When I first started my manufacturing business, outsourcing metal parts seemed like the best option. But delays and rising costs forced me to rethink my strategy. That’s when I turned to CNC machining.

Bringing CNC machining in-house was a game-changer, but finding the right machine?

That was a challenge. Not all CNC machines are made for heavy-duty metalwork.

After years of trial and error, I’ve learned what works and what doesn’t. This guide is built on real experience, helping you avoid costly mistakes when choosing a CNC machine.

You’ll discover the best CNC machines for metalwork, with details on precision, durability, and efficiency. By the end, you’ll have the confidence to make an informed decision.

So, let’s get started!

Quick Comparison Chart

Choosing the right CNC machine for your business isn’t just about specs—it’s about matching performance with your workflow, space, and long-term goals. Below is a detailed comparison of all 8 machines we’ve covered, helping you decide which model fits your exact production needs.

| Machine | Machine Type | Work Area Size | Best For | Spindle Speed (Max) | Price Range (USD) | ATC Option | Precision/Build Quality |

| Tormach 1100MX | CNC Mill | 18″ x 11″ x 16.25″ | Prototyping, small part production | 10,000 RPM | $20,000 – $30,000 | Optional | High – Industrial-grade |

| Haas Mini Mill | CNC Mill | 16″ x 12″ x 10″ | Small machine shops, light metalwork | 6,000 RPM (15K upgrade) | $35,000 – $45,000 | Optional | Very High – Industry standard |

| 1530 Multi-Spindle (Blue Elephant) | CNC Router | 59″ x 118″ (1500x3000mm) | Mass production, wood, panel furniture | 18,000 RPM | $11,000 – $13,500 | Multi-Spindle Alt | High – Cast frame & pneumatic |

| SYIL X5 | CNC Mill | 11.8″ x 10.2″ x 11.8″ | Startups, education, compact shops | 20,000 RPM | ~$25,000+ | Included | High – Mineral casting frame |

| Pocket NC V2-50 | 5-Axis Desktop Mill | ~5″³ envelope | Education, R&D, prototyping | 50,000 RPM | ~$9,900 | No | Very High – Micro precision |

| ShopSabre 23 | CNC Router | 30″ x 40″ x 5″ | Sign making, wood, plastic | 24,000 RPM (optional) | Starting ~$10,795 | Upgradeable | Industrial-grade router |

| Grizzly G0704 | Mill/Drill | 7″ x 27″ | Budget-conscious users, hobbyists | 2,250 RPM | ~$2,095 | No | Medium – Entry-level build |

| OMNI 1325 CNC Router | CNC Router | 51″ x 98″ (1300x2500mm) | Furniture, signage, aluminum panels | ~24,000 RPM | ~$10,000 – $15,000 | Customizable | High – Heavy-duty frame |

Whether you’re a manufacturer looking to scale or a workshop adding capabilities, this table gives you a clear side-by-side view to guide your next investment. Precision, footprint, speed, and price—now you can match the right machine to the right job.

1. Tormach 1100MX

I remember the first time I saw the Tormach 1100MX in action. It was at a small machine shop, and the owner—who had previously relied on outsourcing—was now running complex metal parts in-house. No delays. No quality issues. Just pure control.

That’s when it hit me. A CNC machine isn’t just a tool, it’s a game-changer. And the Tormach 1100MX? It’s one of the best in its class.

Features

The 1100MX is designed for small-to-medium businesses that need industrial-level precision without the industrial-level price tag. It’s compact, powerful, and packed with features that make metal cutting smooth and efficient. Here’s what sets it apart:

- Rigid Construction: Built with cast iron, it can handle serious metal cutting without flex or chatter.

- High-Speed Spindle (10,000 RPM): Faster speeds mean cleaner cuts and better finishes.

- PathPilot® Control System: Tormach’s intuitive software makes CNC machining easier and more accessible.

- Automatic Tool Changer (ATC) Available: If you need to automate, the ATC saves time and boosts productivity.

- Plug-and-Play Setup: Unlike some machines that require weeks of installation, you can get the 1100MX up and running fast.

Ideal For

If you’re running a small fabrication shop, prototyping lab, or looking to bring metalwork in-house, this machine is for you. It’s ideal if you want to stop relying on outsourcing and take full control of production.

If you’re producing custom parts, aerospace components, or precision tools, the 1100MX delivers the accuracy and consistency you need—without the footprint of a full-size mill.

Pros & Cons

Pros:

- Affordable: Compared to industrial machines, it offers great value.

