There’s nothing worse than spending thousands on a CNC machine, only to realize it doesn’t do what you need.

I’ve seen it happen too many times.

A small business owner buys a machine for furniture production, only to find out it can’t handle hardwood. A hobbyist picks a budget-friendly model, only to struggle with software that requires hours of troubleshooting.

I’ve worked with CNC machines for years, testing them for precision, durability, and reliability. I’ve also talked to manufacturers, repair technicians, and business owners who live and breathe CNC work.

In this guide, I’ll show you 7 of the best desktop CNC machines available today. Whether you need a machine for wood, metal, or plastics, I’ll help you find the right one for your needs. By the end, you won’t just know which machines are worth considering, you’ll know which one is right for you.

Let’s begin!

Quick Comparison

Before we break each machine down in detail, here’s a side-by-side comparison to help you spot key differences:

| Feature | Inventables X-Carve | Carbide 3D Shapeoko 4 | Blue Elephant 1212 | Bantam Tools Desktop CNC | Nomad 3 Desktop CNC | SainSmart Genmitsu 3018-PROVer | Next Wave CNC SHARK SD120 |

| Work Area | 29.5” x 29.5” x 4.5” | Varies by model | 1200 x 1200mm (47” x 47”) | 7″ x 9″ x 3.3″ | 8″ x 8″ x 3″ | 260 x 155 x 35mm (10.2” x 6.1” x 1.4”) | 12″ x 24″ |

| Spindle Power | Makita router | Makita router | 1.5kW water-cooled | 250W spindle | 130W spindle | 775 motor, 12V-24V, 10,000 RPM | Uses palm routers like DeWALT 611 |

| Speed & Precision | Up to 30,000 RPM | Router-dependent | Up to 24,000 RPM | 10,000-28,000 RPM | 9,000-24,000 RPM | 10,000 RPM, good for soft materials | Router-dependent, speeds up to 35,000 RPM |

| Materials Supported | Wood, plastic, soft metals | Wood, plastic, soft metals | Wood, acrylic, plastic, MDF, foam | Wood, plastics, soft metals | Wood, plastics, soft metals | Wood, plastics, soft aluminum, PCBs | Wood, plastics, soft metals |

| Software Compatibility | Easel | Carbide Create, Carbide Motion | ArtCAM, Type3, Mach3 | Bantam Tools Milling Software | Carbide Motion, MeshCAM, Carbide Create | Grbl-based (Candle) | VCarve Desktop, Ready2Control |

| Connectivity & Controls | USB, Easel interface | USB | USB, Mach3 | USB | USB | USB, offline controller included | Touchscreen pendant, USB |

| Build Quality | Aluminum frame | Aluminum frame | Heavy-duty steel frame | Fully enclosed, powder-coated steel | Fully enclosed, metal frame | Aluminum frame, ABS Z-axis | Aluminum InterLoc T-Slot bed |

| Ease of Assembly | DIY kit | DIY kit | Pre-assembled | Fully assembled | Fully assembled | Semi-assembled, 15-30 min setup | Fully assembled |

| Noise & Power Consumption | Moderate, depends on router | Moderate, depends on router | Quiet, water-cooled spindle | Moderate, 350W power | Quiet, 110V/220V | Moderate noise, 24V power supply | Noise depends on router choice |

| Price | $2,599 | $1,800+ | $3,500 – $4,800 | $6,999 | $2,800 | $300-$500 | $2,174.99 |

| Best For | Hobbyists, small businesses, educators | Hobbyists, small businesses, educators | Small businesses, workshops, engraving | Prototyping professionals, educators, advanced users | Precision work, small businesses, makers | Beginners, hobbyists | Woodworkers, engravers, educators |

Now that you’ve seen the numbers, let’s go beyond the specs and talk about what using each of these machines actually feels like.

1. Inventables X-Carve

When you’re picking a CNC machine, you don’t want something that limits you. You want a machine that adapts to your needs, whether you’re making intricate engravings or cutting out custom furniture parts.

That’s where the Inventables X-Carve stands out. It’s modular, meaning you can upgrade and customize it as your skills grow. It doesn’t lock you into a fixed system.

What do you plan to create?

