When I bought my first CNC machine, I thought I knew what I needed.

I was wrong.

The machine I picked was too complicated, too expensive, and not suited for my actual projects. It took months and a lot of frustration before I figured out what I should have bought instead.

After that experience, I became determined to understand CNC machines inside and out.

I spent years testing different models, troubleshooting issues, and helping others from machine dealers to repairers and woodworking professionals find the right machines for their needs.

Along the way, I learned what really matters when choosing a CNC machine and how to avoid costly mistakes. In this article, I’ll compare 7 CNC machines for woodworking, breaking down precision, price, production capacity, and the best applications for each one.

By the end, you’ll have a clear path to the right CNC machine without the costly trial and error.

So let’s begin!

Quick Comparison Chart

Before diving into full details, take a look at this quick table. It highlights the main differences at a glance.

| Machine | Work Area (mm) | Spindle Type | Frame Type | Axis Type | Best For |

| BobsCNC Evolution 4 | 610 x 610 x 85 | Router (DIY add-on) | Wooden | 3-axis | Hobbyists, beginners |

| Shapeoko 4 XXL | 838 x 838 x 101 | Trim Router | Aluminum | 3-axis | Small shops, furniture makers |

| Blue Elephant 5 Axis | Custom sizes | High-power spindle | Heavy-duty steel | 5-axis | Mold makers, custom furniture, pro users (Highly capable & trusted for advanced work) |

| Laguna SmartShop II | Varies by model | ATC (optional) | Steel | 3-axis | Production furniture shops |

| ShopSabre 23 | 610 x 1219 (approx.) | Trim Router | Welded steel | 3-axis | Cabinet shops, machine repairers |

| Biesse Rover A FT | Full 4×8 sheet size | Industrial spindle | Steel | 3-axis | High-volume panel furniture production |

| HOMAG CENTATEQ P-110 | Varies by config | Industrial spindle | Modular steel | 3-axis | Large manufacturers, machine dealers |

Ready to explore more? We’ll go through each CNC router one by one next.

1. BobsCNC Evolution 4

When I first got into CNC woodworking, I didn’t want to spend thousands on a machine I might mess up. I needed something simple. Something I could actually learn.

That’s when I came across the BobsCNC Evolution 4. I’ll admit—the wooden frame threw me off. But the more I read, the more it made sense for beginners.

I decided to give it a try. A few evenings later, I had it built and run in my garage. It wasn’t perfect, but it taught me more than I expected.

Key Features

- Cutting area: 610mm x 610mm x 85mm (24″ x 24″ x 3.3″)

- Open-frame design for easy access

- Uses a standard router (commonly the DeWalt 660)

- Arduino-based control system

- Works with GRBL software

- Compatible with Universal Gcode Sender (UGS) for machine control

Pros

- Budget-friendly

- Lightweight and portable

- Comes as a DIY kit

- Clear instructions make it beginner-friendly

- Great for learning CNC basics

Cons

- Wooden frame isn’t as rigid as metal

- Not ideal for cutting hardwoods or dense materials

- Accuracy drops at higher speeds

- Not suited for long production runs

Best For

- Hobbyists working in garages or small workshops

- Beginners learning how CNC works

- DIYers who enjoy assembling machines

If you want to learn the CNC process step by step—and don’t mind building your own machine—the Evolution 4 gives you that hands-on experience.

2. Shapeoko 4 XXL

If you’ve been using a beginner CNC and feel like you’ve outgrown it, the Shapeoko 4 XXL might be your next step.

I used it to help a friend build a set of custom wood signs. The cuts were smooth, and the machine felt stable the whole time.

You’ll get a bigger work area, a stronger frame, and software that’s easy to learn. It’s a solid pick if you’re running a small shop or ready to take on more serious woodworking projects.

Key Features

- Cutting area: 838mm x 838mm x 101mm (33″ x 33″ x 4″)

- Runs a DeWalt or Makita trim router (sold separately)

- Strong aluminum frame for improved rigidity

- Upgraded Z-axis for smoother, deeper cuts

- Compatible with Carbide Create and other G-code software

- Includes homing switches and steel-reinforced belts

Pros

- Large workspace for furniture and signage

- Sturdy design keeps cuts accurate

- Great balance between price and performance

- User-friendly design software included

- Active online community and support

Cons

- Not made for full-scale production

- Assembly requires several hours

- Dust control system not included

Best For

- Furniture makers working with panels or softwood

- Small advertising and sign businesses

- Hobbyists who want to move beyond beginner machines

If you’re ready to take on bigger projects with better results, the Shapeoko 4 XXL is a reliable choice that won’t overwhelm you.