- High Spindle Speed: 10,000 RPM allows for precision metal cutting.

- Compact Yet Powerful: Fits in smaller shops while delivering solid performance.

- User-Friendly Software: PathPilot is intuitive and easy to use.

Cons:

- Not as Powerful as Full-Scale Industrial Mills: Limited for heavy-duty production.

- ATC is Optional: Requires an additional investment.

- May Require Accessories: Advanced metalwork might need extra tooling.

Price & Value

The Tormach 1100MX gives you an industrial-level CNC experience at a fraction of the cost. Expect to invest around $20,000–$30,000, depending on upgrades like the ATC and enclosure.

2. Haas Mini Mill

I’ll be honest—when I first considered the Haas Mini Mill, I was skeptical. Could a machine this compact really handle serious metalwork? But after seeing it in action at a local shop, my doubts disappeared. The precision, speed, and reliability were impressive, and it was clear why so many small-to-medium businesses swear by it.

If you need a CNC mill that delivers industrial performance without taking up industrial space, the Haas Mini Mill is a strong contender.

Features

The Mini Mill is part of Haas’ trusted lineup of CNC machines, built with the same quality and precision as their larger models but designed for shops that need big capabilities in a smaller footprint. Here’s why it’s a go-to choice for many manufacturers:

- Compact Yet Powerful: Despite its size, it offers the rigidity and durability needed for high-precision metal cutting.

- Standard 6,000 RPM Spindle (Optional 15,000 RPM Upgrade): Offers flexibility for both standard and high-speed machining.

- Haas Control System: Known for its ease of use, it simplifies programming and operation.

- Built-in Coolant System: Helps maintain temperature control and prolongs tool life.

- Reliable Brand Support: Haas has one of the strongest service and support networks in the industry.

Ideal For

If your business is short on space but high on demand, the Mini Mill is a perfect fit. It’s ideal for small manufacturers, machine shops, and prototyping facilities that need an affordable, high-quality CNC solution.

Pros & Cons

Pros:

- Industrial-Grade Performance: Compact but powerful enough for real manufacturing.

- User-Friendly Haas Control System: Great for machinists of all experience levels.

- Brand Reliability: Haas machines are well-supported and built to last.

- Upgrade Options: Can be enhanced with a high-speed spindle and other add-ons.

Cons:

- Limited Work Envelope: Not ideal for machining large parts.

- Base Model Lacks Some Features: Upgrades can drive up the cost.

- Higher Entry Cost Than Some Competitors: More expensive than some small CNC mills, but you’re paying for quality.

Price & Value

The Haas Mini Mill is an investment in quality and long-term reliability. Expect pricing to start around $35,000–$45,000, depending on optional upgrades like the high-speed spindle and automatic tool changer.

While it costs more than entry-level CNC machines, it delivers professional-grade performance that justifies the price.

3. 1530 Multi-Spindle CNC Router by Blue Elephant

I recall visiting a manufacturing facility where the production team struggled with frequent tool changes and downtime. Their operations were sluggish, and morale was low. Then, they invested in the 1530 Multi-Spindle CNC Router with Pneumatic System, and everything changed. Productivity soared, and the team regained its enthusiasm.

If you’re aiming to boost efficiency without compromising quality, this machine deserves your attention.

Features

This CNC router is engineered for businesses seeking high productivity and versatility. Its design caters to complex tasks with precision and speed. Key features include:

- Triple Spindle Configuration: Three spindles operate sequentially, mimicking the functionality of an Automatic Tool Changer (ATC) but at a more accessible price point.

- Integrated Rotary Device: Ideal for processing cylindrical items like stair handrails and sculptures, enhancing the machine’s versatility.

- User-Friendly DSP Control System: Equipped with a USB port, this system simplifies operation, reducing the learning curve for your team.

- Robust HQD Air-Cooling Spindle: Operating at speeds up to 18,000 RPM, it ensures precise and efficient cutting.

Ideal For

- Furniture Manufacturers: Crafting intricate designs on doors, windows, and cabinets.

- Decorative Woodwork Producers: Creating detailed frames, screens, and ornamental pieces.

- Mass Production Facilities: Businesses requiring consistent, high-volume output without sacrificing precision.

Pros & Cons

Pros:

- Cost-Effective ATC Alternative: Achieves multi-tool functionality without the high investment of traditional ATC systems.

- Enhanced Versatility: The rotary device expands processing capabilities, accommodating a wider range of projects.

- Efficient Operation: High spindle speed and user-friendly controls streamline workflows, boosting overall productivity.