- Wood signs with fine lettering? The X-Carve handles sharp details.

- Engraved acrylic logos? No problem.

- Custom parts for your business? It cuts clean and accurately.

It’s not a machine you’ll outgrow quickly. It’s one you can build around.

The X-Carve is ideal for:

- Hobbyists crafting personalized items.

- Small business owners producing custom products.

- Educator teaching CNC machining basics.

It excels at:

- Sign-making

- Engraving .

- Furniture components

However, it’s important to note that the X-Carve is not suited for heavy-duty industrial tasks. It’s best for light to medium projects.

Key Features & Specifications

- Work Area: Approximately 29.5″ x 29.5″ x 4.5″. This size accommodates a variety of project dimensions.

- Spindle Power: Compatible with the Makita Variable Speed Compact Router, offering reliable cutting performance.

- Speed & Precision:

- RPM: Adjustable speeds up to 30,000 RPM, depending on the router used.

- Accuracy: Capable of precise cuts suitable for detailed designs.

- Materials Supported: Works well with wood, plastic, and soft metals like aluminum.

- Software Compatibility: Integrates seamlessly with Easel, Inventables’ user-friendly CAD/CAM software.

- Connectivity & Controls: Connects via USB; controlled through the Easel software interface.

- Build Quality: Constructed with a sturdy aluminum frame, ensuring durability.

- Ease of Assembly: Comes as a DIY kit. Assembly requires time and patience but is manageable with provided instructions.

- Noise & Power Consumption: Noise levels vary based on the spindle used; generally moderate and suitable for workshop environments.

Performance

The X-Carve handles detailed engravings and sign-making well. It’s precise, especially with fine text and logos. The Makita router provides good speed control, allowing smooth cuts on different materials.

However, it’s not as fast or powerful as industrial machines. It’s great for custom projects, small runs, and personal use, but not for mass production.

What makes it stand out?

- Bigger work area than most desktop CNCs

- Customizable, you can upgrade parts as needed

- Active user community, lots of resources and support

Software

- Works best with: Easel (web-based, easy to use)

- Beginner-friendly? Yes, Easel is simple and has pre-set design tools

- File formats supported: SVG, DXF – compatible with most design software

Durability

- Frame: Aluminum structure, built for stability

- Spindle Motor: Needs regular cleaning and checks

- Maintenance Tips:

- Keep rails and belts clean to avoid accuracy issues

- Lubricate moving parts to reduce friction

- Check and tighten screws periodically

Pricing

- Price Range: Around $2,599 for the 1000mm model

- Budget-friendly? More affordable than high-end industrial machines

- Is it worth the price?

- Yes, if you need a versatile and expandable CNC machine

- No, if you need something that cuts thick metals or heavy materials

- Comparison with similar models:

- Larger work area than some competitors

- Easier software, but requires assembly

- More customizable than pre-assembled models

- What’s included? Most packages come with a waste board and tool kit

Pros & Cons

Before deciding, consider the following:

| Pros | Cons |

| Versatile and customizable | Assembly can be time-consuming |

| Strong community support | Requires regular maintenance |

| Compatible with various materials | Limited to light and medium-duty projects |

| User-friendly software (Easel) | Not suitable for heavy industrial use |

The Inventables X-Carve is a solid choice for hobbyists, educators, and small business owners seeking an affordable, versatile CNC machine. Its adaptability and supportive community make it a valuable tool for creative projects.

However, if your work demands heavy-duty machining, exploring industrial-grade alternatives would be advisable.

2. Carbide 3D Shapeoko 4

I’ve used CNC machines that required endless tweaking. Loose belts. Bad alignment. A software setup that felt like a puzzle. It took more time to troubleshoot than to cut anything.

That’s why the Carbide 3D Shapeoko 4 was such a relief. It’s built solid, so you don’t have to constantly adjust things. It cuts wood, plastics, and soft metals with accuracy.

And the software? Straightforward, even if you’re new to CNC work.

If you want a machine that works when you need it to, without constant frustration, the Shapeoko 4 is a solid choice.

