A few years ago, I walked into a shop that was struggling with production delays. They were using knee mills for jobs that required heavier cutting, and the inefficiencies were adding up. After switching to bed mills for those tasks, their output increased, and costs dropped.

That experience showed me that choosing the right mill is more than just a preference—it. It directly impacts productivity and profit.

I’ve worked with manufacturers, machine dealers, and repair shops that rely on both knee mills and bed mills. I know the real differences, beyond just specs on paper. This review is based on practical experience in real shops.

In this article, you’ll get a direct comparison of knee mills and bed mills. By the end, you’ll understand their advantages, limitations, and which one suits your operation best.

Let’s break it down!

1. What is Knee Mill?

Have you ever struggled with a machine that just couldn’t handle the workload? If so, you’re not alone. I’ve seen many shops start with knee mills because they’re versatile and relatively affordable. But are they the right choice for every job?

A knee mill is a vertical milling machine where the table moves up and down along a knee—a structure that slides on the main column. Unlike bed mills, where the table remains fixed, knee mills allow for manual and automated adjustments, making them useful for precision work, small-batch jobs, and repairs.

How Knee Mills Operate in Industrial Settings

In a knee mill, the spindle remains stationary while the table moves. This movement lets operators adjust the height of the workpiece, which is useful for light to medium machining. The operator can fine-tune the position of the part, making knee mills great for prototyping, one-off parts, and repairs.

However, that same flexibility can slow down production when machining large, heavy parts. Constantly adjusting the knee adds setup time, and the table’s movement can reduce stability on deep cuts.

Common Applications of Knee Mills in Manufacturing

Knee mills remain a popular choice for various small-scale and manual machining tasks. Typical applications include:

- Custom Machining: Ideal for short-run jobs and prototyping due to their quick setup and manual flexibility.

- Maintenance and Repair Work: Allows for fast modifications or part fixes without complex programming.

- Training and Education: Widely used in vocational schools and training centers to teach manual milling techniques.

If your shop handles custom parts, small batches, or frequent repairs, a knee mill is a practical, cost-effective solution. However, for larger production volumes or heavy-duty materials, limitations in rigidity and capacity may become a factor.

Advantages and Limitations of Knee Mills

Advantages:

- More Flexibility: Adjustable table height makes it easier to work on varying part sizes.

- Lower Initial Cost: Generally more affordable than bed mills or CNC machining centers.

- Easier to Operate Manually: Preferred for training new machinists and quick, hands-on adjustments.

- Compact Size: Fits well in smaller shops where floor space is limited.

- Quick Setup Changes: Ideal for shops handling frequent changeovers, small orders, or single-part runs.

- Good for Light-Duty Machining: Suitable for materials like aluminum, plastic, and mild steel.

- Lower Energy Consumption: Consumes less power than heavier, high-capacity machines.

Limitations:

- Less Rigidity: The moving knee can introduce flex, making it harder to maintain tolerances during heavy cuts.

- Limited for High-Volume Production: Manual adjustments slow down cycle times compared to automated systems.

- Smaller Load Capacity: Not built for handling large, heavy, or high-precision components.

Is a Knee Mill Right for Your Operation?

If your work revolves around small-batch runs, repairs, or prototyping, a knee mill delivers the flexibility and affordability you need. But if you’re scaling up to heavier materials or full-scale production, the rigidity and capacity of a bed mill may serve you better in the long run.

2. What is Bed Mill?

The first time I worked with a bed mill — the Blue Elephant, to be exact — I noticed the difference right away. The machine felt solid. No shaking, no unnecessary movements — just pure stability. After years of constantly adjusting knee mills for deeper cuts, the bed mill handled the job with ease. I could push harder, cut deeper, and work on larger parts without constant tweaking.

A bed mill is a vertical milling machine where the table remains fixed while the spindle moves up and down. This design makes it stronger, more rigid, and better suited for heavy-duty machining and high-production work. If you need precision on large parts or deep cuts, a bed mill is often the better choice.