Cons:

- Additional Accessories Needed: Depending on your specific applications, further investments in accessories might be required to fully utilize the machine’s capabilities.

Price & Value

Investing in the 1530 Multi-Spindle CNC Router offers a balance between functionality and cost. Prices typically range from $11,000 to $13,500, depending on the chosen configuration.

This investment can lead to significant improvements in production efficiency and product quality, delivering substantial returns over time.

4. Syil X5

The first time I encountered the SYIL X5, a colleague had just set one up in his small workshop, and he couldn’t stop raving about how this compact machine transformed his operations. He produced intricate parts with remarkable precision. It was clear that the SYIL X5 was a game-changer for small-scale manufacturers.

Features

The SYIL X5 is engineered for individuals and businesses requiring a compact yet powerful CNC milling solution. Its design caters to hobbyists and professionals, offering capabilities typically found in larger, more expensive machines. Key features include:

- Compact Design: With dimensions of 560×260 mm for the table and axis travels of 300×260×300 mm, the X5 fits comfortably in workshops with limited space.

- High-Speed Spindle: The 20,000 RPM direct-coupled BT30 spindle ensures precise and efficient milling operations.

- Automatic Tool Changer (ATC): Equipped with a 16-pocket high-speed servo tool changer, the X5 minimizes downtime between tool changes, enhancing productivity.

- Mineral Casting Machine Frame: Manufactured by SCHNEEBERGER, the mineral casting bed provides high rigidity and excellent thermal stability, contributing to machining accuracy.

- User-Friendly Control System: The SYIL X5 offers compatibility with various control systems, including Siemens SINUMERIK 828D, providing an intuitive interface for operators.

Ideal For

- Small Workshops and Startups: Its compact size and affordability make it accessible for businesses with limited space and budget.

- Educational Institutions: The user-friendly interface and comprehensive capabilities make it suitable for training purposes in technical education settings.

- Hobbyists and DIY Enthusiasts: Individuals seeking to undertake precise milling projects at home will find the X5 to be a valuable tool.

Pros & Cons

Pros:

- Affordable: Offers a cost-effective solution without compromising on essential features.

- High Precision: Capable of delivering accurate machining results suitable for intricate designs.

- Compact Footprint: Occupies minimal space, making it suitable for environments with limited room.

Cons:

- Limited Work Envelope: The smaller table size and axis travel may not accommodate larger workpieces.

- Power Constraints: While suitable for various materials, it may not handle heavy-duty milling tasks as efficiently as larger machines.

Price & Value

The SYIL X5 is positioned as an affordable CNC milling solution, with prices starting around $24,990. Additional features and upgrades, such as advanced control systems or enhanced spindles, can increase the overall investment.

