I still remember the first time I struggled with an outdated CNC machine in my fabrication shop. Projects took longer than they should have, and the final cuts were never as precise as I wanted.

It cost me time, money, and customers.

That’s when I knew upgrading was the only option. But finding the right CNC machine for metal fabrication wasn’t easy.

After years of experience in the industry, I’ve tested and researched countless machines. This guide is built on real-world experience, not just specs on paper.

In this article, you’ll find the best CNC machines for metal fabrication—tested for precision, durability, and efficiency. By the end, you’ll have the information you need to make the best choice for your business.

So, let’s get started!

Quick Comparison Chart

When choosing a CNC machine for metal fabrication, it’s essential to compare key factors like machine type and user-friendliness. Below is a side-by-side comparison of some of the top machines for metal fabrication:

| Machine | Best For | Axis Control | Material Compatibility | Ease of Use | Notable Feature |

| Mazak QT-Compact 200MSY | Complex turning & milling | 4-Axis | Steel, alloys, aluminum | Medium | Y-axis and sub-spindle for multi-tasking |

| Haas VF-2 | Industrial milling | 3-Axis | Steel, titanium, aluminum | High | Rigid construction and customizable tooling |

| Blue Elephant Metal Cutter | Sheet metal cutting | 3-Axis | Stainless steel, aluminum | Medium | Ideal for large flat-sheet precision cuts |

| Tormach 1100MX | Prototyping, small shops | 3-Axis | Aluminum, steel, brass | Very High | PathPilot software; compact & affordable |

| DMG MORI DMU 50 | Aerospace, complex geometry | 5-Axis | All metals including titanium | Medium | Advanced 5-axis capability with high precision |

| Okuma GENOS L3000 | Heavy-duty metal turning | 2-Axis | Cast iron, steel, hardened metals | Medium | Excellent thermal stability and power |

| Lincoln Electric Torchmate 4800 | Cutting thick metal sheets | 2-Axis | Mild steel, stainless, aluminum | High | Touchscreen interface & HD plasma cutting |

| CNC Masters Supra | Education, small production | 3-Axis | Aluminum, steel | Very High | Simple programming, budget-friendly |

| ShopSabre IS510 | Aluminum sheet & metal panels | 3-Axis | Aluminum, sheet metal | High | Heavy-duty frame and servo-driven motors |

This table offers a quick overview to help compare machines across critical categories. Always consider your shop size, workload, and technical needs when selecting the right CNC solution.

1. Mazak QT-Compact 200MSY

Type: CNC Lathe Best for: High-speed turning and multi-axis machining

Imagine a machine that seamlessly integrates high-speed turning with multi-axis capabilities, all within a compact footprint. The Mazak QT-Compact 200MSY is designed to elevate your production efficiency, handling complex geometries with precision.

Is your current equipment limiting your production potential? Its robust construction and advanced features make it an invaluable asset for manufacturers aiming to optimize their operations.

Key Features

- Y-Axis Milling: Enables intricate milling operations without additional setups.

- Sub-Spindle: Facilitates simultaneous front and back-end machining, reducing cycle times.

- Mazatrol SmoothG Control: Offers intuitive programming and real-time monitoring for enhanced productivity.

- C-Axis Indexing: Allows precise angular positioning in 0.001° increments, expanding machining versatility.

- Rigid Construction: Ensures stability and accuracy during heavy-duty operations.

Parameters

- Main Spindle Speed: Up to 5,000 RPM

- Sub-Spindle Speed: Up to 6,000 RPM

- X-Axis Travel: 215 mm

- Y-Axis Travel: 100 mm

- Z-Axis Travel: 605 mm

Advantages & Drawbacks

Advantages

- Enhanced machining flexibility

- Reduced setup times

- High-precision capabilities

Drawbacks

- Higher initial investment

- Requires skilled operators

- Potentially increased maintenance complexity

2. Haas VF-2

Type: CNC Vertical Mill Best for: Industrial-grade metal fabrication

Ever worked with a machine that feels like an extension of your own hands? That’s the Haas VF-2.

I remember the first time I put it to work—effortless precision, raw power, and zero hesitation. If you need a CNC mill that can handle demanding production, tight tolerances, and high-speed machining, this is it. The VF-2 isn’t just a machine—it’s a workhorse built to dominate metal fabrication.