It’s great for:

- Hobbyists : Personal engraving, furniture parts, or home décor

- Small business owners : Sign-making, custom product manufacturing

- Educators : Teaching CNC basics in schools or workshops

It works well for:

- Sign-making : Sharp details and smooth engraving on wood and acrylic

- Engraving : Text, logos, and patterns on plastics and soft metals

- Prototyping : Cutting parts for models and product testing

Limitations

- Won’t handle thick or heavy metals

- Works best for light to medium workloads

Key Features & Specifications

| Feature | Details |

| Work Area | Standard: 16″ x 16″ XL: 16″ x 33″ XXL: 33″ x 33″ Why it matters: Lets you work on projects of different sizes |

| Spindle Power | Compatible with Carbide Compact Router or Makita Trim Router Strong enough for wood, plastics, and soft metals |

| Speed & Precision | Up to 30,000 RPM, depending on the router High accuracy for detailed cuts and engraving |

| Materials Supported | Wood : Hardwood, MDF, plywood Plastics : Acrylic, HDPE, polycarbonate Soft metals : Aluminum, brass |

| Software Compatibility | Works with Carbide Create and Carbide Motion Also supports other CAD/CAM software that exports G-code |

| Connectivity & Controls | USB connection : Requires a computer to run |

| Build Quality | Sturdy aluminum frame for stability |

| Ease of Assembly | DIY kit : Takes time to assemble but comes with instructions |

| Noise & Power Consumption | Moderate noise : Varies based on the router used |

Performance

Some machines vibrate so much they ruin the precision of the cuts. The Shapeoko 4 has a solid aluminum frame that keeps it stable, so your cuts stay clean.

It’s precise enough for fine engraving but strong enough for deeper cuts in wood and soft metals. The Makita router gives you speed control, which helps when switching between materials.

What makes it stand out :

- A solid frame that keeps vibrations low

- A flexible work area for both small and large projects

- Upgradeable parts, so you don’t outgrow it too quickly

It’s not an industrial workhorse, but if you need consistent accuracy on smaller projects, it’s a great fit.

Software

- Works best with : Carbide Create (simple, easy to learn)

- Is it beginner-friendly? : Yes, Carbide Create is designed for first-time CNC users

- File formats supported : SVG, DXF – standard formats for most design programs

Durability

- Frame : Aluminum structure, built for stability and long-term use

- Spindle Motor : Needs regular cleaning and occasional maintenance

- Maintenance Tips :

- Keep rails and belts clean to maintain accuracy

- Lubricate moving parts to keep everything running smoothly

- Check and tighten screws regularly

- Spare Parts Availability : Carbide 3D sells upgrades and replacements, so you won’t struggle to find parts

Pricing

The Shapeoko 4 is priced at around $1,800 for the standard model. It’s more affordable than industrial machines but not the cheapest CNC option available.

For the price, you get a versatile and upgradeable machine that works well with wood, plastics, and soft metals. If you need a heavy-duty CNC for thick metal cutting, this may not be the best fit.

Compared to similar models, the Shapeoko 4 offers a larger work area, easy-to-use software, and customization options that many pre-assembled machines don’t have.

Pros & Cons

No machine is perfect. Here’s what to consider :

| Pros | Cons |

| Sturdy aluminum frame | Takes time to assemble |

| Handles wood, plastics, and soft metals | Requires regular cleaning and maintenance |

| Beginner-friendly software | Not designed for thick metal cutting |

| Upgradeable parts and accessories | USB connection only, no wireless option |

If you need a fully assembled, plug-and-play machine, this might not be the right fit. But if you’re comfortable with a DIY setup and want something you can upgrade over time, it’s a great long-term investment.

I remember the first time I saw a CNC machine in action. The precision, the hum of the spindle, and the intricate designs it could carve left me in awe. Years later, when I came across the Bantam Tools Desktop CNC Milling Machine, those memories resurfaced. This compact machine promises to bring professional-grade milling to your workspace. Let’s take a closer look at whether it delivers.

3. Blue Elephant 1212 Desktop Advertising CNC Machine

I remember the first time I needed a desktop CNC machine. I wanted something compact but powerful. Something that could handle detailed engraving without taking up too much space.

After searching through endless options, I came across the Blue Elephant 1212 Desktop Advertising CNC Machine. It stood out for its precision, durability, and ease of use.