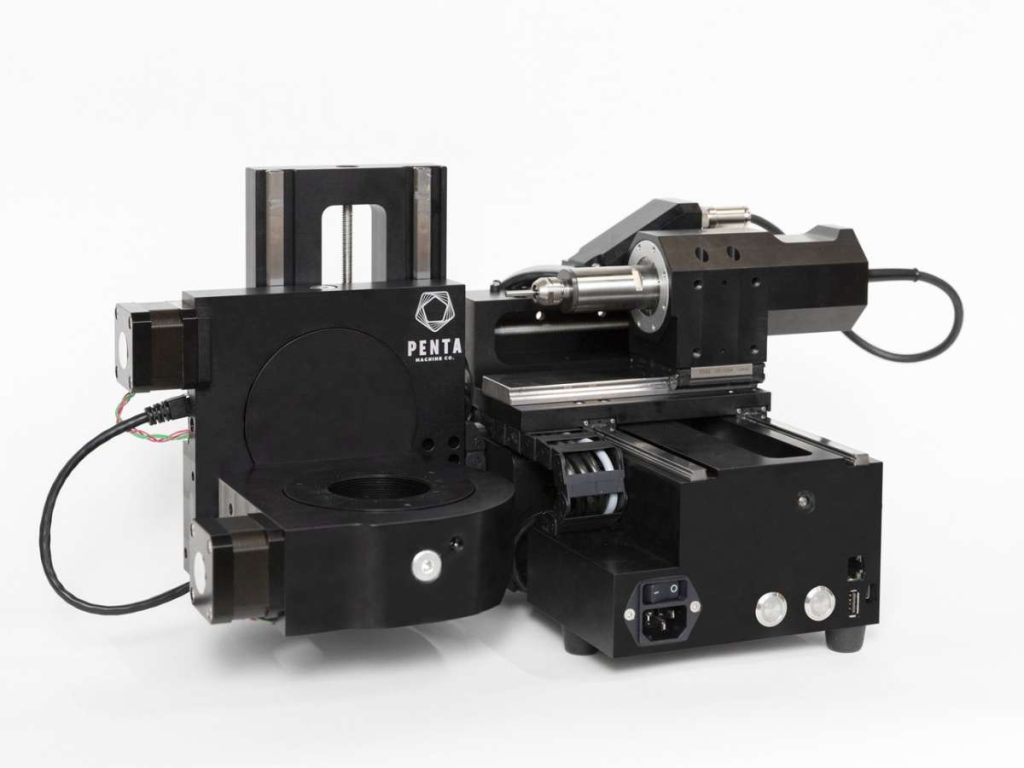

5. Pocket NC V2-50

The Pocket NC V2-50 is a compact yet powerful 5-axis CNC milling machine designed to bring advanced machining capabilities to small workshops, educational institutions, and home environments. Despite its small footprint, it offers features that rival larger industrial machines, making it an excellent choice for precision manufacturing.

Features

The Pocket NC V2-50 is built for high-precision machining in a space-efficient package. It allows users to create complex geometries and intricate designs with ease. Key features include:

- 5-Axis Simultaneous Machining: Allows for detailed, multi-angle cuts, expanding design possibilities.

- High-Speed Spindle: Operates between 1,000 and 50,000 RPM, handling materials like aluminum, delrin, and even G5 titanium.

- Compact Footprint: Measuring approximately 17.5 inches by 12.5 inches, it fits comfortably on a desktop.

- User-Friendly Interface: Compatible with standard G-code and includes a built-in simulator for easy operation.

- Precision Engineering: Features a spindle runout of 0.0001 inches and repeatability of ±0.002 inches for high-quality machining.

Ideal For

- Educational Institutions: Provides students with hands-on experience in 5-axis machining at an accessible price.

- Small Businesses and Startups: Offers advanced manufacturing capabilities without requiring large industrial equipment.

- Hobbyists and Makers: Enables precision machining projects in a home or small workshop setting.

Pros & Cons

Pros:

- Affordable 5-Axis Machining: A cost-effective entry into advanced manufacturing.

- Compact and Portable: Fits in tight spaces and requires minimal setup.

- High Precision: Capable of producing intricate parts for prototyping and small-scale production.

Cons:

- Limited Work Envelope: Small axis travel restricts the size of machinable parts.

- Material Limitations: While it can handle titanium, it performs best with softer materials like aluminum and delrin.

- Air Supply Requirement: High-speed spindle requires an external air compressor, adding setup complexity.

Price & Value

The Pocket NC V2-50 is priced around $9,900, making it an affordable solution for precision 5-axis machining. Given its capabilities, it delivers substantial value for educational purposes, prototyping, and small-scale production.

6. ShopSabre 23 CNC Router

The ShopSabre 23 brings industrial-grade CNC capabilities to a compact, desktop-sized machine, making it an excellent choice for businesses seeking precision and versatility without sacrificing valuable floor space.

Features

Designed with a focus on rigidity and accuracy, the ShopSabre 23 incorporates features typically found in larger industrial machines:

- Industrial Ball Screw Design: Utilizes ball screws on all axes, ensuring precise motion control and reducing maintenance compared to rack and pinion systems.

- Robust Construction: Built with a welded, precision-ground tubular steel frame and gantry, providing stability and durability for consistent performance.

- High-Performance Linear Guide Rails: Equipped with 25mm precision HiWin rails, enhancing accuracy and extending machine lifespan.

- Advanced Control System: Features the ShopSabre WINCNC industrial controller, offering user-friendly operation with at-machine CAD/CAM capabilities.

- Versatile Spindle Options: Comes standard with a 3.5HP 110V router, with upgrades available to HSD Italian spindles for enhanced performance.

Ideal For

- Educational Institutions: Provides students with hands-on experience using industrial-grade equipment in a manageable size.

- Small to Medium-Sized Workshops: Offers professional capabilities without requiring extensive space, suitable for custom fabrication and prototyping.

- Hobbyists and Entrepreneurs: Delivers high-quality machining for personal projects or small business production runs.

Pros & Cons

Pros:

- Industrial-Grade Components: Ensures high precision and durability, uncommon in desktop-sized machines.

- User-Friendly Interface: The integrated PC system with Windows OS simplifies operation and reduces the learning curve.

- Customizable Options: Offers various upgrades, including spindle enhancements and dust collection systems, to tailor the machine to specific needs.

