fix the workpiece and ensure the accuracy and stability of the cutting. Modern beam saws are usually equipped with advanced computer control systems. Through the control system, the operator can input parameters such as cutting size and shape to control the operation and cutting process of the sawing machine. This automated system can improve production efficiency and cutting accuracy.

What is the differences between a beam saw and a panel saw?

Beam saws and panel saws are two common types of industrial sawing machines used for cutting wood and panels. They have some differences in structure and function.

Function

Beam saws usually have a large beam (beam) under which the saw blade is fixed. A panel saw is usually a vertical saw with a fixed vertical saw blade.

Cutting capacity

Due to the characteristics of the beam structure, Beam saw is able to handle larger size workpieces. They are typically used to cut large lumber or boards and can handle wide work surfaces. Panel saws are suitable for handling smaller sized workpieces because their work tables are relatively small.

Cutting method

Beam saws are usually automated and allow continuous cutting. They are equipped with advanced control systems that allow for precise cutting to preset sizes and shapes. Panel saw usually requires manual operation by the operator to cut individual workpieces.

Productivity

Due to the automated nature of beam saws, they are generally more productive than panel saws. Beam saw can improve production efficiency by optimizing cutting patterns and reducing waste, suitable for large-scale production.

Application

Beam saw is mainly used for cutting large wood and boards, such as making furniture, doors and windows, etc. Panel saw is suitable for cutting smaller boards, and is often used to make cabinets, furniture parts and decorative materials.

How many types of beam saw machine?

Blue Elephant CNC Machinery Company provides customers with 3 main beam saw machine types- ELECNC280, ELECNC330C, and ELECNC280HG.

ELECNC-280 intelligent computer beam saw machine

ELECNC-330C rear feeding beam saw machine

ELECNC-280HG front loading beam saw machine

Why would you use a beam saw machine?

A beam saw machine is a powerful tool used in woodworking and other industries for cutting large panels or sheets of material. Here are some reasons why you would use a beam saw machine.

Precise and Efficient Cutting

Beam saws are designed to make accurate and clean cuts in various materials such as wood, plywood, MDF (medium-density fiberboard), particleboard, and even plastic or aluminum sheets. They can handle large panel sizes with ease and are capable of making both straight and angled cuts.

Increased Productivity

Beam saws are highly automated machines that can significantly increase productivity compared to manual cutting methods. They are equipped with advanced features such as computer numerical control (CNC) systems, automatic feeding, and optimizing software, which help minimize material waste and optimize cutting patterns.

Increased Accuracy and Consistency

The CNC control system of a beam saw ensures precise and repeatable cutting results. This level of accuracy is essential when working on projects that require tight tolerances, such as fitting components together or achieving seamless joins.

Time and Cost Savings

By automating the cutting process, beam saw machines can significantly reduce production time and labor costs. The optimization software used in conjunction with these machines can calculate the most efficient way to cut multiple panels from a single sheet, minimizing material waste and maximizing the yield.

How much is the beam saw machine price?

The beam saw machine price varies by many factors, such as brand, model, features and quality. Here are some common computer beam saw price ranges for your reference.

- Entry-level computer beam saws are typically priced between $20,000 and $30,000. For instance, the Blue Elephant ELE-280 intelligent beam saw machine price is about $28,000.

- Intermediate computer beam saw prices range from $30,000 to $40,000. For instance, the Blue Elephant ELE-330 high-speed beam saw machine price is about $35,000.

- Advanced computer beam saw prices start at $40,000 and up. These computer saws are usually manufactured by reputed brands with advanced features and higher performance. So the Blue Elephant ELE-280 intelligent beam saw machine price is about $42,000 or more.

It should be noted that this is only an approximate price range, and the actual price may vary due to different regions and sales channels. When shopping for a computer saw, you should also consider your needs and budget, and do the comparison and research to find the best product for you.

How thick can a beam saw machine cut?

A standard beam saw is typically designed to cut through wood-based panels, such as plywood or particleboard, with a maximum thickness ranging from 1 inch (25.4 mm) to 3 inches (76.2 mm). Some heavy-duty industrial beam saws may have even higher cutting capacities, allowing them to handle thicker materials.

But Blue Elephant can provide beam saw machines cutting longer and thicker panels. Take the most common and entry-level beam saw machine- ELE280 automatic computer beam saw as an good example. This beam saw machine for sale can cut the panel with the length of 2700mm and the thickness of 100mm. If necessary, it can also be customized and advanced to cut the wood panel with the length of 3700mm. Therefore, the Blue Elephant beam saw machine is the best choice for manufacturers who has needs of processing large and thick panels.

How to maintain a beam saw machine for long lifetime?

- Remove dust and residue from inside and above the machine every shift.

- Focus on cleaning and checking the lubrication status of the manipulator guide rail and saw blade lifting guide rail.

- Regularly tighten the screws of each moving part.

- The electrical cabinet is regularly cleaned of dust, and the contactors are cleaned from top to bottom.

- Regularly check and fasten the screws of the main power supply to prevent the motor from being damaged due to a lack of phase due to loose lines.