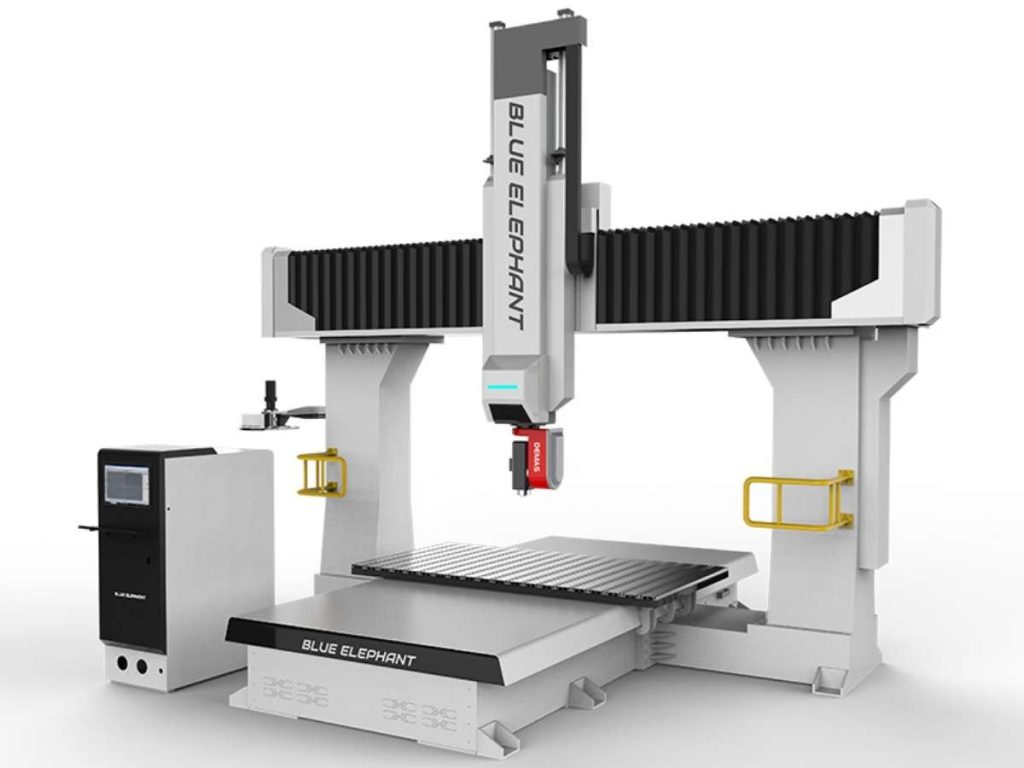

3. Blue Elephant 5 Axis CNC Routers

The first time I saw a Blue Elephant 5 Axis CNC in motion, I stood still and just watched. The spindle didn’t just move—it flowed, tilting and turning like a dancer carving wood midair.

Thick hardwood blocks were sliced with clean, smooth passes. No chatter. No rough edges. Just crisp curves and sharp angles from every direction.

If you’re working with complex shapes, deep grooves, or parts that need to be cut from multiple angles, this machine gives you the freedom—and control—to bring it to life.

Key Features

- 5-axis movement: Allows the spindle to tilt and rotate, reaching under surfaces and carving deep 3D shapes

- Heavy-duty frame: Keeps the machine stable, even during high-speed cutting

- High-power spindle: Easily cuts through dense materials like hardwood, foam, or resin

- Software compatibility: Works with Fusion 360, ArtCAM, UG, and other advanced design tools

- Post-sales support: Blue Elephant offers training, service, and fast technical help after delivery

Pros

- Excellent for detailed 3D carving and undercuts

- Cuts multiple angles in a single setup—no flipping the workpiece

- Delivers a smooth, professional surface finish

- Supports advanced design workflows and custom work

- Built to handle large-scale or repeat jobs with consistency

Cons

- The learning curve is steep—but training and help are available

Best For

- Machine dealers supplying advanced workshops

- Professional mold designers and pattern makers

- Furniture production teams needing sculpted, multi-angle parts

At Blue Elephant, we build CNC machines that prioritize precision, durability, and efficiency. With advanced automation and reliable performance, our machines help you work smarter, cut faster, and achieve better results.