Cons:

- Limited Work Area: With a cutting area of 30″ x 40″ and a 5″ Z-axis clearance, it may not accommodate larger projects.

- Higher Initial Investment: Compared to other desktop CNC routers, the ShopSabre 23’s industrial features come at a higher price point.

- Learning Curve: While user-friendly, operators without CNC experience may require time to fully utilize its capabilities.

Price & Value

ShopSabre 23 starts at $10,795, with financing options available as low as $188.44/month. Additional features and upgrades can increase the overall investment. Considering its industrial-grade components and precision, it offers substantial value for those seeking a durable and versatile CNC solution.

7. Grizzly G0704

When precision and versatility are paramount, the Grizzly G0704 stands out as a top choice for hobbyists and professionals. This benchtop mill/drill offers features typically found in larger industrial machines, all within a compact footprint.

Features

- Variable-Speed 1 HP Motor: Provides spindle speeds from 50–1125 RPM in low and 100–2250 RPM in high, accommodating various materials and cutting conditions.

- Dovetail Column: Ensures stability and precision during operations, a feature often reserved for larger machines.

- Digital Spindle Scale: Offers accurate readings in both metric and inches, enhancing precision in machining tasks.

- R-8 Spindle Taper: Compatible with a wide range of standard tooling, increasing the machine’s versatility.

Ideal For

- Small Business Owners: Looking to perform precision milling without investing in larger, more expensive equipment.

- Hobbyists and DIY Enthusiasts: Seeking a reliable and versatile milling machine for personal projects.

- Educational Institutions: Needing a durable and functional mill for instructional purposes.

Pros & Cons

Pros:

- Compact Design: Ideal for workshops with limited space.

- Cost-Effective: Offers industrial-level features at a more accessible price point.

- Versatile Applications: Suitable for a variety of materials and milling tasks.

Cons:

- Plastic Gear Drive: Some users have reported noise and durability concerns, with recommendations for aftermarket belt drive replacements.

- Light-Duty Limitations: May struggle with larger end mills or heavy-duty milling tasks.

Price & Value

The Grizzly G0704 is priced around $2,095, offering a balance between affordability and functionality. Its combination of features and performance makes it a valuable addition to any workshop.

8. Omni 1325 CNC Router

When it comes to reliable and efficient CNC routing, the OMNI 1325 CNC Router stands out as a robust solution for both businesses and individual craftsmen. Designed to handle a variety of materials with precision, this machine caters to diverse cutting and engraving requirements.

Features

- Generous Working Area: With a standard working area of 1300mm x 2500mm, the OMNI 1325 accommodates large sheets, making it ideal for sizable projects.

- High-Quality Components: Equipped with a robust spindle and reliable drive systems, this router ensures consistent performance and longevity.

- User-Friendly Interface: The machine’s control system is designed for intuitive operation, allowing users to manage complex tasks with ease.

- Versatile Material Compatibility: Capable of cutting and engraving materials such as wood, acrylic, aluminum, and more, the OMNI 1325 offers flexibility for various applications.

Ideal For

- Small to Medium-Sized Enterprises: Ideal for businesses involved in sign-making, cabinetry, furniture production, and other industries requiring precise cutting and engraving.

- Educational Institutions: Suitable for training purposes, providing students with hands-on experience in CNC operations.

- Individual Craftsmen and Hobbyists: For those seeking to enhance their craftsmanship with precise and efficient cutting capabilities.

Pros & Cons

Pros:

- Durable Construction: Built with high-quality materials, ensuring long-term reliability.

- High Precision: Delivers accurate cuts, essential for detailed designs and intricate patterns.

- Customizable Options: Offers various configurations to meet specific needs, including different spindle powers and additional accessories.

Cons:

- Learning Curve: Users new to CNC machinery may require time to fully master the machine’s capabilities.

- Space Requirements: Due to its size, adequate workshop space is necessary for proper operation and safety.

Price & Value

The OMNI 1325 CNC Router is competitively priced, offering a balance between cost and functionality. Investing in this machine provides value, especially considering its durability and versatility.

Conclusion

Investing in CNC machining changed my business forever. It eliminated outsourcing headaches, improved quality, and gave me control. But getting the right machine was the real game-changer.

Now, you have everything you need to make an informed decision. You know which CNC machines are built for metalwork, and which ones to avoid.

Are you ready to take your production to the next level?

Don’t wait until the wrong machine costs you time and money.

Contact us today, and let’s find the best CNC machine for your business.