It’s built for small businesses, workshops, and craft enthusiasts who need accuracy without investing in a massive machine.

This CNC machine is a great fit for:

- Small business owners making custom products

- Hobbyists who want precision without a steep learning curve

- Workshops that need an affordable desktop machine

It works well for:

- Sign-making

- Engraving (logos, text, detailed patterns)

- Small model-making

Its compact size makes it great for home workshops. But if you need a machine for mass production, you’ll want something larger.

You can find it on the official website: Blue Elephant 1212 Desktop Advertising CNC Machine

Key Features & Specifications

- Work Area: 1200 x 1200 mm (about 47” x 47”)

- Spindle Power: 1.5 kW water-cooled spindle for smooth, precise cuts

- Speed & Precision:

- Up to 24,000 RPM spindle speed

- High accuracy for fine details

- Materials Supported: Wood, acrylic, plastic, MDF, and foam

- Software Compatibility: Works with ArtCAM, Type3, and other popular CAD/CAM programs

- Connectivity & Controls: USB interface, Mach3 control system

- Build Quality: Sturdy frame designed for long-term use

- Ease of Assembly: Pre-assembled, so setup is quick

- Noise & Power Consumption: Runs quietly compared to larger machines

Performance

The Blue Elephant 1212 delivers solid performance. It cuts precisely and handles fine details well. Whether you’re making intricate engravings or basic sign designs, it keeps lines clean and accurate.

It balances speed and precision, making it efficient for small businesses and workshops. It’s easy enough for beginners but still powerful enough for experienced users.

Compared to similar machines, it offers:

- A larger work area than most desktop models

- Better cooling for longer run times

- Less vibration, leading to smoother cuts

However, since it’s a desktop machine, it’s not built for large-scale production or deep metal cutting.

Software

It works with:

- ArtCAM (good for engraving and sign-making)

- Type3 (useful for lettering and intricate designs)

- Other CAD/CAM programs that support G-code

File formats supported include:

- DXF

- G-code

- SVG

This means you can import designs from most standard software without conversion issues.

Durability

The frame is solid, built to handle regular use. The spindle motor is water-cooled, meaning it runs longer without overheating.

Maintenance is simple:

- Keep the rails and spindle clean

- Check for loose connections regularly

- Lubricate moving parts to keep cuts smooth

Spare parts are easy to find, and the manufacturer provides support if needed.

Pricing

The price ranges from $3,500 to $4,800, depending on where you buy it.

For the price, you get:

- High precision

- A solid work area

- Reliable software compatibility

Compared to others in this range, it offers better stability and accuracy. Some similar models lack the same cooling and spindle power, making this a good value for its category.

Pros & Cons

Like any CNC machine, the Blue Elephant 1212 has strengths and limitations. Here’s a quick look at what it does well and where it falls short:

| Pros | Cons |

| High accuracy for engraving | Not suitable for cutting metals |

| Good cooling system for longer jobs | Work area may be small for some users |

| Sturdy frame reduces vibration | Limited to small and medium-sized projects |

| Pre-assembled—easy setup | |

| Quiet operation |

If you need a compact, reliable CNC machine for engraving, sign-making, or small projects, this is a strong choice. It’s affordable, easy to use, and precise. For most small business owners, workshops, and hobbyists, it delivers great results.

4. Bantam Tools Desktop CNC

I remember the first time I powered up the Bantam Tools Desktop CNC Milling Machine. The soft hum of the spindle, the smooth precision of the cuts, it felt like unlocking a new level of craftsmanship.

If you’ve ever struggled with inconsistent results on a smaller machine, you’ll appreciate how this one steps up.

- Compact, but powerful: This machine fits neatly on your workbench, but it has the muscle to cut through aluminum, brass, and hardwoods without hesitation.

- High precision: Need tight tolerances? The Bantam delivers repeatability within +/- 0.001” (0.025 mm).

- Beginner-friendly, expert-approved: Whether you’re just getting started or refining intricate designs, the user-friendly software keeps things simple while allowing for advanced controls.

Does it replace a full-sized industrial CNC? No.