4. Laguna Tools SmartShop II

I walked into a busy workshop one afternoon. The Laguna Tools SmartShop II was running non-stop, slicing through sheet after sheet of plywood. One of the workers glanced over and said, “It just runs. That’s why we rely on it.”

That moment stuck with me. I thought, This isn’t just a machine—it’s a workhorse. The speed, the control, the clean finish—it all came together like clockwork.

If you need a CNC router that can handle long hours and tough materials, the SmartShop II is built for it. It’s made in the U.S. and known for solid performance and strong after-sales support.

Key Features

- Vacuum table: Holds your material tight without clamps

- Servo motors: Quieter, faster, and more precise than standard stepper motors

- Automatic Tool Changer (ATC): Switches tools automatically—great for multi-bit jobs

- Heavy steel frame: Reduces vibration and boosts accuracy

- U.S.-based support: Helpful when you need parts or answers quickly

Pros

- Fast, accurate, and consistent under heavy use

- Great for full-scale production jobs

- ATC and vacuum tables save time and improve workflow

- Strong frame built for long-term durability

- Excellent customer service based in the U.S.

Cons

- Higher upfront cost

- May need upgrades in your shop (power or dust extraction)

Best For

- Commercial furniture or cabinet production

- Busy workshops with high output

- Shops ready to scale and invest in long-term performance

If you want a serious production machine that keeps up with your workload, the Laguna SmartShop II delivers. It’s powerful, smartly designed, and ready to run hour after hour without slowing you down.

5. ShopSabre 23

If you’re ready to move beyond entry-level machines, the ShopSabre 23 gives you that next step in power and reliability.

You might not need a massive industrial machine—but you do need something tougher, something that just works. If that sounds like you, this CNC is worth a close look.

It’s made in the U.S. and built for serious woodworking. Whether you’re cutting cabinets, building signs, or doing custom work, the ShopSabre 23 gives you strength without going over budget.

Key Features

- Welded steel frame: Strong and rigid for stable cuts

- Ball screw drive system: Reduces friction for smoother movement and more precise cuts

- 3-axis system: Handles most routing, engraving, and drilling tasks

- Mid-range pricing: Delivers pro-grade results without full industrial costs

- U.S.-based support: Help is available when you need it

Pros

- Accurate and reliable performance

- Built with long-lasting parts

- Helpful support team

- Smooth motion with minimal vibration

- Good match for growing businesses

Cons

- Limited to 3-axis cutting

- Software can be hard to learn if you’re just starting out

Best For

- Cabinet shops handling regular panel work

- Machine repairers needing a reliable CNC in-house

- Medium-sized woodworking businesses growing their output

If you’re running a busy workshop and want a machine that keeps up without constant maintenance, the ShopSabre 23 is ready. It’s tough, steady, and built for everyday use.

6. Biesse Rover A FT

If you’re running a high-output shop and need serious automation, the Biesse Rover A FT might be exactly what you’re looking for.

You won’t be lifting sheets, jogging the spindle, or stopping between jobs. This machine does the heavy work for you. I’ve seen it in a panel furniture plant, and it was impressive. It moved fast. It cut clean. And it barely needed human help once things were loaded.

Made in Europe, this machine is built for nested-based cutting. That means it cuts entire sheets into parts in a single setup—great for cabinet or panel furniture production.

Key Features

- Full table nesting: Lays out and cuts multiple parts from a single sheet

- Automatic loading/unloading: Reduces manual labor and boosts efficiency

- High-power spindle: Cuts through plywood, MDF, and laminated boards with ease

- Strong vacuum hold-down system: Keeps your material flat and secure during fast cuts

- Integrated software: Works with Biesse’s own CAD/CAM tools for full control

Pros

- Fast and highly automated

- Reduces labor time and handling

- Excellent for big production runs

- Delivers clean cuts with tight tolerances

- Built for nonstop, high-volume work

Cons

- Comes with a high price tag

- You’ll need training and factory setup to run it properly

Best For

- Dealers selling to large manufacturers

- Woodworking factories doing batch production

- Panel furniture makers with high volume needs

If you’re producing hundreds—or thousands—of pieces a day, the Biesse Rover A FT gives you the speed and automation to keep up. It’s not for every shop, but if you’re scaling fast and need precision at speed, this machine can handle the pressure.