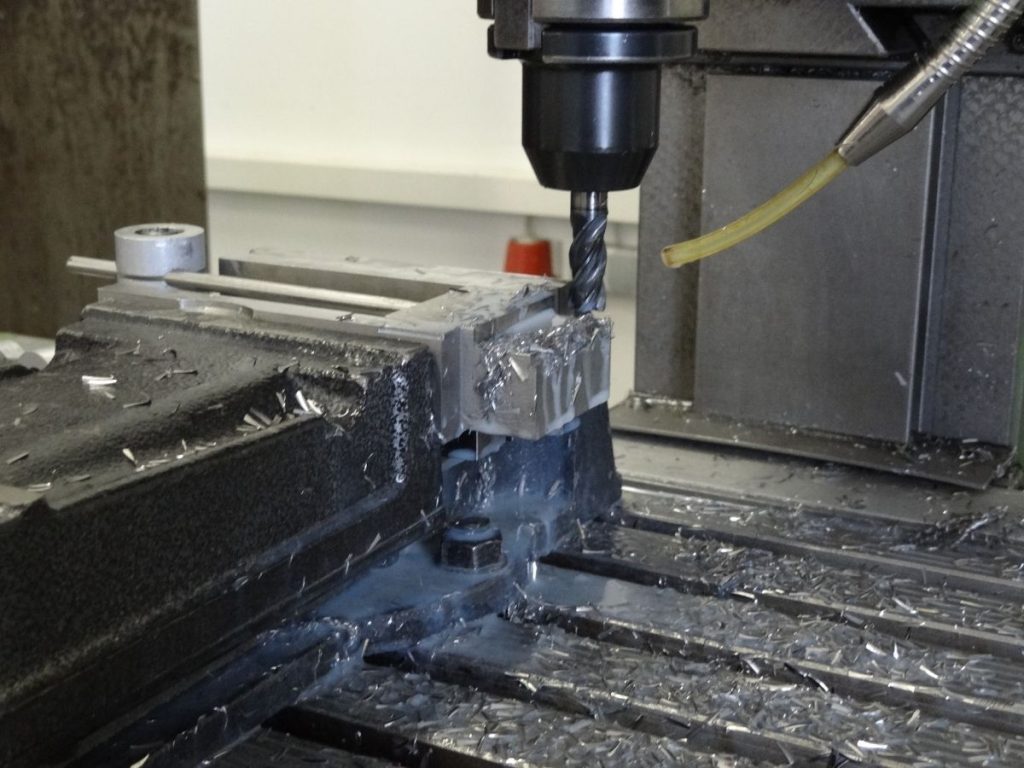

How Bed Mills Handle Heavy-Duty Machining

Unlike knee mills, where the table moves, a bed mill keeps the workpiece stationary. Instead, the spindle moves up and down, allowing for more stability, better accuracy, and deeper cuts. This design reduces vibration, which means better surface finishes and longer tool life.

For large and heavy parts, a bed mill is often the only choice. The rigid structure can handle high-load machining, making it ideal for production work, mold making, and industrial applications.

Industries That Benefit from Bed Mills

Bed mills are commonly used in sectors where precision, strength, and consistency are non-negotiable. Key industries include:

- Aerospace and Automotive: For producing high-tolerance, complex components.

- Mold and Die Making: The structural rigidity allows for deep, accurate cavity machining.

- Heavy Equipment Manufacturing: Capable of cutting large, thick metal parts with consistency.

If your operations involve high-volume machining, large parts, or deep material removal, a bed mill can improve throughput and reduce rework.

Advantages and Limitations of Bed Mills

Advantages:

- More Stability: The fixed table design increases accuracy when machining heavy parts.

- Better Suited for High-Production Work: Reduced setup time and higher efficiency in batch machining.

- Handles Larger Loads: Designed to accommodate thick, dense materials.

- Supports Deep Cuts: Rigid construction allows for aggressive cutting without sacrificing precision.

- Longer Tool Life: Less vibration helps minimize tool wear.

- Consistent Repeatability: Ideal for CNC machining and volume production.