Key Features

- High-performance spindle for aggressive metal cutting

- Rigid cast-iron construction—built for stability and durability

- Extensive tool compatibility—handles a wide range of machining needs

- Fast rapids and tool changes to maximize productivity

- Haas intuitive control system for streamlined operation

Parameters

- Spindle Speed: 8,100 RPM (upgradeable to 15,000 RPM)

- X/Y/Z Travel: 30” × 16” × 20”

- Rapid Traverse Rate: 1,000 IPM

- Spindle Motor: 30 HP

- Tool Capacity: 20+1 tool changer

Advantages & Drawbacks

Advantages

- Exceptional precision, even at high speeds

- Robust and reliable for industrial workloads

- Strong aftermarket support and Haas service network

Drawbacks

- Higher upfront cost compared to entry-level mills

- Can require a learning curve for beginners

- Space-intensive—needs room to operate efficiently

3. Blue Elephant’s CNC Milling Machine for Metal Sheet Cutting

Type: CNC Milling Machine Best for: Large-scale metal sheet fabrication

I recall the first time I encountered the Blue Elephant CNC Milling Machine—its sheer size and robust design immediately signaled its capability. For businesses aiming to elevate their metal sheet fabrication processes, this machine stands as a formidable ally.

It’s engineered to handle extensive workloads, ensuring precision and efficiency in every cut. Is your current equipment meeting the demands of your production line?

Key Features

- Expansive Cutting Area: Accommodates large metal sheets, reducing the need for multiple setups.

- High-Power Spindle: Ensures smooth and precise cutting through various metal thicknesses.

- Sturdy Construction: Built with a rigid frame to minimize vibrations, enhancing accuracy.

- Advanced Control System: User-friendly interface allowing for intricate designs and operations.

- Efficient Chip Removal: Integrated system to maintain a clean working environment and prolong machine life.

Parameters

- Spindle Speed: Up to 24,000 RPM

- X/Y/Z Travel: 600mm × 500mm × 200mm

- Table Size: 800mm × 700mm

- Positioning Accuracy: ±0.02mm

- Max. Cutting Speed: 15,000 mm/min

Advantages & Drawbacks

Advantages

- High Precision and Repeatability

- Suitable for Large Workpieces

- Durable Build Quality

Drawbacks

- Requires Significant Floor Space

4. Tormach 1100MX

Type: CNC Mill Best for: Small shops and prototyping

I remember the first time I fired up the Tormach 1100MX, it felt like unlocking a new level of precision without breaking the bank. If you’re running a small shop or need a powerful prototyping machine, this CNC mill delivers. It’s affordable, easy to use, and surprisingly capable of its size.

Key Features

- Budget-friendly without compromising quality

- User-friendly PathPilot control system—intuitive, no steep learning curve

- High-precision machining—perfect for detailed metalwork

- Compact yet powerful—fits in smaller workspaces

- Rigid cast-iron frame for stability

Parameters

- Spindle Speed: 10,000 RPM

- X/Y/Z Travel: 18” × 11” × 16.25”

- Rapid Traverse Rate: 135 IPM

- Spindle Motor: 2HP, BT30

- Tool Capacity: 10-station automatic tool changer (optional)

Advantages & Drawbacks

Advantages

- Affordable entry into CNC milling

- Compact but capable of industrial-level precision

- Strong community and support network

Drawbacks

- Not ideal for heavy-duty production

- Limited tool capacity unless upgraded

- Lacks some automation found in larger machines

5. DMG MORI DMU 50

Type: 5-Axis CNC Mill Best for: Complex part machining and aerospace

The DMG MORI DMU 50 stands as a testament to precision engineering, tailored for industries where accuracy is paramount. Its 5-axis simultaneous machining capabilities make it indispensable for crafting intricate components, particularly in aerospace and other high-precision sectors.

Key Features

- High Rigidity: Constructed with a monolithic machine bed, the DMU 50 offers exceptional stability, minimizing vibrations during machining.

- Precise 5-Axis Control: The swivel rotary table allows for simultaneous 5-axis machining, accommodating workpieces up to 300 kg.

- Efficient Chip Management: Integrated systems ensure optimal chip removal, maintaining a clean workspace and prolonging machine life.

- Advanced Spindle Options: Equipped with a speedMASTER spindle, offering speeds up to 15,000 rpm, with optional upgrades to 20,000 rpm for enhanced versatility.

- User-Friendly Interface: Features the ERGOline Control with a 21.5″ multi-touch screen and CELOS, streamlining operations and reducing setup times.

Parameters

- X-Axis Travel: 650 mm (25.6 in)

- Y-Axis Travel: 520 mm (20.5 in)

- Z-Axis Travel: 475 mm (18.7 in)

- Table Load Capacity: Up to 300 kg (661.4 lbs)

- Spindle Speed: Standard at 15,000 rpm, with optional upgrade to 20,000 rpm

Advantages & Drawbacks

Advantages

- Exceptional precision and accuracy

- Versatile machining capabilities

- Robust construction ensuring durability

Drawbacks

- Higher initial investment

- Requires skilled operators

- Complex maintenance procedures

6. Okuma GENOS L3000

Type: CNC Lathe Best for: Heavy-duty turning operations

The Okuma GENOS L3000 is a powerhouse in the realm of CNC lathes, meticulously engineered for heavy-duty turning operations. Its advanced features make it an ideal choice for industries requiring precision and reliability.