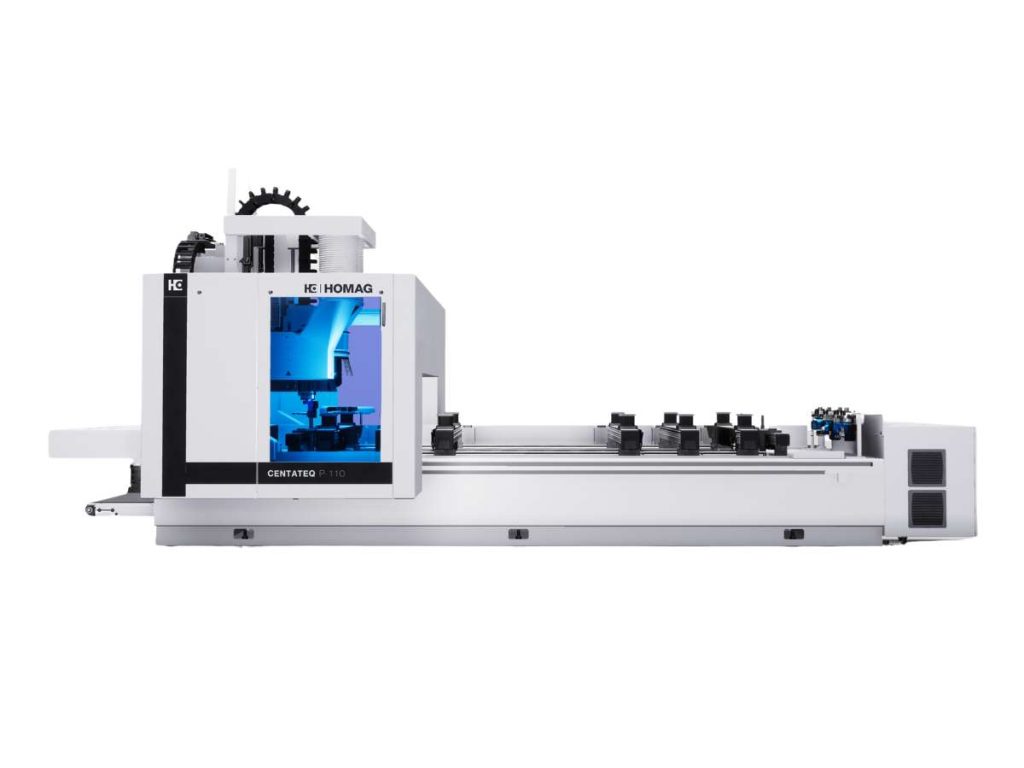

7. HOMAG CENTATEQ P-110

At a trade show last year, I saw a small team run the HOMAG CENTATEQ P-110 like it was second nature. One operator told me, “It’s like having an extra employee—one that never gets tired.”

The touchscreen lit up with each step. It routed, drilled, and cut without a pause. I stood there thinking, This thing doesn’t just work—it works smart.

If you run a professional shop and want high precision with less hands-on labor, this machine can make your daily workflow smoother and more reliable.

Key Features

- High-end automation: Reduces manual steps with smart, pre-programmed tasks

- Touchscreen interface: Easy to operate and read, even for multi-step jobs

- Modular design: Add tools, zones, or automation features as your needs grow

- Solid construction: Built to stay accurate through long shifts

- Software integration: Works with HOMAG’s own digital tools for streamlined setup

Pros

- Very precise, even on complex cuts

- Designed for non-stop use in large shops

- Intuitive controls through a modern interface

- Expandable system with smart add-ons

- Trusted support from a well-known global brand

Cons

- Expensive compared to mid-range CNCs

- Not ideal for beginners—needs trained staff to run efficiently

Best For

- Large manufacturers produce furniture, cabinetry, or wood panels

- Machine dealers looking to offer long-term, high-value machines

- Factories with experienced teams ready for automation

If you’re serious about scaling production and need a machine that won’t slow you down, the HOMAG CENTATEQ P-110 is a powerful tool. It’s not just about cutting wood—it’s about cutting wasted time, too.

Conclusion

Every minute spent on an inefficient CNC costs you time and money. The right machine boosts production, reduces errors, and helps you grow your business.

I’ve seen it firsthand. I was frustrated with slow production—until i made the switch. Now, I handle more orders in less time and his profits prove it.

What’s holding you back? A better, faster, more profitable workflow is within reach.

Make the investment that pays off.

Contact us today, and let’s find the CNC that works for your business.