- Stronger Spindle Power: Can handle tough materials like stainless steel, titanium, and cast iron.

- Lower Maintenance Costs: Fewer moving parts mean reduced wear and simpler upkeep.

Limitations:

- Higher Initial Cost: Bed mills are more expensive than knee mills upfront.

- Less Flexibility for Small-Batch Jobs: Setup changes can take more time.

- Requires More Space: Larger footprints may not suit all shop environments.

Is a Bed Mill Right for Your Shop?

If your shop prioritizes precision, spindle strength, and production efficiency—especially when working with large or tough materials—a, a bed mill is a strong long-term investment. But if your work involves frequent setup changes, custom prototypes, or limited floor space, a knee mill might offer more flexibility.

3. Knee Mills Vs. Bed Mills: Key Difference

Choosing the right machine can make or break efficiency in a shop. I know the struggle with slow production times simply because they were using the wrong mill for the job. A knee mill might work well for one operation but fall short in another. Bed mills, on the other hand, handle heavy cuts with stability but come at a higher cost.

If you’re deciding between a knee mill and a bed mill, understanding their differences is critical. The table below breaks down how they compare in structure, performance, and application.

| Category | Knee Mill | Bed Mill |

| Machine Structure | Movable knee supports the table | Fixed table with a moving spindle |

| Table Movement | Table moves up and down | Table remains stationary |

| Spindle Movement | Spindle remains fixed | Spindle moves up and down |

| Rigidity & Stability | Less rigid, more vibrations on deep cuts | Highly rigid, better for deep cuts and precision work |

| Load Capacity | Limited load capacity, best for smaller parts | Higher load capacity, suitable for large/heavy parts |

| Precision & Accuracy | Good for manual operations, but less stable on heavy machining | More consistent accuracy on high-volume machining |

| Production Speed | Slower due to frequent adjustments | Faster due to fewer manual adjustments |

| Best for | Small-batch jobs, repairs, prototypes | High-volume production, large workpieces |

| Common Applications | Custom machining, maintenance, training | Aerospace, automotive, mold making, industrial machining |

| Initial Cost | Lower compared to bed mills | Higher upfront investment |

| Maintenance & Longevity | More wear on moving parts, requires frequent adjustments | More durable with fewer moving parts, lower long-term maintenance |

| Space Requirement | Smaller footprint, suitable for limited space | Requires more space due to larger size |

4. Factors to Consider When Choosing Between Knee Mills & Bed Mills

Investing in the right mill saves time, money, and frustration. I’ve watched businesses struggle with machines that couldn’t keep up with demand, leading to delays and unnecessary costs. Choosing wisely means thinking beyond price and considering how the machine will perform daily. Here are the considerations I can give:

Production Requirements

I recommend a knee mill if your shop handles custom machining, prototypes, or repair work. It allows for quick adjustments and is ideal for small runs and light materials. But if you need to machine heavy parts, make deep cuts, or run high-volume production, a bed mill is the better option. It offers greater stability, precision, and efficiency for demanding jobs.

Space, Budget, and Operator Skill Level Considerations

A knee mill works well if you have limited shop space and need a lower upfront cost. It’s also easier for machinists who prefer manual adjustments. But if you have the space and want to reduce operator workload and improve consistency, a bed mill is worth the investment. I suggest considering how often you’ll run the machine—higher production needs favor bed mills.

Long-Term Maintenance and Cost Efficiency

More moving parts mean more maintenance. Knee mills require frequent adjustments and higher upkeep costs over time. If you want a machine that lasts longer with less downtime and fewer repairs, a bed mill is the best choice. Its rigid design and lower maintenance needs make it the more cost-effective choice in the long run.

Conclusion

The choice between a knee mill and a bed mill comes down to what your operations needs most. Knee mills offer flexibility and lower cost while bed mills provide stability for heavy-duty work.

So the question is: Are you using the best mill for your operations?

Don’t wait to upgrade your workflow.

At Blue Elephant, we offer CNC machines built for precision, efficiency, and lasting performance including custom solutions.

Contact us today and let’s find the best fit for your needs!