Key Features

- Thermal Stability: Incorporates Thermo-Friendly Construction, including the Thermo Active Stabilizer (TAS-C), to automatically compensate for thermal effects, maintaining tight tolerances during prolonged operations.

- High-Speed Performance: Equipped with an integral spindle motor, the GENOS L3000 offers spindle speeds up to 3,800 RPM, facilitating efficient machining of various materials.

- User-Friendly OSP Control: Features Okuma’s proprietary OSP-P300LA control system, providing intuitive operation and seamless integration with other shop floor technologies.

- Optional Milling and Y-Axis Capabilities: Offers high-speed milling and Y-axis options on specific models, allowing users to select the best specifications for their workpiece length and shape.

- Compact Footprint: Despite its robust capabilities, the GENOS L3000 maintains a compact design, optimizing valuable floor space without compromising performance.

Parameters

- Max Turning Diameter: Up to 340 mm (13.39 inches)

- Max Turning Length: Up to 500 mm (19.69 inches)

- Spindle Speed Range: 38 to 3,800 RPM

- Spindle Motor Output: 22/15 kW (20 min/continuous)

- Number of Tools: 12-position turret, with options for VDI or radial multitasking configurations

Advantages & Drawbacks

Advantages

- Exceptional precision and accuracy

- Versatile machining capabilities

- Robust construction ensuring durability

Drawbacks

- Higher initial investment

- Requires skilled operators

- Complex maintenance procedures

7. Lincoln Electric Torchmate 4800

Type: CNC Plasma Cutter Best for: High-definition metal cutting

The Lincoln Electric Torchmate 4800 is a robust CNC plasma cutting system designed for expanding fabrication shops. Its 4×8 cutting area and industrial-grade components make it ideal for high-definition metal cutting tasks. This machine comes fully assembled, allowing you to start cutting within 30 minutes of setup.

Key Features

- Advanced Motion Control: Ensures precise and smooth cutting operations.

- Industrial-Grade Durability: Built with high-quality components for long-lasting performance.

- Touchscreen Interface: User-friendly 20-inch touchscreen with CAD/CAM software for intuitive operation.

- Integrated Water Table: Reduces dust and fumes, providing a cleaner work environment.

- High-Speed Plasma Cutter: Equipped with FlexCut 80 or optional FlexCut 125 for faster cut speeds and reduced consumable costs.

Parameters

- Cutting Area: 4 ft x 8 ft (1,250 mm x 2,500 mm)

- Maximum Material Thickness: Up to 1 inch (25.4 mm) for mild steel

- Cutting Speed: Up to 500 inches per minute (12,700 mm/min)

- Table Dimensions: 74 in x 114 in x 63 in (1,879.6 mm x 2,895.6 mm x 1,600.2 mm)

- Weight: Approximately 1,847 lbs (837.79 kg)