But for rapid prototyping, small production runs, and intricate designs, it’s a serious contender. If you’re looking for reliability in a desktop format, this might be the one.

The Bantam Tools Desktop CNC is best for:

- Prototyping Professionals: Engineers and designers who need fast, precise milling.

- Educational Institutions: Schools and universities looking for hands-on CNC training.

- Hobbyists and Makers: Anyone interested in creating detailed custom designs.

This machine works well for:

- Milling aluminum prototypes

- Cutting detailed designs in wood and plastics

- Creating custom PCBs for electronics projects

Limitations:

- Not built for industrial production

- Not suitable for cutting hardened steel

Key Features & Specifications

| Feature | Details |

| Work Area | 7” x 9” x 3.3” (178 mm x 229 mm x 83 mm). Good size for desktop projects. |

| Spindle Power | 250W. Provides enough power for cutting various materials. |

| Speed & Precision | 10,000 to 28,000 RPM. Repeatability of +/- 0.001” (0.025 mm). |

| Materials Supported | Aluminum 6061, brass, copper, engineering plastics, hardwoods. |

| Software Compatibility | Works with Bantam Tools Milling Machine Software. Supports .brd, .svg, .dxf. |

| Connectivity & Controls | USB interface. User-friendly software. |

| Build Quality | Fully enclosed, powder-coated steel frame. Durable and safe. |

| Ease of Assembly | Arrives fully assembled. Ready to use out of the box. |

| Noise & Power Consumption | Uses 350W. Moderate noise. Hearing protection recommended. |

Performance

The Bantam Tools Desktop CNC delivers precise cuts. The rigid frame minimizes vibration, which helps with accuracy.

The machine handles aluminum well but requires the right speeds and feeds. For wood and plastics, cutting is smooth and efficient. Small details come out clean, making it ideal for fine work.

However, it’s not designed for heavy-duty tasks.

Software

- Supported Software: Bantam Tools Milling Machine Software

- Best for Beginners? Yes, but learning CNC basics helps

- File Formats – .brd, .svg, .dxf

The software is straightforward and designed for easy use. Importing files is simple, and the machine follows toolpaths accurately. While experienced users might prefer more advanced control, the interface makes it accessible.

Durability

The frame is sturdy, built from powder-coated steel.

Motors and linear rails feel solid. With regular maintenance, like cleaning dust and chips and lubricating moving parts, it runs reliably. Spare parts are available through Bantam Tools, though some may take time to ship.

Pricing

The Bantam Tools Desktop CNC is priced in the mid-to-high range. It’s not the cheapest desktop mill, but its accuracy and build quality justify the cost. For those needing precision in a compact machine, it’s a solid investment. Compared to similar options, it offers a stable build, a well-designed interface, and support for aluminum cutting. It doesn’t include many extras, so you may need to purchase bits and accessories separately.

Pros & Cons

| Pros | Cons |

| High precision | Not suited for heavy-duty production |

| Compact design | Limited material compatibility |

| Good software support | Higher price compared to entry-level machines |

| Arrives fully assembled | May require additional accessories |

| Works with aluminum | Not for cutting hardened steel |

The Bantam Tools Desktop CNC is a well-built, precise milling machine. It’s best for professionals, educators, and makers who need accuracy in a small footprint.

While it isn’t for industrial use, it’s a great option for prototyping and small-scale production. If you need something more powerful, consider a larger CNC. But if you want a reliable desktop mill, this one is worth considering.

5. Nomad 3 Desktop CNC

The first time I used a CNC machine, I was excited, until I realized how complicated it could be. Setting up, calibrating, troubleshooting… it felt like a never-ending checklist.

The Nomad 3 changed that.

- It arrives fully assembled, which means no frustrating setup.

- The software is straightforward, guiding you through every step.

- The enclosed design keeps things clean, no flying debris.

If you’ve been hesitant to try CNC machining because it seems too technical, this machine makes the learning curve manageable.

The Nomad 3 is a great fit for:

- Engineers and Designers: Ideal for small, precise prototypes.

- Educators: Helps students learn CNC machining with hands-on experience.

- Hobbyists and Makers: Perfect for those crafting detailed pieces at home.