Advantages & Drawbacks

Advantages

- High precision and repeatability

- User-friendly operation

- Comprehensive support and warranty

Drawbacks

- Significant initial investment

- Requires adequate shop space

- Dependence on consumable availability

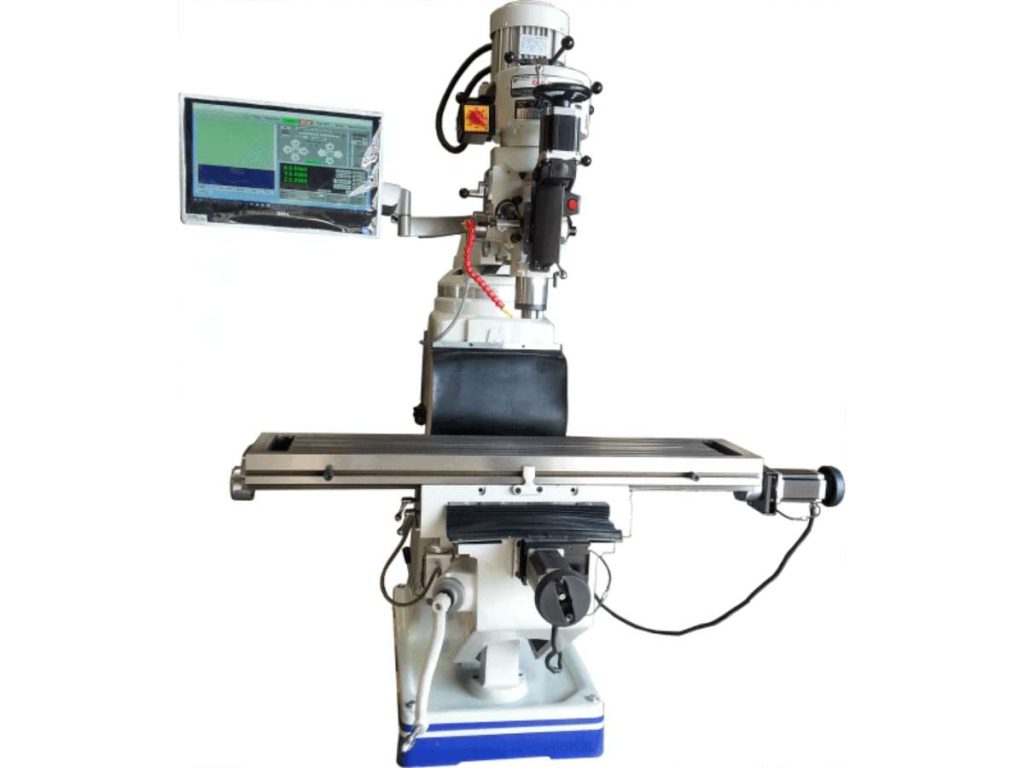

8. CNC Masters Supra

Type: CNC Vertical Knee Mill Best for: Precision milling for small to medium

The CNC Masters Supra is a versatile CNC vertical knee mill designed to meet the precision milling needs of small to medium-sized shops. Its construction and user-friendly interface make it ideal for both novice and experienced machinists.

Whether you’re crafting intricate components or handling routine milling tasks, the Supra delivers consistent performance that enhances your shop’s productivity.

Key Features

- Versatile Power Levels: Equipped with a 3 HP variable speed spindle motor, the Supra accommodates a wide range of milling applications.

- Precision Cutting Capabilities: The machine’s design ensures high-precision milling, suitable for detailed and complex parts.

- User-Friendly Interface: The Master MX software provides an intuitive platform for CNC programming, reducing the learning curve for operators.

- Robust Construction: Built with heavy-duty cast iron, the Supra ensures durability and stability during operation.

- Manual and CNC Operation: Offers the flexibility to switch between manual machining and CNC control, catering to various project requirements.

Parameters

- Table Size: 9″ x 49″

- X-Axis Travel: 34″

- Y-Axis Travel: 11.5″

- Z-Axis Travel: 16″ (Knee)

- Spindle Speed: Variable, up to 5,600 RPM

Advantages & Drawbacks

Advantages

- High precision and repeatability

- Flexible operation modes

- Durable build quality

Drawbacks

- Requires adequate shop space

- Higher initial investment

- Learning curve for CNC programming

9. ShopSabre IS510

Type: CNC Router Best for: Small-scale production and precision

The ShopSabre IS510 is a high-performance CNC router engineered for precision and efficiency in small-scale production environments. Its sturdy construction and advanced features make it ideal for industries such as automotive, aerospace, and custom woodworking, providing significant capabilities to enhance production quality and efficiency.

Key Features

- Robust Milling Capability: Designed to handle various materials, including wood, metal, and plastic, ensuring versatility in applications.

- Advanced Spindle Options: Equipped with a 10 HP HSD spindle, offering speeds up to 24,000 RPM for efficient cutting.

- User-Friendly Control System: Features the WINCNC industrial controller, providing an intuitive interface for operators.

- High Precision: Achieves repeatability of +/- .001”, ensuring consistent accuracy in machining tasks.

- Durable Construction: Built with a welded aerospace-milled structural steel frame, ensuring stability and longevity.

Parameters

- X-Axis Travel: 75 inches

- Y-Axis Travel: 125 inches

- Z-Axis Travel: 16 inches

- Table Size: 65 inches x 125 inches

- Rapid Feed Rate: Up to 2,100 IPM

Advantages & Drawbacks

Advantages

- High precision and repeatability

- Versatile machining capabilities

- Durable build quality

Drawbacks

- Higher initial investment

- Requires adequate shop space

- Learning curve for new operators

Conclusion

I made the mistake of buying the wrong CNC once. I won’t make it again. And now, you don’t have to either.

This guide gave you the best CNC machines for metal fabrication machines that deliver precision, speed, and reliability. The choice is in your hands.

So, what’s your next move? Will you invest in a machine that helps your business grow?

If you need guidance, contact us today!

Let’s find the perfect CNC for you.