It works well for:

- Creating 2D and 3D parts from aluminum, brass, hardwoods, and plastics

- Producing small metal components with fine details

- Crafting intricate jewelry or custom engravings

Limitations:

- Not built for large-scale industrial production

- Small work area limits project size

Key Features & Specifications

| Feature | Details |

| Work Area | 8″ x 8″ x 3″ (X, Y, Z). Good for small to medium projects. |

| Spindle Power | 130W with speeds from 9,000 to 24,000 RPM. Handles various materials well. |

| Materials Supported | Non-ferrous metals (aluminum, brass), hardwoods, plastics. |

| Software Compatibility | Works with Carbide Motion, Carbide Create (2D CAD/CAM), and MeshCAM (3D CAM). Supports Windows and macOS. |

| Build Quality | Sturdy aluminum frame. Enclosed design for dust control and noise reduction. |

| Ease of Assembly | Ships fully assembled. Ready to use out of the box. |

| Noise & Power Consumption | Quieter operation due to enclosure. Uses standard 110V or 220V outlet. |

Performance

The Nomad 3 is precise. Its rigid aluminum frame keeps vibrations low, which helps with accuracy. The high-speed spindle cuts smoothly, especially in softer metals and wood. It handles aluminum well, but projects take time with the small work area. It’s best for detailed work rather than large-scale milling.

Software

- Supported Software: Carbide Motion, MeshCAM, Carbide Create

- User Experience: Easy for beginners, but knowing basic CNC concepts helps

- File Formats: Supports STL, DXF, and common CAD/CAM files

The included software makes setup simple. You can go from design to cutting without needing third-party tools.

Advanced users may want more control, but for most, the software is well-designed and efficient.

Durability

The Nomad 3 is built to last. Its metal frame is solid, and components feel high-quality. Regular cleaning and lubrication help keep it running smoothly. Carbide 3D provides replacement parts, but availability may vary.

Pricing

The Nomad 3 is priced around $2,800.00. This positions it as a premium desktop CNC machine.

Considering its precision, build quality, and included software, it offers good value for professionals and serious hobbyists. While there are cheaper alternatives, the Nomad 3’s features and performance justify the investment

Pros & Cons

| Pros | Cons |

| High precision | Small work area |

| Enclosed design | Not suited for large-scale production |

| Good software support | May need additional accessories |

| Ready to use out of the box | Slower on tougher materials |

| Works with aluminum | Higher price for hobbyists |

The Nomad 3 Desktop CNC offers precision, a strong build, and an easy-to-use software suite. It’s not meant for large projects, but if you need accuracy in a small machine, it’s a great option.

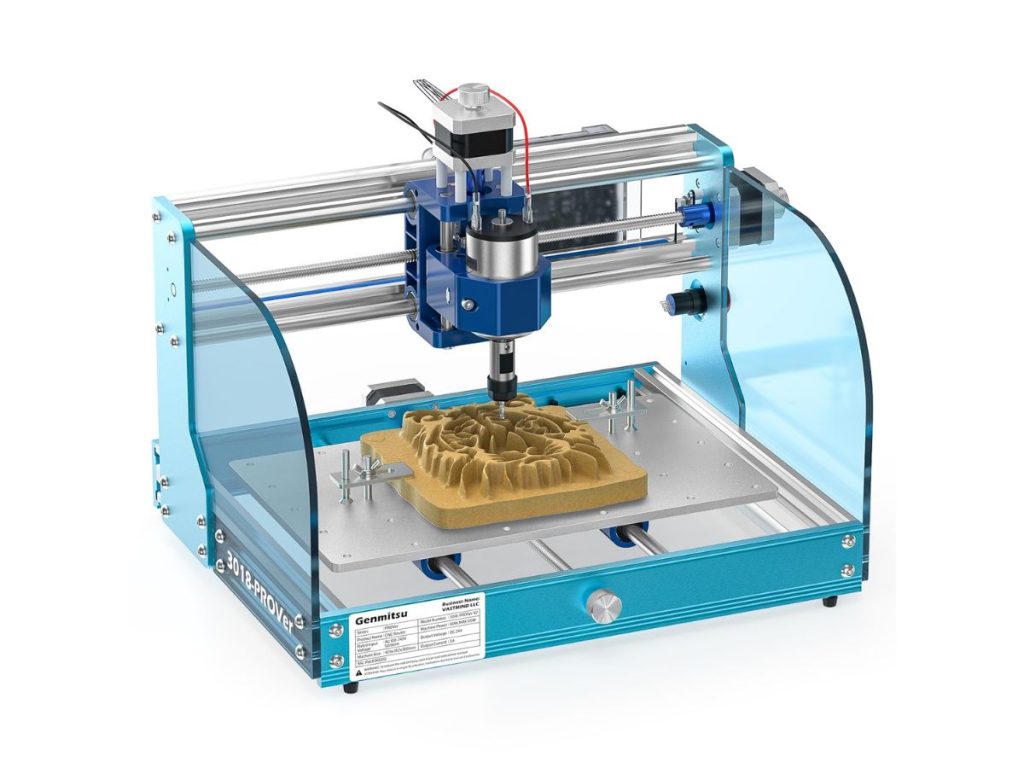

6. SainSmart Genmitsu 3018-PROVer

The SainSmart Genmitsu 3018-PROVer caught my attention as a potential bridge between beginner aspirations and functional reality. This machine stands out for its affordability and user-friendly features, making it a popular choice among hobbyists and newcomers.

The 3018-PROVer is great for:

- Hobbyists and DIYers: If you want to experiment with CNC at home, this is a solid choice.

- Students and educators: Perfect for learning CNC basics without spending too much.

- Small business owners: Great for engraving wood, plastic, and soft metals for custom products.

This machine works well for:

- Engraving signs, jewelry, and custom pieces

- Cutting wood, acrylic, and PCBs

- Small-scale projects with fine details

Limitations:

- Not designed for heavy-duty cutting

- Struggles with harder metals like steel

Key Features & Specifications

| Feature | Details |

| Work Area | 260 x 155 x 35mm (10.2 x 6.1 x 1.4 inches). Ideal for small projects. |

| Spindle Power | 775 motor, 12V-24V, 10,000 RPM. Works well for soft materials. |

| Speed & Precision | Spindle runs at up to 10,000 RPM. Produces clean cuts with the right settings. |

| Materials Supported | Wood, plastics, acrylics, soft aluminum, PVC, and PCBs. |

| Software Compatibility | Works with Grbl-based software (Candle). Compatible with Windows, macOS, and Linux. |

| Connectivity & Controls | USB interface. Includes an offline controller. |

| Build Quality | Aluminum frame with ABS components. Sturdy for its size. |

| Ease of Assembly | Semi-assembled. Takes about 15-30 minutes to complete. |

| Noise & Power Consumption | Moderate noise. Uses a 24V power supply. |

Performance

The 3018-PROVer delivers good precision for its price.

It cuts soft materials cleanly, and with the right adjustments, it handles PCBs well.

The all-aluminum frame reduces vibrations, helping with accuracy. It’s not the fastest machine, but for small, detailed work, it does the job.

Software

- Supported Software: Works with Grbl-based software like Candle.

- Best for Beginners? Yes. The software is easy to navigate, even if you’re new.

- File Formats: Supports standard G-code files.

The learning curve is manageable.

The software is simple, and you can find plenty of online tutorials. If you’re used to more advanced CAD/CAM programs, you might find it limiting, but it’s good for getting started.

Durability

The frame is solid, and the machine feels well-built for an entry-level CNC.

Regular cleaning helps maintain accuracy.

Lubricating the rails and checking for loose screws keeps it running smoothly. Spare parts are available, including upgraded spindles and laser modules if you want to expand its capabilities.

Pricing

The 3018-PROVer is one of the most affordable desktop CNC machines.

It’s a great entry-level option for learning CNC without a big investment. Compared to higher-end models, it has limitations, but for small projects, it offers good value.

You can also upgrade parts over time, making it a flexible choice.

Pros & Cons

| Pros | Cons |

| Affordable | Small cutting area |

| Beginner-friendly | Struggles with hard metals |

| Pre-assembled frame | Requires fine-tuning for best results |

| Upgradeable | Slower than high-end CNC machines |

The SainSmart Genmitsu 3018-PROVer is a good starting point for CNC machining. It’s affordable, easy to assemble, and capable of detailed work.

If you need a beginner-friendly CNC that doesn’t break the bank, this is one to consider.

7. Next Wave CNC SHARK SD120

Some CNC machines require hours of setup and constant adjustments before they even cut properly. The Next Wave CNC SHARK SD120 isn’t one of them.

- Ships fully assembled, you’ll be cutting within minutes, not days.

- Sturdy aluminum T-slot bed keeps materials in place for precision cuts.

- Handles routers up to 35,000 RPM so you can cut at the speed that works for you.

I’ve worked with CNCs that needed tweaking every single job.

Not this one.

If you want reliability in a desktop CNC, this is it.

The SHARK SD120 is ideal for:

- Hobbyists: If you love making custom signs, ornaments, or decorative carvings, this machine is a great fit.

- Small business owners: Great for engraving, detailed woodworking, and custom designs.

- Educators: Perfect for classrooms and training programs teaching CNC basics.

It excels at:

- Carving and engraving wood, plastics, and soft metals

- Creating detailed signs, plaques, and decorative pieces

- Small-scale precision parts

While versatile, it’s not designed for heavy industrial applications or cutting hard metals.

Key Features & Specifications

| Feature | Details |

| Work Area | 12″ x 24″ table. Great for medium-sized projects. |

| Spindle Compatibility | Works with palm routers like DeWALT 611, Porter-Cable 450, and Bosch PR20. |

| Speed & Precision | Supports routers up to 35,000 RPM. Delivers clean, detailed cuts. |

| Materials Supported | Wood, plastics, soft metals. |

| Software Compatibility | Comes with VCarve Desktop and Ready2Control. Works with multiple file formats. |

| Connectivity & Controls | Controlled via a touchscreen pendant or computer. Flexible and easy to use. |

| Build Quality | Strong aluminum T-Slot bed for stability. Reduces vibrations for better accuracy. |

| Ease of Assembly | Ships fully assembled. Ready to use out of the box. |

| Noise & Power Consumption | Depends on the router used. Moderate noise levels. |

Performance

The SHARK SD120 offers solid performance for a desktop CNC. It runs smoothly, and the aluminum frame keeps vibrations low, which helps with accuracy.

Cuts are clean, especially on wood and acrylic.

If you’re working with soft metals like aluminum, using the right speeds and feeds is important for good results.

Software

- Supported Software: Comes with VCarve Desktop and Ready2Control.

- User Experience: Beginner-friendly, but also has features for advanced users.

- File Formats: Supports a variety of CAD/CAM formats, making it flexible for different workflows.

The included software is easy to learn, especially for those new to CNC. More experienced users may prefer additional CAD/CAM software for extra control.

Durability

This CNC feels well-built. The aluminum T-slot bed is sturdy, reducing movement and improving precision. Maintenance is simple:

- Keep the work area clean.

- Check screws and fasteners periodically.

- Lubricate moving parts to keep them running smoothly.

Spare parts and support are available, making long-term use easier.

Pricing

The SHARK SD120 is priced around $2,174.99. It’s in the mid-range for desktop CNC machines.

Compared to competitors, it offers:

- A pre-assembled design, saving setup time.

- A strong frame, reducing vibration and improving accuracy.

- Touchscreen control, which makes operation smoother.

Pros & Cons

| Pros | Cons |

| Comes fully assembled | Router not included |

| Strong aluminum frame | Limited to soft materials |

| Easy-to-use software | Higher price compared to entry-level models |

| Touchscreen control | Not built for industrial-scale work |

The Next Wave CNC SHARK SD120 is a well-built, user-friendly CNC that works great for woodworking, engraving, and detailed carving.

While it’s not meant for industrial use, it offers great precision and ease of use for medium-sized projects.

Conclusion

We started with a simple question: Which CNC is right for you? Now, you have the answers.

You’ve seen the options, the pros, the cons. You know what each machine is built for.

But knowledge alone won’t move the needle.

Your ideas deserve more than “someday.” They deserve to be made real.

So, what’s your next move? Let’s talk about which CNC will take your projects to the next level.

Contact us today!